Method for producing hexamethylenediamine key intermediate 6-aminocapronitrile by continuous gas-phase two-step method

A technology of aminocapronitrile and hexamethylenediamine, which is applied in the field of preparation of 6-aminocapronitrile, can solve the problems such as easy coking of the catalyst, achieve the effect of reducing catalytic polymerization, avoiding polymerization reaction, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

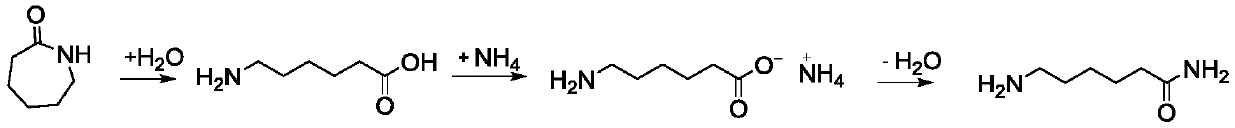

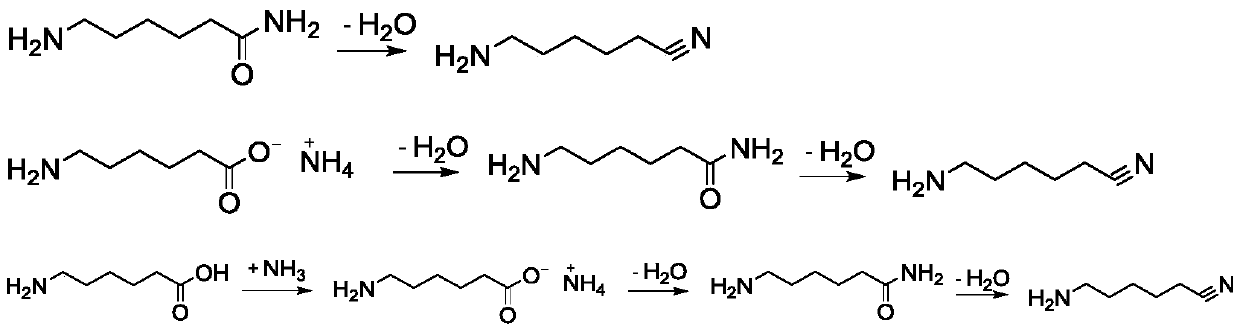

Method used

Image

Examples

Embodiment 1

[0037] Heat water to 500°C, caprolactam and water are simultaneously pumped into the first reactor filled with inert filler (porcelain balls) at a weight ratio of 1:8, at a gauge pressure of 3MPa, a reaction temperature of 500°C and a residence time of 1s. Hydrolysis reaction to obtain hydrolyzed material (amino caproic acid). Mix 500°C ammonia gas 0.5 times the weight of caprolactam with the hydrolyzed material, pump it into the second reactor filled with silica catalyst, and catalyze it at 300°C, gauge pressure 0.1MPa, reaction temperature 350°C and residence time 2s Ammonification and dehydration reactions generate 6-aminocapronitrile, the one-pass conversion rate of caprolactam is 95.6%, and the one-pass life of the catalyst is determined to be 1320h when the aminocapronitrile selectivity is less than 98%.

Embodiment 2

[0039] Heat 1% ammonia water to 400°C, and simultaneously pump caprolactam and water into the first reactor filled with solid acid (ZSM-5) at a weight ratio of 1:5. The hydrolysis reaction was carried out at a time of 0.6 s to obtain the hydrolyzed material (aminocaproic acid). Mix 400°C ammonia with 3 times the weight of caprolactam with the hydrolyzed material, pump it into the second reactor filled with alumina catalyst, and catalyze it at 400°C, gauge pressure 0.6MPa, reaction temperature 450°C and residence time 0.5s Ammonification and dehydration reactions generate 6-aminocapronitrile, the one-pass conversion rate of caprolactam is 97.1%, and the one-pass life of the catalyst is determined to be 1400h when the aminocapronitrile selectivity is less than 98%.

Embodiment 3

[0041] Heat 10% ammonia water to 400°C, and simultaneously pump caprolactam and ammonia water into the first reactor filled with solid acid (ZSM-5) at a weight ratio of 1:5. Under 0.6s, the hydrolysis and ammoniation reaction is carried out to obtain the hydrolyzed material. Mix 400°C ammonia with 3 times the weight of caprolactam with the hydrolyzed material, send it into the second reactor filled with alumina catalyst, and catalyze it at 400°C, gauge pressure 0.6MPa, reaction temperature 450°C and residence time 0.5s Ammonification and dehydration reactions generate 6-aminocapronitrile, the one-pass conversion rate of caprolactam is 98.8%, and the one-pass life of the catalyst is judged to be 1500h when the aminocapronitrile selectivity is less than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com