Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Wide range of applicable materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

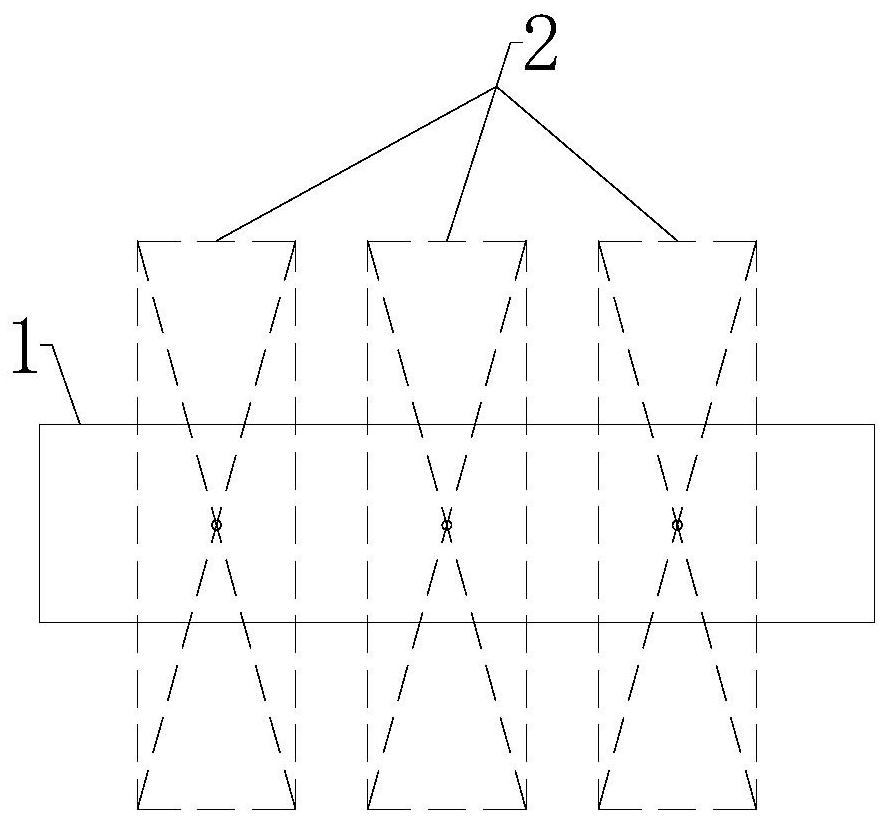

Preparation method of three-dimensional artificial random porous structure tissue engineering scaffold

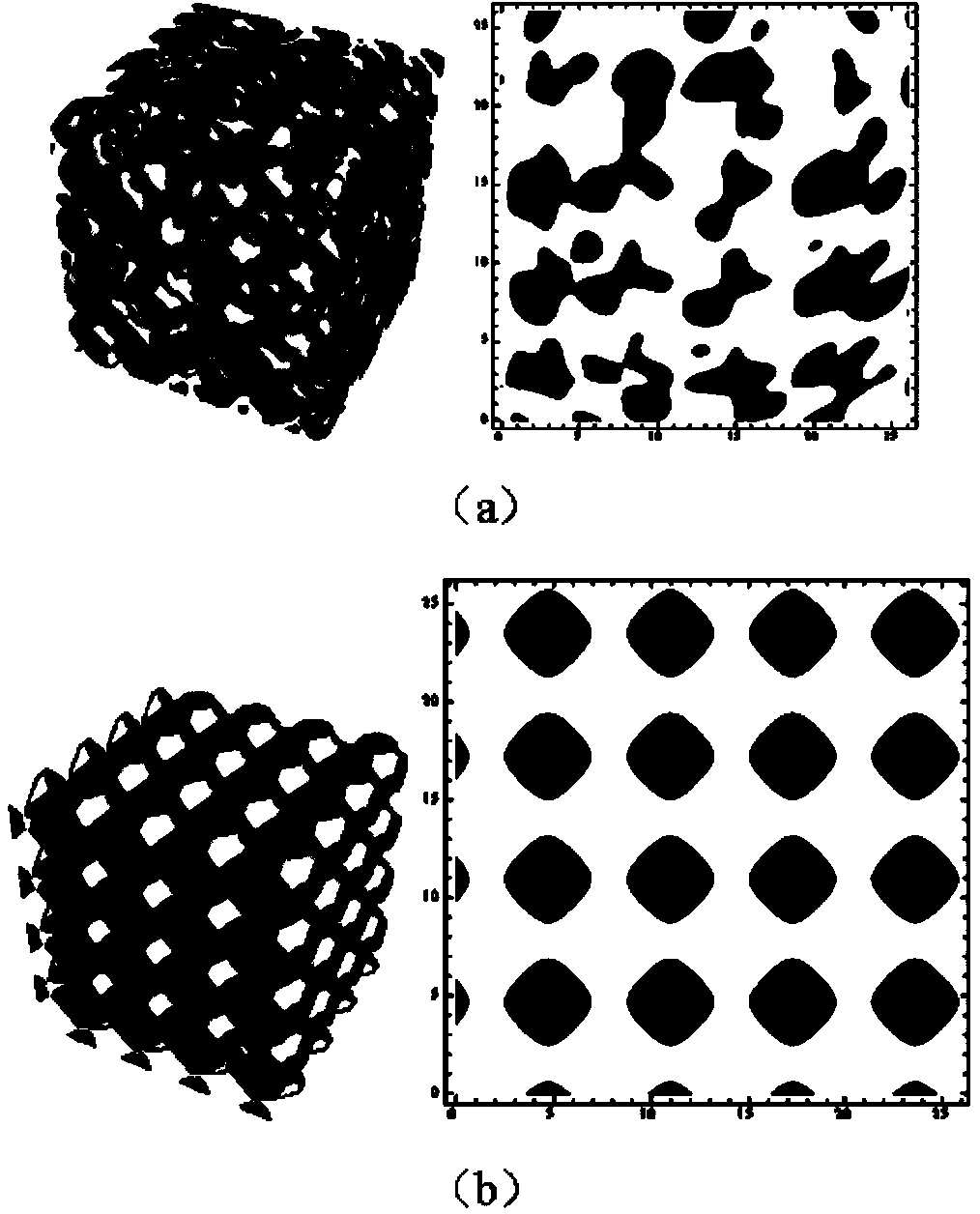

The invention relates to a preparation method of a three-dimensional artificial random porous structure tissue engineering scaffold, belonging to the technical field of biomaterials. The invention aims to solve the design and manufacturing problems of the bionic structure of tissue engineering scaffold, provides a design method for constructing a random distributed scaffold porous structure with a bionic shape under expected porosity and pore size requirements, and molds by using a 3D additive manufacturing method to produce tissue substitute. The preparation method provided by the invention has the following advantages that the scaffold has a 3D through-hole structure meeting bionic requirements, and ensures nutrient substance transfer and waste metabolism and has certain bionic mechanical properties; the porosity and pore size distribution range of the scaffold can be conveniently controlled, and the random pore structure with expected function gradient is constructed to realize the bionic characteristic of the structure; and the method is suitable for a large range of materials such as metal materials, non-metal materials and medical high molecular materials, and can meets user-personalized tissue repair requirements.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

