Stock level detecting method

A technology of material level detection and material level, which is applied in the field of material level detection, can solve the problems of low precision, unstable precision, high price, etc., and achieve the effect of wide application of materials, good economy and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

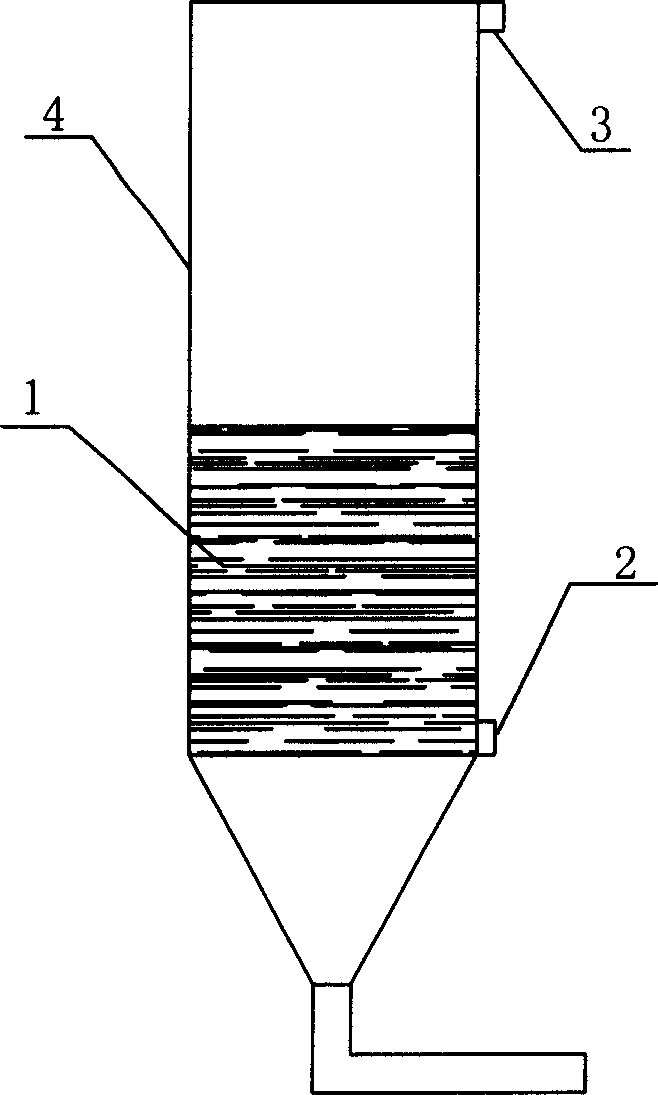

[0021] Such as figure 1 As shown, a vibration signal with a frequency of 30 kHz and a power of 10 watts is applied at the bottom transmitting position 2 on the outer surface of the silo 4 silo wall, and the vibration signal is received at the top receiving position 3 on the outer surface of the silo 4 silo wall. For a plexiglass silo with a diameter of 300mm and a wall thickness of 5mm, polyethylene particles with a built-in particle size of 0.3mm are used as static materials. When the height of the material level increases by 1cm, the amplitude of the vibration signal is attenuated by 5%. By comparing the attenuation of the energy of the received vibration signal and the energy of the applied vibration signal, the height of the material level in the silo can be determined.

