Antistatic polymer film and preparation method thereof

A polymer film and antistatic technology, which is applied in conductive coatings, coatings, polyamide coatings, etc., can solve the problems of the decline in the mechanical properties of polymer materials, achieve good compatibility, prolong service life, and increase stretching intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

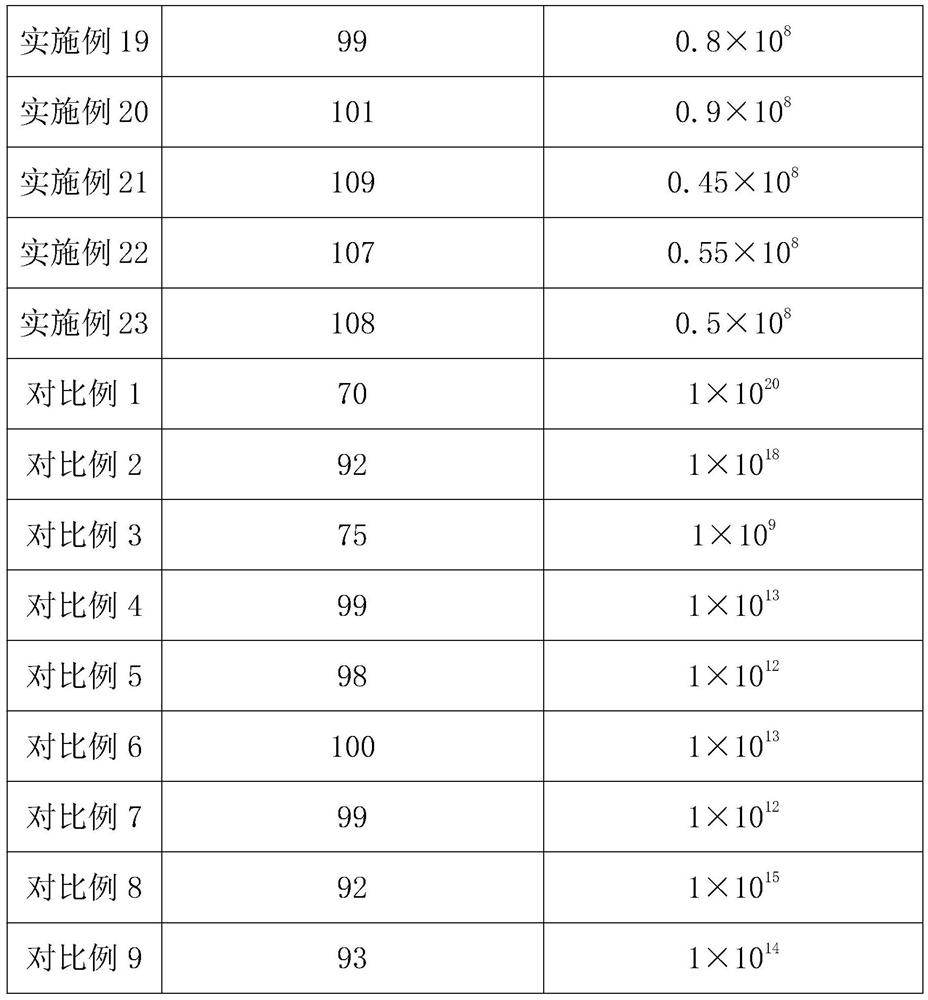

Examples

Embodiment 1-11

[0050] Taking Example 1 as an example, Example 1 discloses an antistatic polymer film, which is characterized in that the raw materials include the following components by weight: 20 parts of polymer material, 5 parts of carbon nanotubes, and 2 parts of antistatic agent .

[0051] The antistatic agent comprises the following components by weight: 3.4 parts of 1,6-caprolactam, 2.8 parts of sodium alkylsulfonate, and 3.8 parts of 6-aminocaproic acid.

[0052] The polymer material is polystyrene.

