High-speed continuous photocuring type 3D printing device and working method thereof

A 3D printing and light curing technology, applied in manufacturing auxiliary devices, 3D object support structures, manufacturing tools, etc., can solve the problem of affecting light efficiency and quality of formed parts, oxygen and ultraviolet light permeable Teflon materials are expensive and printing. Speed and quality limitations, etc., to solve the problem of rapid resin reflow in large areas, realize rapid resin replenishment, and achieve high-speed continuous printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

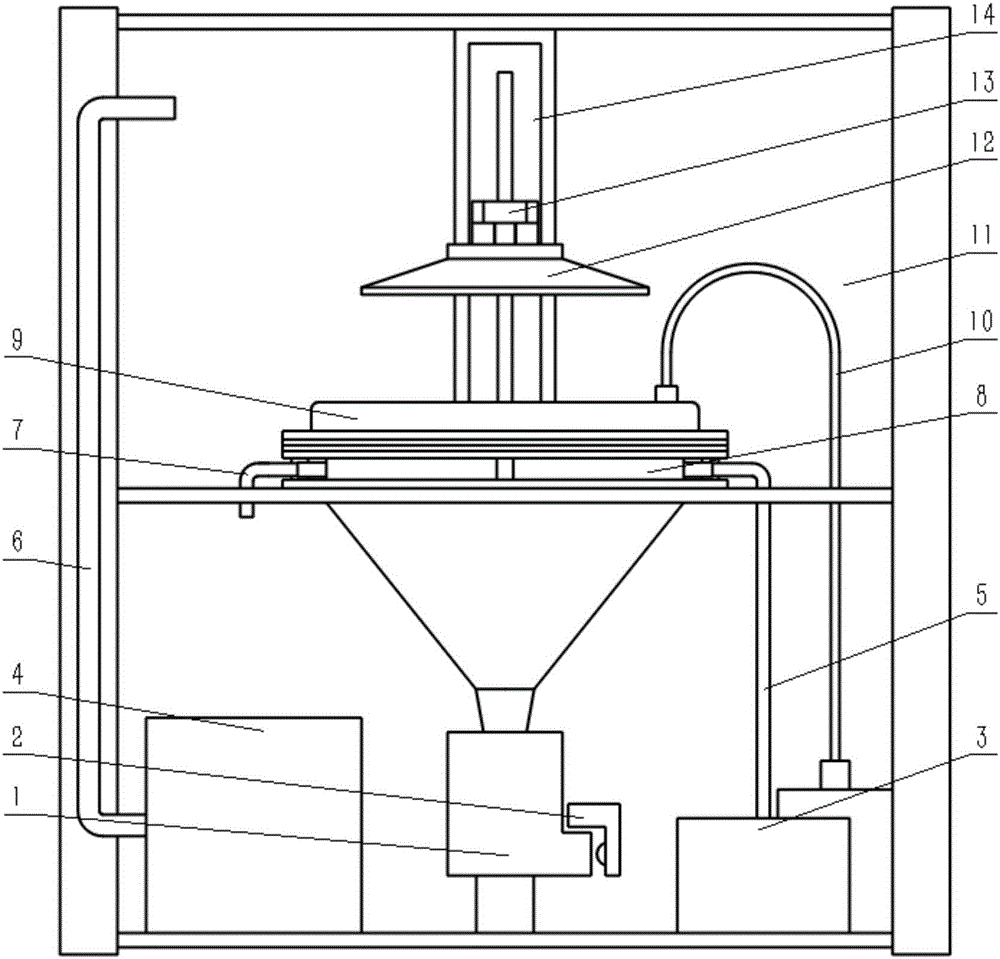

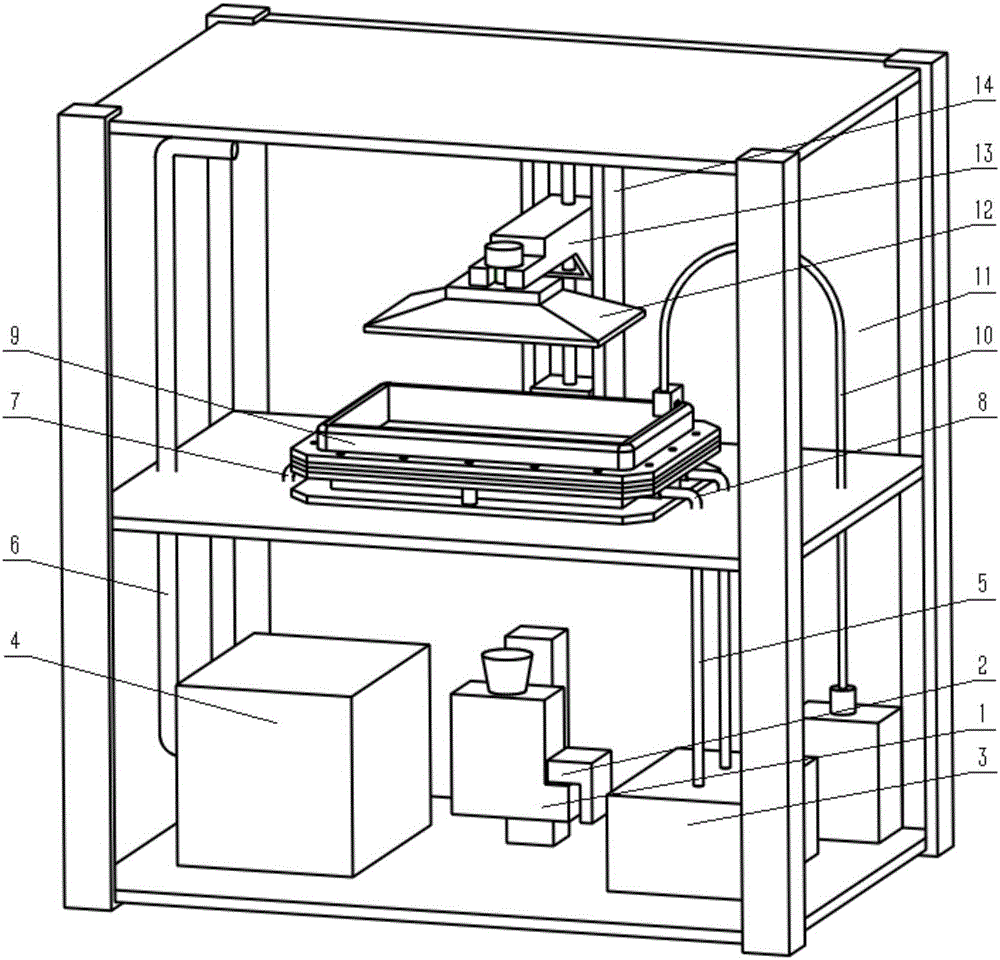

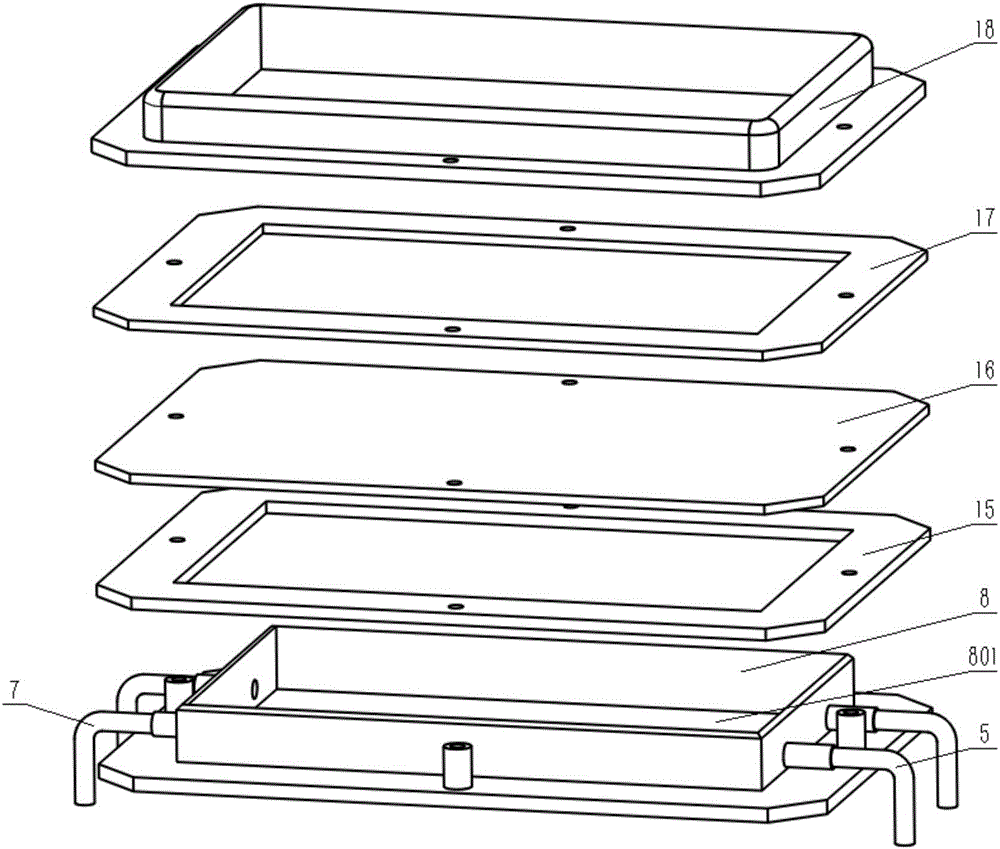

[0061] figure 1 It is a schematic diagram of the structure and principle of the high-speed continuous photocuring 3D printing device of Embodiment 1 of the present invention, figure 2 It is a three-dimensional view of the structure and