A kind of high temperature resistant foaming agent and preparation method thereof

A foaming agent and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant foaming agent and its preparation, can solve the problems of no foam performance, cannot meet the needs of foam flooding, poor thermal stability of foaming agent, etc., and achieve low foaming performance and low cost , good foam stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

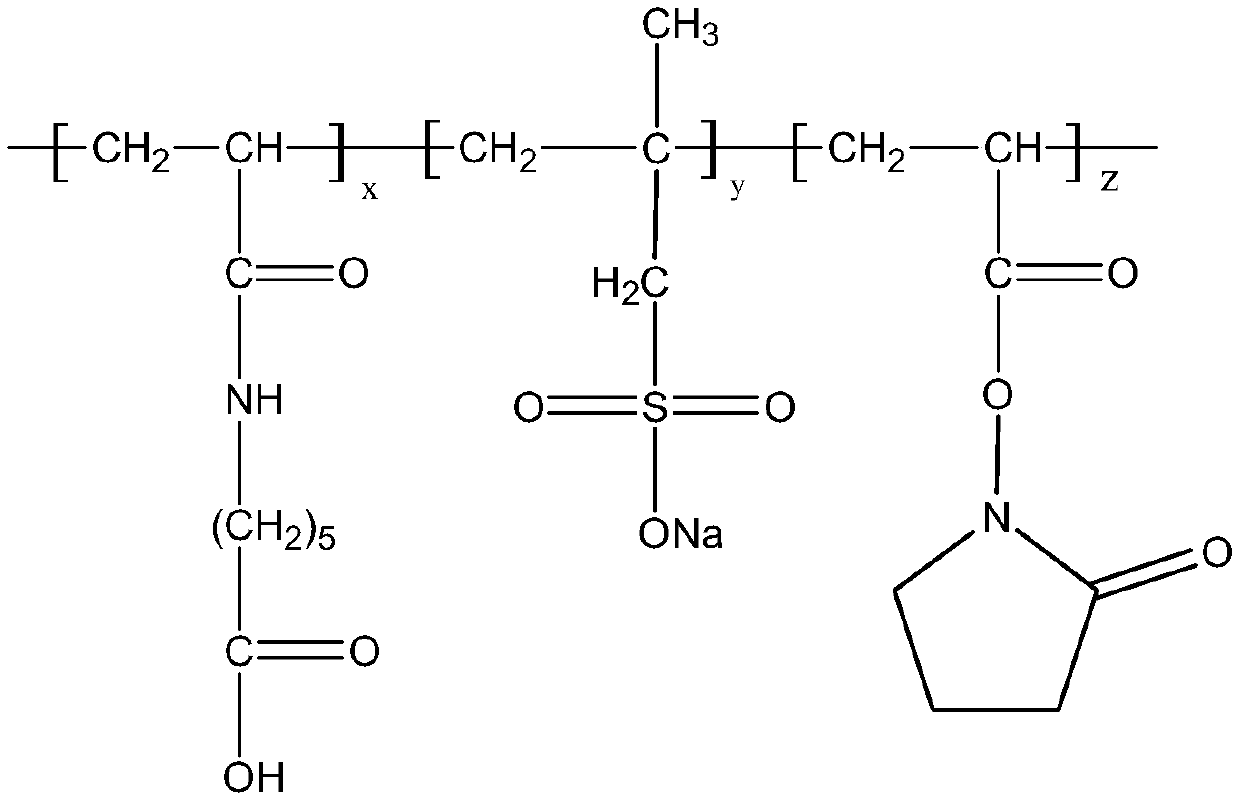

Method used

Image

Examples

Embodiment 1

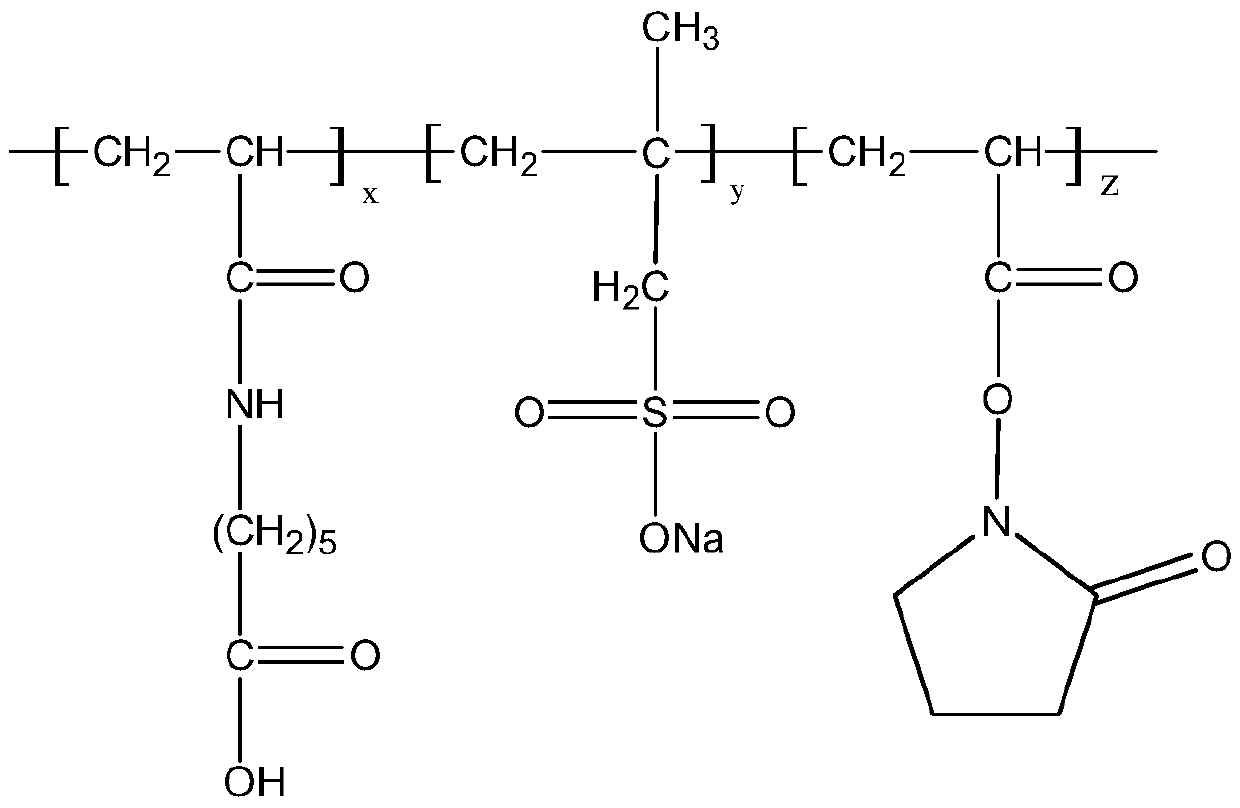

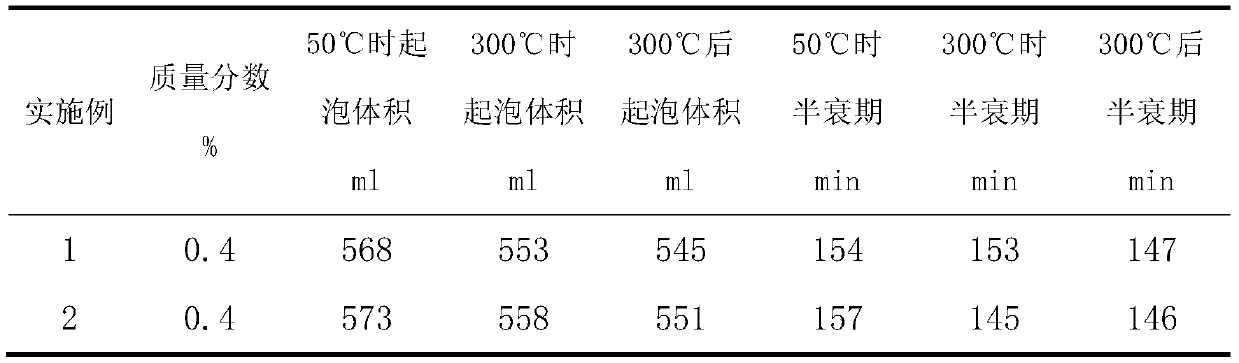

[0032] Example 1: Foaming agent temperature resistance test

[0033] Pour 1.5 g of sodium methacrylate sulfonate into a solution into a four-necked flask, fix the four-necked flask on the iron stand, pay attention to the distance between the flask and the constant temperature magnetic stirrer, and ensure that the bottom of the flask just touches the bottom of the oil bath. Put on the spherical condenser pipe and turn on the condensate water switch. 5g of 6-acrylamidocaproic acid and 3.5g of 1-acryloyloxy-2-pyrrolidone were dissolved in water to prepare a solution and transferred to a drip pump, and the speed of the drip pump was adjusted for use. Put 0.4g K 2 S 2 O 8 It is prepared into a solution and added to the flask containing the sodium methacrylate sulfonate solution. When the magnetic stirrer is heated to 30 ° C, open the flask containing 6-acrylamidohexanoic acid and 1-acryloyloxy- The drip pump of 2-pyrrolidone mixed solution was switched on and off, and the mixed...

Embodiment 2

