Sulfosuccinate salt type oil displacement agent, synthesis method and application thereof in tertiary oil recovery field

A technology of sulfosuccinate and synthesis method, applied in the field of tertiary oil recovery, in the field of sulfosuccinate salt type oil displacement agent, can solve the problem of poor stability of compound system, easy change of chemical structure, and poor oil displacement efficiency and other problems, to achieve good emulsification, low price, good viscosity reduction and displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

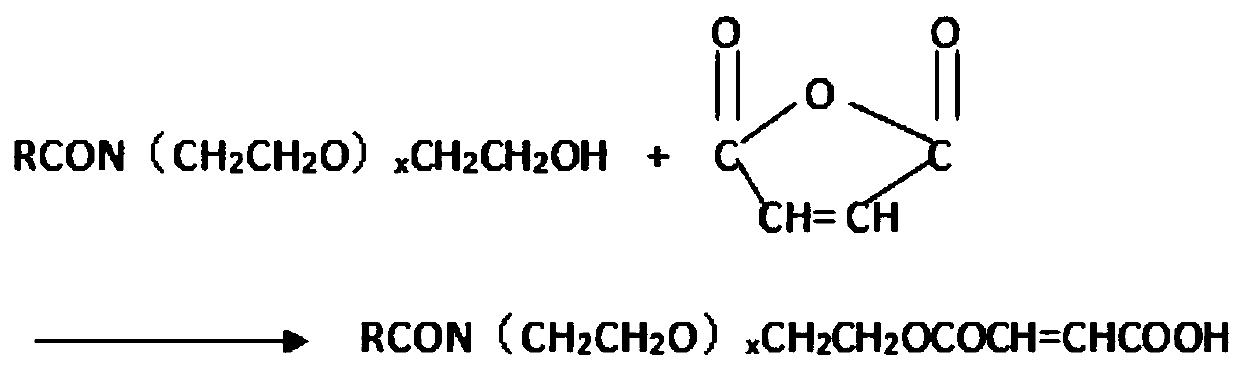

[0032] The synthetic method of sulfosuccinate salt type oil displacement agent comprises the following steps:

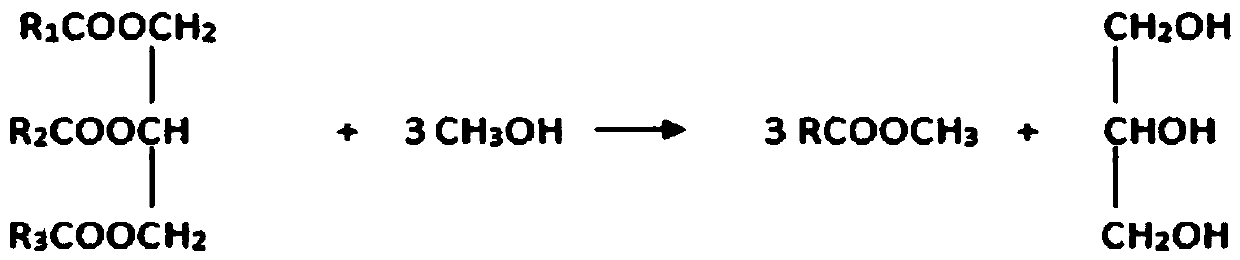

[0033] 1) Add vegetable oil to the reaction kettle. The vegetable oil is one or a mixture of coconut oil, palm oil, and soybean oil. Add a certain amount of methanol and potassium hydroxide. The molar ratio of vegetable oil to methanol is 1:3-4 , the amount of potassium hydroxide added is 0.5-2% of the total mass of all materials, heated to 60-90 ° C, stirred for 3-5 hours, and left to stand for 0.5 hours to separate glycerin and methanol to obtain vegetable oil fatty acid methyl ester;

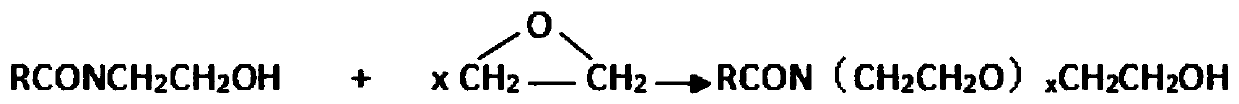

[0034] 2) Add a certain amount of monoethanolamine and alkali catalyst to the vegetable oil fatty acid methyl ester prepared in step 1), the alkali catalyst is one or more mixtures in sodium hydroxide, potassium hydroxide, sodium methylate, and the vegetable oil fatty acid methyl ester The molar ratio of ester to monoethanolamine is 1:1-1.05, the amount of alkali catalyst added is 0...

Embodiment 1

[0039] 1) Add vegetable oil to the reactor, the vegetable oil is palm oil, add a certain amount of methanol and potassium hydroxide, the molar ratio of vegetable oil to methanol is 1:3, the amount of potassium hydroxide added is 1% of the total mass of all materials, heat After stirring at 80°C for 4 hours, let stand for 0.5 hour, separate glycerin and methanol, and obtain vegetable oil fatty acid methyl ester;

[0040] 2) Add a certain amount of monoethanolamine and alkali catalyst to the vegetable oil fatty acid methyl ester prepared in step 1), the alkali catalyst is potassium hydroxide, the molar ratio of vegetable oil fatty acid methyl ester to monoethanolamine is 1:1~1.03, the alkali catalyst The addition amount is 2% of the total mass of all materials, the temperature is raised to 100° C., and the reaction is stirred for 4 hours to obtain vegetable oil fatty acid monoethanolamide;

[0041] 3) Put the vegetable oil fatty acid monoethanolamide into the pressure reaction ket...

Embodiment 2

[0048] 1) Add vegetable oil to the reactor, the vegetable oil is coconut oil, add a certain amount of methanol and potassium hydroxide, the molar ratio of vegetable oil to methanol is 1:4, the amount of potassium hydroxide added is 1.5% of the total mass of all materials, heat After stirring at 70°C for 4 hours, let stand for 0.5 hour, separate glycerol and methanol, and obtain vegetable oil fatty acid methyl ester;

[0049] 2) Add a certain amount of monoethanolamine and alkali catalyst to the vegetable oil fatty acid methyl ester prepared in step 1), the alkali catalyst is sodium hydroxide, the molar ratio of vegetable oil fatty acid methyl ester to monoethanolamine is 1:1.05, and the addition amount of alkali catalyst It is 1.5% of the total mass of all materials, the temperature is raised to 80° C., and the reaction is stirred for 5 hours to obtain vegetable oil fatty acid monoethanolamide;

[0050] 3) Put the vegetable oil fatty acid monoethanolamide into the pressure rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com