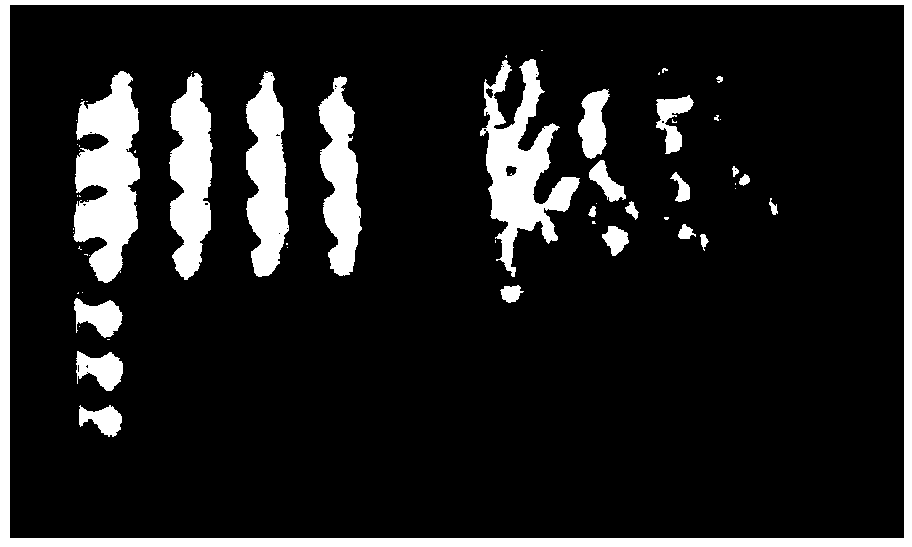

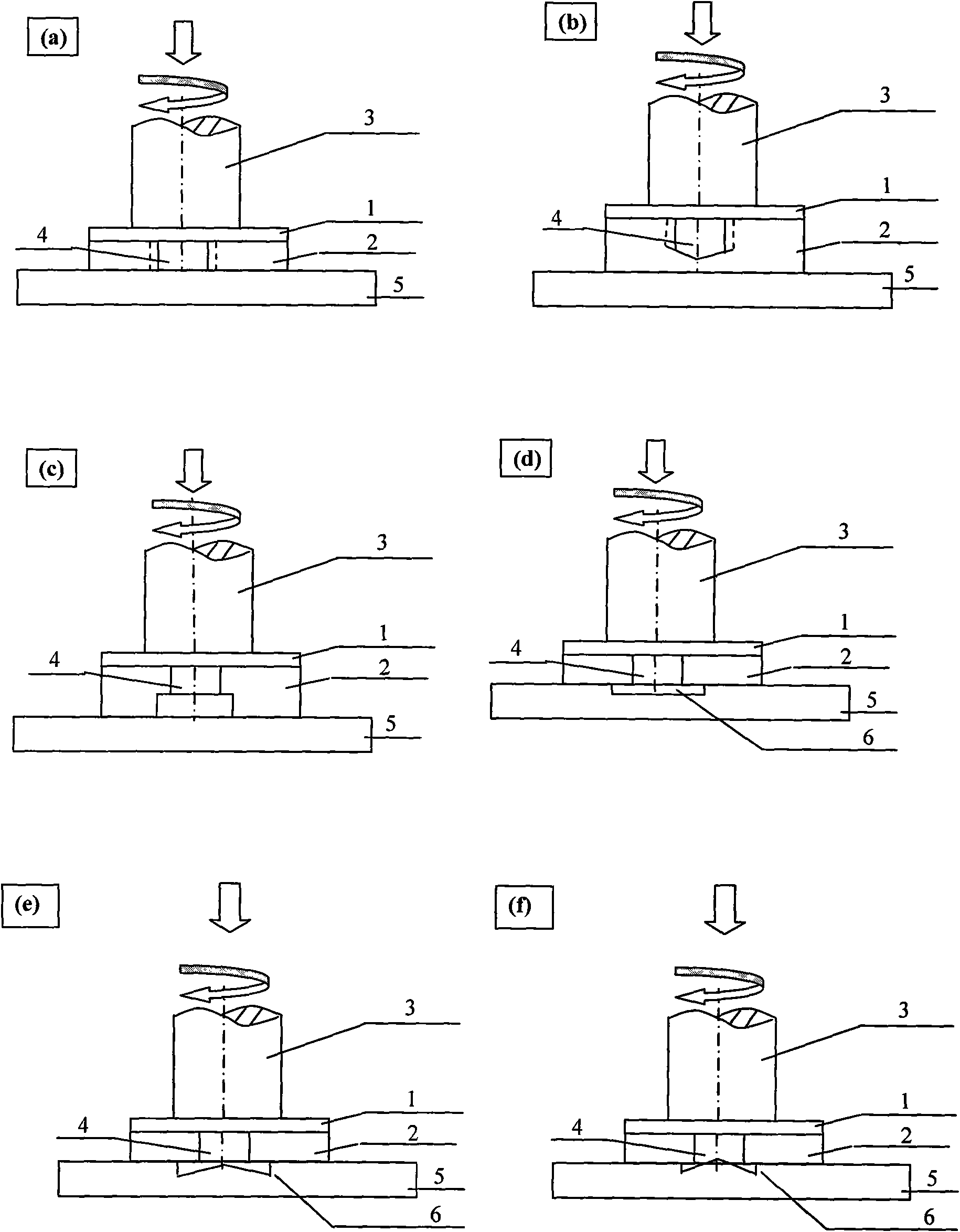

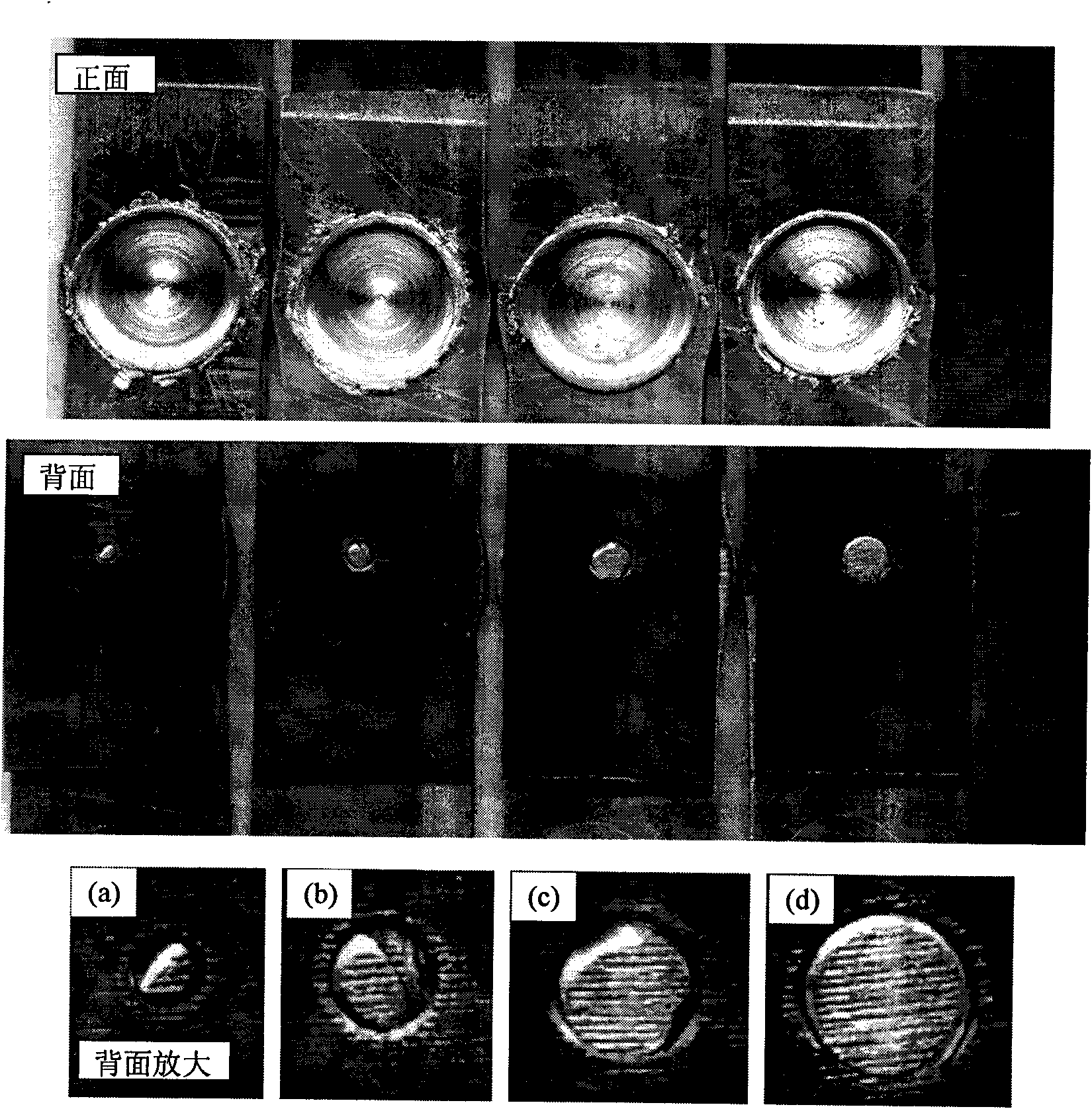

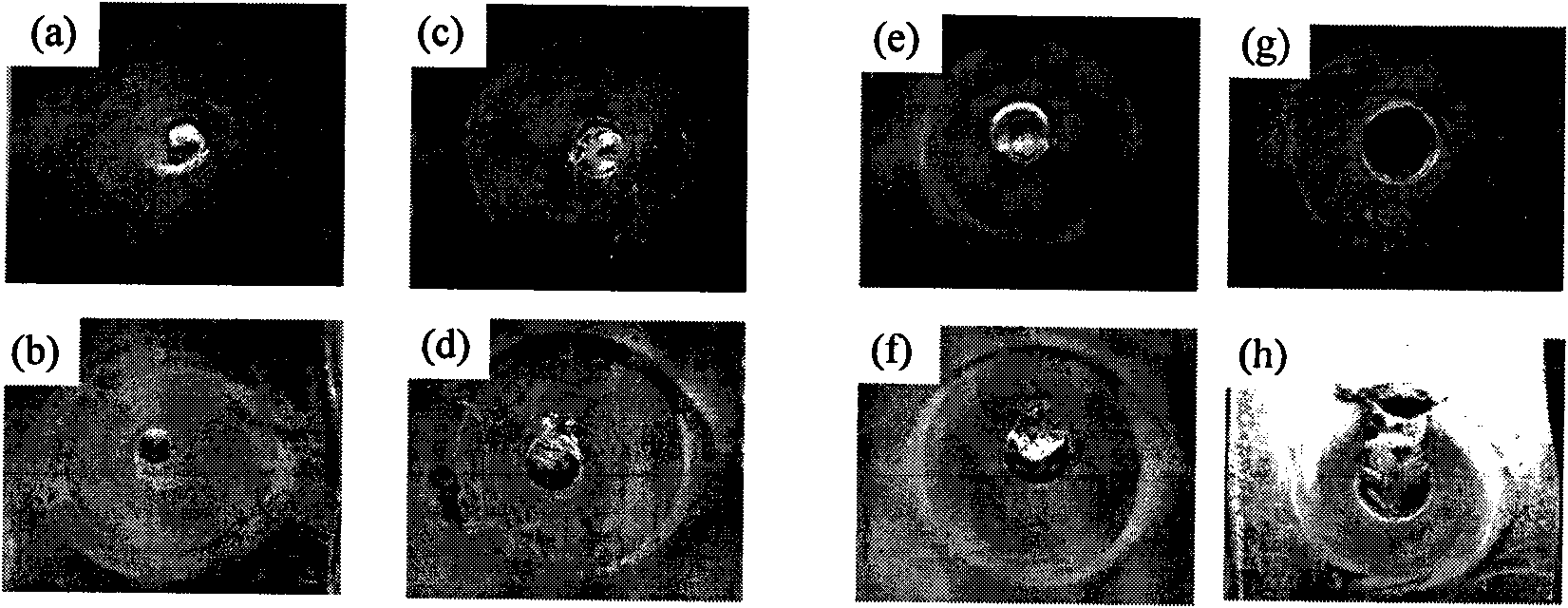

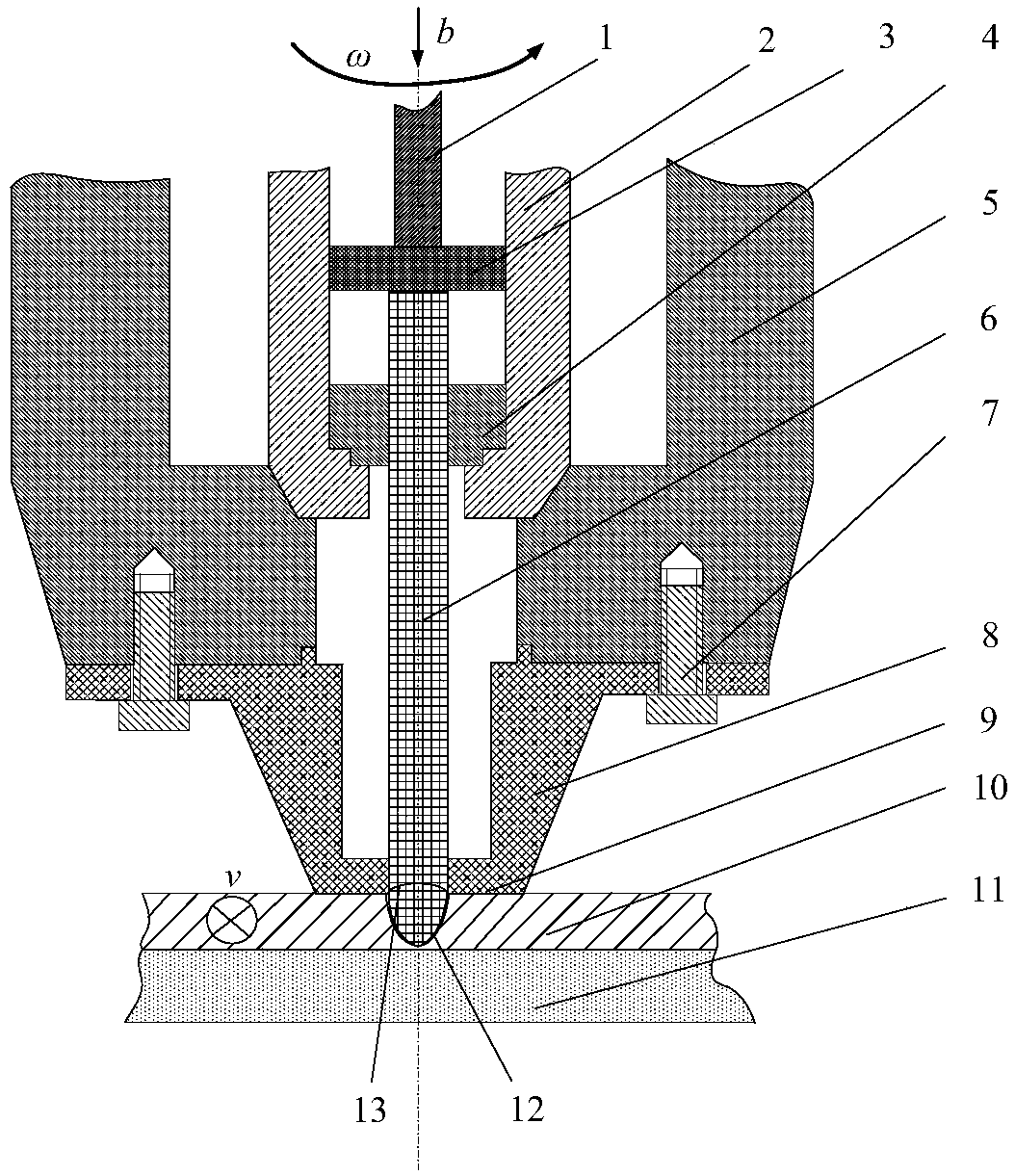

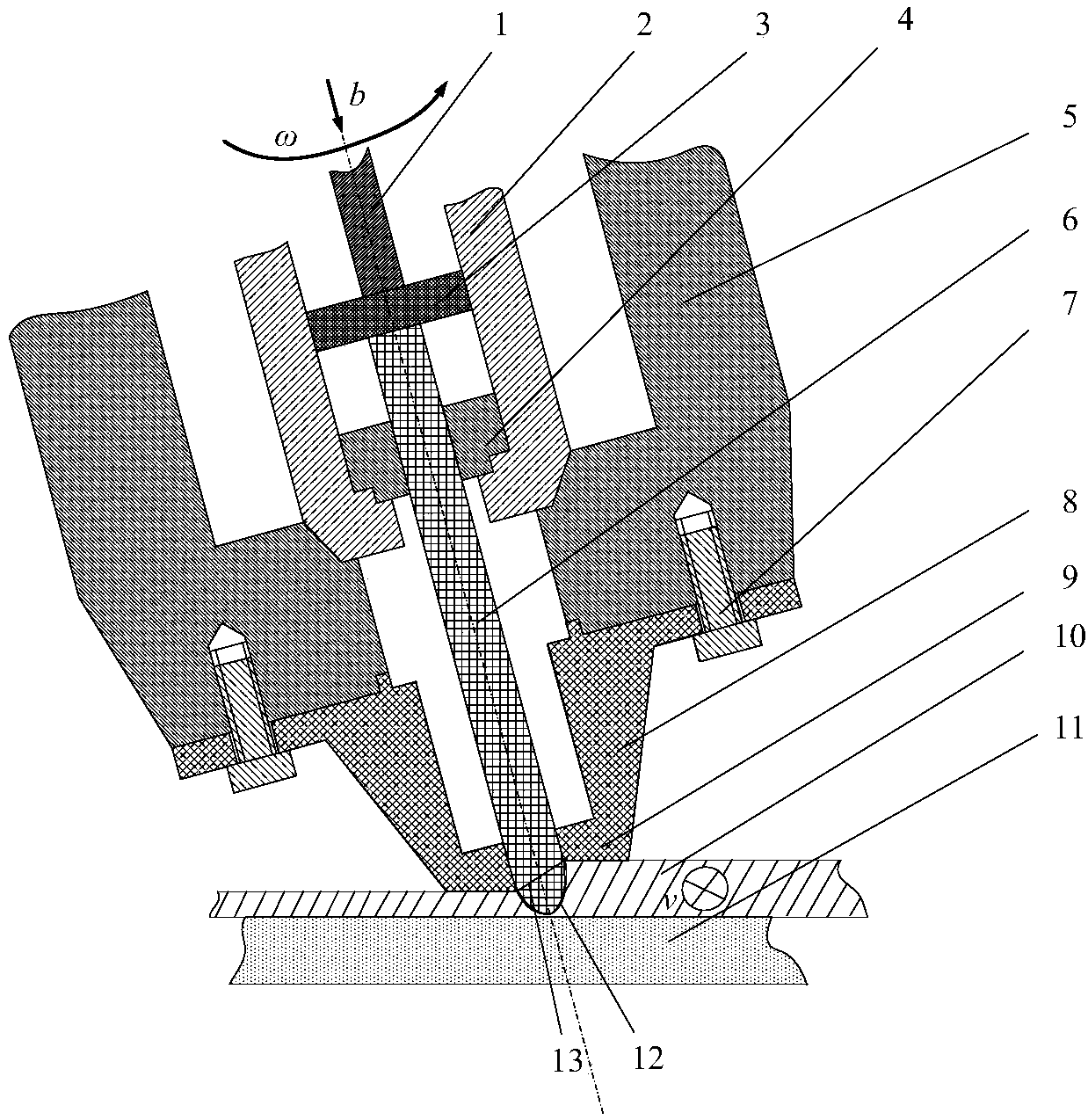

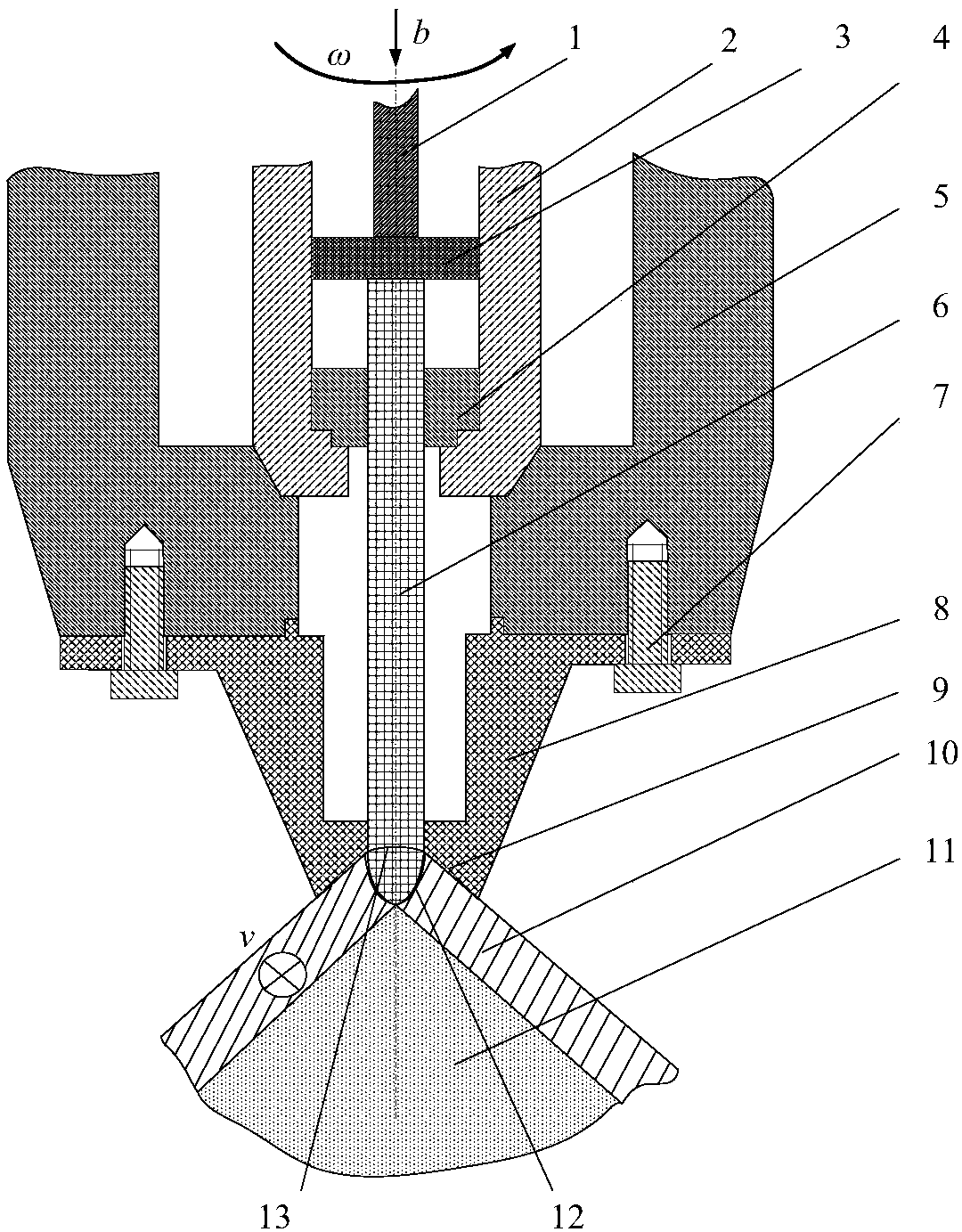

Embedded stirring friction spot welding method

InactiveCN101670482AAvoid wear and tearImprove flatnessNon-electric welding apparatusKeyholeMagnesium

The invention relates to an embedded stirring friction spot welding method which can be used for the overlapping spot welding of heterogeneous or homogeneous metal and is particularly suitable for theoverlapping between aluminum or magnesium and a harder heterogeneous metal material. The method comprises the following procedures: firstly, drilling on a harder second base material in advance and tapping in a hole or respectively drilling two coaxial holes with unequal diameters on both surfaces of the harder second base material; adopting a subplate with a glenoid die on light holes with equaldiameters; then assembling in an overlapping form and demanding that an aluminum plate is arranged above the harder second base material and the hole of the harder second base material, which has a small diameter, is arranged at the upper side; starting a pin-free type stirring head to rotate and leading the pin-free type stirring head to be in contact with the surface of an upper base material;limiting the press depth of the stirring head within 0.25-1 mm or so without penetrating through the welding interface; rubbing for several seconds and then rotatably extruding an upper plate into thehole of a harder lower plate to finish welding. Compared with the traditional stirring friction spot welding technology, the method prevents the abrasion of the hard second base material on a tool, prolongs the service life of the tool, has no keyhole on a joint and has smooth appearance.

Owner:XI AN JIAOTONG UNIV

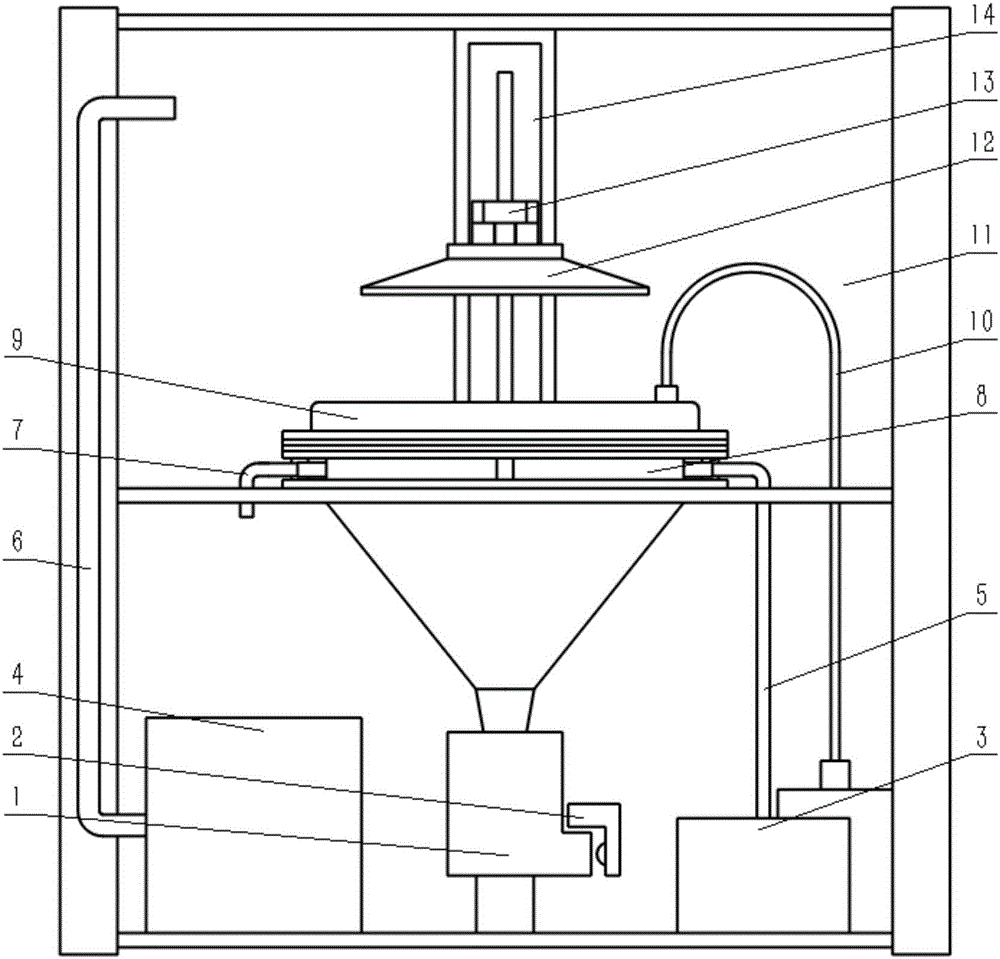

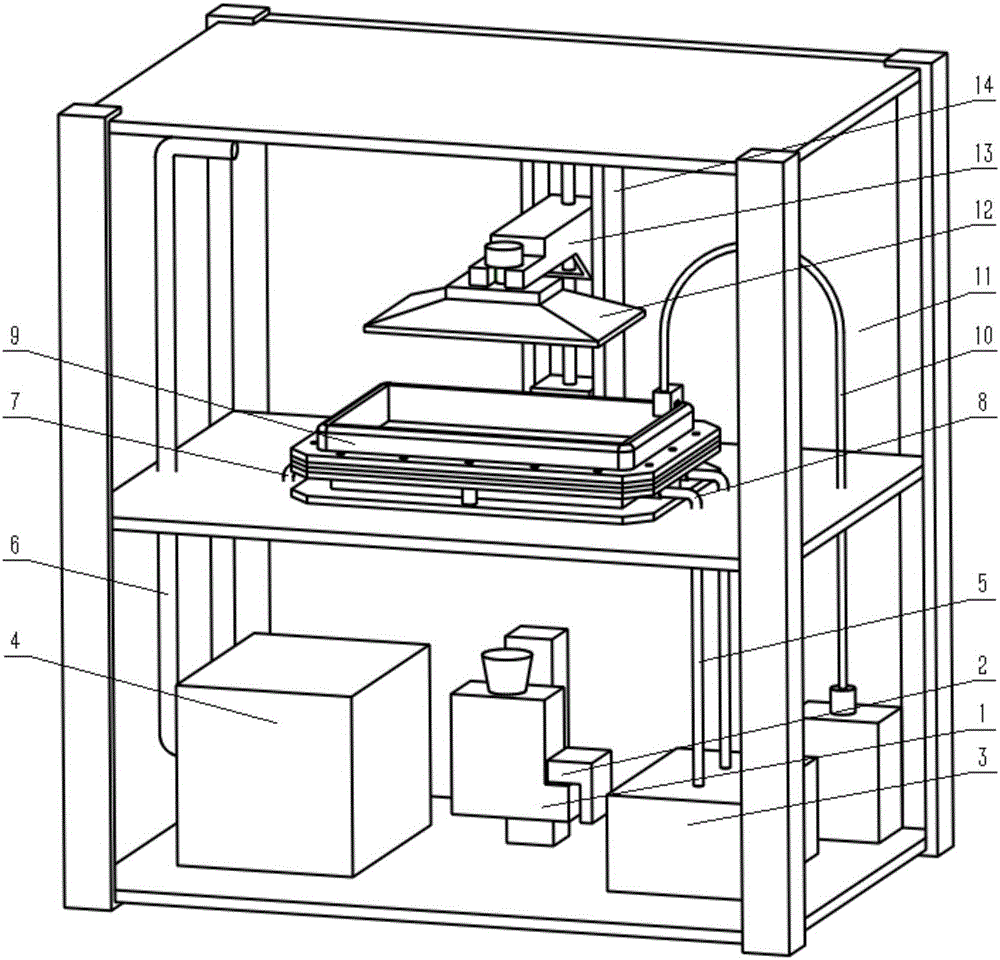

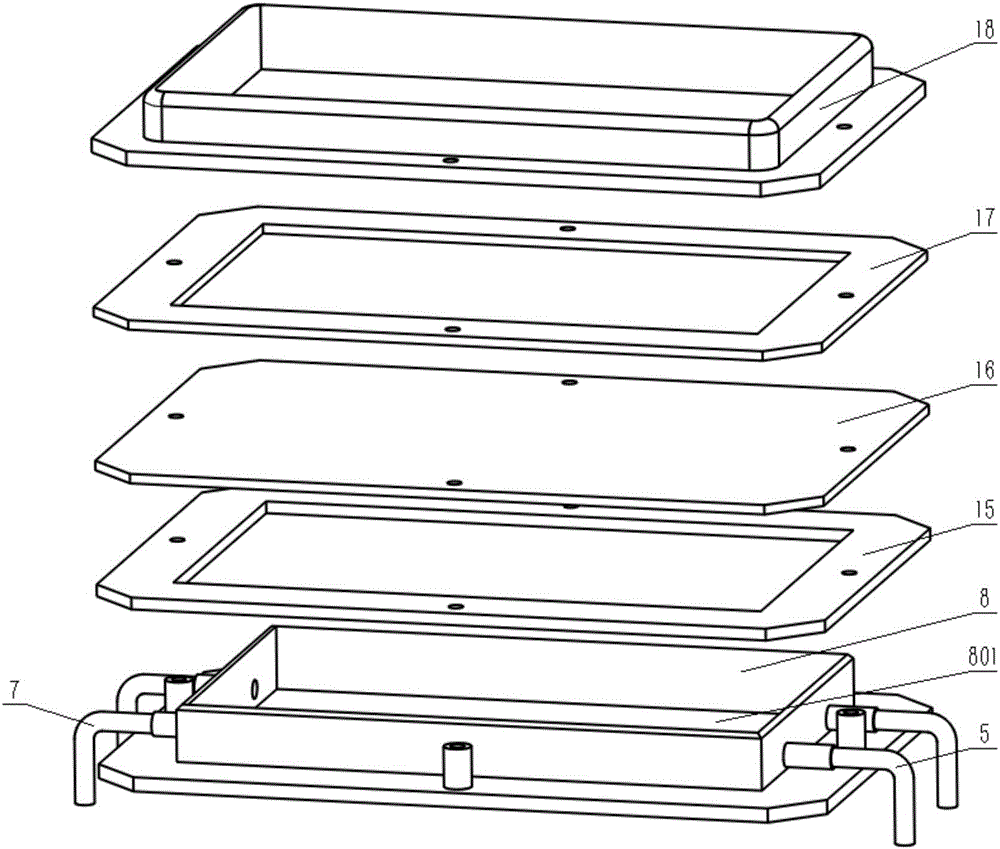

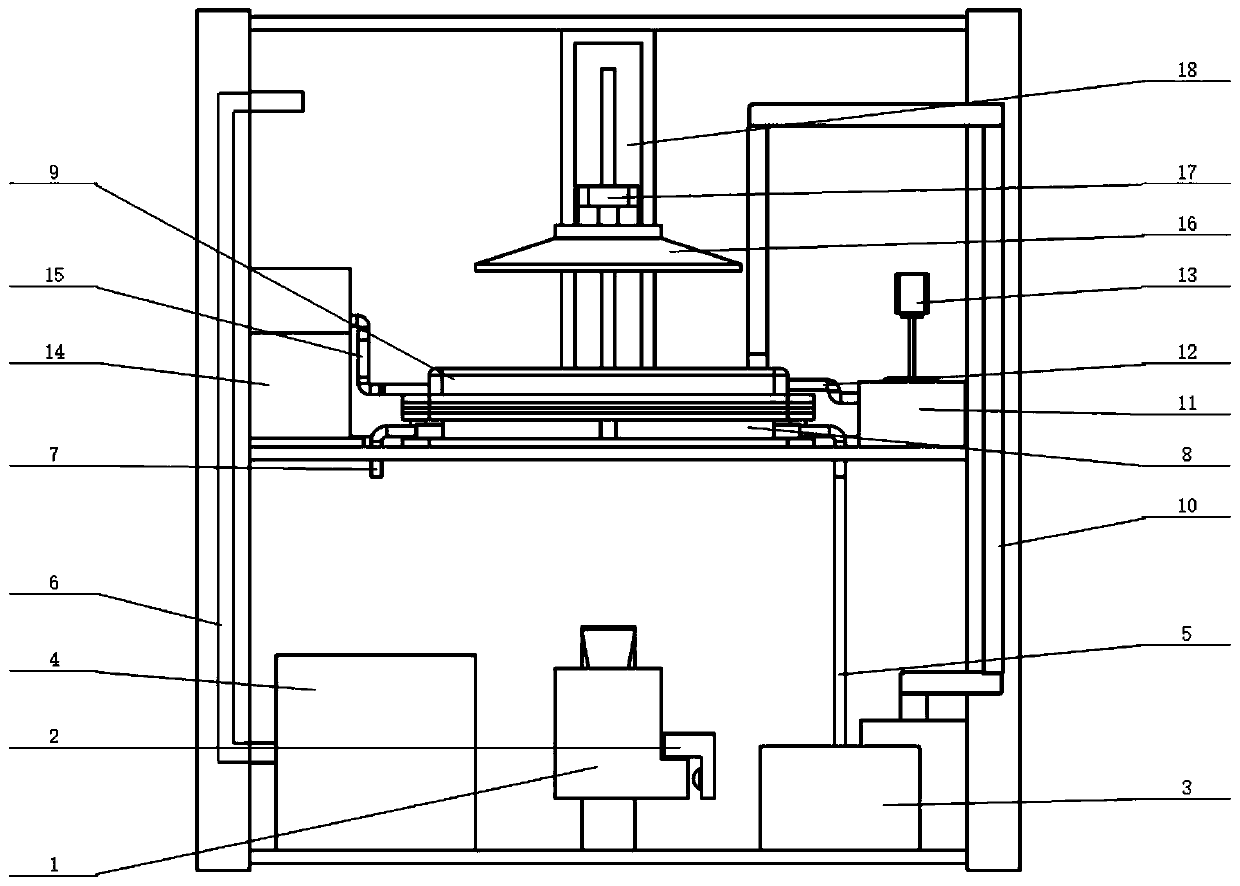

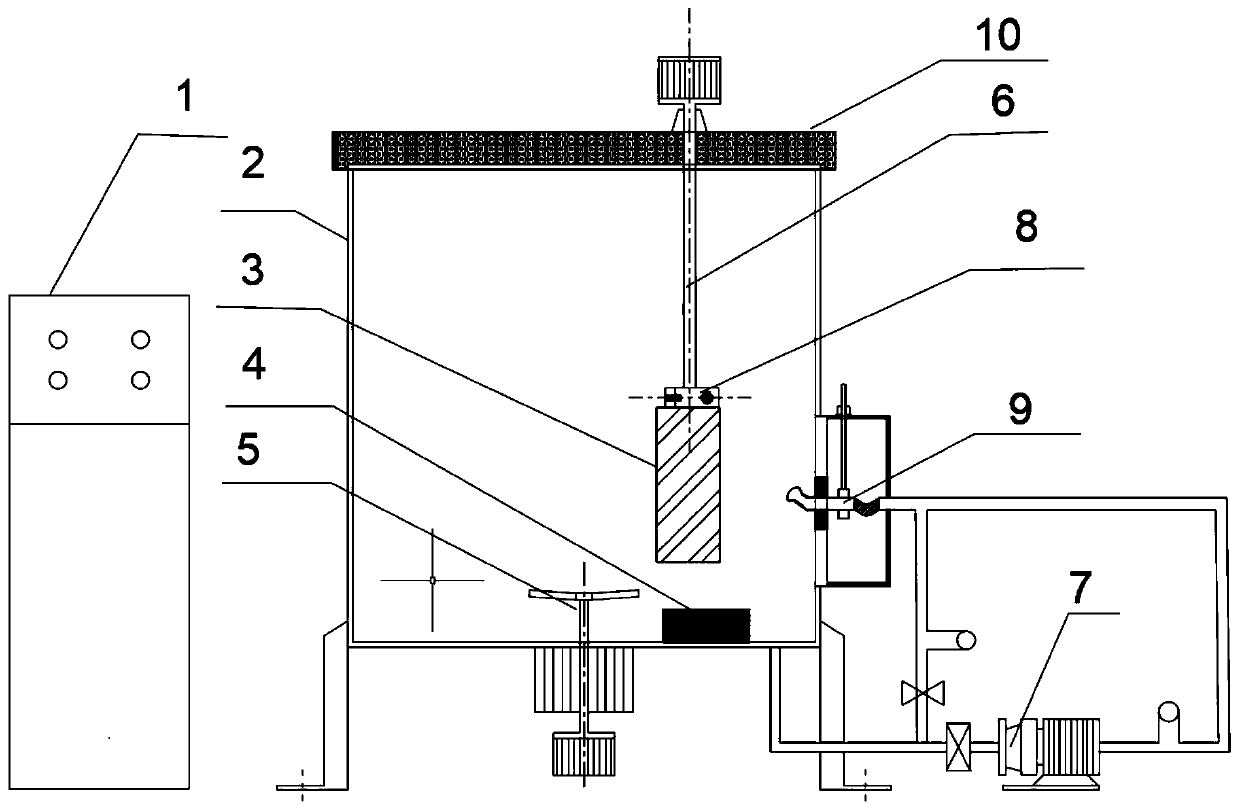

High-speed continuous photocuring type 3D printing device and working method thereof

ActiveCN106426915ALow costEfficient continuous printingManufacturing irradiation arrangementsManufacturing material handlingLiquid surfacesOxygen rich

The invention discloses a high-speed continuous photocuring type 3D printing device and a working method thereof. The 3D printing device comprises a machine case body which is divided into an upper cavity and a lower cavity by a middle partition board, wherein an image forming module is arranged in the lower cavity, a window box and an oxygen supply cooling module are arranged in the upper cavity and are combined to be fixedly mounted on the middle partition board, the oxygen supply cooling module is arranged right below the window box, and the image forming module I is arranged right below the window box; a printing platform is arranged right above the window box and is mounted on a Z-direction worktable; and the window box is connected with a raw material feeding unit. The 3D printing device is integrated with the advantages of a compound oxygen-rich film, oxygen supply cooling and liquid surface auxiliary pressurization of the window box, so that the low-cost and efficient continuous printing of large-sized products with arbitrary shapes is realized, the range of applicable materials is wide, the printed products are high in precision and quality and good in uniformity, and the process is stable and reliable. An industrial-grade solution is provided for the high-speed continuous photocuring type 3D printing.

Owner:SHENZHEN ELEGOO TECH CO LTD

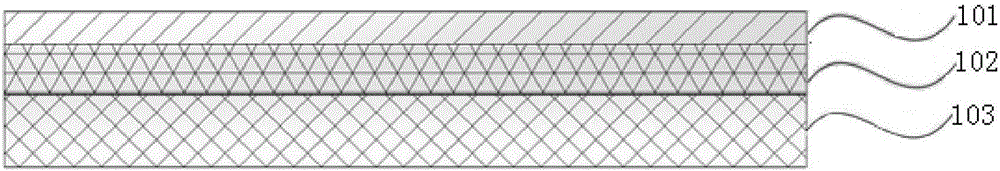

Anticoagulation high polymer biomaterial as well as preparation method and application thereof

ActiveCN106730051AGuaranteed persistenceGuaranteed stabilityPharmaceutical containersMedical packagingPlasma technologyAnticoagulant

The invention discloses an anticoagulation high polymer biomaterial which comprises a substrate layer, an anticoagulation coating, and a plasma polymerization layer positioned between the substrate layer and the anticoagulation coating, wherein the substrate layer is made of a biomedical material; the plasma polymerization layer is an allylamine plasma polymerization membrane layer deposited on the substrate layer; the anticoagulation coating is an anticoagulant layer fixed on the plasma polymerization layer; and the anticoagulants comprise hirudin, heparin and the like. Anticoagulant molecules are fixedly grafted on the material surface by utilizing the pulsed plasma technology and surface heparin grafting method, and effective molecule orientation is remained by heparin molecules, so the anticoagulant performance is close to the performance of heparin molecules in the solution. Meanwhile, the heparin molecules are difficultly scoured off by blood, the persistence and stability of the anticoagulation effect are guaranteed, and the service life is long. The invention further discloses a preparation method and application of the anticoagulation high polymer biomaterial.

