Brominated polymer flame retardant and preparation method thereof

A technology of brominated polymers and flame retardants, applied in the field of green brominated polymer flame retardants and its preparation, can solve the problem of poor fire resistance of polystyrene foam boards and poor thermal stability of hexabromocyclododecane , aquatic organisms and environmental hazards, etc., to avoid bromine substitution, facilitate biodegradation, and reduce the difficulty of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

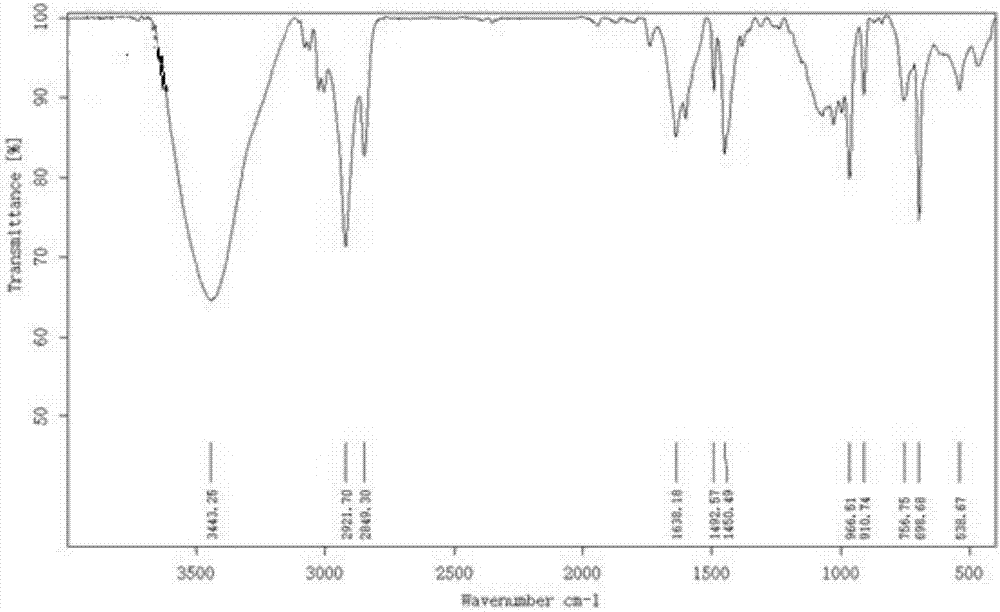

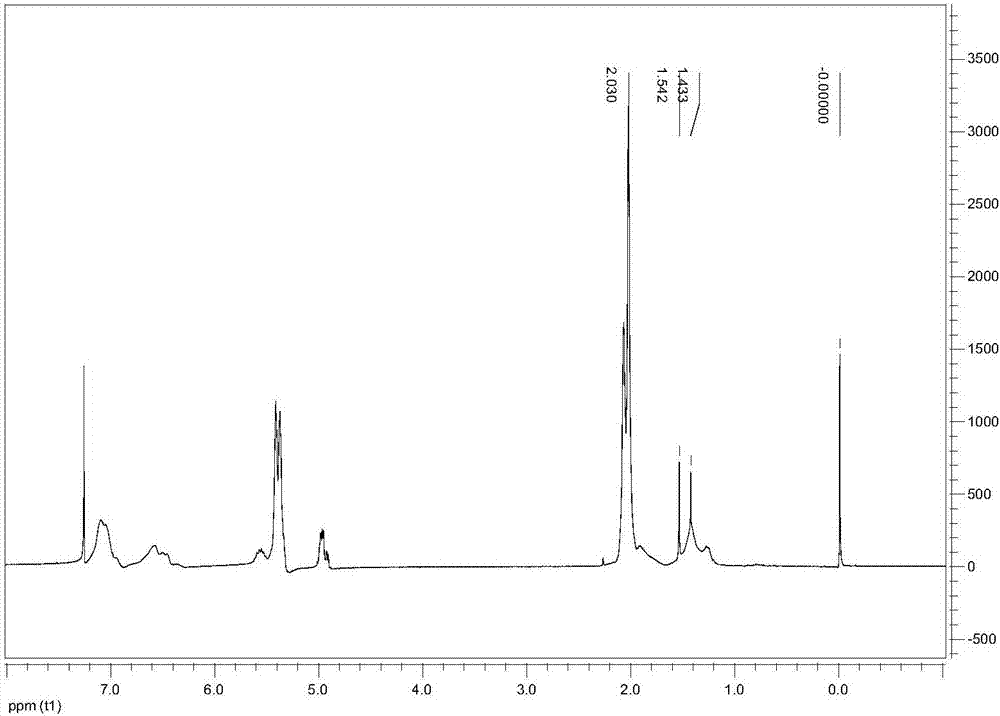

[0037] 5g styrene-butadiene copolymer (abbreviated as SBS, butadiene content is 60%) was dissolved in 120ml chloroform solvent to form solution A, while stirring under 0 ℃ ice-water bath conditions, 25.3ml of Bromine-chloroform solution (wherein the volume ratio of bromine in the bromine-chloroform solution to chloroform is 1:10) is slowly added dropwise to solution A at a speed of 1d / 2s, dropwise After completion, keep the reaction at 0°C for 2h, raise the temperature to 25°C for 1h, raise the temperature to 50°C for 1h, raise the temperature to 75°C for 2h, then cool down to room temperature for 20min, use methanol as the anti-solvent for precipitation, and filter the precipitate Afterwards, repeat the process of dissolving-anti-solvent method precipitation-filtering until the off-white precipitate is obtained, which is styrene-butadiene brominated copolymer (abbreviation Br-SBS), and the obtained Br-SBS is vacuum-dried to remove residual solvents and anti-solvents.

Embodiment 2

