Radial fixed bed reactor for oxy-dehydrogenation of butylene

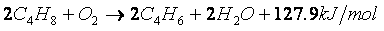

A radially fixed bed, oxidative dehydrogenation technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problem of low butene conversion selectivity, uneven fluid distribution, large reactor pressure drop, etc. problems, to achieve the effect of improving conversion rate and selectivity, uniform gas distribution, and improving reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

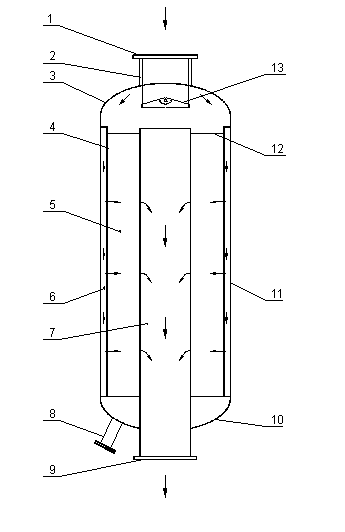

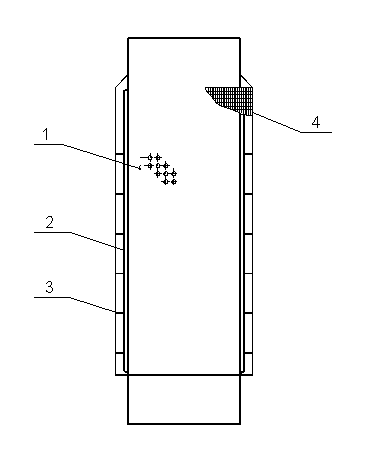

[0033] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant, the reactor adopts figure 1 The structural type of the reactor is a cylindrical container composed of an upper head, a cylindrical shell and a lower head. The upper head of the reactor is provided with a feed port, and a gas pre-distributor is provided in the feed port. The lower head of the reactor is provided with a discharge port and a catalyst discharge port; in the cylindrical shell of the reactor, a fan-shaped tube distributor, a catalyst bed, and a porous wall tube in the center are arranged in sequence from the outside to the inside; the fan-shaped tube The distributor is composed of a plurality of circularly arranged fan-shaped cylinders uniformly arranged along the inner wall of the reactor shell. The fan-shaped cylinder distributor adopts the form of uniform opening or segmented opening porosity, and its fan-shaped surface is close to the catalyst side, and Open distribution holes, commu...

Embodiment 2

[0037] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant, the reactor adopts figure 1 The structural type of the reactor is a cylindrical container composed of an upper head, a cylindrical shell and a lower head. The upper head of the reactor is provided with a feed port, and a gas pre-distributor is provided in the feed port. The lower head of the reactor is provided with a discharge port and a catalyst discharge port; in the cylindrical shell of the reactor, a fan-shaped tube distributor, a catalyst bed, and a porous wall tube in the center are arranged in sequence from the outside to the inside; the fan-shaped tube The distributor is composed of a plurality of circularly arranged fan-shaped cylinders uniformly arranged along the inner wall of the reactor shell. The fan-shaped cylinder distributor adopts the form of uniform opening or segmented opening porosity, and its fan-shaped surface is close to the catalyst side, and Open distribution holes, commu...

Embodiment 3

[0041] A 100,000 tons / year butene oxidative dehydrogenation to butadiene plant, the reactor adopts figure 1 The structure type, the raw material mixture enters the gas distributor 2 with a conical single-stage baffle 13 from the feed port 1, and then enters the fan-shaped cylinder distributor 6 located on the outer ring of the reactor, and the reaction gas passes through the hole fan-shaped cylinder distributor The distribution holes on the top enter the catalyst bed 5, and the top of the catalyst bed 5 is provided with ceramic balls 4 and a cover plate 12. The reactant gas flows out of the catalyst bed and enters the inner porous wall cylinder 7, and finally flows out of the reactor through the discharge port 9.

[0042] The feed air volume is 36000 kg / h, the butene raw material is 20000 kg / h, the reaction feed temperature is 320°C, the discharge temperature is 480°C, the pressure is 0.12MPa, the reactor diameter is 3200mm, the catalyst bed is 6000mm high and 650mm thick, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com