Owner:スンナテクノロジーズシャンハイカンパニーリミテッド

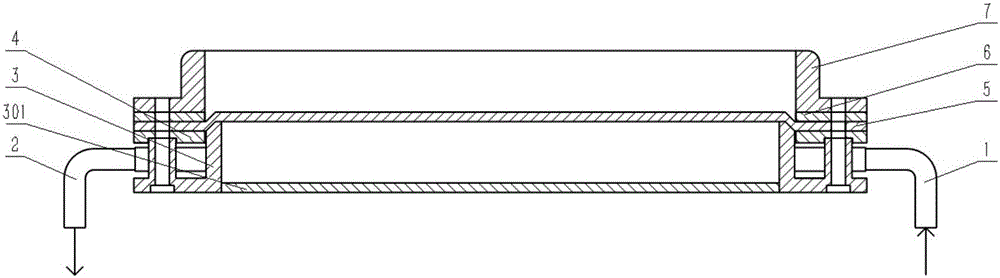

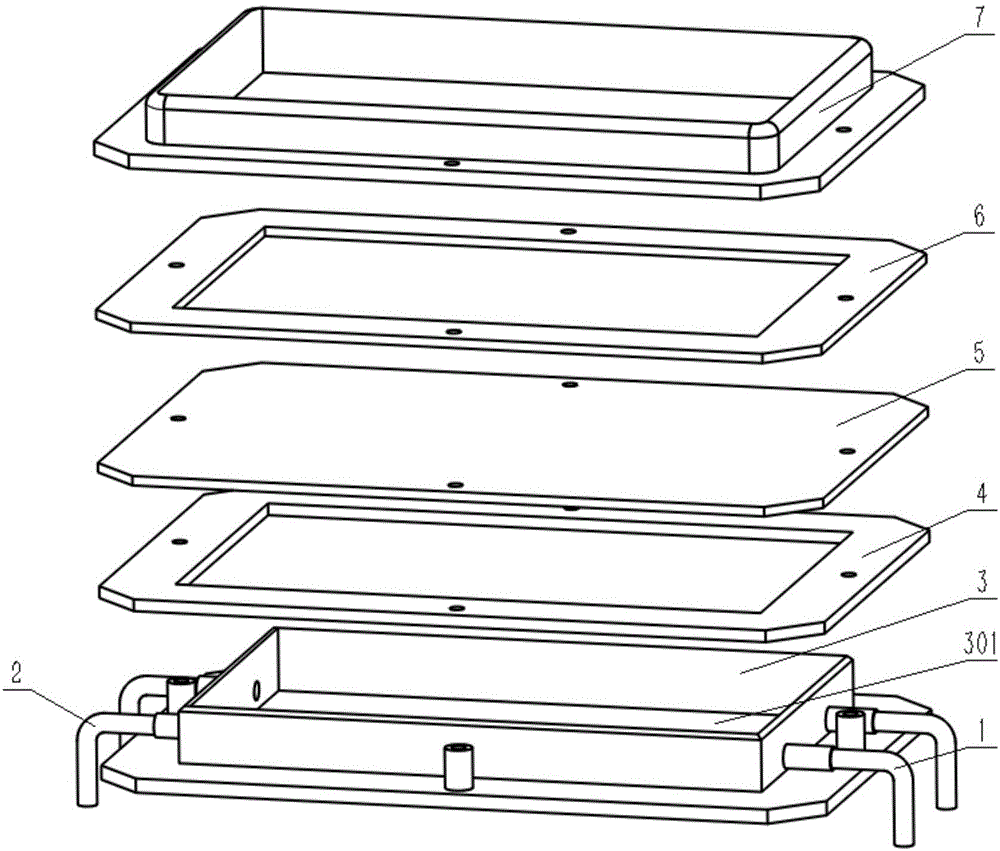

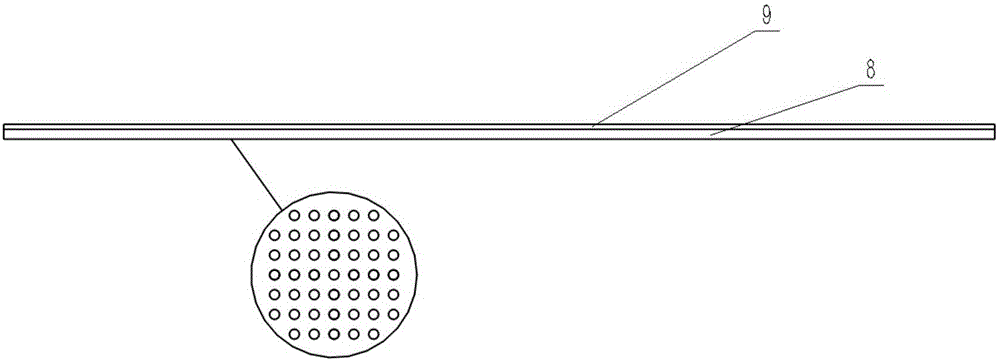

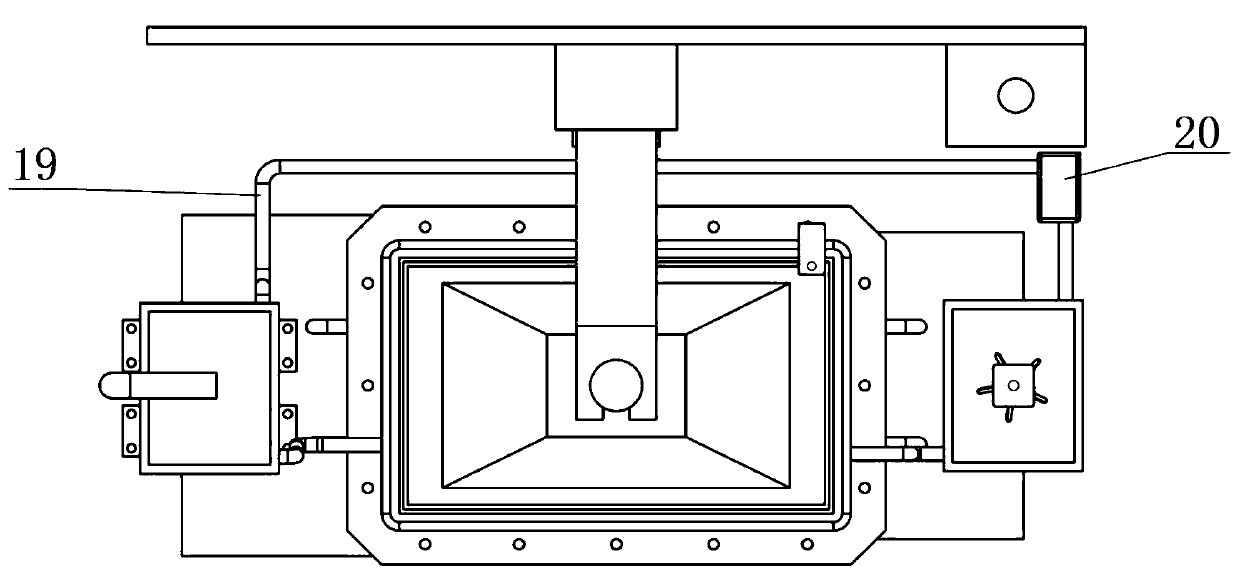

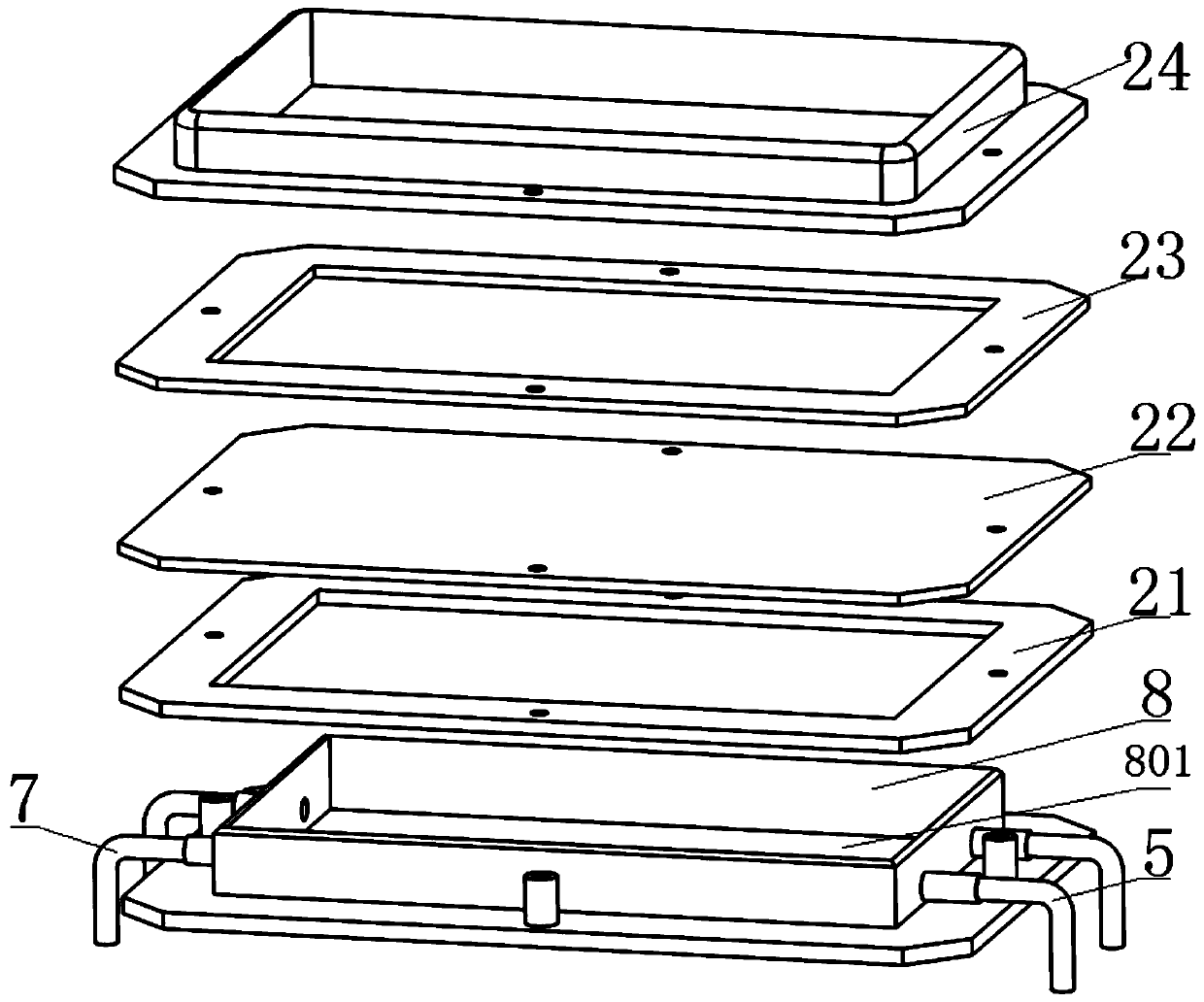

Forming window for high-speed continuous photocuring 3D printing

ActiveCN106273516AEfficient printingTroubleshoot quick fixesAdditive manufacturing apparatusCooling chamberEngineering

The invention discloses a forming window for high-speed continuous photocuring 3D printing. The forming window applied to a photocuring 3D printer comprises a window box and an oxygen supply cooling module. The photocuring 3D printer is divided into an upper cavity and a lower cavity through a middle partition. The window box and the oxygen supply cooling module are arranged in the upper cavity of the case of the photocuring 3D printer. The window box and the oxygen supply cooling module are fixedly mounted on the middle partition in a combined manner. Two ends of an oxygen supply cooling chamber are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline, and the oxygen supply cooling chamber, the o cooling gas inlet pipeline and the cooling gas outlet pipeline form the oxygen supply cooling module. The forming window has the advantages that low-cost and efficient continuous printing of large-size optional-shape parts can be achieved, the forming window is wide in applicable materials, the precision and quality of the printed parts are high, the printed parts are good in consistency, and process stability and reliability are achieved. In addition, the forming window is high in industrial application value and applicable to a desktop-level 3D printer and industrial 3D printing.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

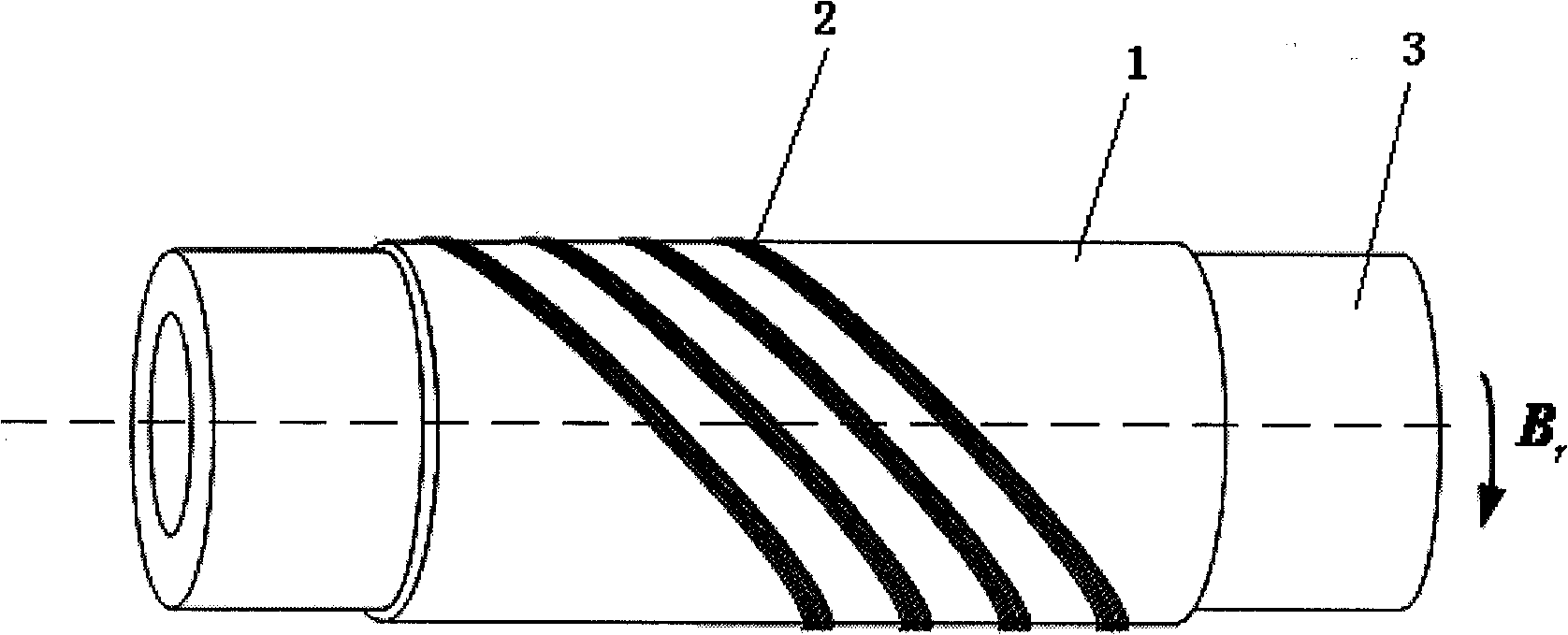

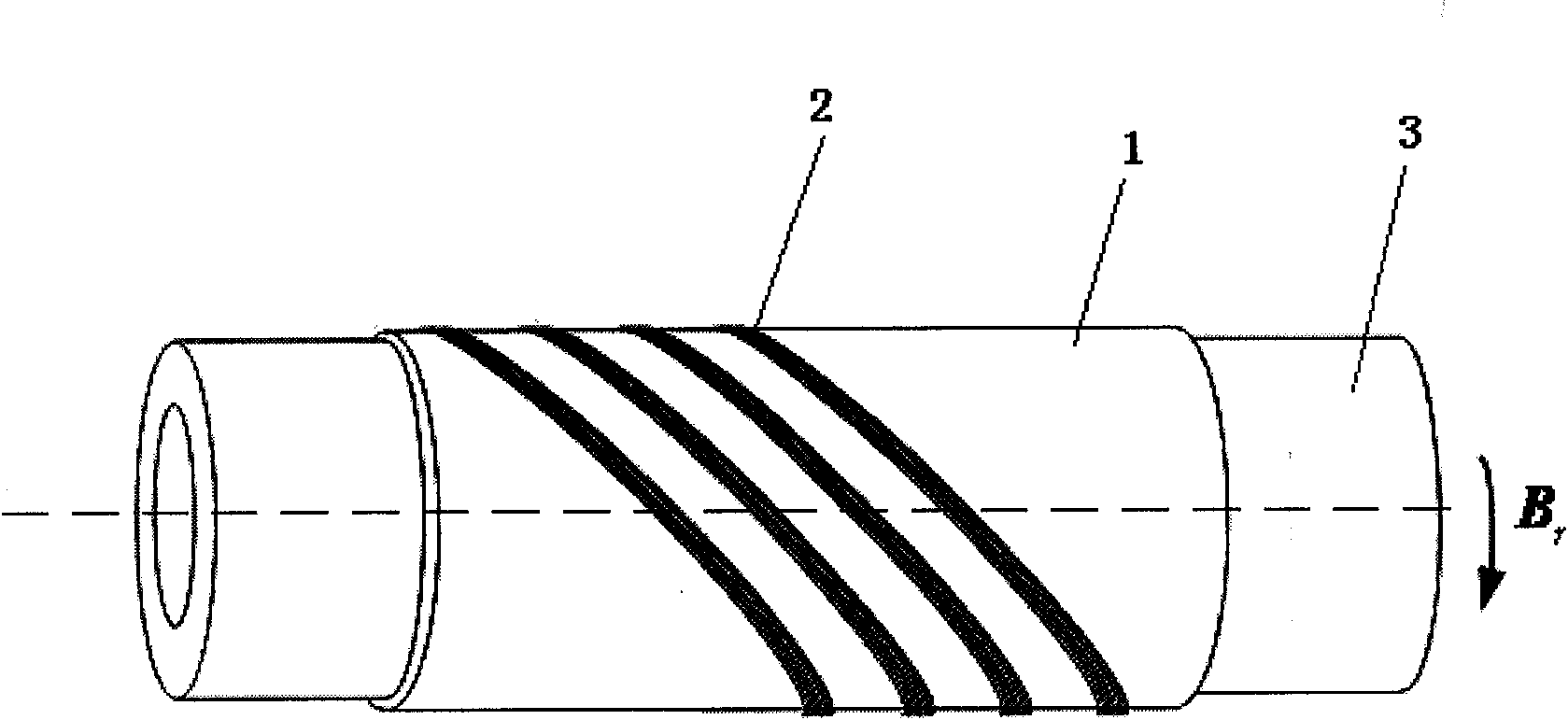

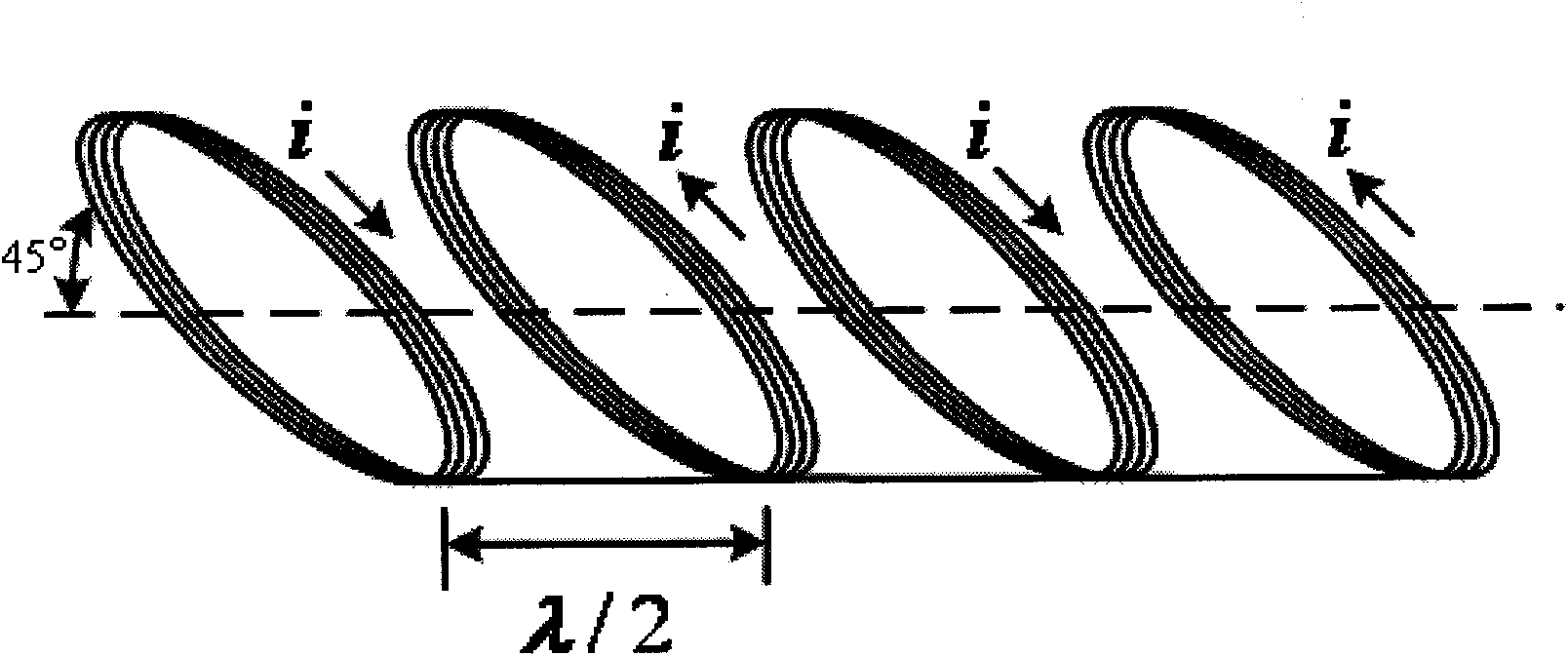

Pipeline axial ultrasonic guided wave energy exchange probe

InactiveCN101813670ALong distanceWith frequency selection functionAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsAlloyUltrasonic guided wave

The invention relates to a pipeline axial ultrasonic guided wave energy exchange probe, which is characterized in that the pipeline axial ultrasonic guided wave energy exchange probe comprises a premagnetized nickel-iron alloy sheet and a plurality of groups of coil belts, wherein the nickel-iron alloy sheet is tightly fixed on the outer wall of a pipeline to be detected in the circumferential direction of the pipeline to be detected, the rest magnetic flux density on the nickel-iron alloy sheet is distributed along the circumferential direction of the pipeline to be detected, a plurality of groups of coil belts are a plurality of groups of coil belts formed by winding a conducting wire on the premagnetized nickel-iron alloy fixed on the outer wall of the pipeline to be detected, the two adjacent groups of coils have the same center distance, and in addition, the two adjacent groups of coils have the opposite winding directions. A pulse power amplifier is connected with the starting end of the conducting wire for winding a plurality of groups of coil belts, and the tail end of the conducting wire for winding a plurality of groups of coil belts is sequentially connected with a wave filter amplification circuit and an oscilloscope. The invention can be widely applied to the field of nondestructive detection of the pipeline.

Owner:TSINGHUA UNIV

Metal surface cleaning anti-scaling agent containing compound acid

InactiveCN103074635ALittle change in temperature differenceEasy to implementActive agentSurface cleaning

The invention belongs to the technical field of chemical cleaning of metal surfaces, and particularly relates to a metal surface cleaning anti-scaling agent containing compound acid. The agent comprises two or more components in parts by weight as follows: 70-98 parts of sulfamic acid, 0.05-20 parts of glycolic acid, 0.05-20 parts of tartaric acid, 0.05-20 parts of lactic acid, 0.05-20 parts of gluconic acid, 0.05-20 parts of salicylic acid, 1.5-1.8 parts of a sulfamic acid corrosion inhibitor and 0.2-0.45 part of a surfactant. The agent utilizes sulfamic acid as the main pickling potion, the material status is solid, therefore the transportation is convenient, the cost is low, the pickling temperature is low, the implementation is facilitated, and time, labor and energy are saved. During water washing after pickling, the temperature difference born by a water wall can be reduced greatly under the condition of insufficient heat source capacity, and the protection of the water wall is facilitated. The agent is further provided with characteristics of simple postprocessing, low cleaning cost, and the like, can be applied to chemical surface cleaning of various metal materials such as carbon steel, stainless steel, alloy steel and the like, and can be widely applied to chemical cleaning of various large-capacity boilers and heat exchangers.