[0039]5g styrene-butadiene copolymer (abbreviated as SBS, butadiene content is 60%) was dissolved in 120ml chloroform solvent to form solution A, while stirring under 0 ℃ ice-water bath conditions, 38.5ml of Bromine-chloroform solution (wherein the volume ratio of bromine in the bromine-chloroform solution to chloroform is 1:10) is slowly added dropwise to solution A at a speed of 1d / 2s, dropwise After completion, react for 2 hours, raise the temperature to 25°C for 1 hour, raise the temperature to 50°C for 1 hour, raise the temperature to 75°C for 2 hours, then naturally lower the temperature to room temperature for 20 minutes, use methanol as the anti-solvent for precipitation, filter the precipitate, and repeat Dissolving-anti-solvent method precipitation-filtering process until the off-white precipitate is obtained, which is styrene-butadiene brominated copolymer (abbreviated as Br-SBS), and the obtained Br-SBS is vacuum-dried to remove residual solvent and anti-solvent. ...

Embodiment 3

[0041] 5g styrene-butadiene copolymer (abbreviated as SBS, butadiene content is 60%) was dissolved in 120ml chloroform solvent to form solution A, while stirring under 0°C ice-water bath conditions, 50.6ml of Bromine-chloroform solution (wherein the volume ratio of bromine in the bromine-chloroform solution to chloroform is 1:10) is slowly added dropwise to solution A at a speed of 1d / 2s, dropwise After completion, react for 2 hours, raise the temperature to 25°C for 1 hour, raise the temperature to 50°C for 1 hour, raise the temperature to 75°C for 2 hours, then naturally lower the temperature to room temperature for 20 minutes, use methanol as the anti-solvent for precipitation, filter the precipitate, and repeat Dissolving-anti-solvent method precipitation-filtering process until the off-white precipitate is obtained, which is styrene-butadiene brominated copolymer (abbreviated as Br-SBS), and the obtained Br-SBS is vacuum-dried to remove residual solvent and anti-solvent. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com