Screw extrusion type film recycling and granulating device

A granulation device and screw extrusion technology, applied in the field of screw extrusion type film recycling granulation device, can solve the problems of increasing the risk of thermal degradation, reducing the physical properties of materials, and high processing costs, achieving good mechanical properties and suitable materials. Wide range and good granulation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

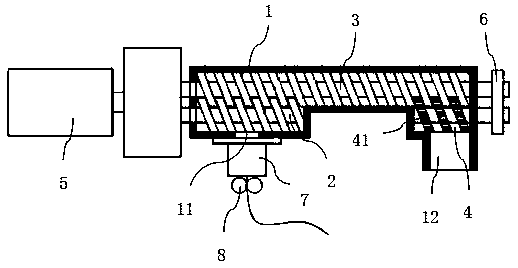

[0018] Such as figure 1 As shown, a screw extrusion type film recovery and granulation device includes a granulation cylinder 1, a feeding screw 2 arranged in the granulation cylinder, a plasticizing screw 3 and a granulation screw 4, and the feeding screw 2 runs through the In the length direction of the granulation cylinder 1, the feeding screw 2 meshes with the head end of the plasticizing screw 3 to extrude and plasticize the film material in the direction of the granulation screw 4, and the granulation screw 4 meshes with the end of the plasticizing screw 3 to produce A plurality of granulating teeth 41 are provided on the flight of the granulating screw 4, and the granulating screw 4 continuously rotates the plasticized film plastic through the granulating teeth 41 to become individual granular , the plasticizing screw 3 is driven to rotate by the motor 5, a synchronous gear is set between the feeding screw 2 and the plasticizing screw 3 to make the feeding screw and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com