Owner:LIAONING ELECTRIC POWER COMPANY LIMITED POWER SCI RES INSTION +3

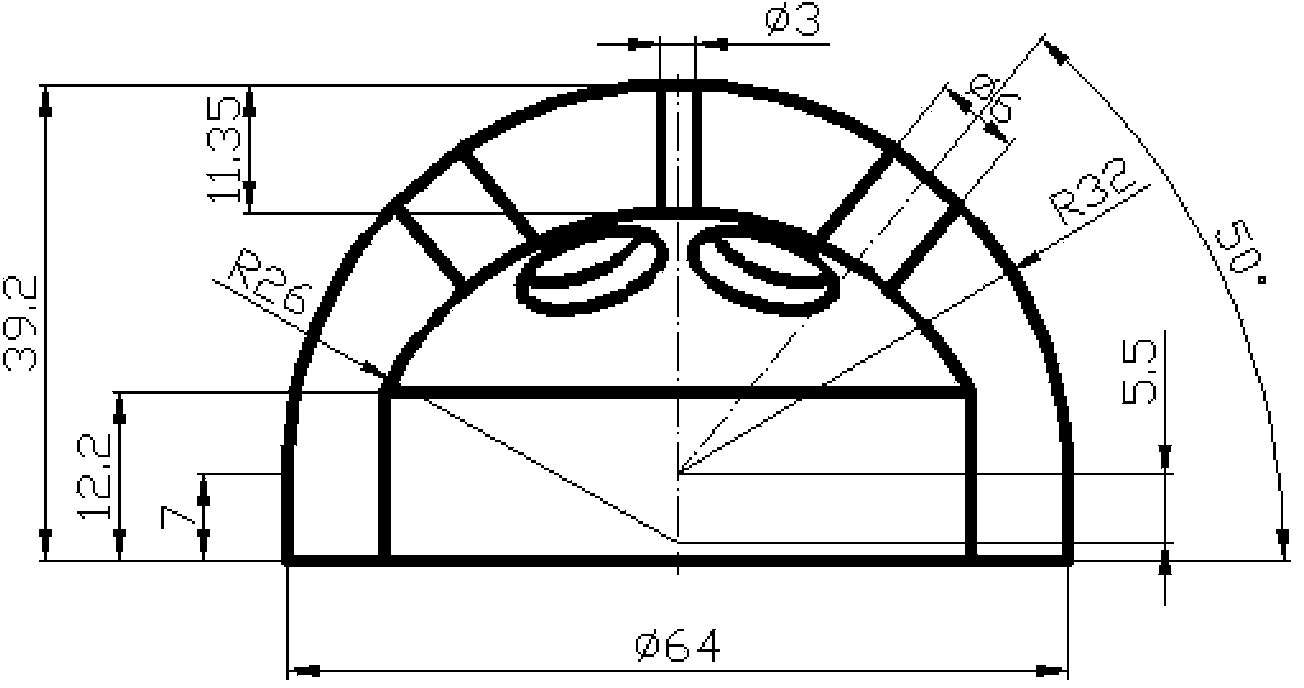

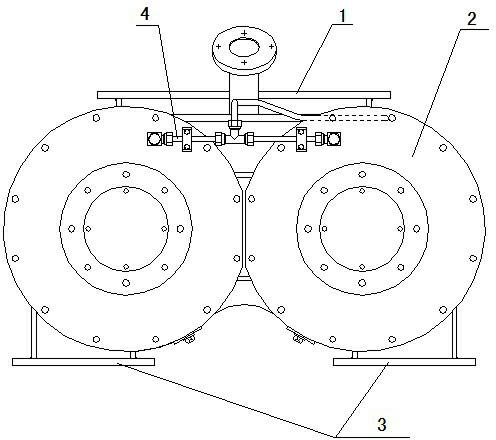

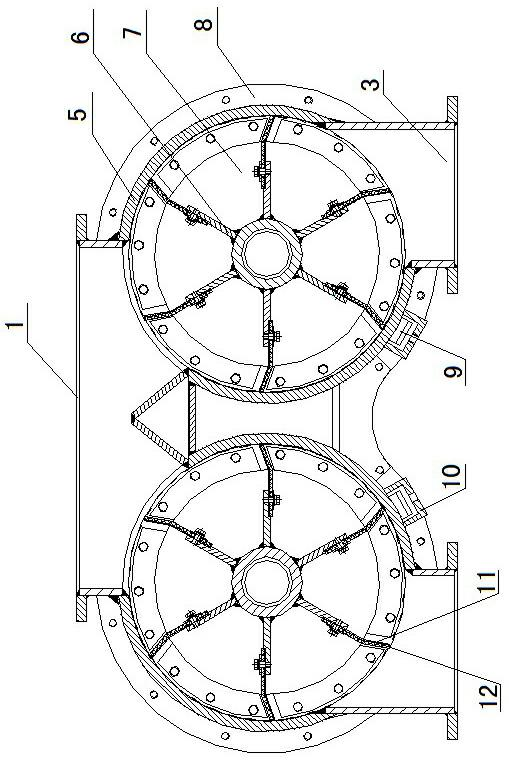

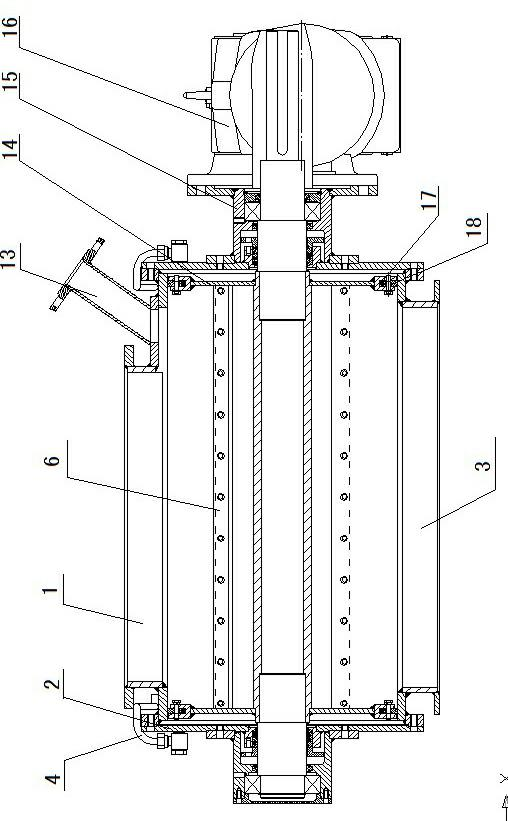

Dual-channel star-shaped feeder

The invention relates to powder material quantitative feeding devices, and in particular relates to a dual-channel star-shaped feeder. The dual-channel star-shaped feeder comprises a dual-cavity shell, two star-shaped impellers and a deceleration motor, wherein the dual-cavity shell consists of a sharing feeding hole, two unique discharging openings and two middle cylindrical cavities arranged in parallel, the two unique star-shaped impellers are respectively arranged in the two cylindrical cavities, and output shafts of the two star-shaped impellers are respectively arranged in shaft holes of the two shaft-mounted deceleration motors; and blades of the star-shaped impellers are elastic blades, the plurality of elastic blades and the end parts of the impellers form star-shaped bays, a floating seal structure is arranged between the outer edge of a baffle of the end part of each impeller and the dual-cavity shell, and the feeding hole and the discharging openings of the dual-channel star-shaped feeder are separated through the floating seal structure. The dual-channel star-shaped feeder disclosed by the invention divides one path of material flow into two paths of quantitative feeding of any proportion, any flow and controllable material flow, has the characteristics of pressure isolation, high temperature resistance and long service life, and solves a material feeding problem of changing a dual-path single system to be a dual-path double system.

Owner:张正旸

Continuous surface exposure ceramic 3D printing device and working method thereof

ActiveCN109795010ARealize continuous surface exposure printingSolve layeringAdditive manufacturing apparatusFeeding arrangmentsLiquid storage tankSlurry

The invention discloses a continuous surface exposure ceramic 3D printing device and a working method thereof. Before printing, a raw material feeding unit pours ceramic slurry into a window box; after a water pump pulls out the ceramic slurry in a first slurry tank, the ceramic slurry is conveyed into a second slurry tank through a second slurry conveying pipeline, the ceramic slurry in the second slurry tank flows into aliquidstorage tank of the window box through the second slurry conveying pipeline, the ceramic slurry in the liquid storage tank of the window box flows into the first slurrytank through the first slurry conveying pipeline, and the circulation flow of ceramic slurry in the first slurry tank, the liquid storage tank, and the second slurry tank is realized throughthe waterpump; and the continuous surface exposure technology is adopted, continuous molding of ceramic 3D printing is realized, and continuous printing is realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Preparation method of co-injection multi-layer structure part

ActiveCN113319284AImprove the bonding strength of the interfaceGood product performanceInterface bondingHeat treating

The invention discloses a preparation method of a co-injection multi-layer structure part. The preparation method of the co-injection multi-layer structure part comprises the following steps of respectively mixing and granulating powder A and powder B formed by mixing bonding powder B1 and strengthening powder B2 with a binder to obtain uniform feeds A and B; then sequentially injecting the two feeds into a mold cavity by utilizing a co-injection molding technology to obtain a product green body, and removing the binder in the green body through a degreasing process; and finally, carrying out co-sintering densification and annealing heat treatment so as to obtain the multi-layer structure part. The preparation method of the co-injection multi-layer structure part provided by the invention has the advantages of being free of component limitation, high in interface bonding strength, simple in process, suitable for large-scale production and the like, is beneficial to improving the comprehensive performance of parts, solves the problems of large component limitation, low interface strength, complex process, high cost and the like in the prior art, and is very suitable for preparing multi-layer structure parts.

