Tissue engineering complex grid shape stent forming method base on core dissolving technology

A technology of tissue engineering and mesh scaffolds, which is applied in the field of forming complex tubular mesh scaffolds in tissue engineering, can solve the problems of inability to form spatial mesh structures, complex tubular mesh scaffold forming methods, and limited types of formable materials, etc., to achieve Rapid forming, large processing capacity and wide range of applicable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

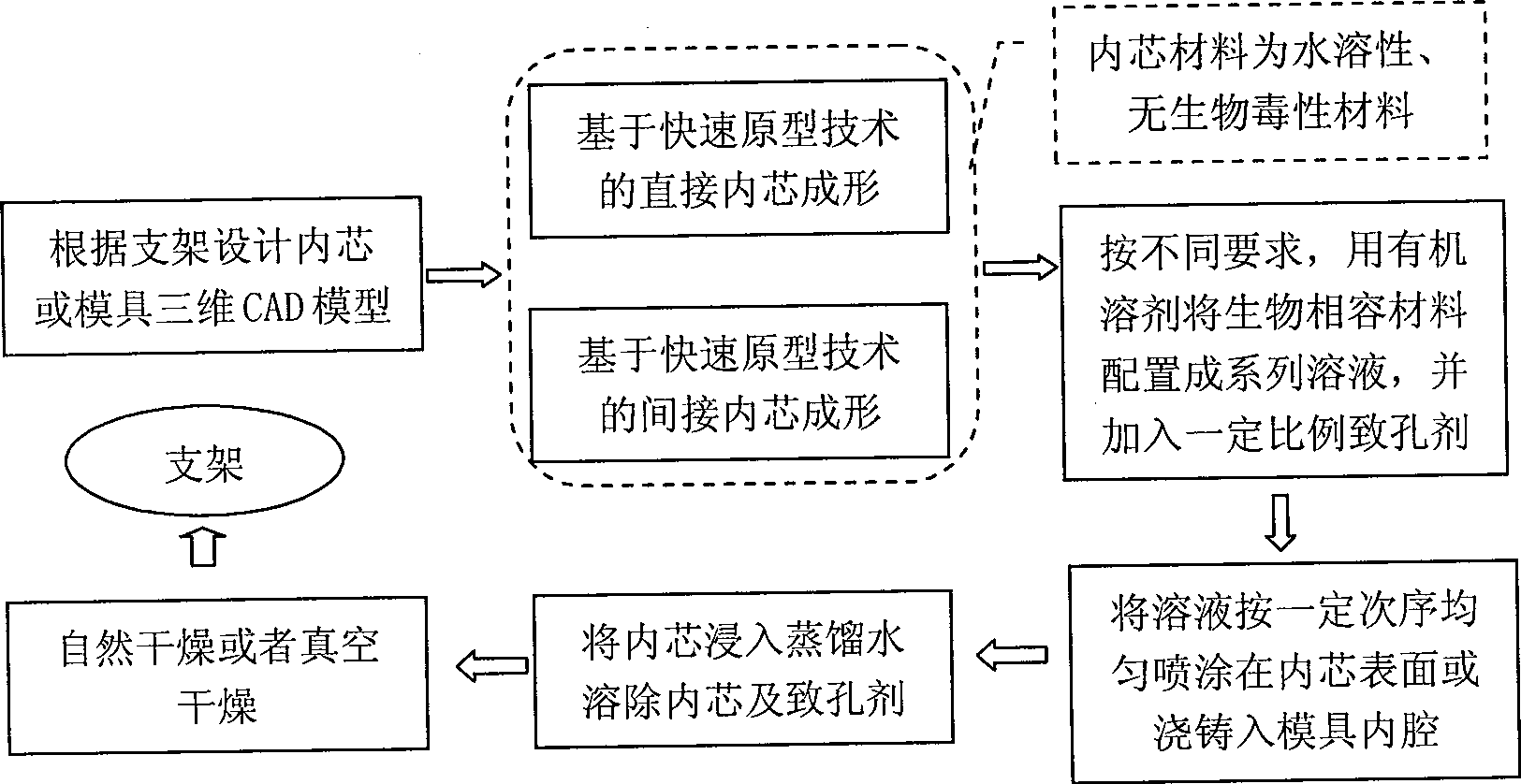

Method used

Image

Examples

Embodiment 1

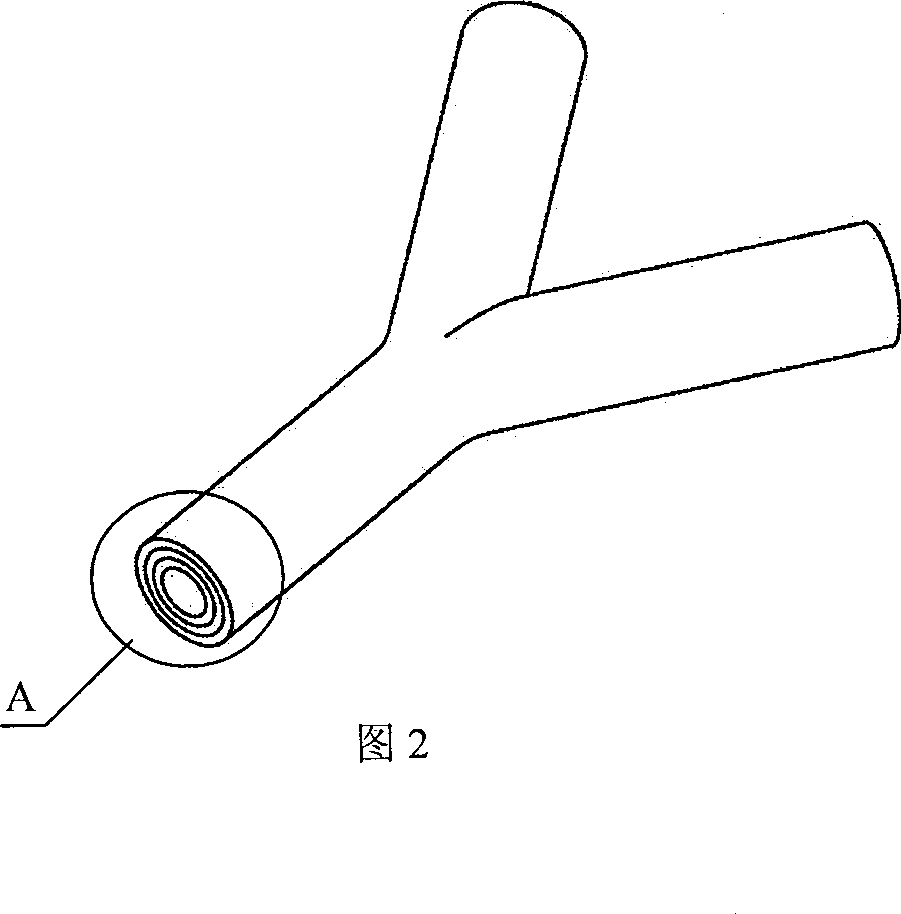

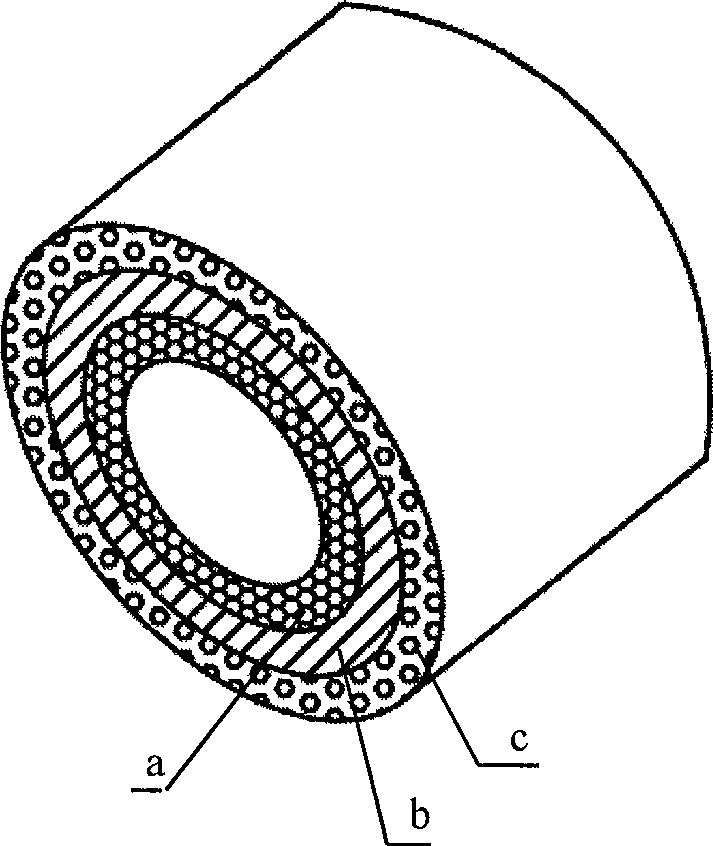

[0035] In a tissue engineering, a tubular network carrier tubular scaffold with a planar bifurcation structure is required. The maximum diameter of the "trunk" is 3mm, and there are two bifurcation structures under the trunk, and the bifurcation diameter is 3mm. The stent tube wall has a three-layer structure. The inner wall needs a microporous structure with a pore size of 70um, the porosity is about 90%, and the material is PLGA. The outer wall needs a microporous structure with a pore size of 120um, the porosity is about 75%, and the material is the same as the inner layer. The middle layer has no microporous structure, and the material is PCL-PET multi-block copolymer.

