The preparation method of MOF/nylon 6 composite material

A technology of MOF and modified nylon, applied in the field of preparation of nano-MOF/nylon 6 composite materials, can solve the problems of affecting the molding processing efficiency of nylon materials, slow crystallization rate, and high injection mold temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

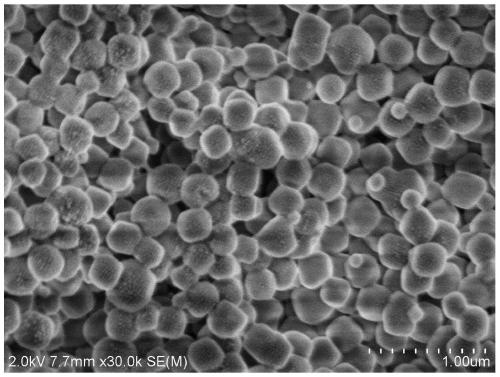

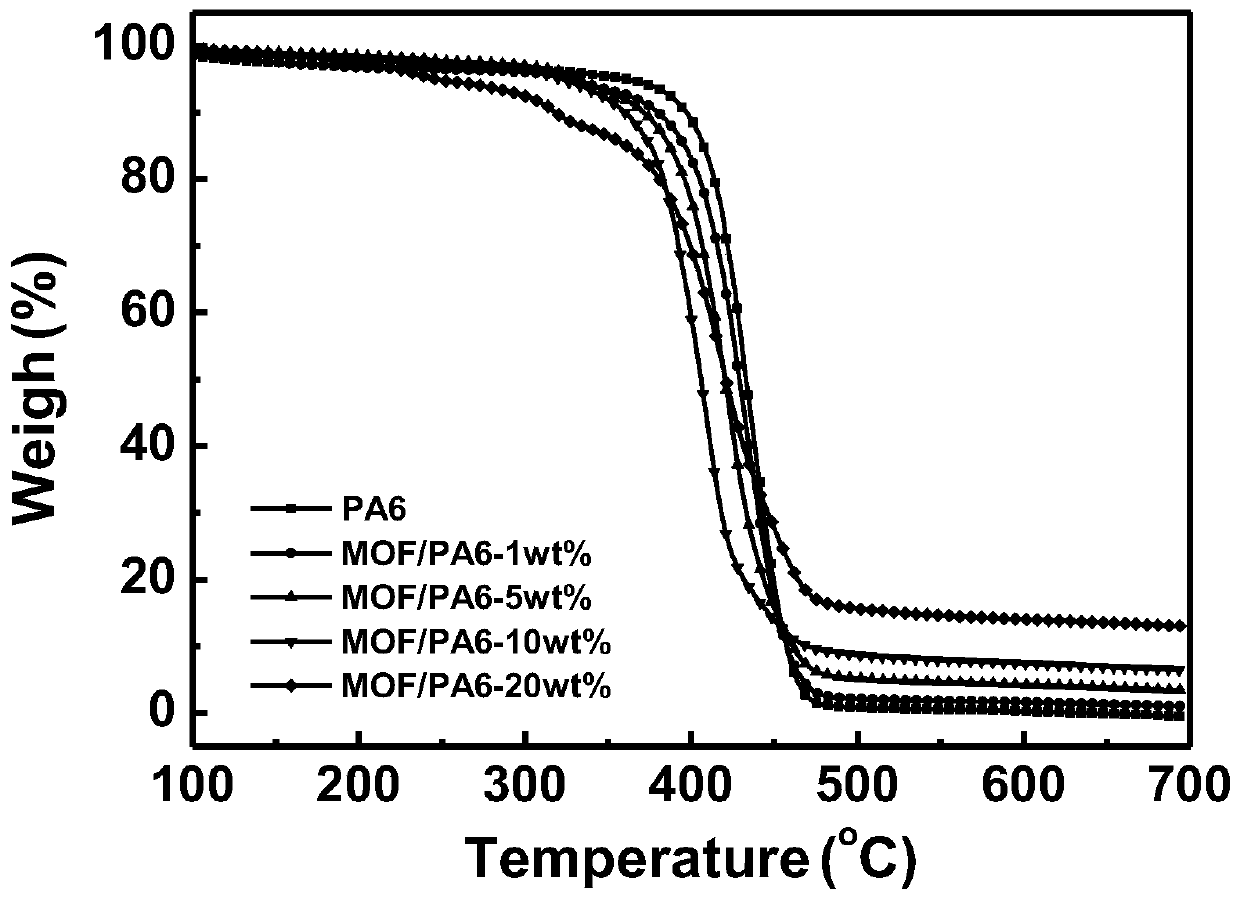

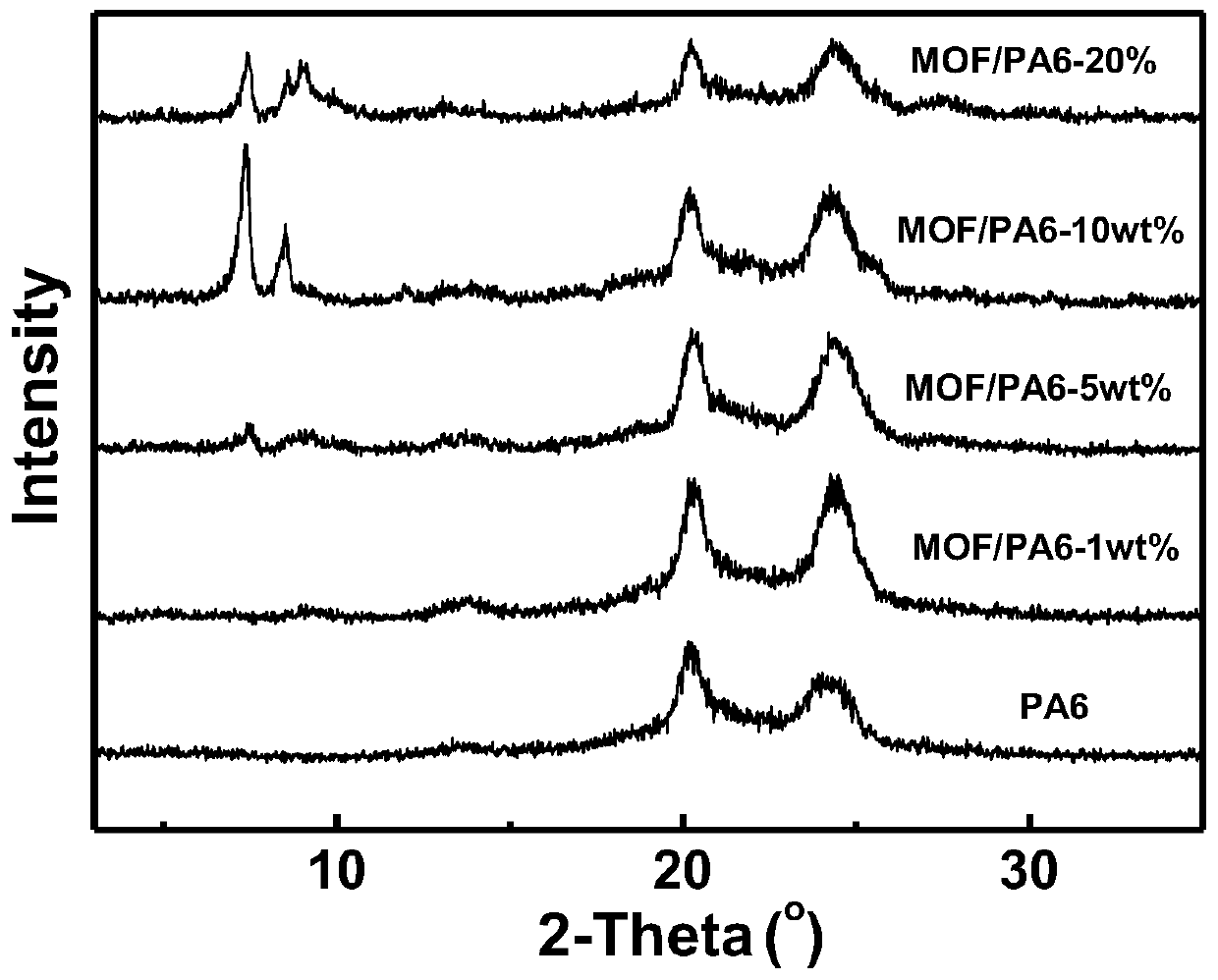

[0012] The method for preparing nanometer MOF / nylon 6 composite material of the present invention, comprises the steps:

[0013] 1. Mix 30wt%-60wt% caprolactam, 5wt%-20wt% precursor for nano-MOF, 20wt%-35wt% polar organic solvent and 1wt%-5wt% water, and react the mixture at 120°C After 24 hours, the nano-MOF dispersion was obtained;

[0014] Wherein, the metal salt of the MOF precursor includes metal zirconium salt and metal cerium salt, and the described organic ligand is terephthalic acid, 2-aminoterephthalic acid, 2-hydroxyterephthalic acid, 2- Nitroterephthalic acid, 2-methylterephthalic acid, 1,4-naphthalene dicarboxylic acid; the polar organic solvents are N,N-dimethylformamide (DMF), N,N-di One of methylacetamide (DEA), N-methylpyrrolidone (NMP), methanol, and ethanol;

[0015] 2. evaporate the polar organic solvent in the nanometer MOF dispersion liquid that is gained by step 1, add 6-aminocaproic acid (taking the gross weight of nanometer MOF dispersion liquid as c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com