[0035] Example 2: Foaming agent temperature resistance test

[0036] Pour 1.75g of sodium methacrylate sulfonate into a solution into a four-necked flask, fix the four-necked flask on the iron stand, pay attention to the distance between the flask and the constant temperature magnetic stirrer, and ensure that the bottom of the flask just touches the bottom of the oil bath. Put on the spherical condenser pipe and turn on the condensate water switch. 5.5g of 6-acrylamidohexanoic acid and 4g of 1-acryloyloxy-2-pyrrolidone were dissolved in water to prepare a solution and transferred to a drip pump, and the speed of the drip pump was adjusted for use. Put 0.4g K 2 S 2 O 8 It is prepared into a solution and added to the flask containing sodium methacrylate sulfonate solution. When the magnetic stirrer is heated to 30 °C, the solution containing 6-acrylamidohexanoic acid and 1-acryloyloxy-2- The drip pump of the pyrrolidone mixed solution is switched on and off, and the mixed ...

Embodiment 3

[0041] Example 3: Foaming agent is resistant to CO 2 test

[0042] The synthetic foaming agent was prepared according to the method of Example 1. The quinone polymerization inhibitor could be tetrachlorobenzoquinone. The foaming agent was prepared into a solution with a mass concentration of 0.4%, divided into two parts, and one part was foamed under normal pressure at 50°C. The foam performance test was carried out in the instrument, and the other part was additionally fed with 100% volume fraction of CO at the same temperature and pressure. 2 Gas for foam performance testing. The test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com