Owner:CENT SOUTH UNIV

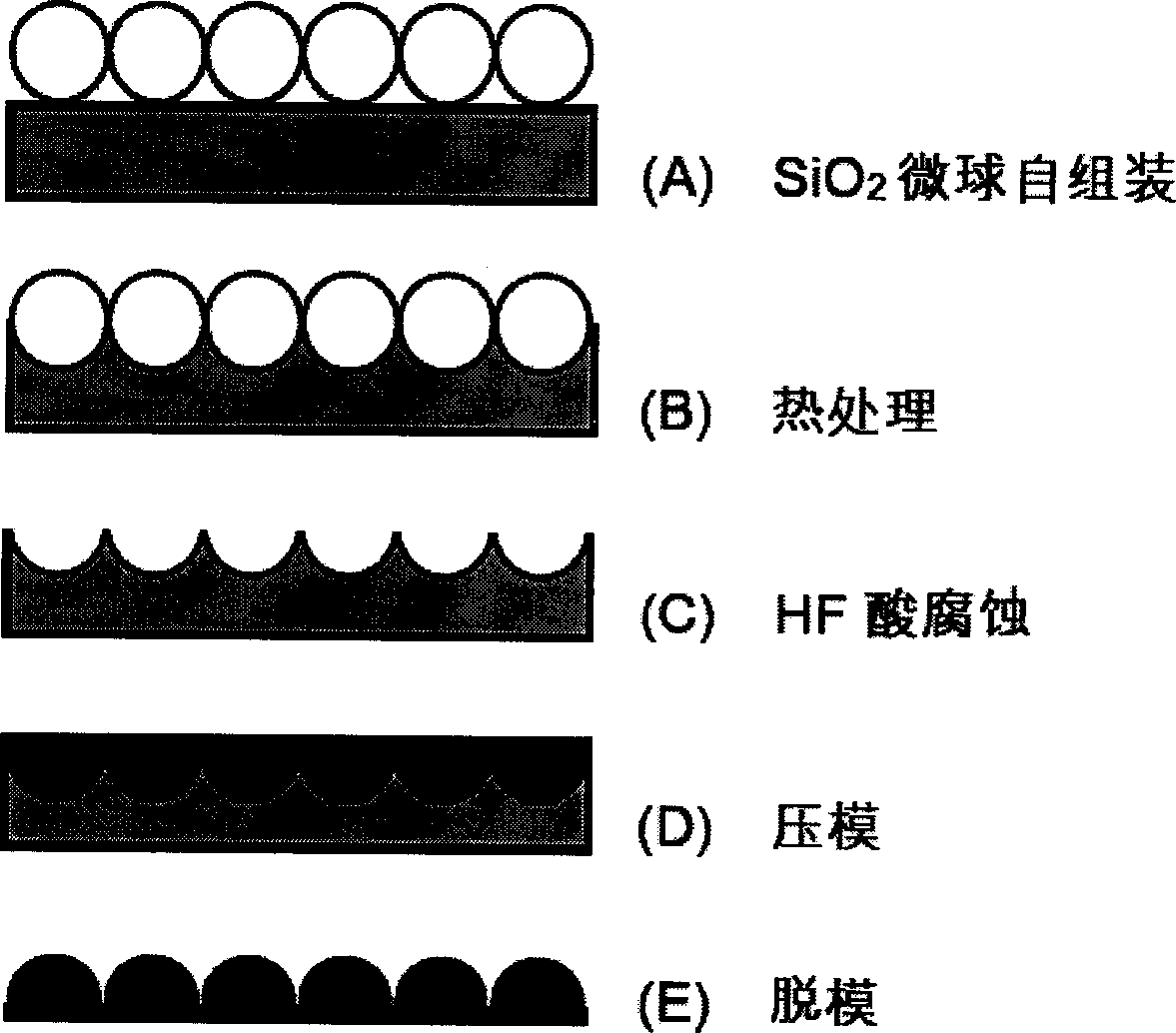

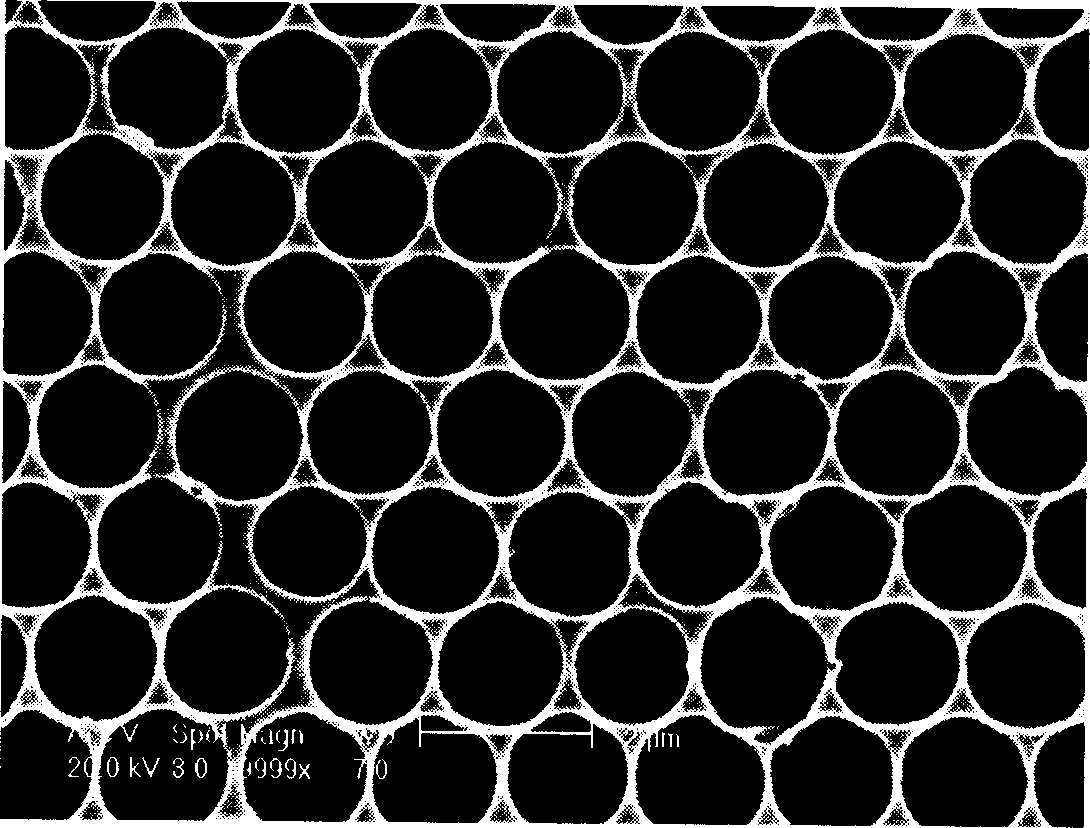

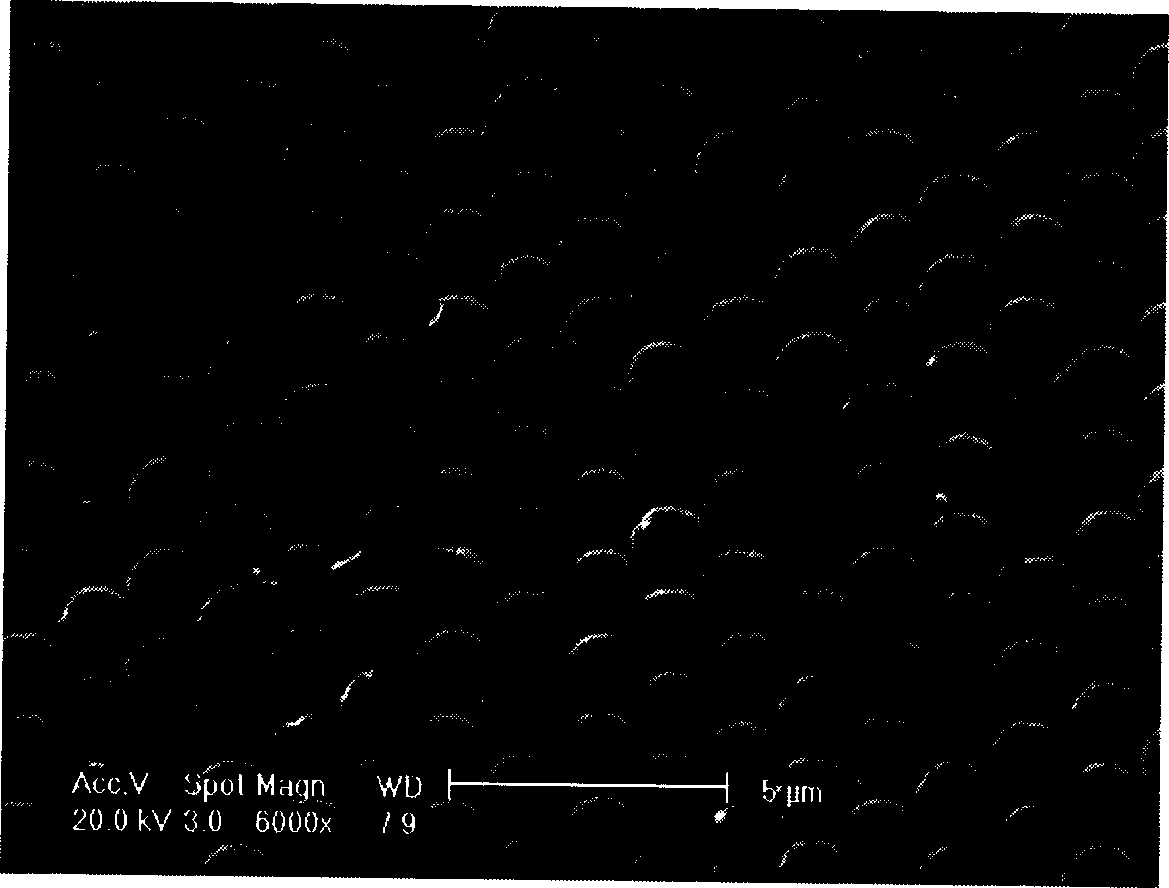

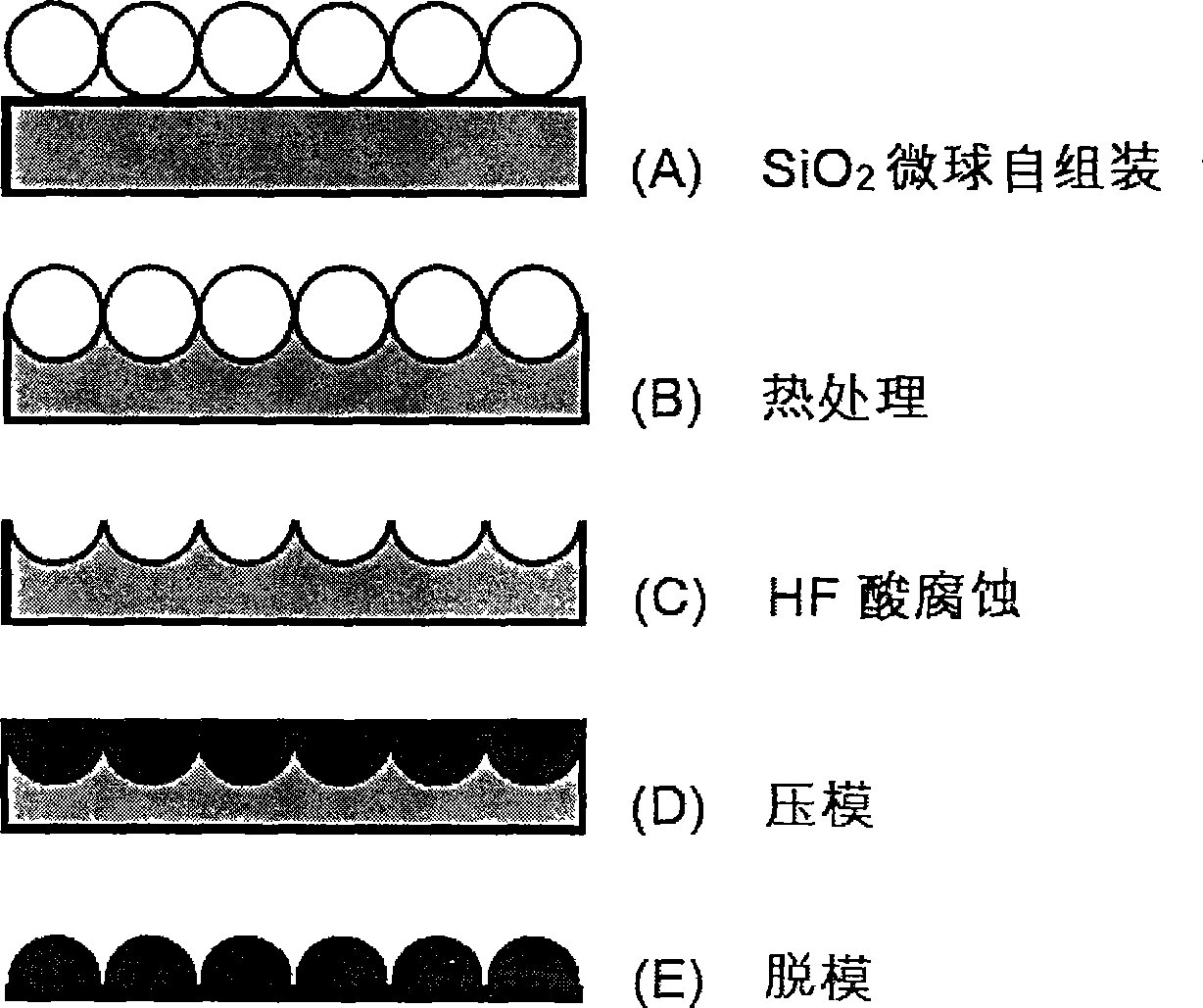

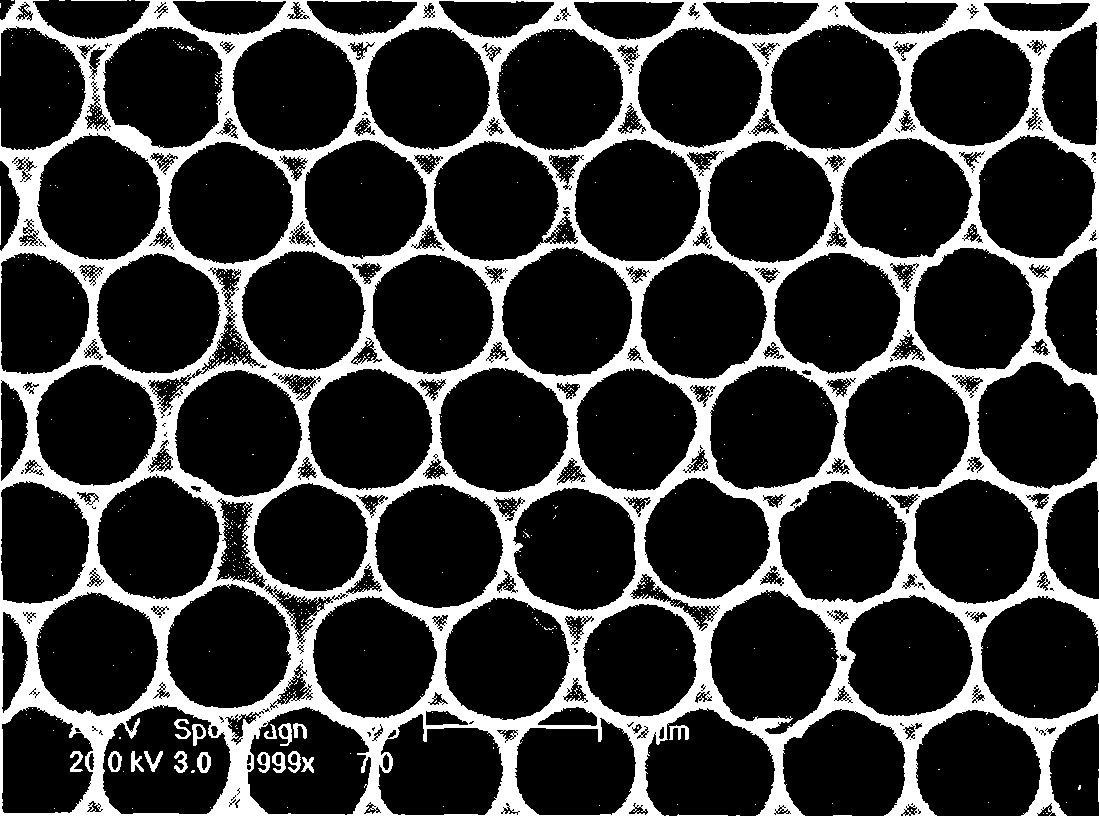

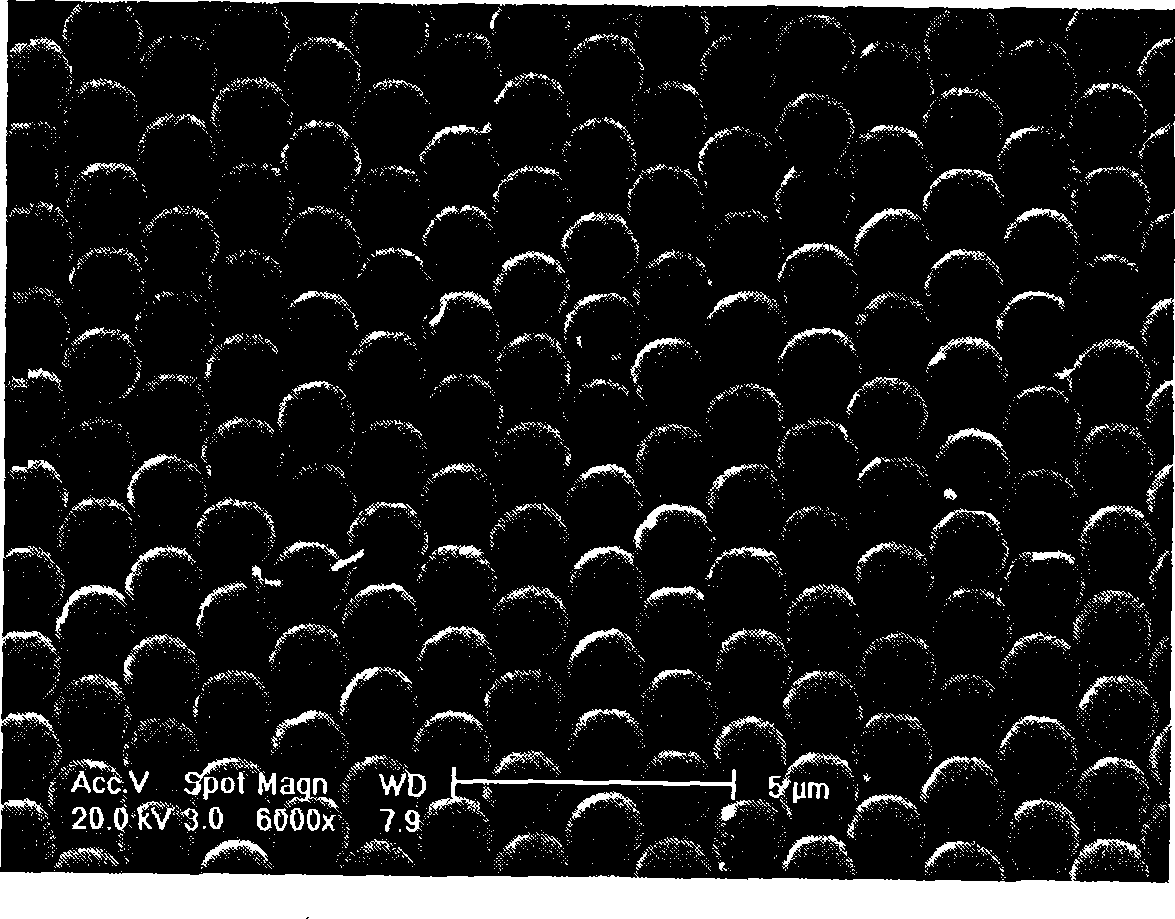

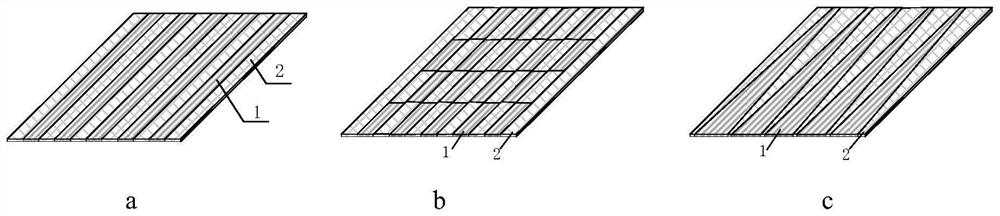

Prepn of submicron/micron micro lens array on polymer surface

InactiveCN1772463ALow costWide range of applicable materialsOptical articlesPolymeric surfaceNanometre

The present invention discloses the preparation of micron / submicron micro lens array on polymer surface and belongs to the field of nanometer / micron micro structure material and preparing technology. The preparation process is combination of self-assembling process and pressure molding process, and includes the first preparation of micron / submicron print die plate via combination of colloid crystal template and hot treatment technology, and the subsequent hot press demolding to prepare micron / submicron micro lens array. The present invention has the advantages of low cost, simple technological process and apparatus, capacity of mass production, high micro lens performance, etc.

Owner:NANJING UNIV

Stationary shaft shoulder friction stir welding method capable of coaxially adding materials by forming groove

InactiveCN109551097AAvoid inclusionsImprove applicabilityNon-electric welding apparatusWeld seamFront edge

The invention provides a stationary shaft shoulder friction stir welding method capable of coaxially adding materials by forming a groove. A U-shaped groove is formed in a base material to be welded,a stationary shaft shoulder is fixed to a main shaft base body, a stirring needle is composed of the same material as the base material to be welded, and the end of the stirring needle is machined into a shape slightly smaller than the section size of the U-shaped groove. Heat is produced by friction when the stirring needle is in contact with the base material to be welded, and meanwhile, a stirring tool keeps moving in the direction of a welding seam. A restrained cavity matched with the shape of the groove of the base material is designed in the front edge of the stationary shaft shoulder of the stirring tool so that the flowing welding seam material cannot emerge from the front end of the shaft shoulder. According to the stationary shaft shoulder friction stir welding method capable ofcoaxially adding the materials by forming the groove, the welding materials can be coaxially added, the joint strength is strengthened, meanwhile, the stationary shaft shoulder technology is adoptedin a combination mode, and the problems that in the traditional friction stir welding process, the welding materials cannot be coaxially added, joint material thinning exists, the joint has differentthicknesses, and the welding difficulty of an angle joint is large are solved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

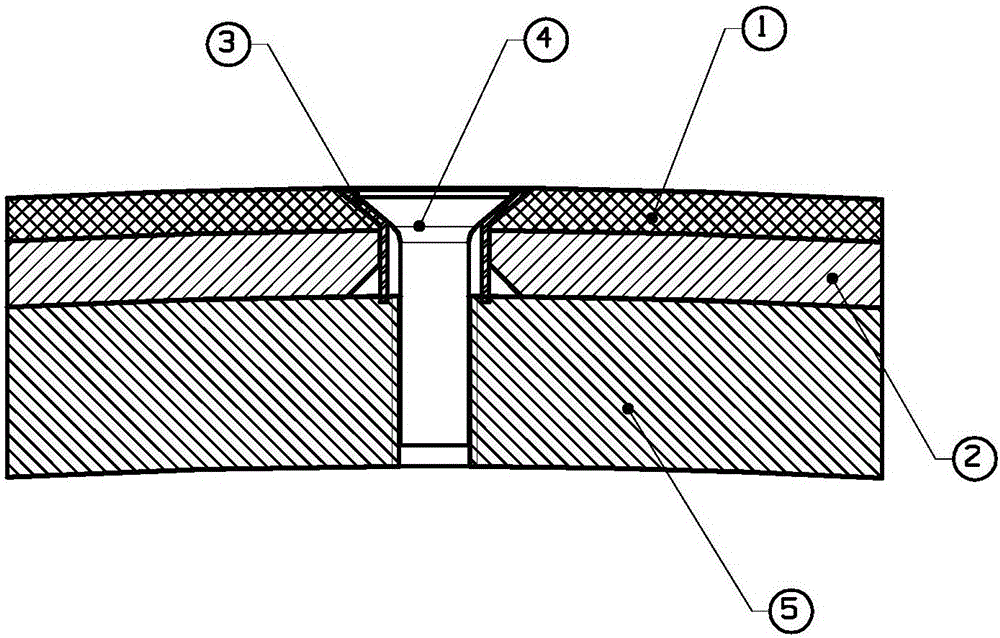

Method for connecting two thin plates by using countersunk riveting bushing

InactiveCN106050845ASimple structureWide range of applicable materialsSheet joiningCountersinkEngineering

The invention discloses a method for connecting two thin plates by using a countersunk riveting bushing, and aims at providing a method which is simple in structure and high in reliability, is capable of decreasing the opening number of thin plates and is suitable for the connection of different thin plate materials. The method is realized through the technical scheme as follows: the lower end of the countersunk riveting bushing for connecting an upper thin plate with a lower thin plate is cylindrical and the upper end thereof is inverted truncated cone-shaped; the wall thicknesses of the upper end and lower end are the same; a connection hole for fixing the thin plates is combined with an external mounting hole; the contact surfaces of the upper and lower thin plates are coated with glue to be adhered and fixed; a through hole and a double-sided countersink are formed in a thick plate; a countersink in the upper surface of the upper thin plate is matched with the truncated cone-shaped appearance of the upper end of the bushing; a 90-degree countersink is formed in the lower surface of the lower thin plate; the upper end of the countersunk riveting bushing is mounted in the countersink of the upper thin plate; at the lower end of the bushing, a riveting tool is used for expanding the 90-degree countersink of the lower thin plate; a countersunk rivet penetrates through a through hole in the countersunk riveting bushing so as to fix a riveted assembling component onto a mounting platform; the upper thin plate and the lower thin plate are connected to form the assembling component.

Owner:10TH RES INST OF CETC

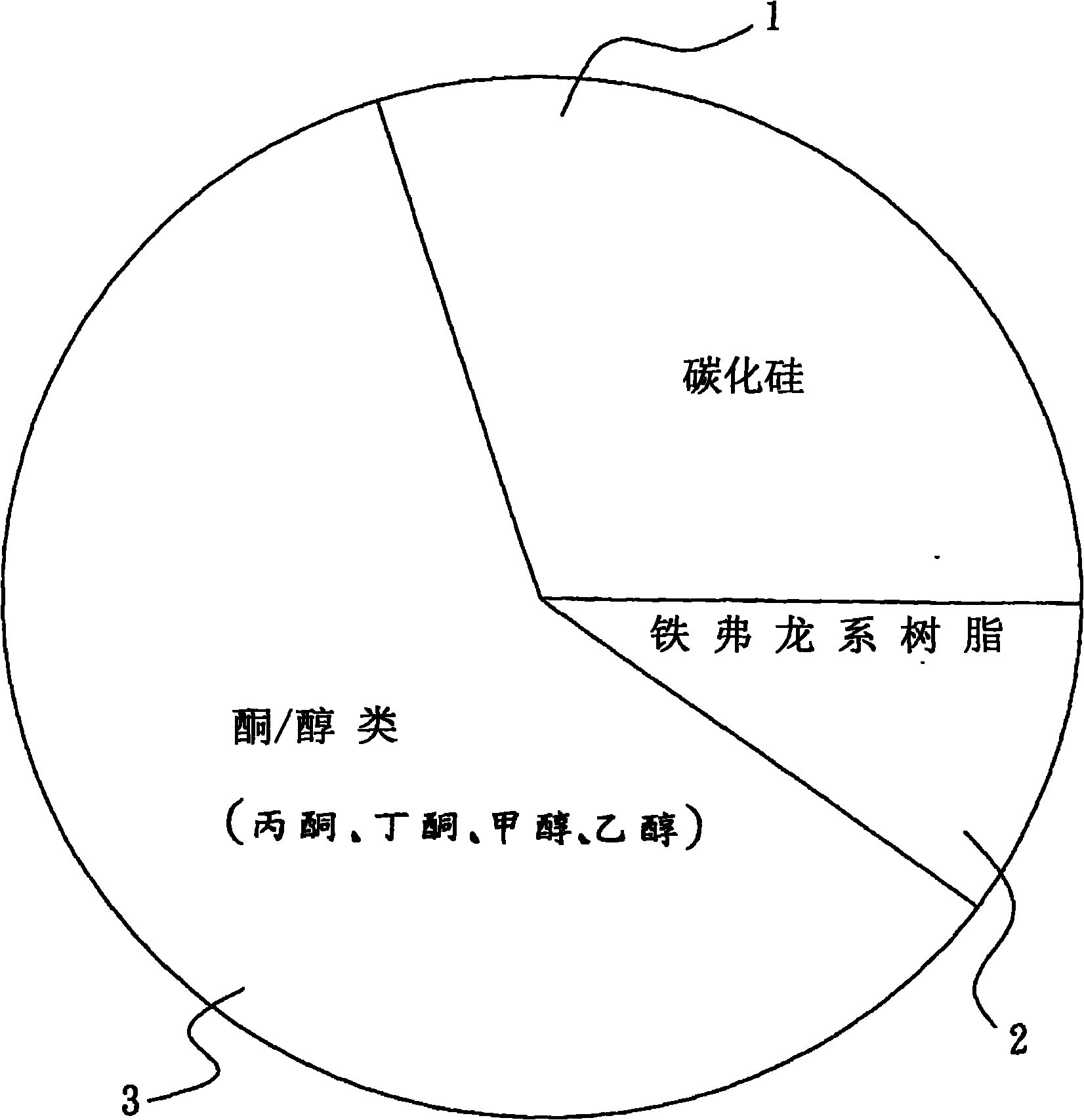

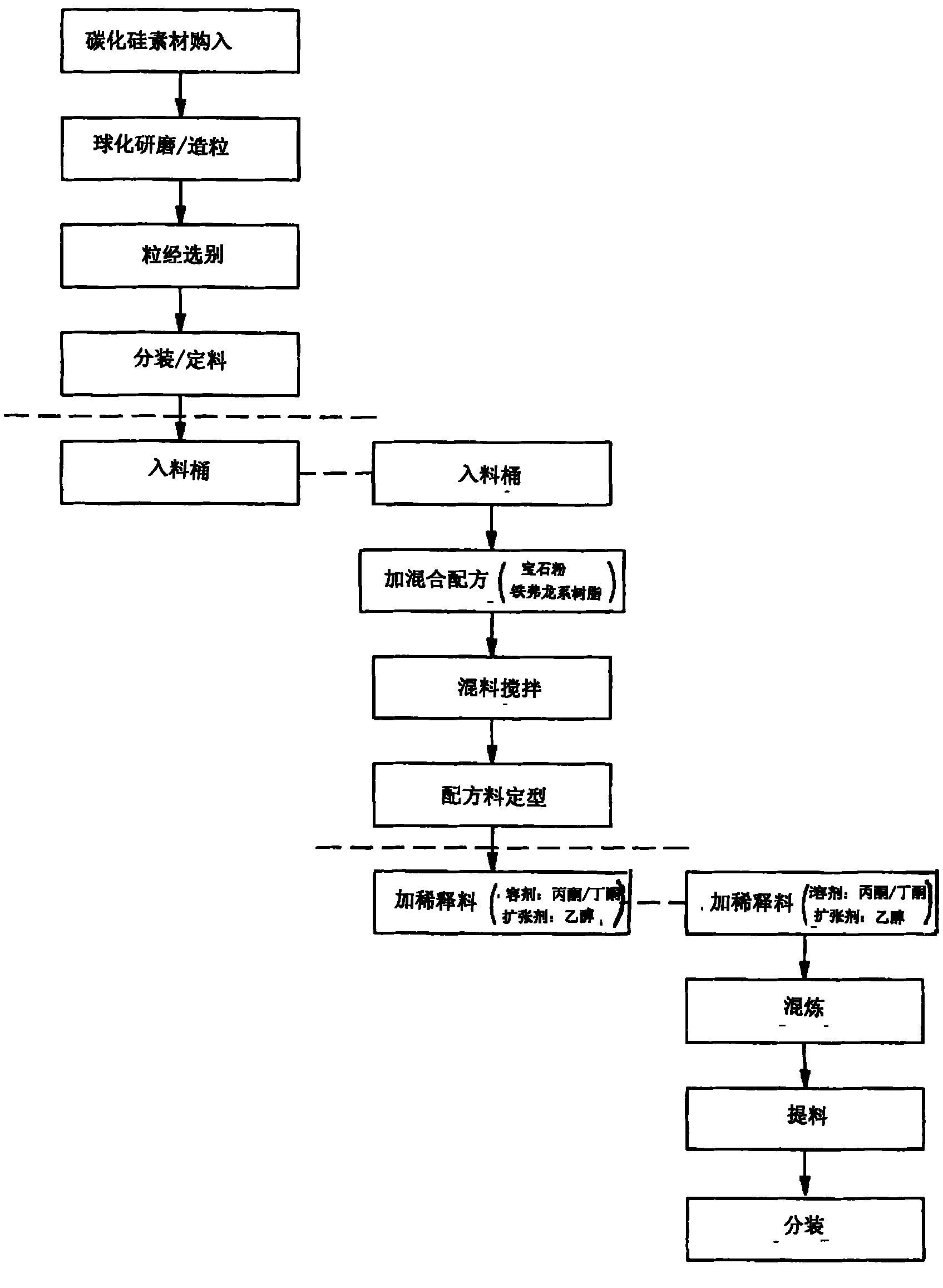

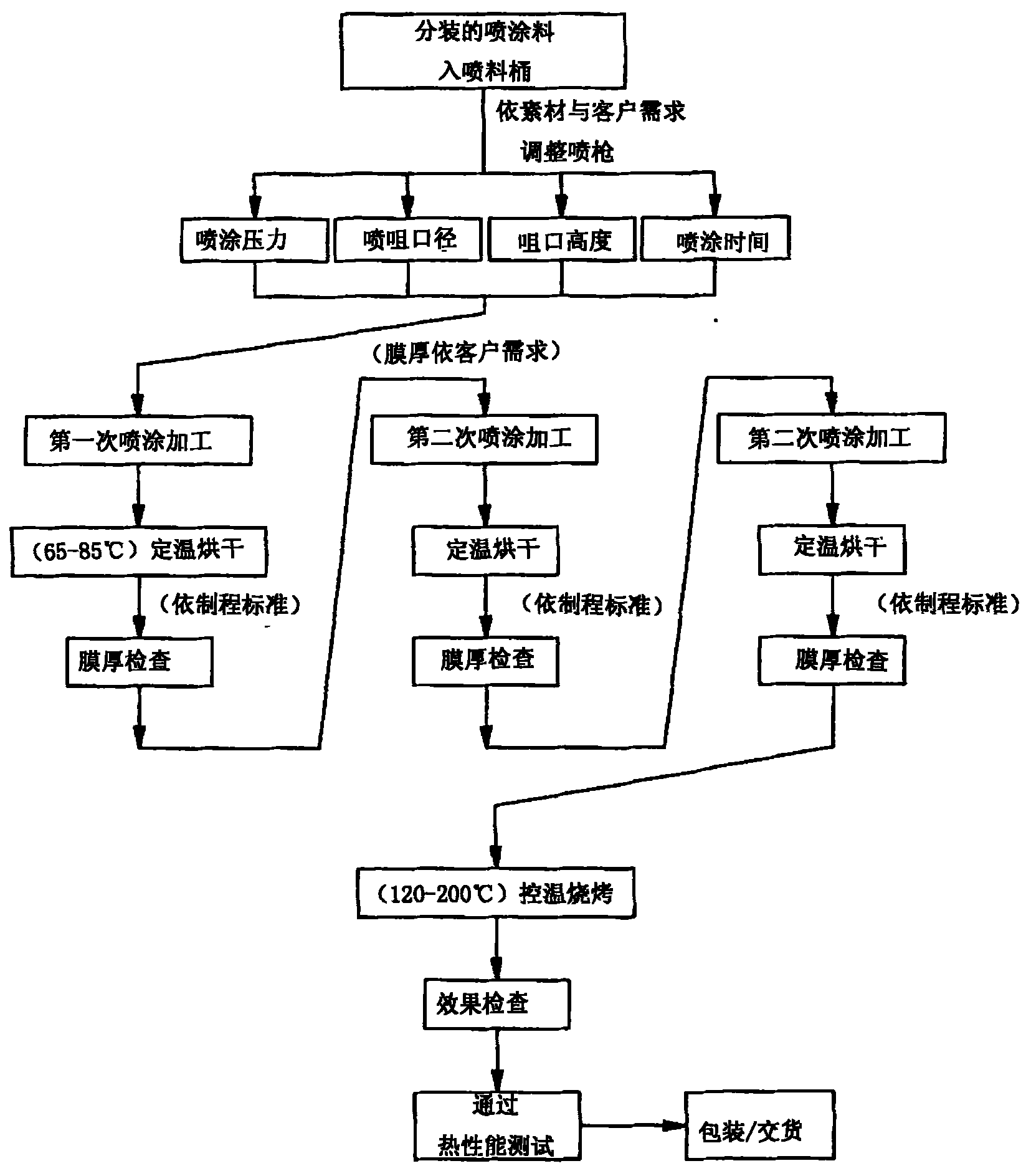

Component sprayed with condensed heat dissipation membrane

The invention discloses a component sprayed with a condensed heat dissipation membrane. Pelleted and selected silicon carbide which is prepared with a weight filling proportion substance, and accounts for 25%-30% of the total amount, teflon resin which is prepared with the weight filling proportion substance and accounts for 10% of the total amount, and a ketone / alcohol dilute material which is prepared with the weight filling proportion substance and is 60%-65% of the total amount are commonly mixed, stirred, and sprayed on the surface of a workpiece to be subject to heat dissipation, and are dried and condensed into a spraying material of the heat dissipation membrane with predetermined thickness, thus simply improving heat dissipation efficiency, and lowering the dependence on a large heat dissipation piece; the component has economical cost, is easy for recycling, and does not need high-pollution anodic antioxidant processing, and has good acid and base resistance and weather fastness.

