Oil slurry scale inhibitor

A scale inhibitor, oil slurry technology, used in the petroleum industry, hydrocarbon oil treatment, treatment equipment corrosion/fouling inhibition, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

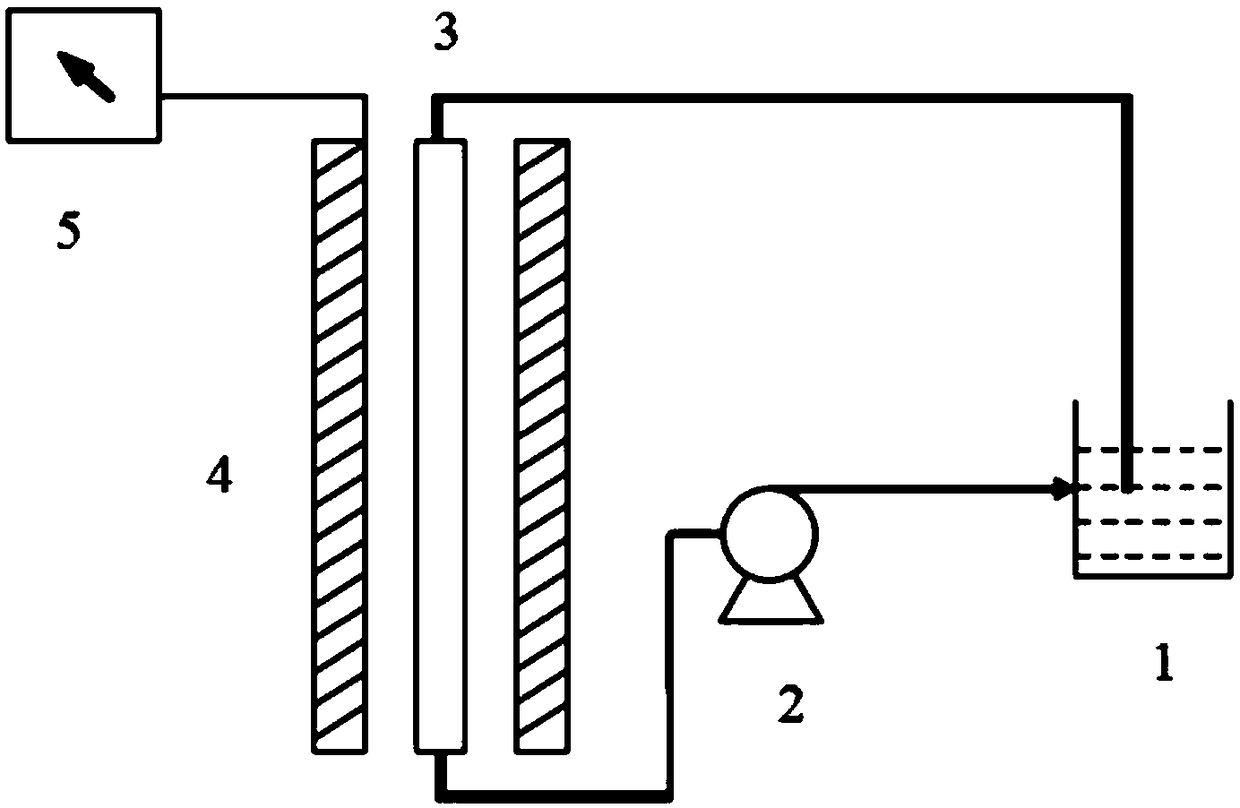

Method used

Image

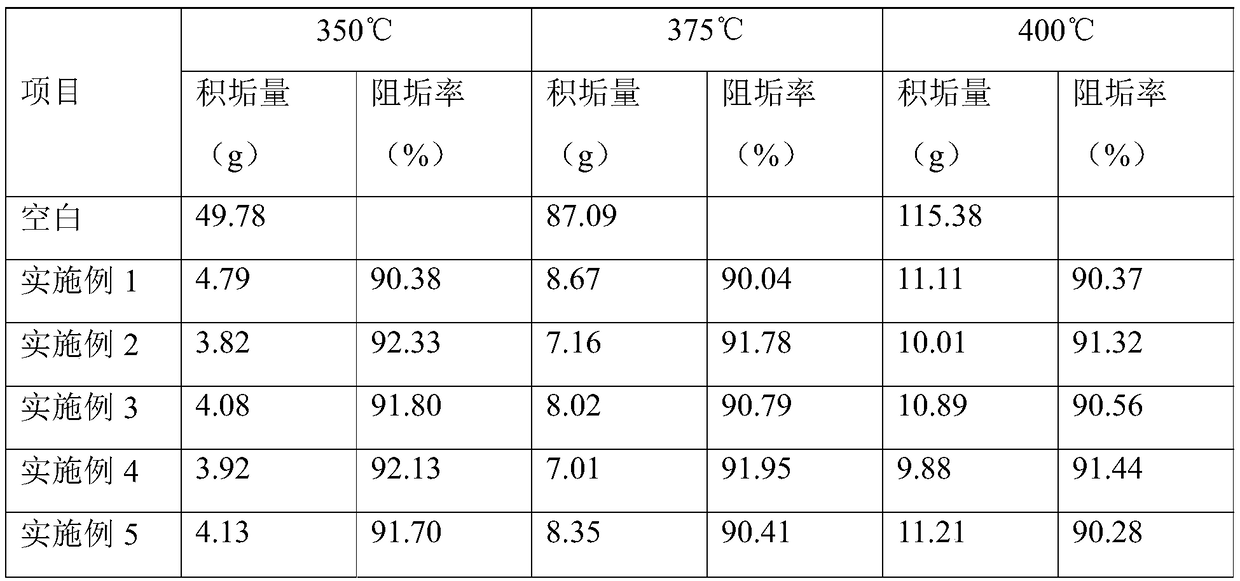

Examples

Embodiment 1

[0036] A kind of oil slurry antiscalant, comprises the component of following mass fraction: polyisobutylene succinimide (cleaning dispersant) 30%, 2,6-di-tert-butyl-1-dimethyl-p-cresol (phenol Amine type antioxidant) 10%, benzimidazole mercaptan (corrosion inhibitor) 5%, detergent T107 0.8%, metal passivator THMD-5 0.5%, the balance is xylene and diesel oil mass ratio 10:1 mixed solvents.

[0037] At a temperature of 40°C, add a cleaning and dispersing agent to the solvent. After it is completely dissolved, add detergent T107, 2,6-di-tert-butyl-1-dimethyl-p-cresol, and metal deactivator THMD-5 in sequence. , benzimidazole mercaptan, stir evenly to obtain oil slurry scale inhibitor, freezing point -14.1°C, kinematic viscosity (20°C) 42.6mm 2 / s.

Embodiment 2