Embodiment 2

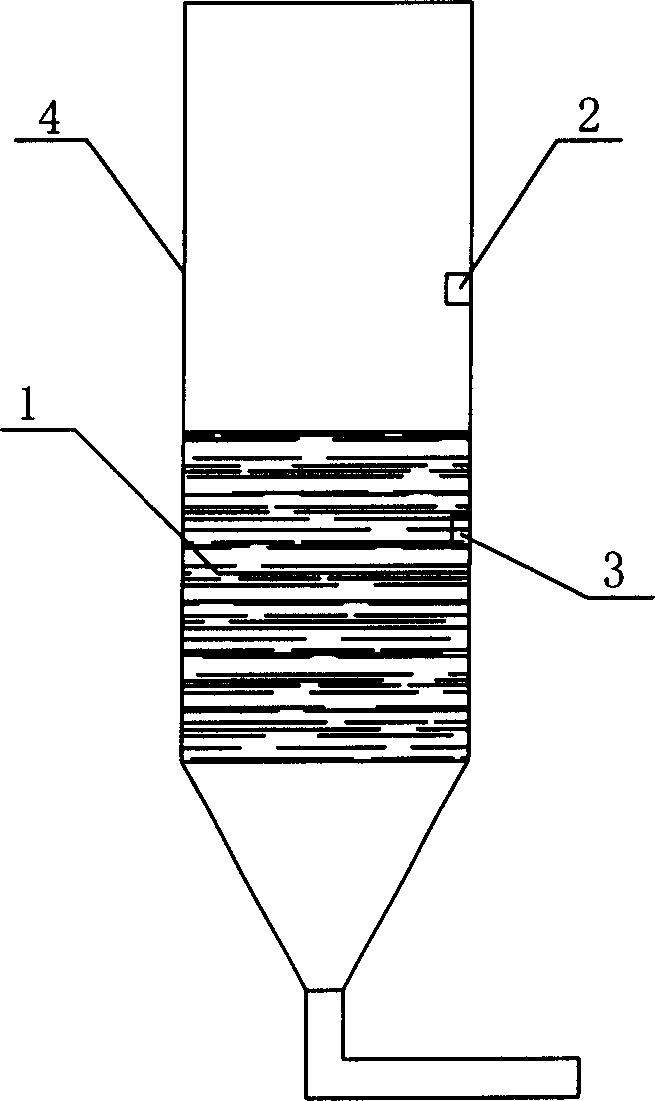

[0023] Such as figure 2 As shown, a vibration signal with a frequency of 20 Hz is applied at the top transmitting position 2 of the inner surface of the silo 4 silo wall, and the vibration signal is received at the bottom receiving position 3 of the inner surface of the silo 4 silo wall. By comparing the difference between the energy of the received vibration signal and the energy of the applied vibration signal, the height of the material level in the silo is determined.

Embodiment 3

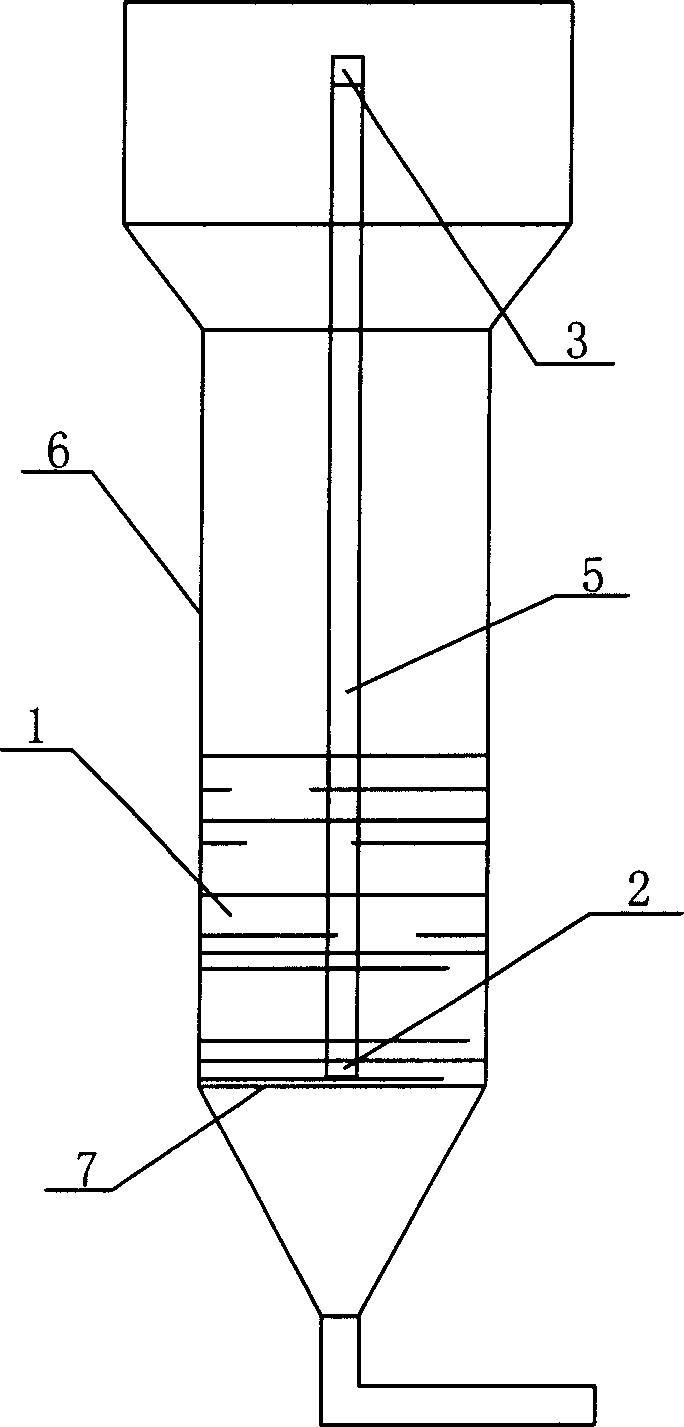

[0025] Such as image 3 As shown, a long sheet 5 is extended from the top of the fluidized bed reactor 6 until it reaches the bottom of the fluidized bed reactor 6, and there is a gas distribution plate 7 at the bottom. The material level in the fluidized bed fluctuates with the blowing of gas. A vibration signal with a frequency of 100 MHz is applied to the transmitting position 2 at the bottom of the elongated sheet 5 and received at the receiving position 3 at the top. By comparing the difference between the energy of the received vibration signal and the energy of the applied vibration signal, the height of the material level in the silo is determined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com