Owner:SHAMROCK OPTRONICS

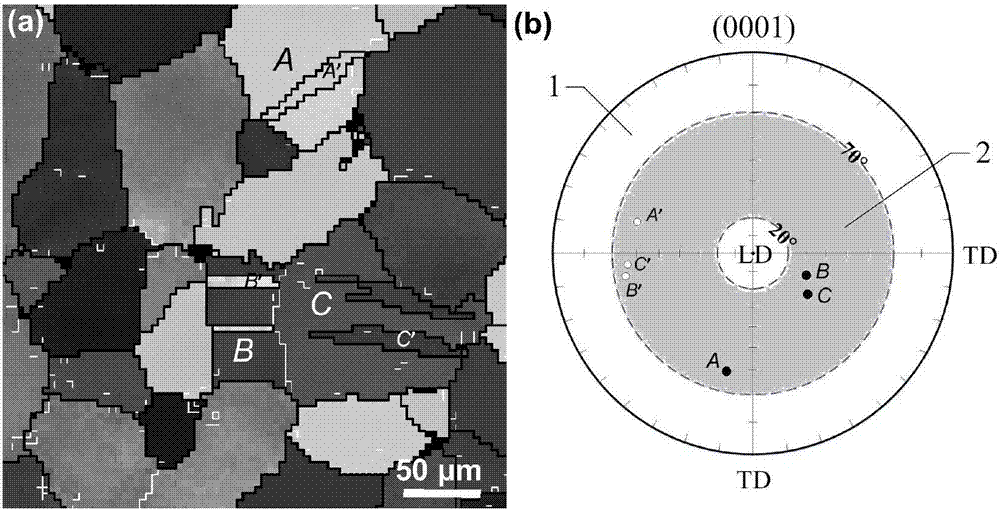

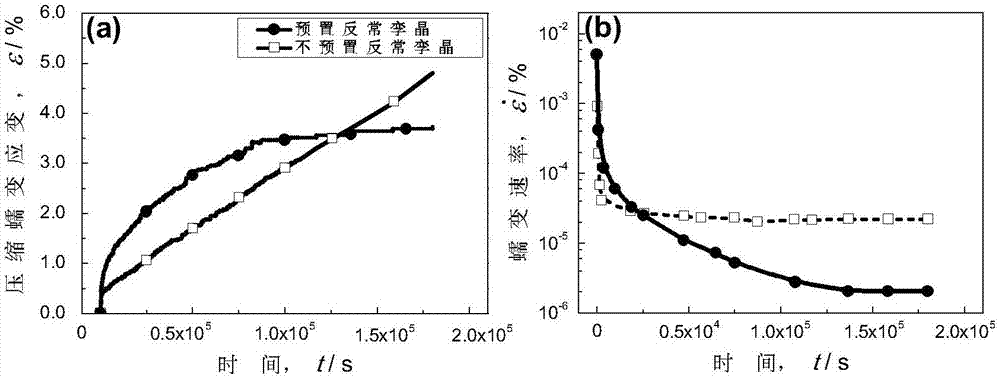

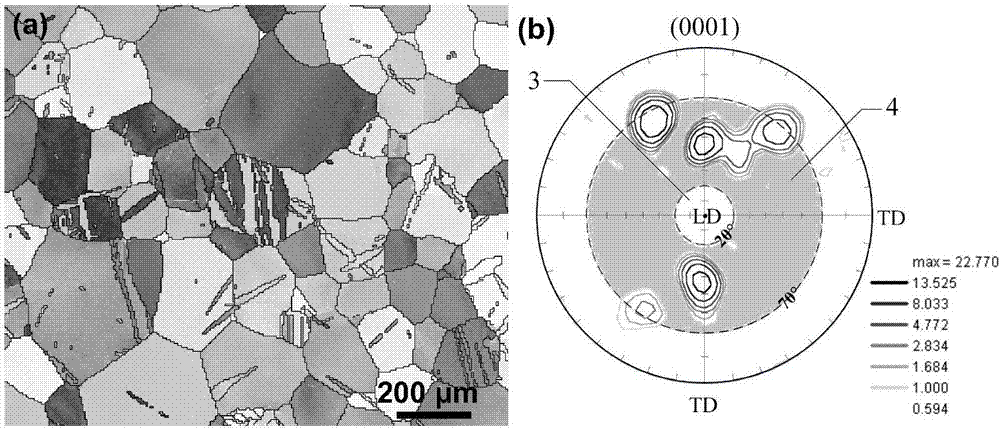

Method for improving high-temperature creep resistance of rare-earth-containing magnesium alloy by virtue of anomalous twin crystals

InactiveCN106978579AImprove high temperature creep resistanceWide range of applicable materialsCrystal twinningRare earth

The invention discloses a method for improving the high-temperature creep resistance of rare-earth-containing magnesium alloy by virtue of anomalous twin crystals. According to the method, the rare-earth containing magnesium alloy is subjected to predeformation treatment in the direction forming a 15-75-degree angle with the normal direction of a base plane at 25-300 DEG C, the true strain amount is 0.001-0.1, {10-12} anomalous twin crystals are prearranged in the rare-earth-containing magnesium alloy through deformation, the rare-earth-containing magnesium alloy with the prearranged anomalous twin crystals and rare-earth-containing magnesium alloy without prearranged anomalous twin crystals are subjected to stretching or compression creep property testing correspondingly within the temperature range from 200 to 350 DEG C, compared with the rare-earth-containing magnesium alloy without anomalous twin crystals, the rare-earth-containing magnesium alloy with the anomalous twin crystals has the advantages that the creep stain is obviously reduced, the steady-state creep rate is obviously lowered, and the creep resistance of is remarkably improved under the equal service conditions. The process which is reasonable in design, low in equipment requirement, convenient to operate, low in cost, high in efficiency and capable of stably improving the high-temperature creep resistance of the rare-earth-containing magnesium alloy is provided.

Owner:CENT SOUTH UNIV

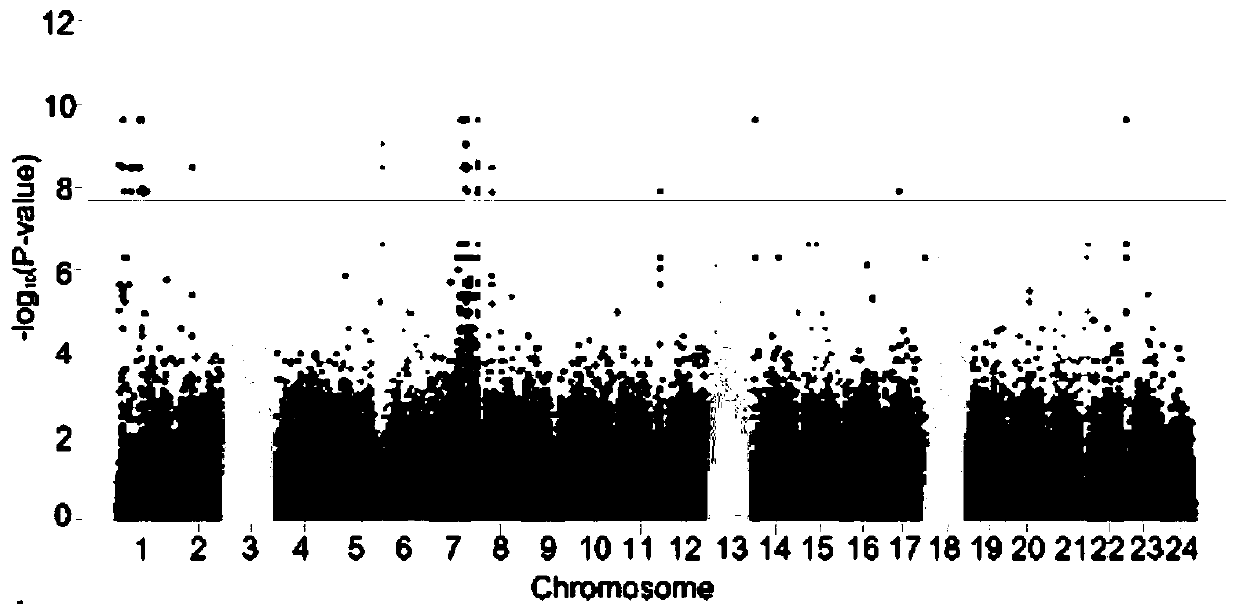

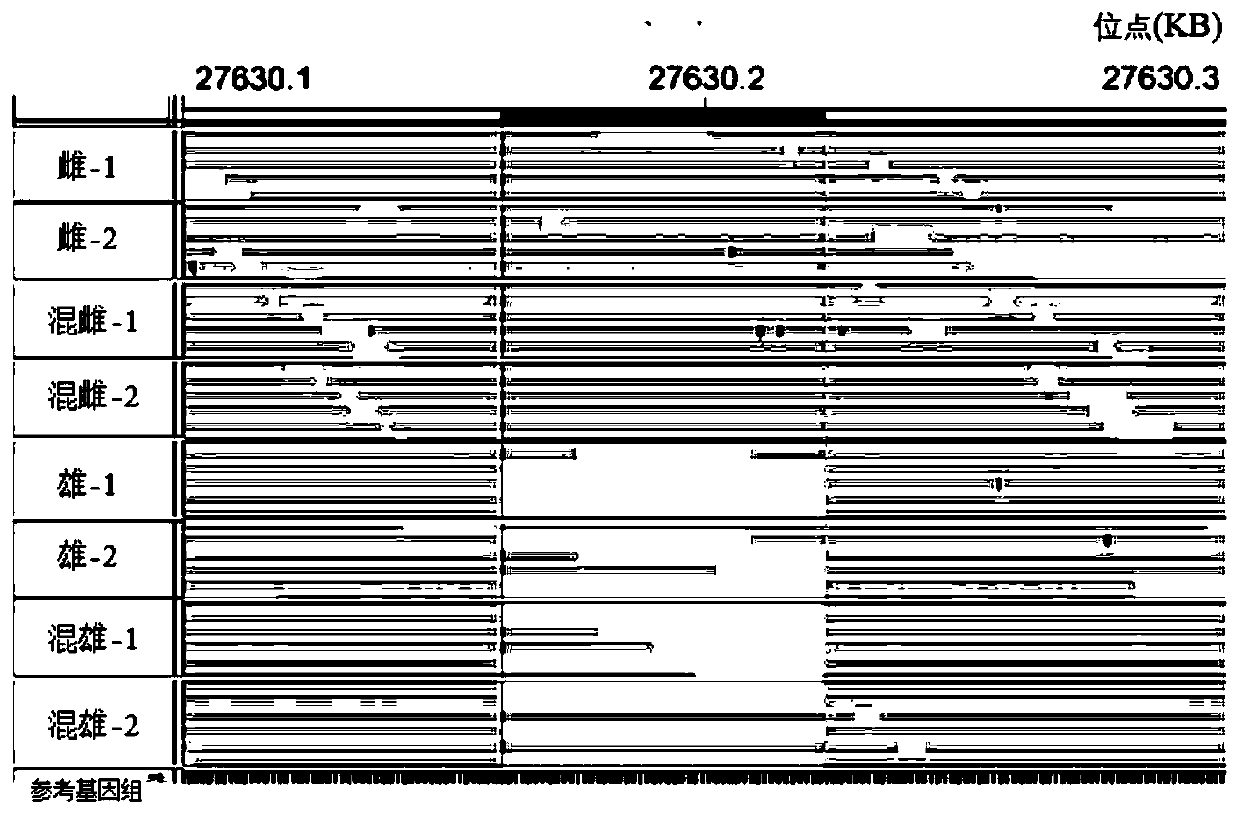

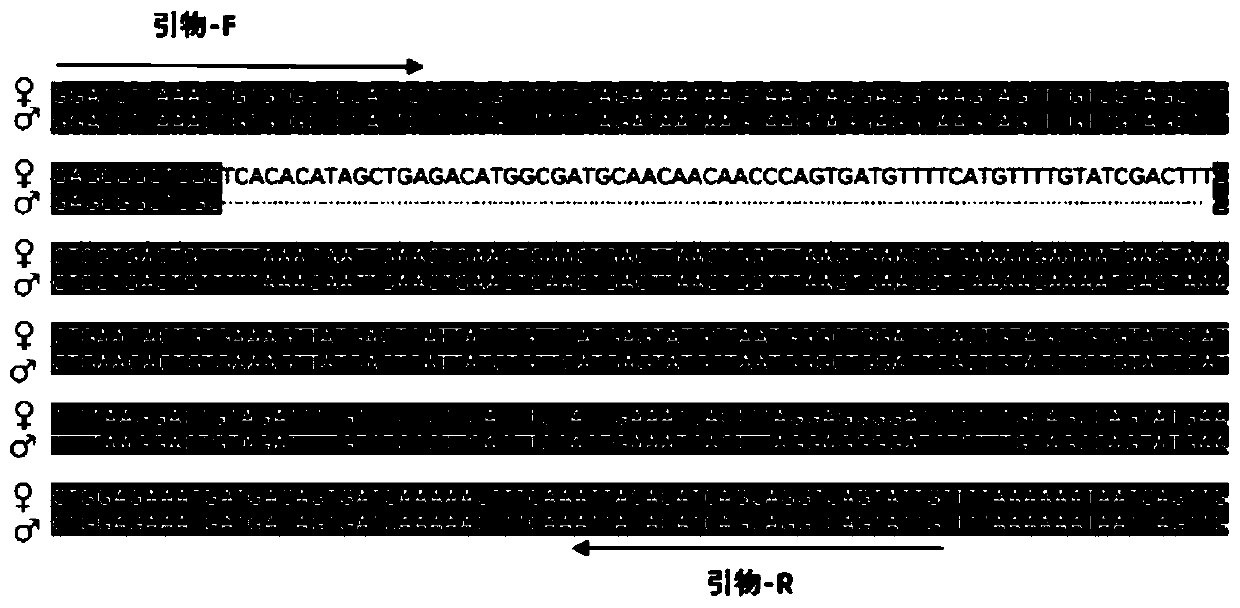

Molecular marker for identifying genetic genders of collichthys lucidus and application thereof

ActiveCN110669836AReduce harmWide range of applicable materialsMicrobiological testing/measurementDNA/RNA fragmentationNucleotideNucleotide sequencing

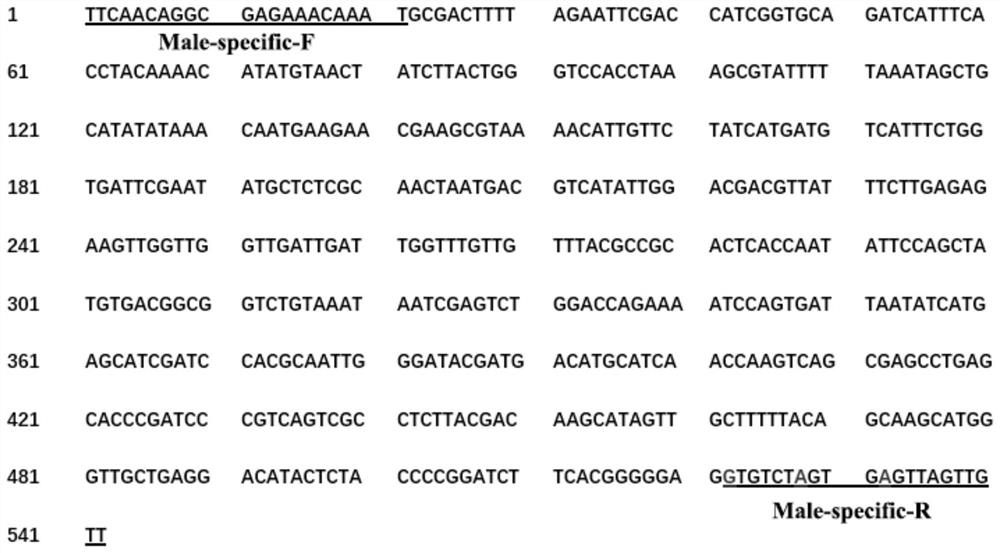

The invention discloses a molecular marker for identifying genetic genders of collichthys lucidus and application thereof. A nucleotide sequence of the molecular marker is as shown in SEQ ID NO:1; andan individual with the nucleotide sequence shown in missing SEQ ID NO:1 is genetic male collichthys lucidus. During detection, SEQ ID NO:2 and 3 are adopted as primers for PCR amplification, when amplified fragments are 460bp and 392bp, collichthys lucidus to be detected has genes of the nucleotide sequence shown in missing SEQ ID NO:1 and is the genetic male collichthys lucidus; and when the 460bp amplified fragment only exists, the collichthys lucidus to be detected does not have the genes of the nucleotide sequence shown in the missing SEQ ID NO:1 and is genetic female collichthys lucidus.The application of the molecular marker for identifying the genetic genders of the collichthys lucidus is suitable for before and after gonadal differentiation of the collichthys lucidus.

Owner:JIMEI UNIV

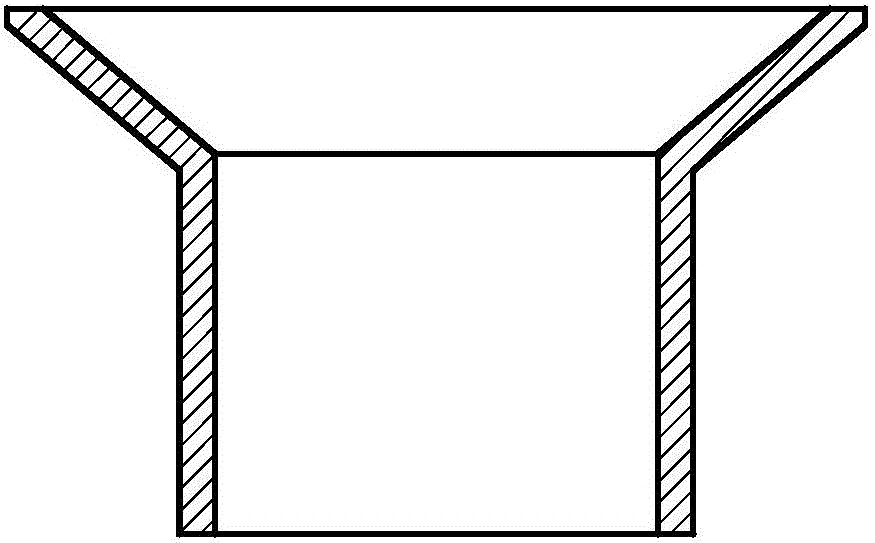

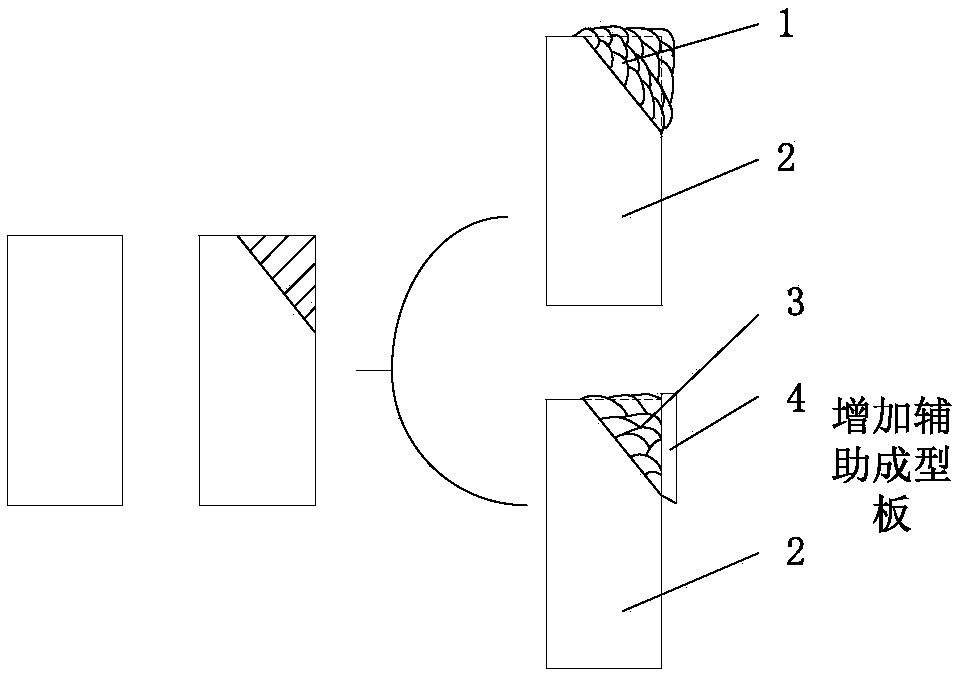

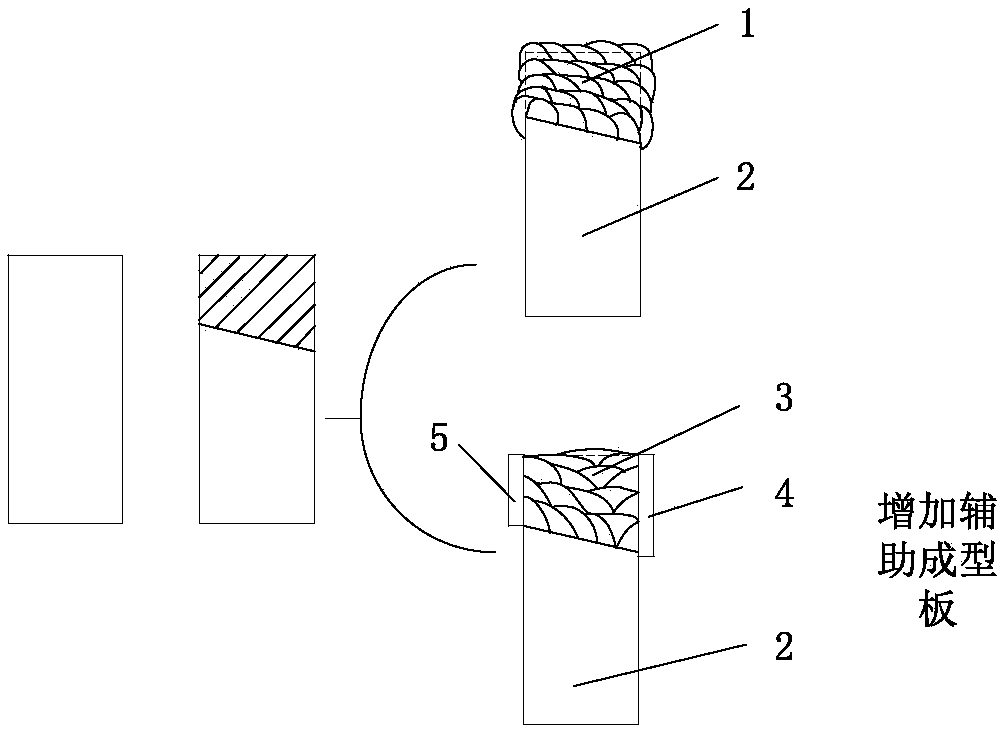

Electric-arc additive manufacturing repair method adopting auxiliary forming plate structure

InactiveCN109551081ANo need to worry about drippingSimple processAdditive manufacturing apparatusArc welding apparatusLiquid metalSpot welding

The invention provides an electric-arc additive manufacturing repair method adopting an auxiliary forming plate structure. The problems that in the existing electric-arc additive manufacturing repairprocess, especially, under the large-area defect additive manufacturing repair working condition, the situation that forming is poor due to the fact that metal flows and is insufficient in constraintoccurs in the open type multi-layer multi-pass stacking process are solved. In the electric-arc additive manufacturing repair process, metal inert gas arc welding (MIG), tungsten inert gas arc welding(TIG) and plasma welding electric arcs are adopted as a heat source, by adding wires, the defect portion is subjected layer-by-layer cladding repair, and under the control of a program, the defect portion of a metal part is gradually formed from line to surface to body according to a three-dimensional digital model. According to the electric-arc additive manufacturing repair method adopting the auxiliary forming plate structure, one or more auxiliary plate structures of which the material is the same as the parent metal are adopted, the auxiliary plate structures and a metal parent part forma repairable zone through spot welding, then, the repairable zone is completely welded through the multi-layer multi-pass stacking method, and finally, auxiliary plates are removed through the machining method.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Method for manufacturing micro-spring

InactiveCN102515092AWide range of applicable materialsControllable shapeSpringsMicrostructural devicesFiberMicron scale

The invention relates to a method for manufacturing a micro-spring by using a fracture control method. According to the method disclosed by the invention, the micro-spring is manufactured on the basis of controlling three-dimensional fracture. The method comprises the following steps of: coating a layer of oxide sol on a hard fiber material of which the diameter is of a micron scale; forming a core-shell-structure spindle knot taking the hard fiber material as a core and the oxide sol as a shell by fracturing a liquid membrane of the oxide sol; and forming the core-shell-structure spindle knot taking the oxide sol as the shell when a solvent in an oxide sol shell layer of the spindle knot is volatilized. Because of a special core-shell structure and heterogeneous core-shell components of the spindle knot, the spindle knot not only has a weak core-shell interface, but also has different thermal expansion coefficients. When the spindle knot is subjected to heating treatment, a core-shell material with different thermal expansion coefficients generates a heat stress. Under the action of the heat stress, the weak interface of the spindle knot cracks, and then the regular micro-spring is formed on the shell layer.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation of submicron/micron micro lens array on polymer surface

