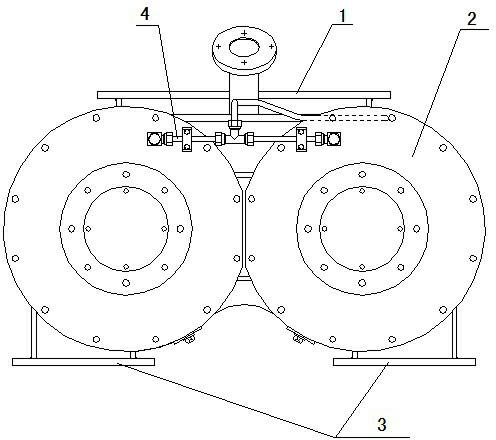

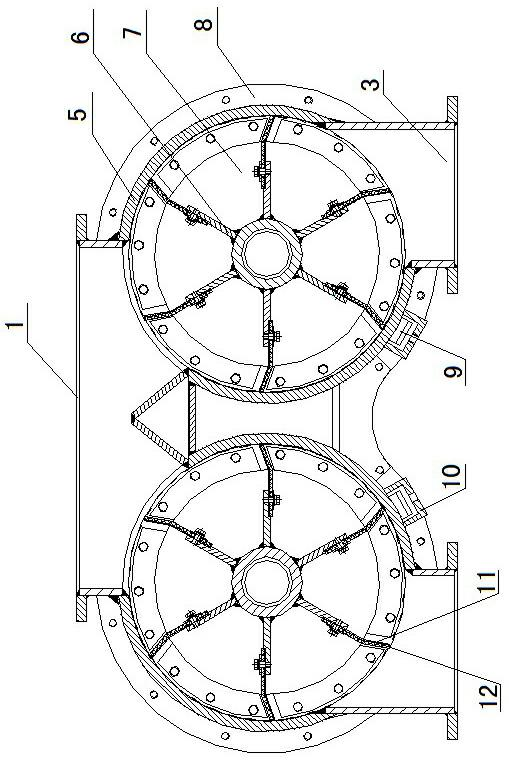

Dual-channel star-shaped feeder

A dual-channel, feeder technology, applied to conveyors, rotary conveyors, transportation and packaging, etc., to achieve the effect of less wear and long service life of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with the examples, and the purpose is only to better understand the contents of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

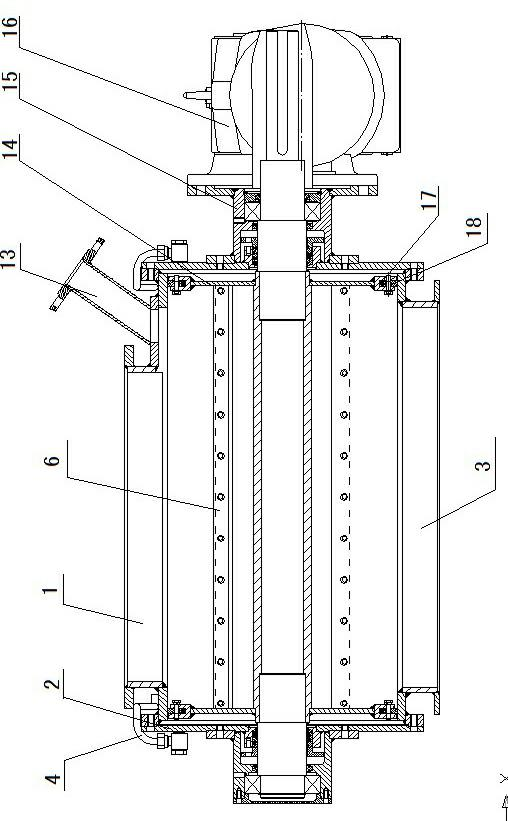

[0024] see figure 1 , figure 2 , The dual-chamber shell 5 of the dual-channel star feeder is made of high-strength wear-resistant steel pipes and steel plates through tailor welding and gold processing. The double-chamber shell 5 has a common feed port 1, two independent discharge ports 3 and two cylindrical cavities 7 in the middle, and connecting flanges 8 connected with the shell end caps 2 at both ends. The shell end cover 2 is made of high-strength wear-resistant steel plate through gold processing, and can be connected with the connecting flange 8 and the bearing seat 15 of the star-shaped impeller 6 to play the role of sealing the double-chamber shell 5 and supporting the star-shaped impeller 6 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com