Formula and preparation method for producing low melting point and high decomposition temperature ternary copolyamide without ring-opening agent

A ternary copolyamide and decomposition temperature technology, which is applied in the formulation and preparation of high decomposition temperature ternary copolyamide materials, to achieve the effects of saving production costs, simplifying the production process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

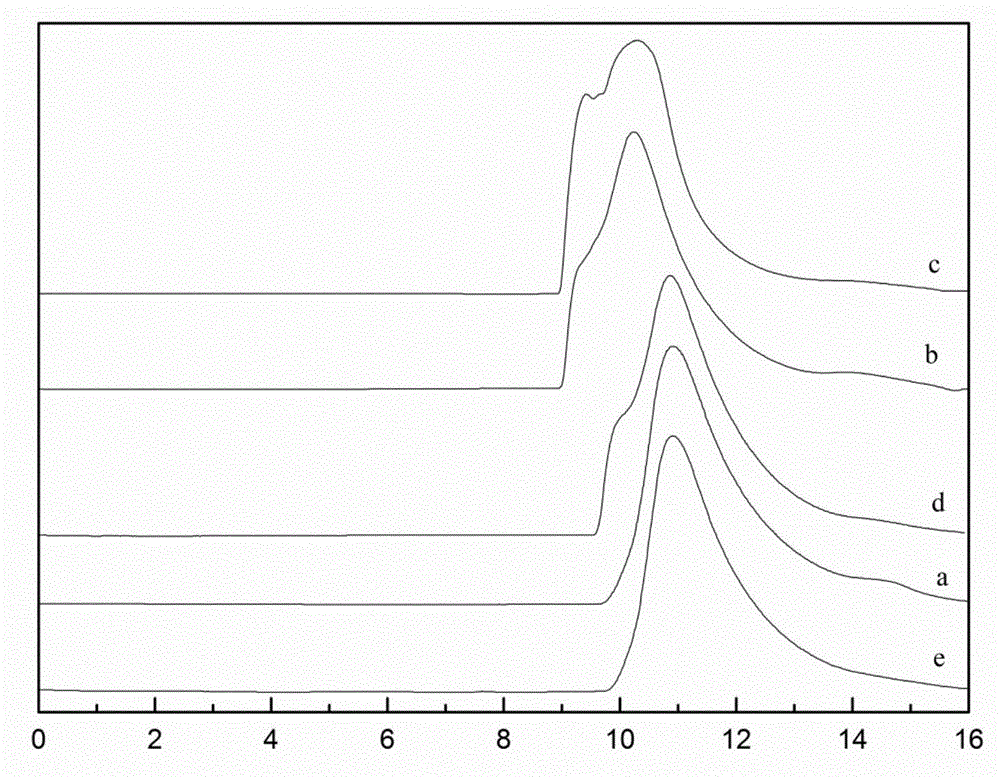

Image

Examples

Embodiment 1

[0031] Add 3000 parts of caprolactam, 60 parts of sebacic acid, 34 parts of hexamethylenediamine into a 10L polymerization kettle, one part has a mass of 1 g, feed nitrogen for 0.5 hours, and then under 2 bar (g) pressure, 230 ° C, nitrogen protection React with a stirring speed of 500 r / min for 8 hours, the conversion rate of caprolactam can reach 96%, the number average molecular weight after drying is about 16000, the melting range is 168 ℃ ~ 202 ℃, the thermal decomposition temperature is 450 ℃, and the tensile strength is 46.7 MPa , Elongation at break 28.3%.

Embodiment 2

[0033] Add 3000 parts of caprolactam, 300 parts of malonic acid, 173 parts of ethylenediamine in a 10L polymerization kettle, one part has a mass of 1 g, and feed nitrogen for 0.5 hour, then at 5 bar (g) pressure, 230 ° C, nitrogen protection and React at a stirring speed of 150 r / min for 8 hours, and the conversion rate of caprolactam can reach 95%. After drying, a terpolymer with a number average molecular weight of about 17,000 and a polyamide segment content of 86.4% is obtained. The melting range is 190 ℃ ~ 215 ℃ , thermal decomposition temperature 445 ℃, tensile strength 46.3 MPa, elongation at break 29.8%.

Embodiment 3

[0035] Add 2000 parts of caprolactam, 20 parts of terephthalic acid and 14 parts of hexamethylenediamine in the polymerization kettle, one part has a mass of 1 g, and feed nitrogen for 0.5 hours, then under 8 bar (g) pressure, 230 ° C, nitrogen protection and After reacting at a stirring speed of 300 r / min for 8 hours, the conversion rate of caprolactam can reach 97%. After drying, a terpolymer with a number average molecular weight of about 28,000 and a polyamide segment content of 98.3% is obtained. The melting range is 195 ℃ ~ 212 ℃ , thermal decomposition temperature 453 ℃, tensile strength 50.1 MPa, elongation at break 26.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com