Magnetizing method of programmable magnetizing equipment

A technology of magnetizing equipment and magnetizing methods, applied in magnetic objects, electrical components, circuits, etc., can solve the problems of low magnetization accuracy, inability to complete anisotropic magnetization, and long proofing cycle, so as to achieve a wide range of applicable materials and shorten the The effect of proofing cycle and excellent service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

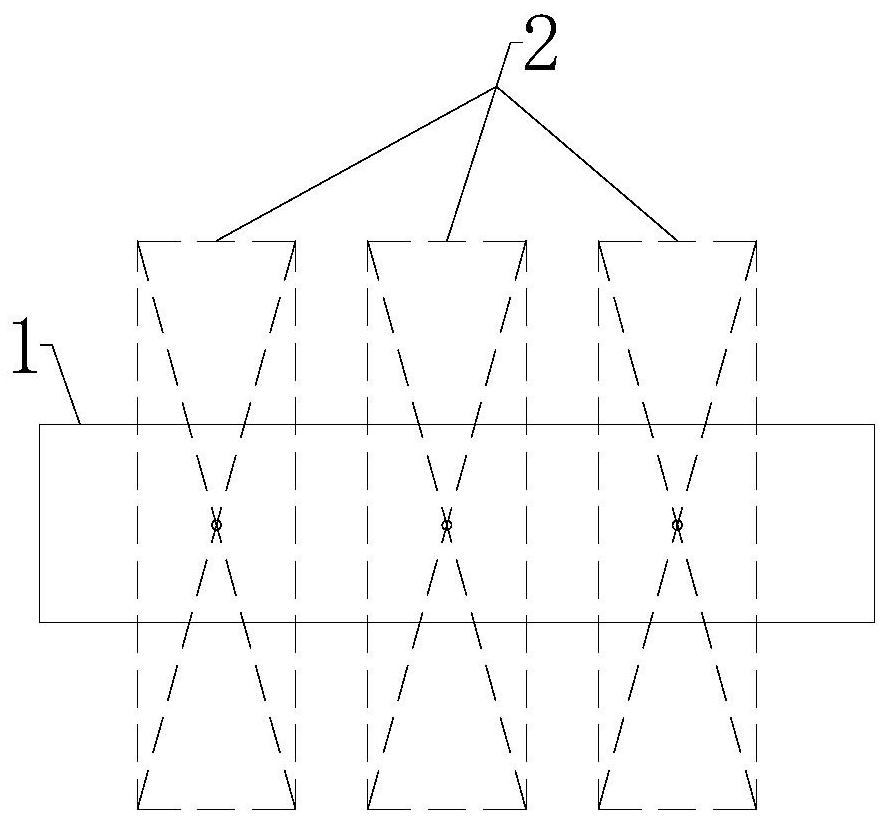

[0037] Embodiment one: if figure 1 — image 3 Shown, a kind of magnetization method of programmable magnetization equipment comprises the following steps:

[0038] (1) Put the magnet on the stage of the magnetizing equipment and fix it;

[0039] (2) Determine the size of the magnet and the relative position coordinates of the magnet through the visual system, upload the magnet profile data to the magnetization program of the computer, and adjust the magnetization position; or, control the position of the stage through the PLC to adjust the magnetization position. Magnetic position; the vision system uses industrial cameras;

[0040] (3) Design the magnetization polarity, magnetization steps, and magnetization power, complete the magnetization design and preview the magnetization effect;

[0041] (4) Start the program, the magnetizing head starts to magnetize the magnet, and releases a strong pulse magnetic field through the iron core for one or more magnetization.

[0042]...

Embodiment 2

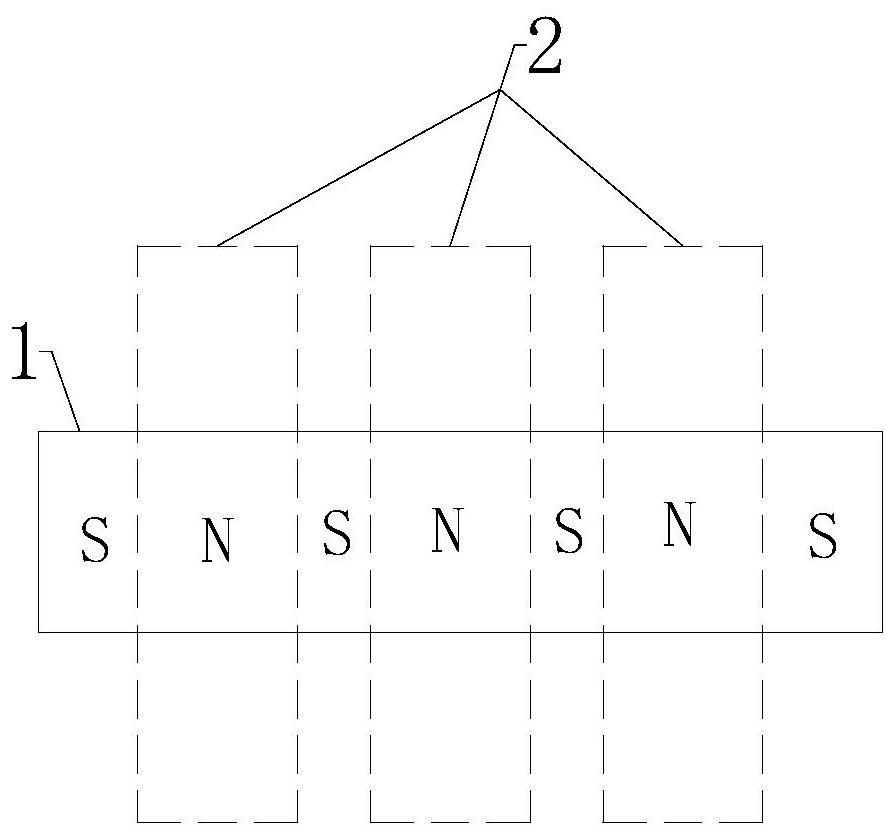

[0046] Embodiment two: if Figure 4 with Figure 5 As shown, in step (1), the magnet is not pre-magnetized and placed on the stage; in step (4), the magnet is not pre-magnetized, and the external cable of the magnetic head is connected to the dual-circuit magnetization power supply at the same time, and the dual-circuit magnetization The power supply includes the built-in capacitor A of the magnetizer and the built-in capacitor B of the magnetizer. Adjust the built-in capacitor A of the magnetizer and the built-in capacitor B of the magnetizer to the same magnetization parameters. One of B is positively connected, the other is reversely connected, and they are discharged in turn to ensure that one of the channels is discharged while the other is disconnected.

[0047] Step (4) specifically includes:

[0048] (41) Firstly charge one side of the magnet with a single pole, which is the first pole, and the default is N facing upward, and the current is connected to the power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com