Owner:NANJING UNIV

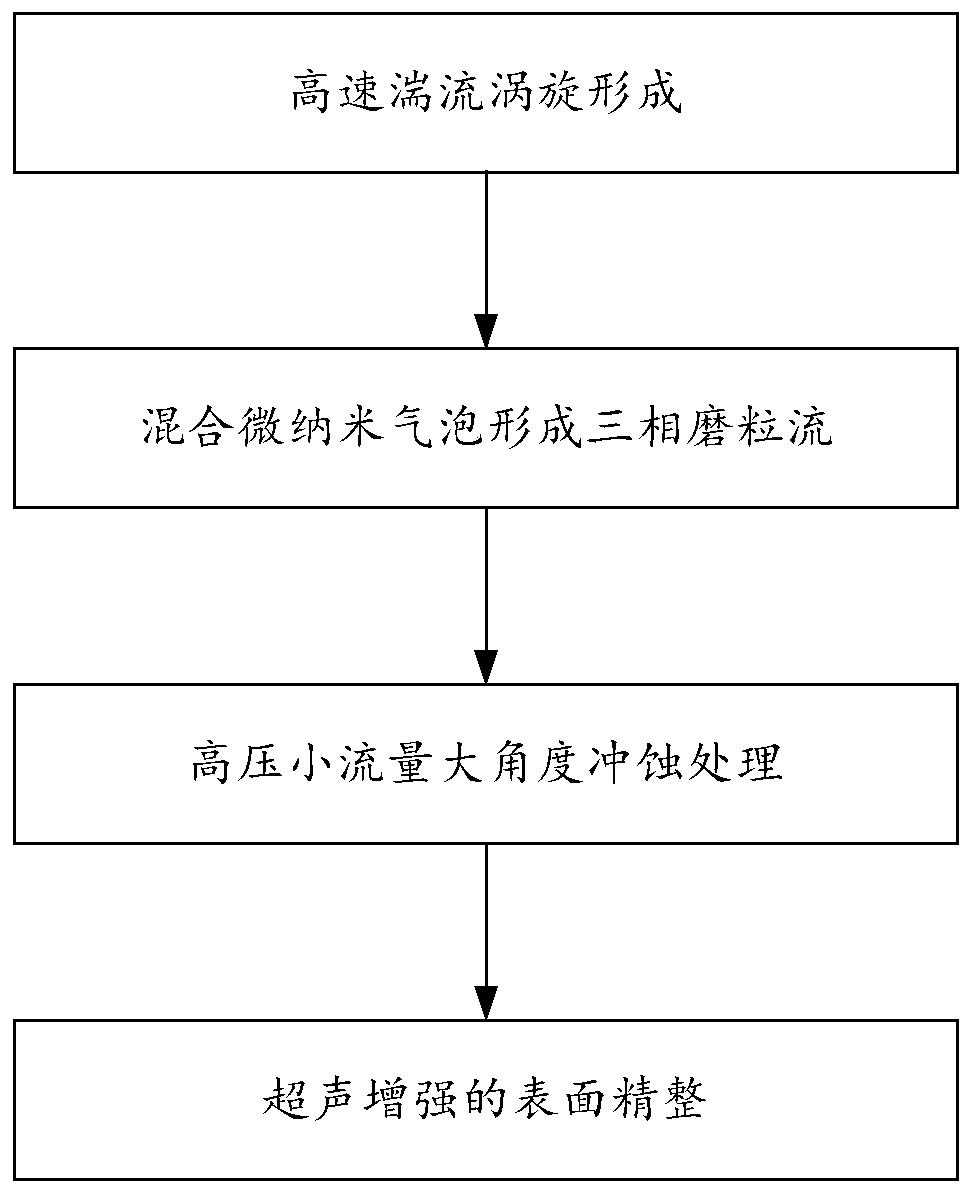

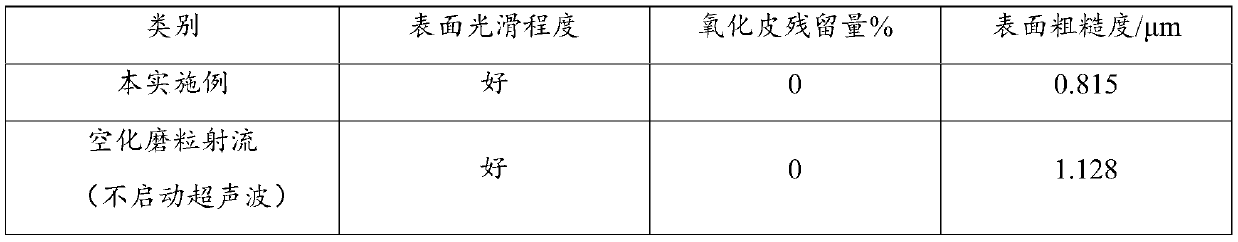

Ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers

ActiveCN110948398AImprove removal efficiencyRealize integrated enveloping processingAbrasive feedersAbrasive machine appurtenancesMicro nanoUltrasonic assisted

The invention provides an ultrasonic-assisted cavitation abrasive grain flow finishing method for titanium alloy surface oxide layers. The method comprises the following steps: stirring a solid-liquidtwo-phase mixed fluid to form high-speed turbulence vortex; extracting the solid-liquid two-phase mixed fluid, mixing the solid-liquid two-phase mixed fluid with micro-nano bubbles to form a high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow; spraying the high-speed and high-pressure gas-liquid-solid three-phase abrasive grain flow to a workpiece in a tank body for staged surface treatment; meanwhile, emitting ultrasonic waves by an ultrasonic device configured below the workpiece to form an ultrasonic cavitation effect, and forming a negative fluctuation environment with positive and negative pressure alternating rapidly in the high-speed fluid in the tank body to cause expansion and compression of micro-nano bubbles in the high-speed fluid. Under the comprehensive action of turbulence, jet, cavitaiton and ultrasonic waves, a manner of combining cavitation abrasive grain jet and turbulence integrated surrounding type processing and ultrasonic enhancement isadopted, synchronous stripping of different in-situ defects of oxide scale and derivative and chain stripping of new defect points can be realized, the removal efficiency is high, and the processinguniformity is good.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

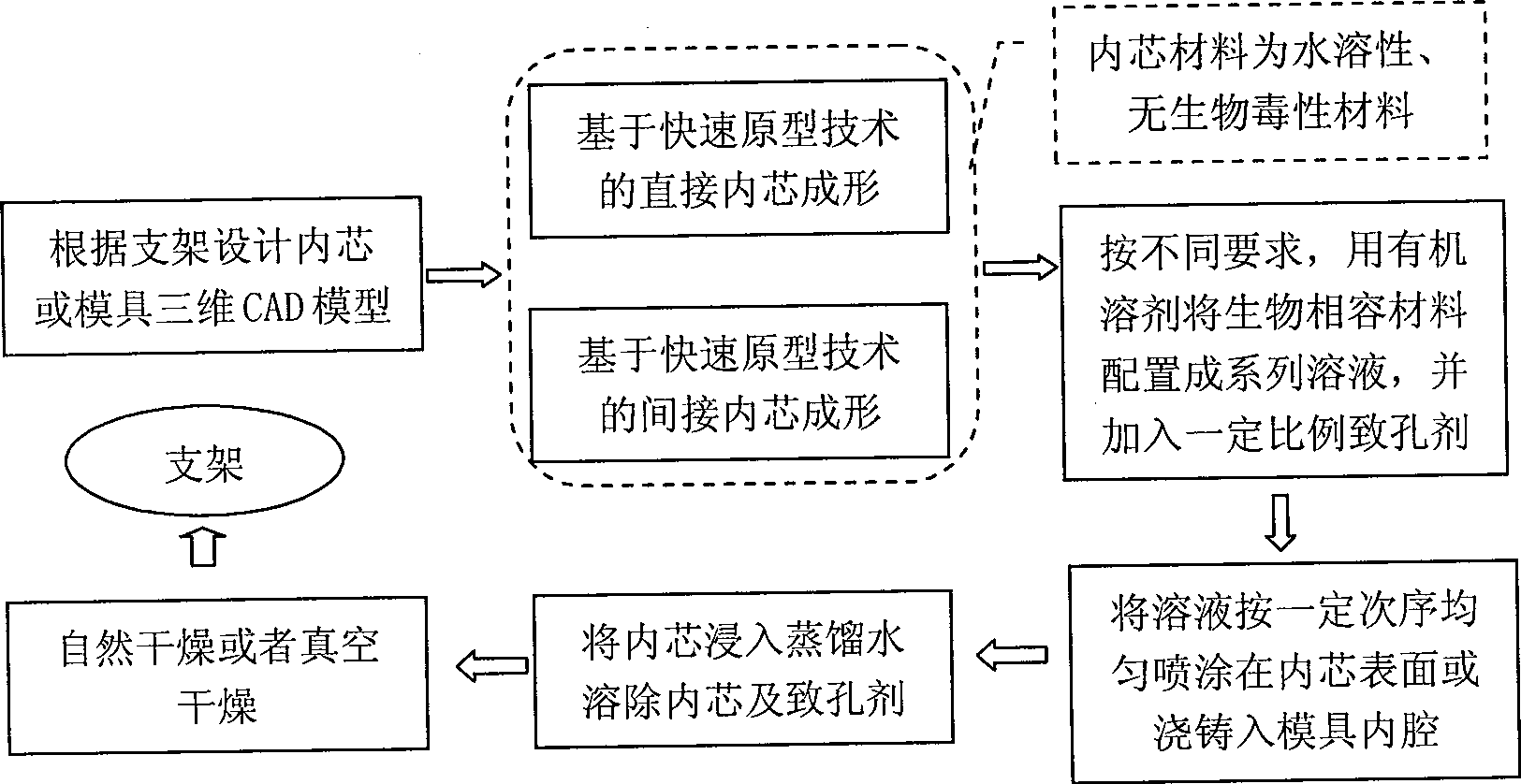

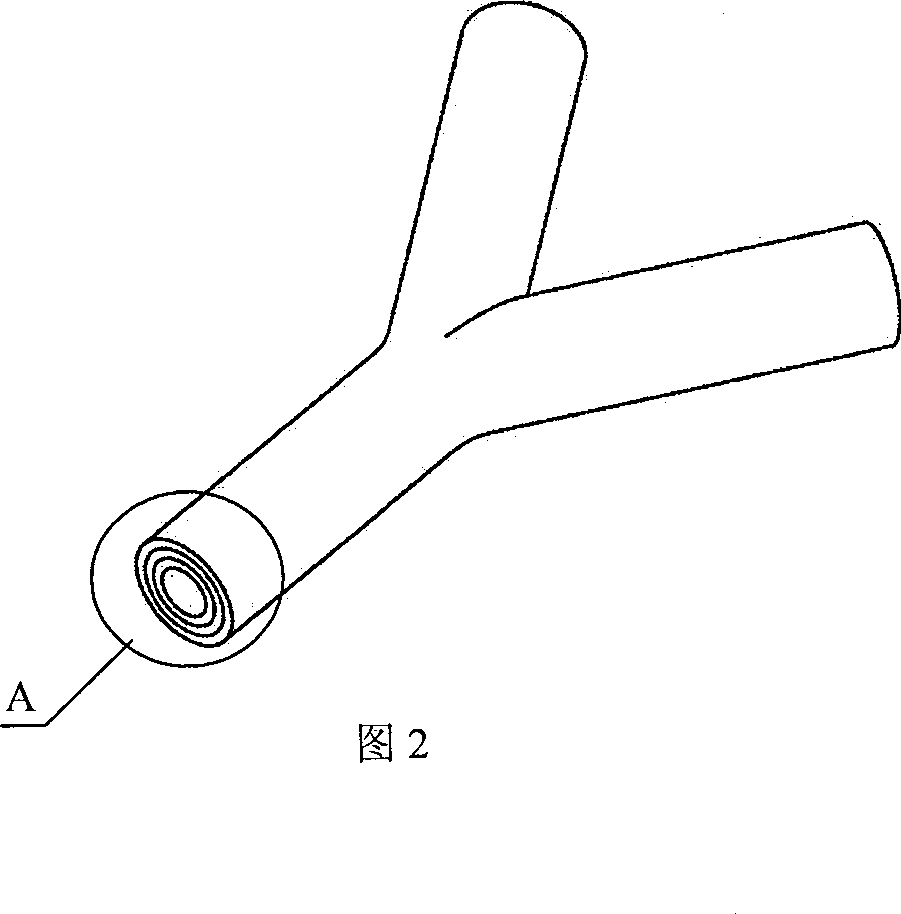

Tissue engineering complex grid shape stent forming method base on core dissolving technology

InactiveCN100490762CAddressing Biocompatibility EffectsShort processBlood vesselsManufacturing technologySpatial structure

Owner:TSINGHUA UNIV

Molecular marker for identifying sex of haliotis discus hannai and primer thereof

InactiveCN113215279AReduce identification errorGender result is accurateMicrobiological testing/measurementDNA/RNA fragmentationPhysiologyGenetics

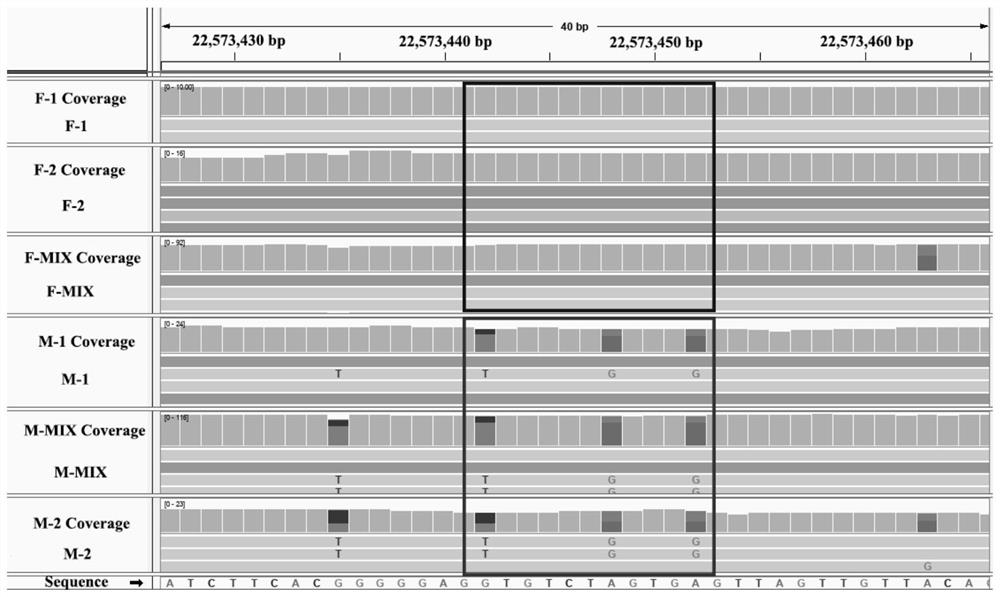

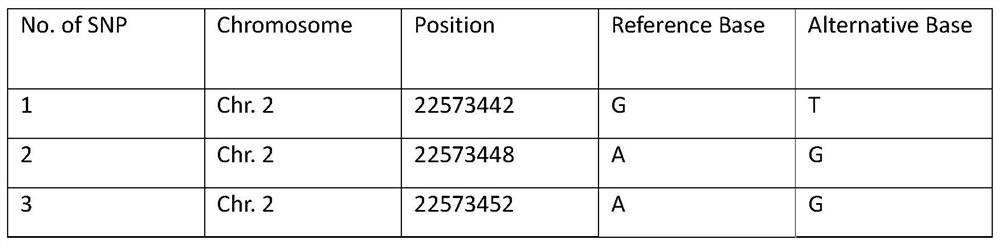

The invention discloses a molecular marker for identifying sex of haliotis discus hannai and a primer thereof. According to the molecular marker, when SNP of 522 bp, 528 bp and 532 bp of SEQ ID NO: 1 are homozygous, the genetic sex is female; and when SNP of 522 bp, 528 bp and 532 bp of SEQ ID NO: 1 are heterozygous, the genetic sex is male. The genetic sex molecular marker has advantages of being applicable to the whole life history, wider in applicable material range and the like.

Owner:JIMEI UNIV

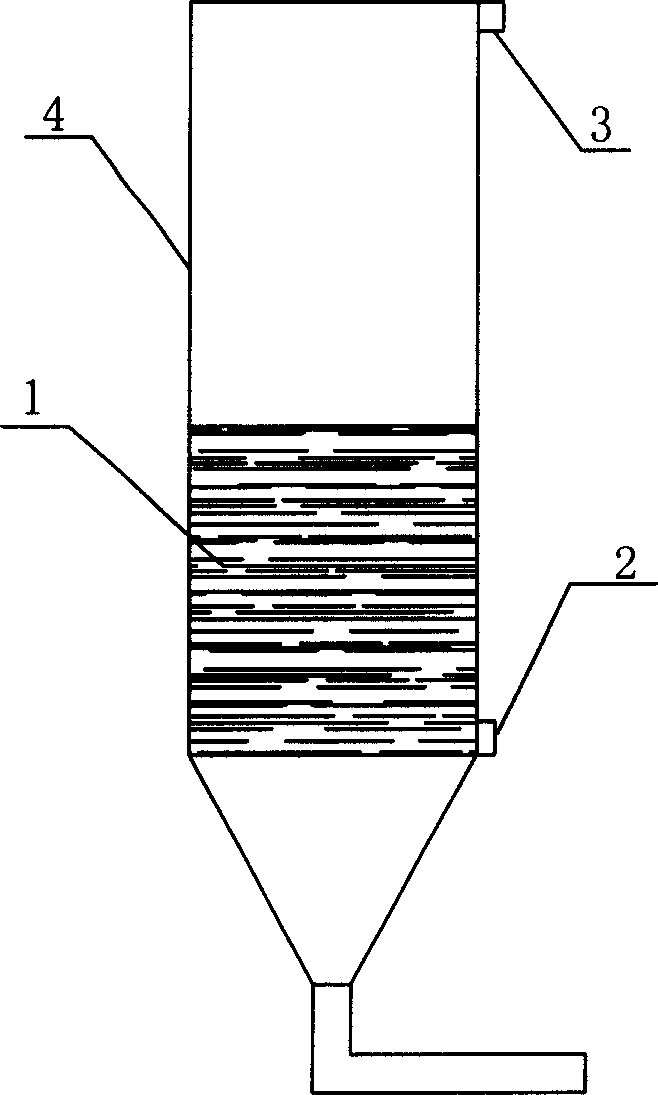

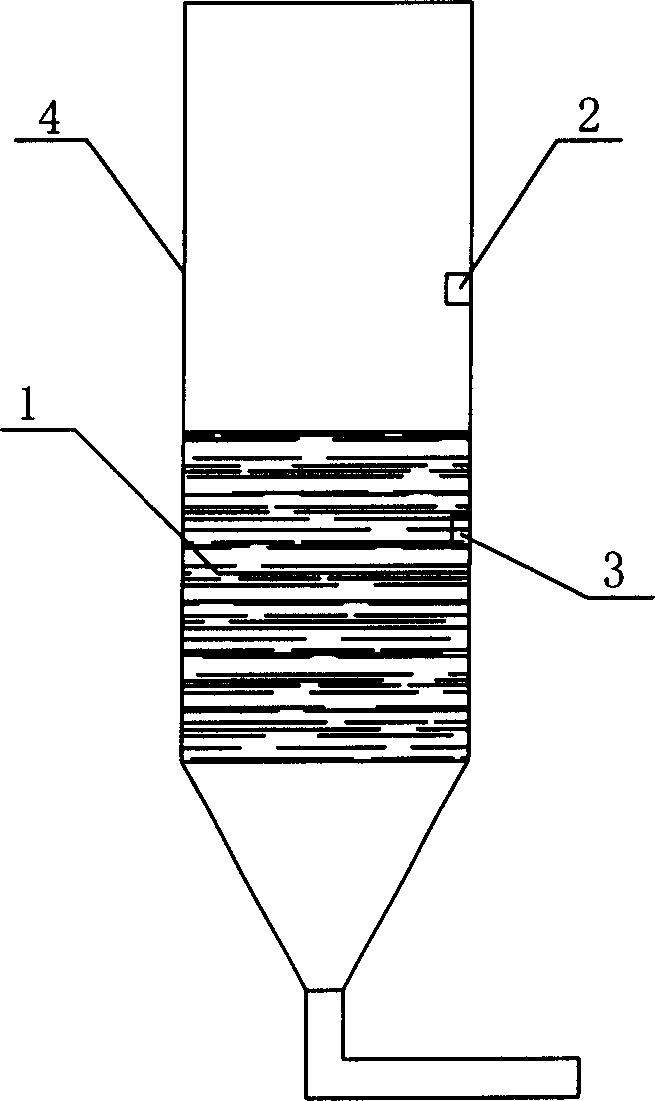

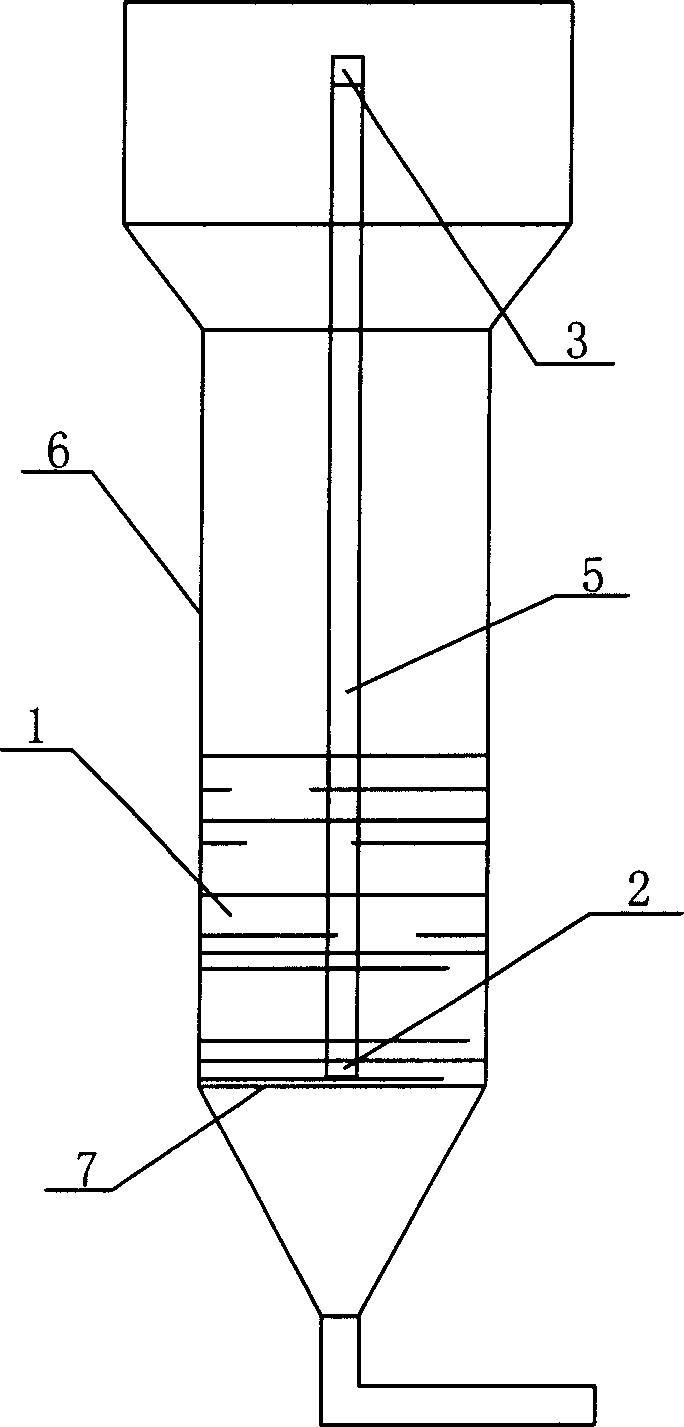

Stock level detecting method

InactiveCN1731108AHigh measurement accuracyWide range of applicable materialsLevel indicators by physical variable measurementCASKAcoustics

The invention discloses a materials bit detecting method which comprises: (1) fixing a vibration signal generator and a vibration signal accepter on the materials bit cask, wherein the vibration signal generator and the vibration signal accepter is fixed on the lower part of the materials bit, while the other one is fixed on the upper part of the materials bit; (2) sending vibration signal by vibration signal generator; (3) accepting the vibration signal by vibration signal accepter; (4) ascertaining the materials bit by the degeneration between the sending position and the accepting position of the vibration signal.

Owner:ZHEJIANG UNIV

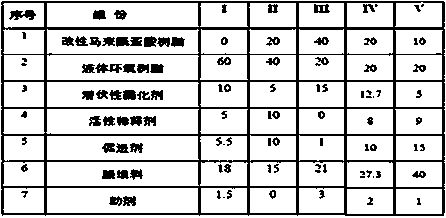

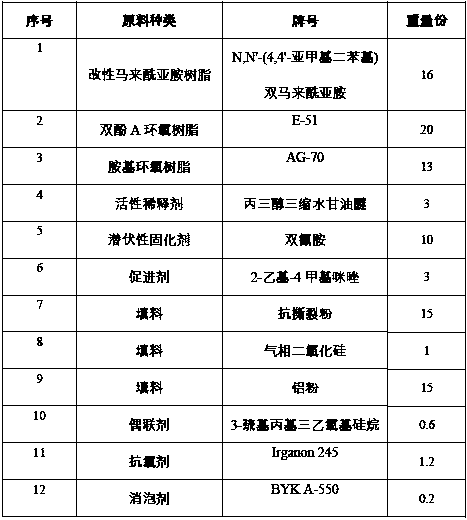

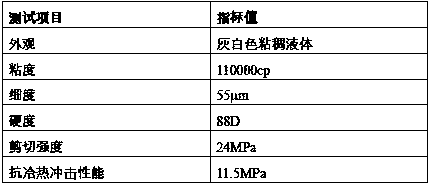

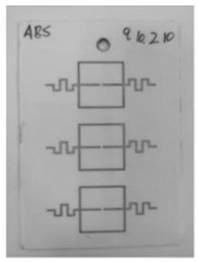

Single-component high-temperature glue and preparation method thereof

PendingCN108314984ASolution to short lifeWide range of applicable materialsNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyImide

The invention discloses single-component high-temperature glue and a preparation method thereof. The single-component high-temperature glue is prepared from the following raw materials in percentage by weight: 0 to 40 percent of modified maleic imide resin, 20 to 60 percent of liquid epoxy resin, 5 to 15 percent of latent curing agent, 1 to 10 percent of accelerant, 0 to 10 percent of active diluting agent, 15 to 40 percent of pigment and filler and 0 to 5 percent of auxiliary agent. The product is composed of a single component and has a good adhering effect on metal materials including an aluminum alloy, stainless steel, casting iron, a nickel-plated layer and the like after being heated and cured; an adhered part can work for a long period under the working condition of 300 DEG C and the service life can reach 1000h or more; meanwhile, the product disclosed by the invention also has the characteristic of rapid curing speed.