[0036] (1) Design the inner core of the stent. Use SolidWorks 3D CAD software to design the 3D structure of the inner core, and output the CAD model of the stent inner core as STL file format.

[0037] (2) The inner core is made by melt extrusion process (MEM process). The inner core forming material i...

Embodiment 2

[0053] Three-dimensional block scaffolds with inner tube network were prepared. Inside the bracket, there is an inner pipe network that communicates with each other. The inner pipe network of the stent has a three-layer space bifurcation structure and four-level pipe diameters, and the diameters are 1200 μm, 900 μm, 600 μm and 300 μm in sequence. The shape of the inner pipe network is as image 3 shown. The manufacturing process of the bracket is as follows:

[0054] (1) According to the shape of the inner pipe network, use Solidworks software to design the inner core of the inner pipe network. According to the appearance and shape of the stent, design the outer contour and inner core of the stent. And output the resulting models as STL files respectively. The inner core shape of the inner pipe network is as follows Figure 4 shown

[0055] (2) The inner core of the inner pipe network is indirectly formed based on the stereolithography process.

[0056] First, the inne...

Embodiment 3

[0066] A common bile duct stent with a planar bifurcated structure was prepared. The macroscopic structure of the stent is a main tube with an inner diameter of 9mm, and two bifurcations with an inner diameter of 8mm and 6mm are divided into two faces. The tube wall requires no microporous structure, and the stent forming material is PLLGA.

[0067] (1) Design the inner core of the stent. Use SolidWorks 3D CAD software to design the 3D structure of the inner core, and output the CAD model of the stent inner core as STL file format.

[0068] (2) Direct forming of inner core based on melt extrusion process.

[0069] The stent outer contour support was fabricated using the MEM250-II melt extrusion molding system produced by Beijing Yinhua Laser Rapid Prototyping and Die Technology Co., Ltd. The forming material is a mixture of maltose, glucose and sucrose. The main process parameters used are: layer thickness 0.20mm, scanning speed 23mm / s.

[0070] (3) 1 g of PLLGA (Mv: 1000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com