Preparation method of co-injection multi-layer structure part

A multi-layer structure and co-injection technology, which is applied in the field of powder co-injection molding, can solve the problems of large interfacial bonding strength due to component differences, difficulty in preparing materials with comprehensive properties, and unfavorable mass production, etc., achieving high interfacial bonding strength and suitable for large Large-scale production, solving the effect of large ingredient restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

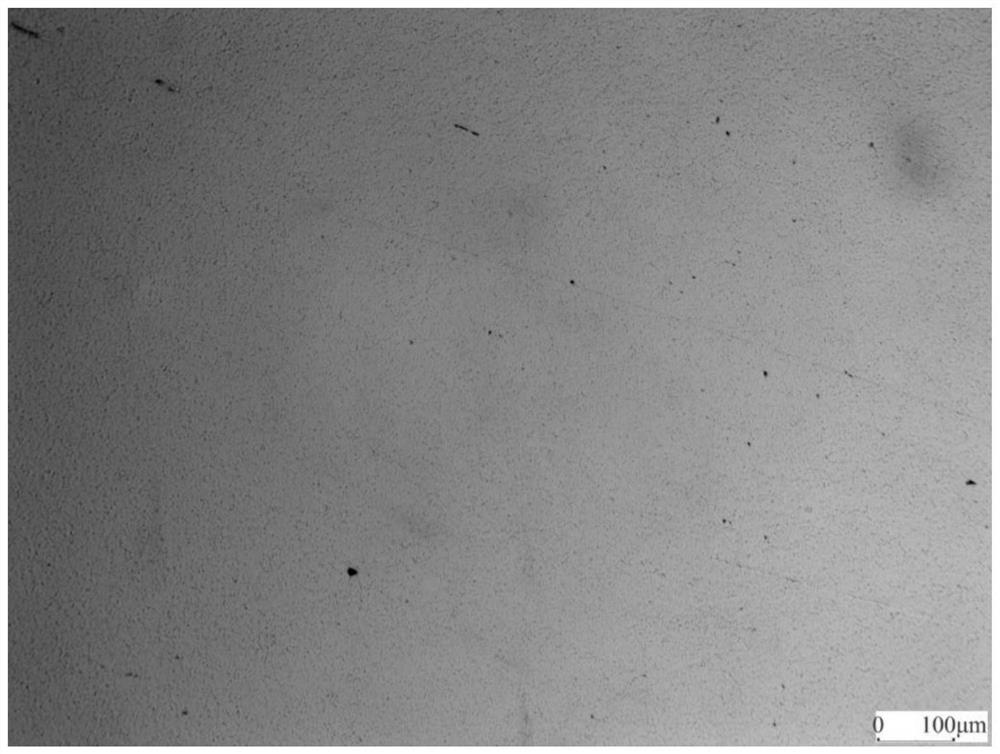

Image

Examples

Embodiment 1-1

[0036] A preparation technology for co-injection multilayer structural parts, the process is as follows:

[0037] A. Raw material preparation: The base material A is 316L stainless steel powder prepared by gas atomization, with an average particle size of 15 μm. Powder B is a mixture of bonding powder B1 and reinforcing powder B2. The composition of the bonding powder B1 is Co-Cu, the average particle size is 15 μm, and the composition of the strengthening powder B2 is ZrO 2 , the average particle size is 300nm, and the volume fraction of bonding powder B1 in powder B is 35%.

[0038] B, prepare binding agent: prepare by following mass percentage, polyoxymethylene (POM) 80%; Polypropylene (PP) 10%; Polyethylene wax (PE wax) 5%; Stearic acid (SA) 5%.

[0039] C, preparation of feed: the binder and 316L stainless steel powder are mixed and granulated according to the volume ratio of 45%:55% to make feed A, the mixing temperature is 155°C, and the mixer speed is 90r / min, The m...

Embodiment 1-2

[0045] A preparation technology for co-injection multilayer structural parts, the process is as follows:

[0046] A. Raw material preparation: The base material A is 316L stainless steel powder prepared by gas atomization, with an average particle size of 15 μm. Powder B is a mixture of bonding powder B1 and reinforcing powder B2. The composition of the bonding powder B1 is Co-Cu, the average particle size is 15 μm, and the composition of the strengthening powder B2 is ZrO 2 , the average particle size is 400nm, and the volume fraction of bonding powder B1 in powder B is 35%.

[0047] B, prepare binding agent: prepare by following mass percentage, polyoxymethylene (POM) 80%; Polypropylene (PP) 10%; Polyethylene wax (PE wax) 5%; Stearic acid (SA) 5%.

[0048] C, preparation of feed: the binder and 316L stainless steel powder are mixed and granulated according to the volume ratio of 45%:55% to make feed A, the mixing temperature is 155°C, and the mixer speed is 90r / min, The m...

Embodiment 1-3

[0054] A preparation technology for co-injection multilayer structural parts, the process is as follows:

[0055] A. Raw material preparation: The base material A is 316L stainless steel powder prepared by gas atomization, with an average particle size of 15 μm. Powder B is a mixture of bonding powder B1 and reinforcing powder B2. The composition of the bonding powder B1 is Co-Cu, the average particle size is 15 μm, and the composition of the strengthening powder B2 is ZrO 2 , the average particle size is 300nm, and the volume fraction of bonding powder B1 in powder B is 35%.

[0056] B, prepare binding agent: prepare by following mass percentage, polyoxymethylene (POM) 80%; Polypropylene (PP) 10%; Polyethylene wax (PE wax) 5%; Stearic acid (SA) 5%.

[0057] C, preparation of feed: the binder and 316L stainless steel powder are mixed and granulated according to the volume ratio of 45%:55% to make feed A, the mixing temperature is 155°C, and the mixer speed is 90r / min, The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com