Owner:SHENZHEN PROSPER DOBOND TECH

Method for manufacturing conductive pattern by selectively activating insulating material through laser and chemical combination

PendingCN113573489ALow costWide range of applicable materialsConductive pattern formationChemical platingCircuit graph

The invention relates to a method for manufacturing a conductive pattern by selectively activating an insulating material through combination of laser and chemistry, and the method comprises the following steps: finding out upper and lower limits of chemical and laser processing intensity, and determining processing parameters within the limits; acquiring the corresponding relation between the beam waist diameter of the focused light beam and the size of the circuit pattern through actual measurement, taking the beam waist diameter of the light beam as a variable, taking energy and power on the unit area as constant quantities, and generating laser machining parameters and machining data for the machining task; changing laser parameters on line, carrying out the laser processing and chemical treatment, and changing the surface performance and morphology of the material. According to the method, the effects of chemical action and laser action are controlled and accumulated, and only the area which is subjected to chemical treatment and laser processing at the same time has the activity needed by chemical plating and the surface state needed by electroplating. The quality is reliable and the speed is fast; the method is environment-friendly, clear in process route, specific in parameters and indexes and controllable in process. The method is suitable for manufacturing circuits on planar and three-dimensional plastic, ceramic and glass entities.

Owner:德中(天津)技术发展股份有限公司

Screw extrusion type film recycling and granulating device

The invention relates to the technical field of film recovery and discloses a screw extrusion type film recycling and granulating device. The device comprises a granulation cylinder, a feeding screw rod,, a plasticizing screw rod and a granulation screw rod, wherein the feeding screw rod, the plasticizing screw rod and the granulation screw rod are arranged in the granulation cylinder; the feedingscrew rod runs through the length direction of the granulating cylinder, the feeding screw rod is meshed with the head end of the plasticizing screw rod, the granulating screw rod is meshed with thetail end of the plasticizing screw rod, a plurality of granulating teeth are arranged on a screw edge of the granulating screw rod, a feeding port is formed in the middle section of the feeding screwrod of the granulating cylinder, and a discharging port is formed in the granulating cylinder and corresponds to the screw edge of the granulating screw rod. Waste plastic film leftover materials areuniformly conveyed through the feeding screw rod; plasticized plastic is obtained through the granulating screw rod with granulation teeth after being plasticized through a plasticizing screw rod, andplastic particles with uniform sizes are prepared from the plasticized plastic; and the device is good in film material granulation adaptability, capable of guaranteeing stable conveying of plastic films, free of heating in the whole process, good in particle material mechanical property keeping, uniform in particle, high in machining efficiency and wide in material application range.

Owner:HUNAN UNIV OF TECH

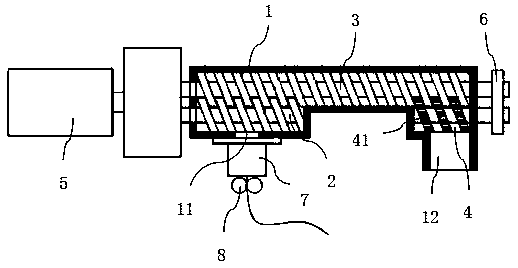

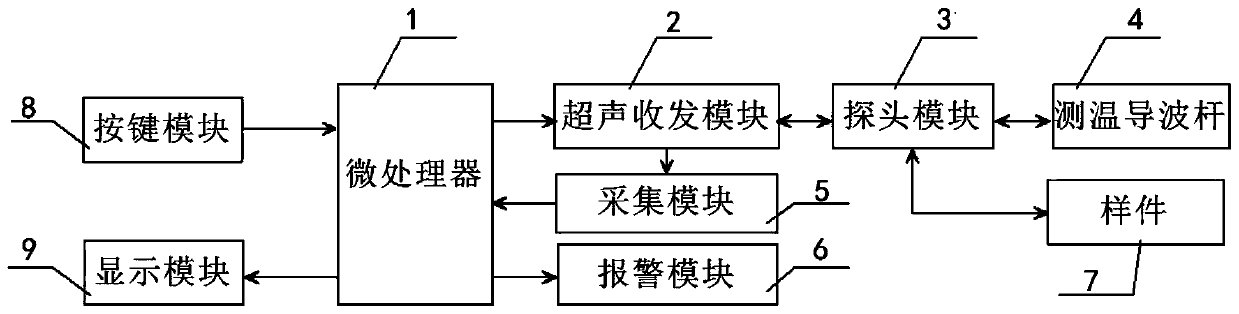

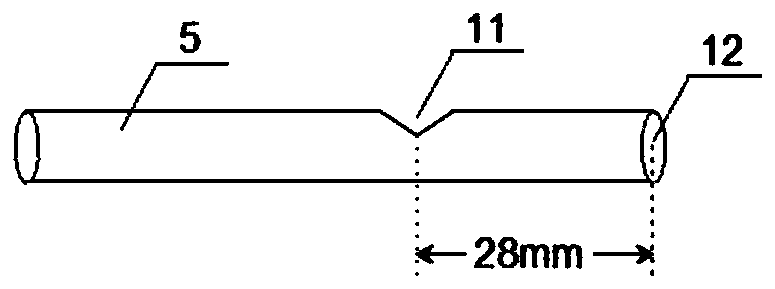

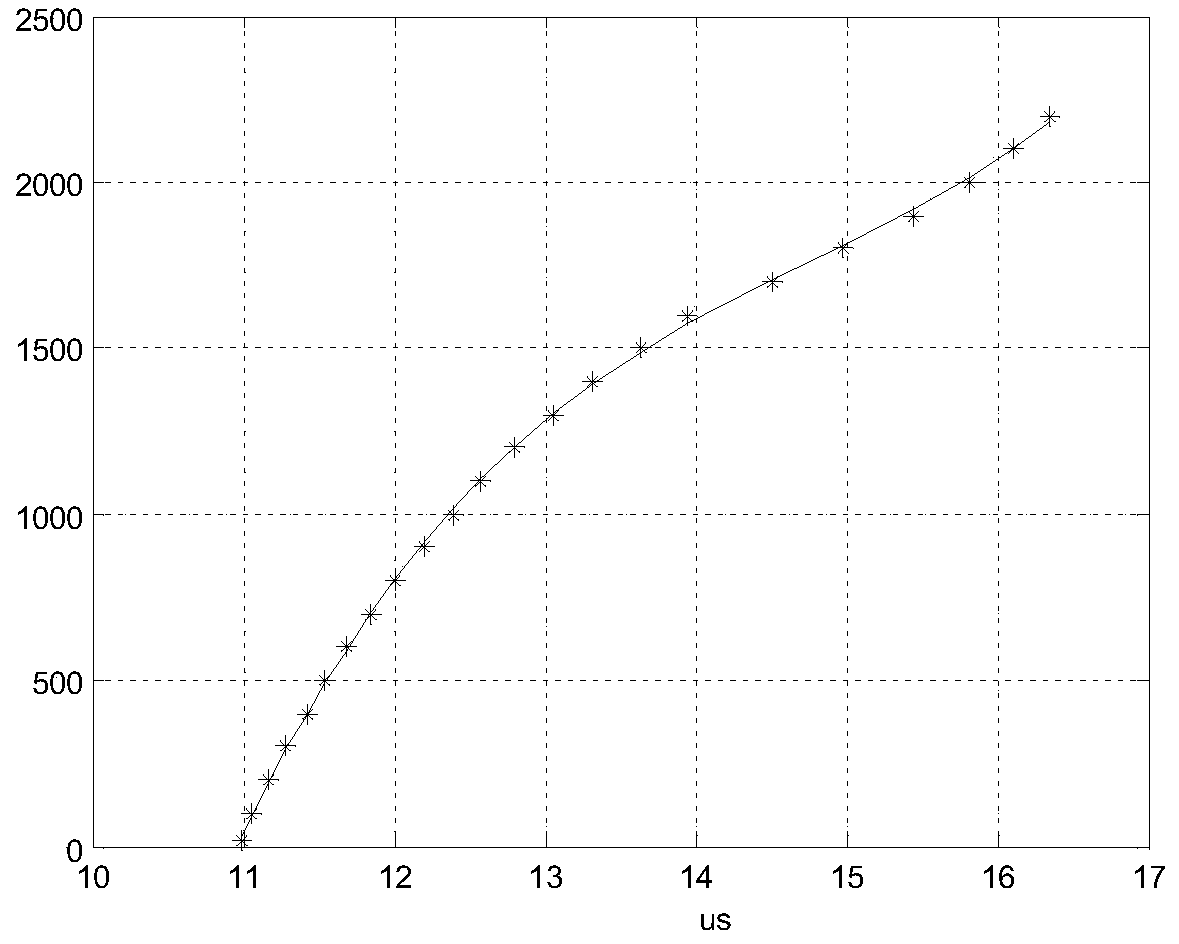

Ultrasonic-based material melting point measuring device

ActiveCN110261424ARealize automatic measurement of melting pointRealize in-situ automatic measurementInvestigating phase/state changeTransceiverEcho signal

The invention discloses an ultrasonic-based material melting point measuring device. The device comprises a microprocessor, an ultrasonic transceiver module, a probe module, a temperature measuring wave guide rod, an acquisition module and an alarm module. The ultrasonic transceiver module is used to emit an ultrasonic signal and receive an ultrasonic echo signal and a temperature value. The probe module is connected to the ultrasonic transceiver module and is used for transmitting an ultrasonic signal to the temperature measuring wave guide rod and a sample piece, and is used for transmitting the ultrasonic echo signal of the sample piece and a temperature measured by the temperature measuring wave guide rod to the ultrasonic transceiver module. The temperature measuring wave guide rod is used for measuring the temperature of a high temperature furnace. The acquisition module is connected to the ultrasonic transceiver module and is used for storing the ultrasonic echo signal and the temperature value. The microprocessor calculates a melting point of the sample piece according to the ultrasonic echo signal and the temperature value, and when the melting point reaches a threshold, the alarm module is controlled to give an alarm. By using the device of the invention, the melting point of the sample piece can be automatically measured, compositions are simple, cost is low, operation is convenient, and a melting point measuring range is large.

Owner:ZHONGBEI UNIV

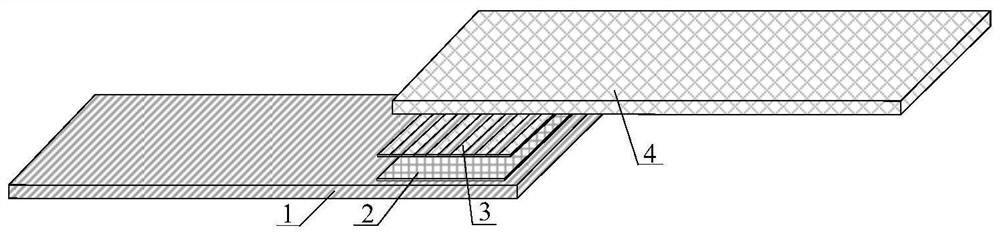

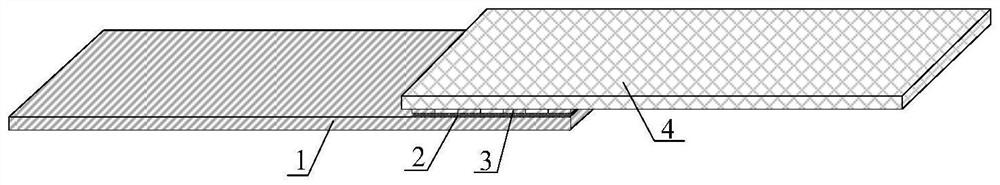

Method for improving interface connection strength of dissimilar resin or dissimilar resin-based composite material welding joint

PendingCN114179368AImprove diffusion connectivityReduce welding costsResin matrixResin-Based Composite

The invention discloses a method for improving the interface connection strength of a dissimilar resin or dissimilar resin-based composite material welding joint, relates to the field of welding, and aims to improve mechanical interlocking connection in the dissimilar resin or dissimilar resin-based composite material welding joint, reduce melting and outflow of low-melting-point resin and achieve the effect of improving the quality of the joint. According to the method, a welding material and a heating element are selected, two kinds of welded resin or resin of two kinds of welded resin-based composite materials are used for manufacturing a composite film layer, a test piece is clamped, and welding is carried out. According to the method, a mechanical interlocking structure can be constructed on the joint interface, diffusion bonding of the joint interface of resin difficult to be compatible is improved, excessive melting and flowing out of low-melting-point resin or low-melting-point resin matrix resin in a resin-based composite material in the welding process are inhibited, joint forming and performance are improved, and the method has good practical application prospects. The method is applied to the field of dissimilar resin welding.

Owner:HARBIN INST OF TECH

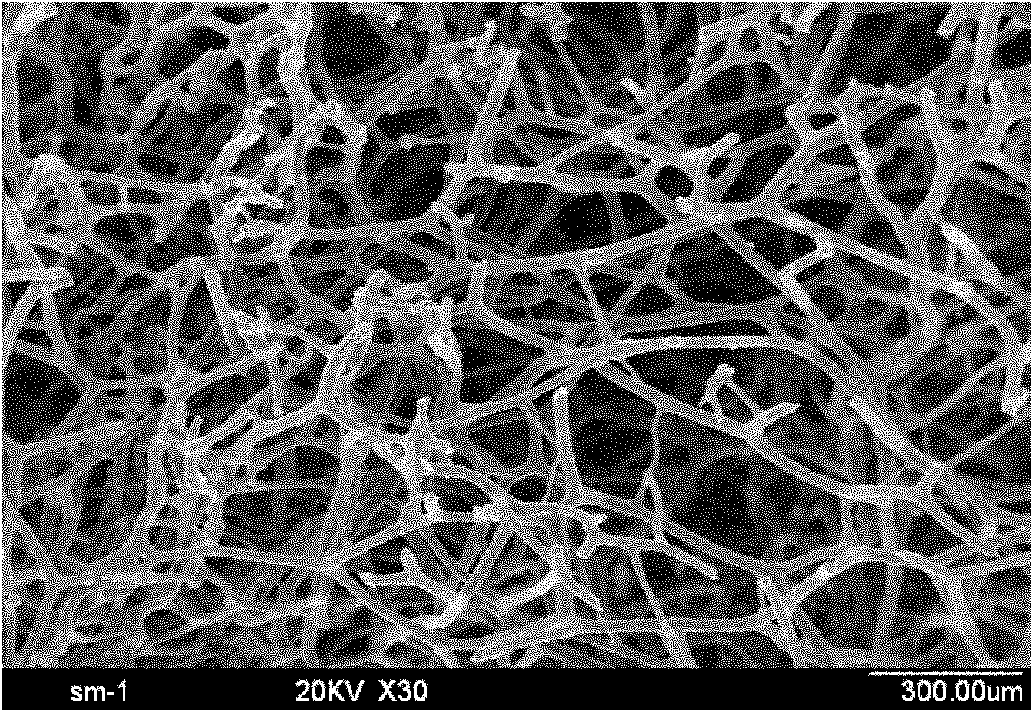

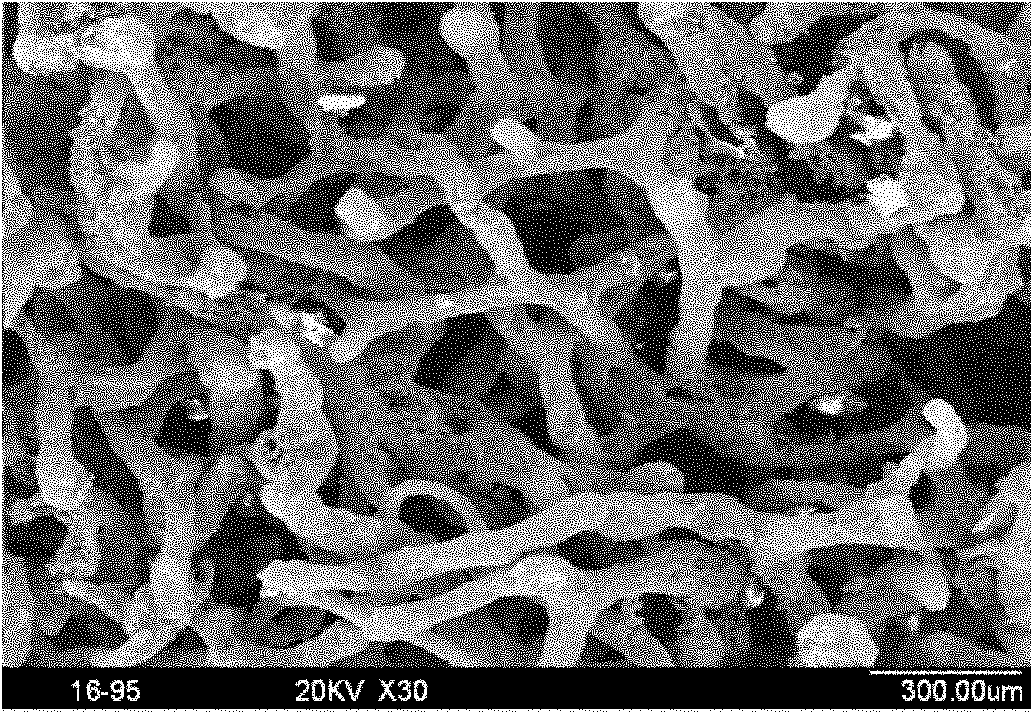

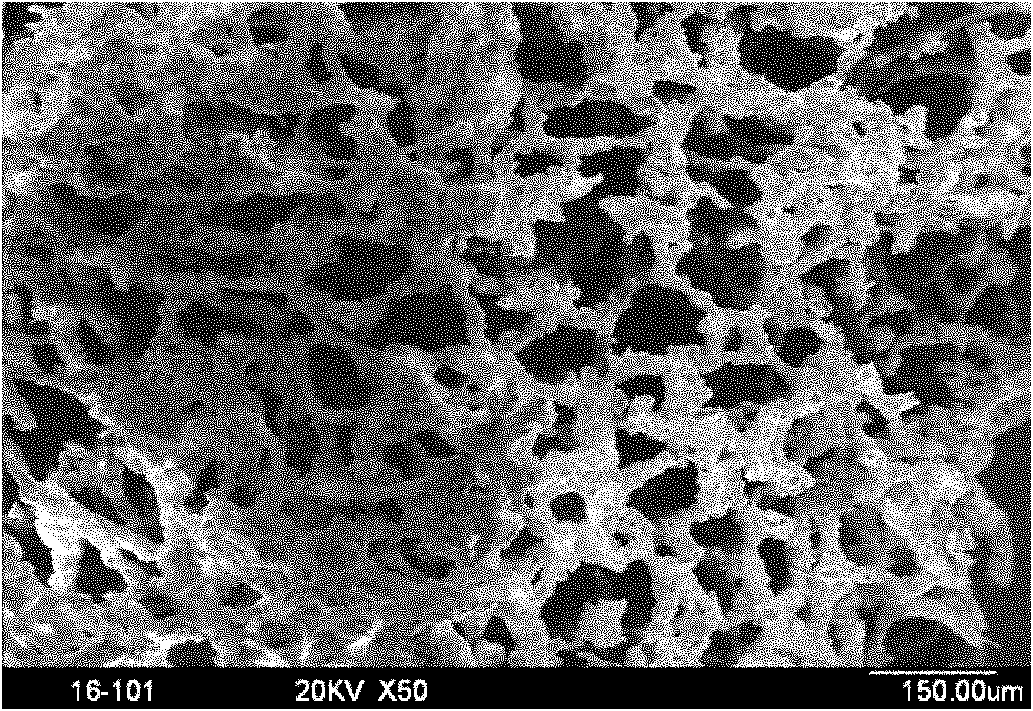

Method for preparing mesh-shaped bionic bone porous stent material

InactiveCN102058902BHigh porosityImprove connectivityImpression capsDentistry preparationsPorosityCalcium silicate

The invention relates to a method for preparing mesh-shaped bionic bone porous stent material, comprising the following steps: taking a multi-cellular marine animal natural sponge processed by organic acid and inorganic alkali solution as a template, impregnating with sol or water based slurry of hydroxylapatite, 45S5 bioactive glass, beta-tricalcium phosphate or calcium silicate, drying, oxidizing, demoulding and sintering at high temperature, thereby preparing the bone tissue engineering stent material in a mesh-shaped pore structure. The pore structural parameters and degradation performance of a porous stent are controlled by adjusting the solid content in the sol or the slurry, impregnation frequency and parameters in the process of oxidizing and demoulding as well as sintering at high temperature. Pore size of the mesh-shaped porous stent produced by adopting the invention is 100-300Mum, porosity is 68-94%, and the porous stent is highly similar to a natural cancellous bone in the shape and pore size. The product prepared by adopting the invention has the characteristics that bionic degree of the porous structure is high, adaptation to materials is high, process is simple and cost is low and the product has a great application potential in the regeneration repairing technology of hard tissue engineering, such as bone, basibranchial bone and teeth.

Owner:XI AN JIAOTONG UNIV

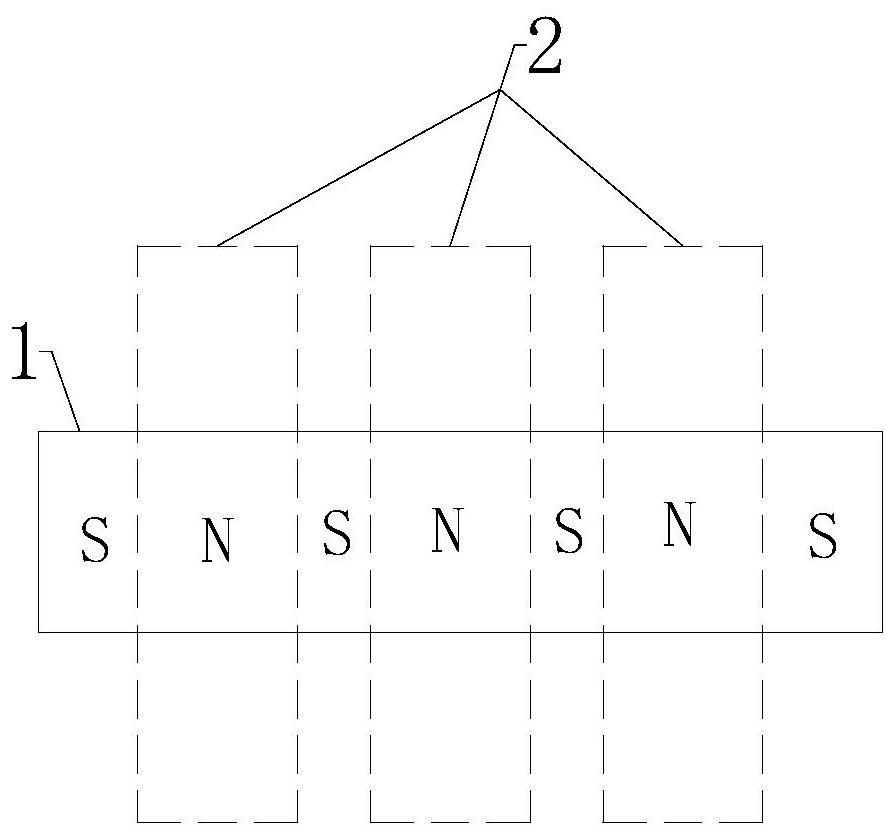

Magnetizing method of programmable magnetizing equipment

PendingCN113744950AExtended service lifeShorten the proofing cycleMagnetic bodiesProcess engineeringMagnetic polarity

The invention discloses a magnetizing method of programmable magnetizing equipment. The magnetizing method comprises the following steps: (1) placing a magnet on an objective table of the magnetizing equipment; (2) adjusting a magnetizing position; (3) designing the magnetizing polarity, the magnetizing step and the magnetizing power, and completing the magnetizing design to preview the magnetizing effect; and (4) starting a program, magnetizing the magnet by a magnetizing head, and carrying out one or more times of magnetizing by releasing a strong pulse magnetic field through the iron core, wherein the magnetizing head adopts a monopole magnetizing head. The service life of the magnetizing head is better than that of a planar multi-stage magnetizing head in the market, the magnetizing head is suitable for proofing and small-batch mass production or large-batch mass production of magnets, and a new magnetizing head does not need to be manufactured during proofing; the size and the position of the magnetic area are grabbed by a visual system to design the magnetizing area or the magnetizing position is controlled through a PLC, so that the system is more accurate, is more suitable for high-precision products, and is suitable for high-quality product sample feeding and small-batch mass production or large-batch mass production in a proofing stage; the special-shaped magnetizing which cannot be completed by a common magnetizing head on the market can be met; and the applicable materials are wide.

Owner:宁波码实智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com