Water-soluble polymer sterilizing agent and preparation method thereof

A water-soluble polymer and solution technology, applied in the fields of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of easy coagulation of fungicides, unsuitable disinfection and sterilization of fungicides, and difficulty in fully contacting pathogens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

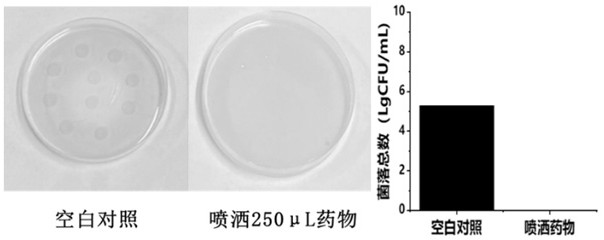

Embodiment 1

[0025] A water-soluble polymer disinfectant, its preparation process is as follows:

[0026] (1) Dissolve 1 part of dextran and 2 parts of 2,3-epoxypropyltrimethylammonium chloride in 20 parts of deionized water, then add 0.2 part of sodium hydroxide to it, and heat the mixture at 50°C Heating in a water bath for 4 h, then rotary evaporation at 80 °C, and drying to obtain cationic glucan.

[0027] (2) Add 0.5 parts of cationic dextran, 2 parts of 2,6-diaminocaproic acid, and 0.2 parts of epichlorohydrin to the container and mix well, adjust the pH of the mixed solution to 12, and then control the solution at 40°C The cross-linking polymerization reaction was carried out for 2h, rotary evaporation was carried out at 60°C, and the active ingredient A was obtained after drying, and 1.5 parts of the A was dissolved with 5 parts of water to obtain the A solution.

[0028] (3) Dissolve 0.81 part of magnesium chloride with 4.5 parts of water to obtain a magnesium chloride solution, ...

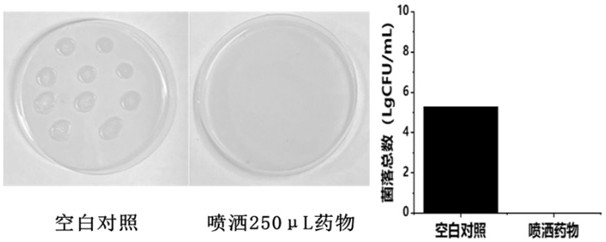

Embodiment 2

[0032] A water-soluble polymer disinfectant, its preparation process is as follows:

[0033] (1) Dissolve 1 part of dextran and 2 parts of 2,3-epoxypropyltrimethylammonium chloride in 20 parts of deionized water, then add 0.2 part of sodium hydroxide to it, and heat the mixture at 50°C Heating in a water bath for 4 h, then rotary evaporation at 80 °C, and drying to obtain cationic glucan.

[0034] (2) Add 1 part of cationic dextran, 3 parts of 2,6-diaminohexanoic acid, and 0.5 part of epichlorohydrin into the container and mix well, adjust the pH of the mixed solution to 13, and then control the solution at 50°C The cross-linking polymerization reaction was carried out for 4 hours, rotary evaporation was carried out at 75° C., and the active ingredient A agent was obtained after drying, and 3.2 parts of agent A were dissolved with 8 parts of water to obtain agent A solution.

[0035] (3) Dissolve 0.912 parts of magnesium chloride with 3.8 parts of water to obtain a magnesium ...

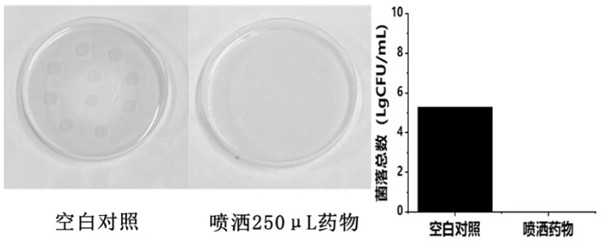

Embodiment 3

[0039] A water-soluble macromolecule disinfectant, the preparation process of which is as follows:

[0040] (1) Dissolve 1 part of dextran and 2 parts of 2,3-epoxypropyltrimethylammonium chloride in 20 parts of deionized water, then add 0.2 part of sodium hydroxide to it, and heat the mixture at 50°C Heating in a water bath for 4 h, then rotary evaporation at 80 °C, and drying to obtain cationic glucan.

[0041] (2) Add 2 parts of cationic dextran, 4 parts of 2,6-diaminocaproic acid, and 0.1 part of epichlorohydrin into the container and mix well, adjust the pH of the mixed solution to 14, and then control the solution to be at 45°C The cross-linking polymerization reaction was carried out for 6 h, and rotary evaporation was carried out at 90 °C. After drying, the active ingredient A agent was obtained, and 3.5 parts of the A agent was dissolved with 10 parts of water to obtain the A agent solution.

[0042] (3) Dissolve 1.296 parts of magnesium chloride with 5.4 parts of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com