[0039]A kind of oil slurry antiscalant, comprises the component of following mass fraction: polyisobutylene succinimide (cleaning dispersant) 30%, polybutadiene hexylene glycol thiophosphate (cleaning dispersant) 3%, 2,6-di-tert-butyl-1-dimethyl-p-cresol (phenolic amine antioxidant) 10%, benzimidazole thiol (corrosion inhibitor) 5%, detergent T107 0.8%, metal passivation Agent THMD-50.5%, the balance is a mixed solvent of xylene and diesel oil with a mass ratio of 10:1.

[0040] The preparation method is the same as in Example 1. The resulting oil slurry scale inhibitor has a freezing point of -14.2°C and a kinematic viscosity (20°C) of 42.9mm 2 / s.

Embodiment 3

[0042] A kind of oil slurry antiscalant, comprises the component of following mass fraction: polyisobutylene succinimide (cleaning dispersant) 32%, polybutadiene hexylene glycol thiophosphate (cleaning dispersant) 4%, 2,6-di-tert-butyl-1-dimethyl-p-cresol (phenolic amine antioxidant) 10%, benzimidazole thiol (corrosion inhibitor) 5%, detergent T107 0.8%, metal passivation Agent THMD-50.5%, the balance is a mixed solvent of xylene and diesel oil with a mass ratio of 10:1.

[0043] The preparation method is the same as in Example 1. The resulting oil slurry scale inhibitor has a freezing point of -13.5°C and a kinematic viscosity (20°C) of 42.4mm 2 / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com