Drying process for Haidao superfine composite fiber slice

A technology of ultra-fine composite fiber and drying process, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, rayon manufacturing, etc., and can solve the problems of inability to dry, low melting point of polyester chips, and slow crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

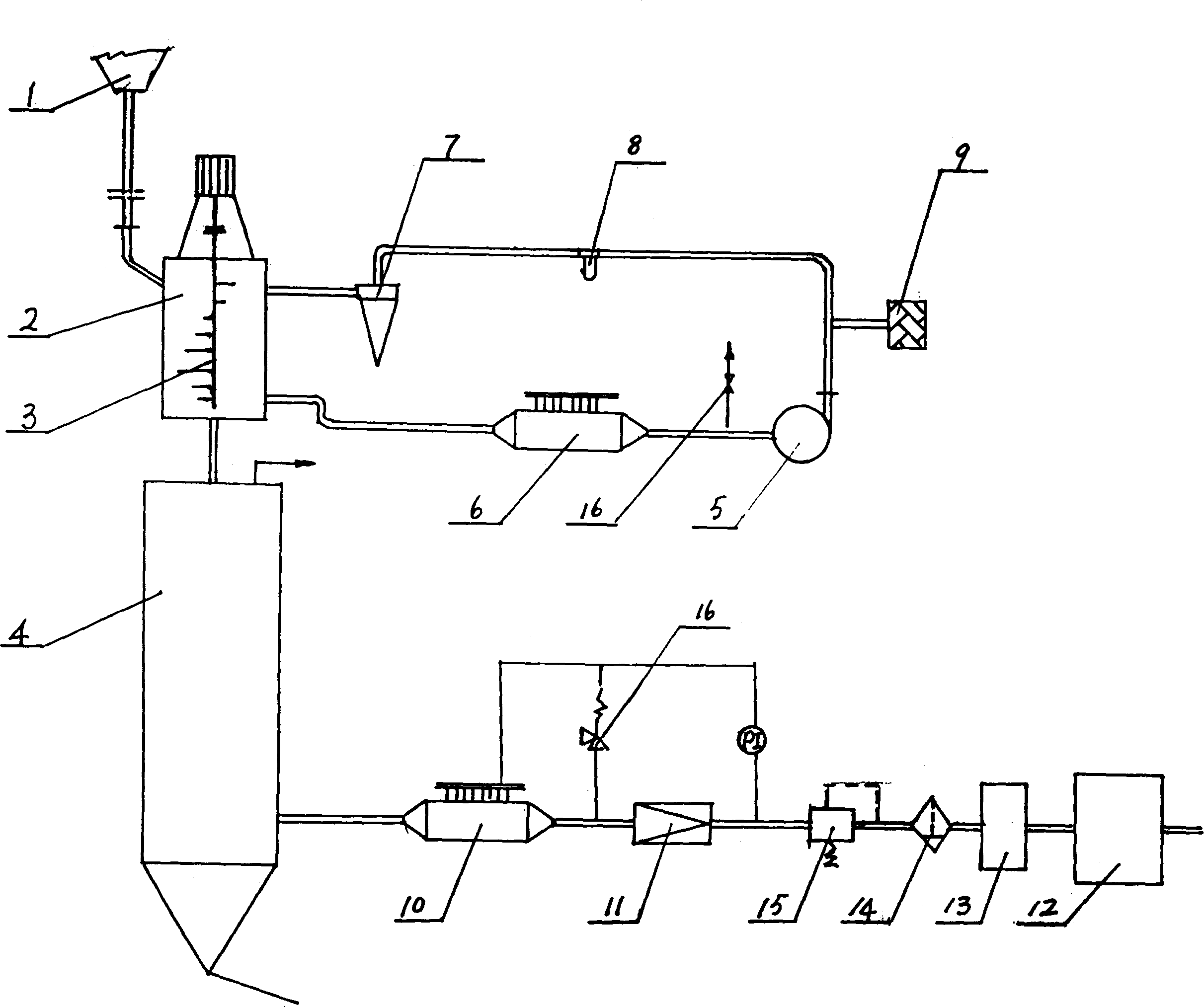

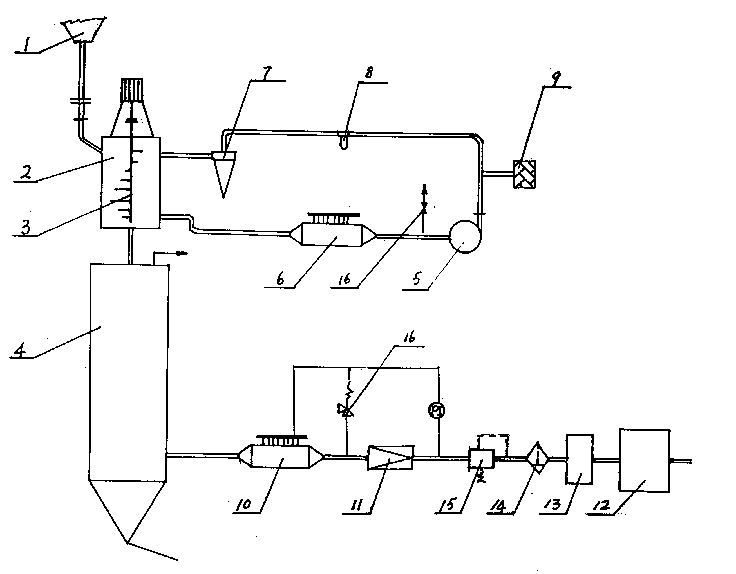

[0012] The sea-island ultrafine composite fiber chip drying process is further explained in conjunction with the process flow chart.

[0013] Drying equipment, including high-level hopper 1, pre-crystallizer 2, agitator 3, drying tower 4, pre-crystallization fan 5, pre-crystallization heater 6, cyclone separator 7, crystallization air filter 8, fresh air filter 9, drying air Heater 10, Raphael nozzle 11, refrigerated dehumidifier 12, molecular sieve dehumidifier 13, air filter 14, pressure reducing valve 15, air release valve 16.

[0014] The slice drying process flow is that the pre-crystallization fan 5 sends the air filtered by the fresh air filter 9 into the pre-crystallization heater 6 for heating, and becomes a pre-crystallization hot air. In order to achieve the stability of the required air volume, the frequency of the pre-crystallization fan 5 is 22HZ. Crystallization hot air enters from the bottom of pre-crystallizer 2. The wet slices are sucked to the high-level ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com