principle of the high-speed continuous light-curing 3D printing device of Embodiment 1 of the present invention. Embodiment 1 The high-speed continuous light-curing 3D printing device includes: DLP optical machine 1, ultraviolet LED lamp 2, oxygen supply cooling unit 3, oil-free air compressor 4, cooling air intake pipeline 5, pressurized air intake pipeline 6, cooling outlet Air pipeline 7 , oxygen supply cooling chamber 8 , window box 9 , raw material supply unit 10 , chassis 11 , printing platform 12 , connecting bracket 13 , and Z-direction workbench 14 . The imaging unit consisting of the DLP optical machine 1 and the ultraviolet LED lamp 2 is located in the lower chamber of the chassis 11; the oxygen supply cooling unit 3 and the oil-fre...

Embodiment 2

[0077] Embodiment 2 The schematic diagram of the structure and principle of the printing device is as follows Figure 4 As shown, the liquid crystal display technology is used to generate a dynamic mask. Wherein imaging is made up of ultraviolet LED module group 19, Fresnel lens 20, liquid crystal display screen 21, and the ultraviolet light that ultraviolet LED module group 19 produces is after being collimated by Fresnel lens 20, irradiates on the liquid crystal display screen 21, and liquid crystal display screen 21 The display screen 21 plays the image information continuously, thereby generating the projected image required for curing.

Embodiment 3

[0079] As another embodiment, the cooling outlet pipeline 7 is set so that the outlet pressure can be adjusted. When the air pressure in the closed space formed by the oxygen supply cooling chamber 8 and the composite oxygen-enriched membrane 16 reaches a certain threshold, it can be discharged through the cooling outlet pipeline 7. By increasing the air pressure in the enclosed space, the rate of oxygen passing through the composite oxygen-enriched membrane is improved ability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com