[0053] The preparation method of antistatic polymer film, comprises the following steps:

[0054] 1,6-caprolactam, sodium alkylsulfonate, and 6-aminocaproic acid are melted and polycondensed to obtain a copolymer product, the heating temperature is 200-280°C, the reaction time is 3 hours, and the reaction process is carried out at 150 rpm Stir the melt at a high speed to finally obtain a copolymerized product; then dry the copolymerized product at a heating temperature of 60° C. and ...

Embodiment 12-19

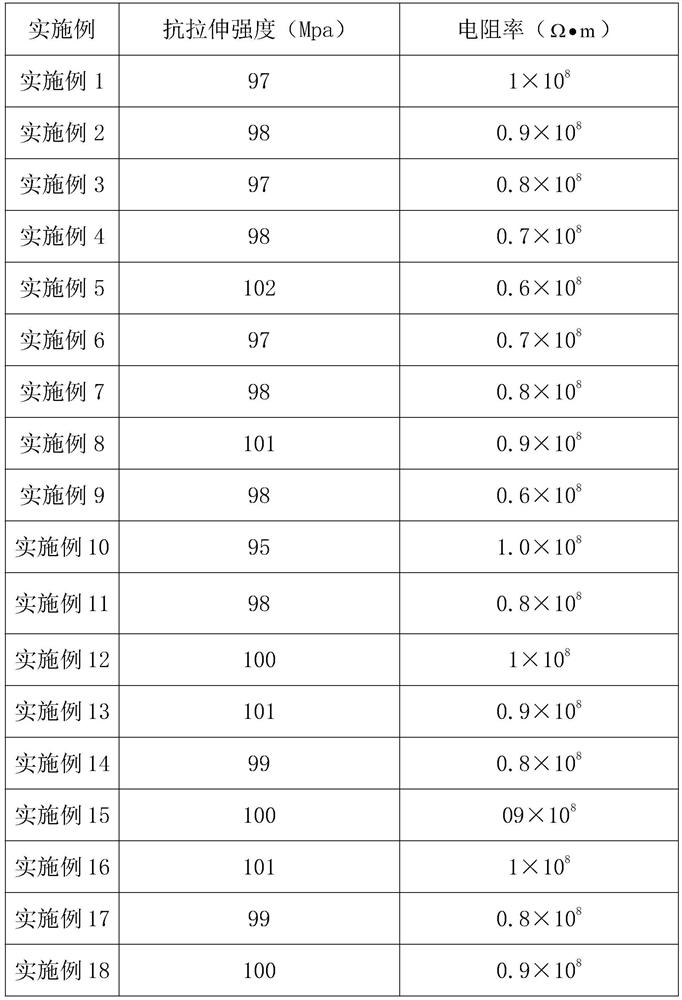

[0062] The difference between Examples 12-19 and Example 5 is that the content of each component in the antistatic agent is different, the unit is gram, and the specific values are shown in Table 2.

[0063] Table 2

[0064] Example 1,6-caprolactam Sodium alkyl sulfonate 6-aminocaproic acid Example 5 3.4 2.8 3.8 Example 12 2 2 2 Example 13 3 1 3 Example 14 5 4 5 Example 15 7 6 6 Example 16 8 5 7 Example 17 3.4 4 3.8 Example 18 3.4 1 3.8 Example 19 3.4 2.8 5 Example 20 5 2.8 3.8

Embodiment 21

[0066] The difference between Example 21 and Example 5 is that the antistatic polymer film of Example 21, the raw materials also include the following components by weight: 1 part of methyl cellulose, 3 parts of sodium dioctyl succinate sulfonate .

[0067] The preparation method of antistatic polymer film, comprises the following steps:

[0068] 1,6-caprolactam, sodium alkylsulfonate, and 6-aminocaproic acid are melted and polycondensed to obtain a copolymer product, the heating temperature is 200-280°C, the reaction time is 3 hours, and the reaction process is carried out at 150 rpm Stir the melt at a certain speed; dry the copolymerized product at a heating temperature of 60°C and a constant temperature time of 3 hours.

[0069] Then dry the obtained solid matter and perform ball milling with a ball-to-material ratio of (27):1 and a rotating speed of 360 rpm to obtain an antistatic masterbatch with a particle size of 0.01-0.1nm;

[0070] Take the polymer material, heat an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com