Continuous surface exposure ceramic 3D printing device and working method thereof

A 3D printing and surface exposure technology, applied in the direction of supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of increasing the molding time of parts, the complexity of printing devices, affecting the quality and accuracy of printed parts, and filling the solidified area of liquid materials, etc. , to achieve the effect of saving the time of cleaning the window box, high printing efficiency, and reducing the cost of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

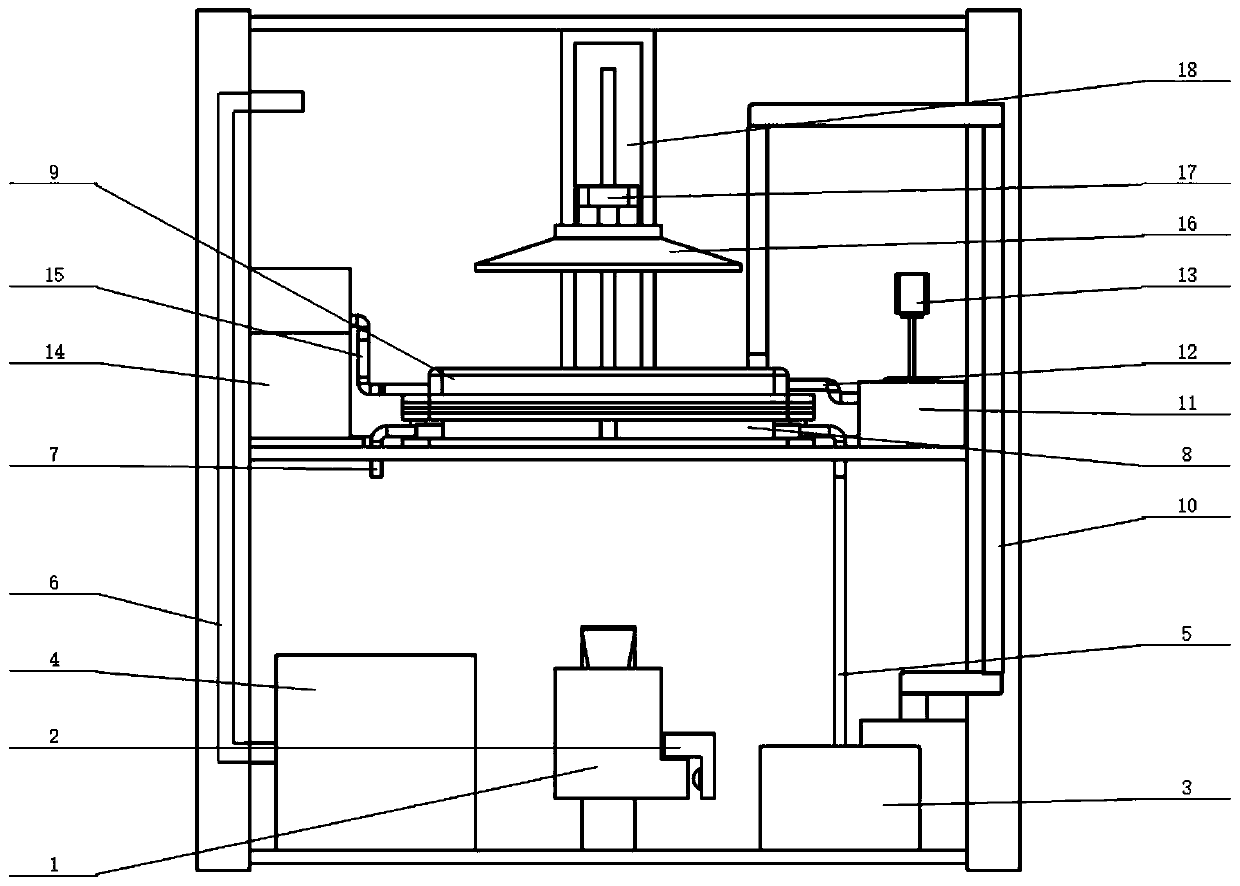

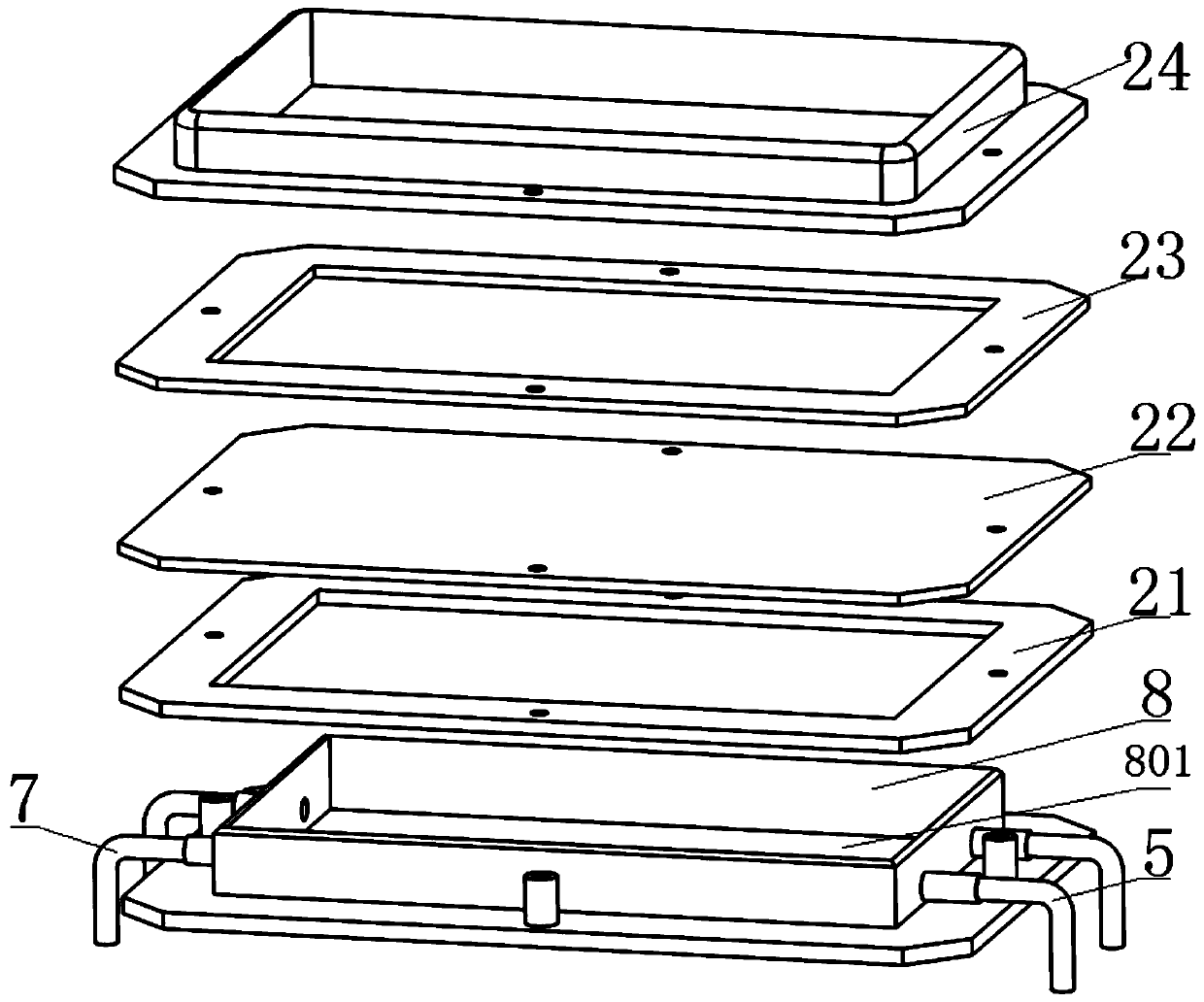

[0060] Such as figure 1 As shown, a continuous surface exposure ceramic 3D printing device includes: a chassis body, the chassis body is divided into an upper chamber and a lower chamber by a middle partition, the lower chamber is provided with an imaging module, and the upper chamber The chamber is equipped with a window box 9, a ceramic slurry circulation delivery module, an oxygen supply cooling module and a hydraulic auxiliary pressure application module, the window box and the oxygen supply cooling module are fixedly installed on the middle partition, and the oxygen supply cooling module is set Directly below the window box, the imaging device is arranged directly below the window box, a printing platform 16 is arranged directly above the window box, and the printing platform is installed on a Z-direction workbench 18. The window The box is connected to the raw material supply unit 10; the window box is provided with a liquid storage tank 24;

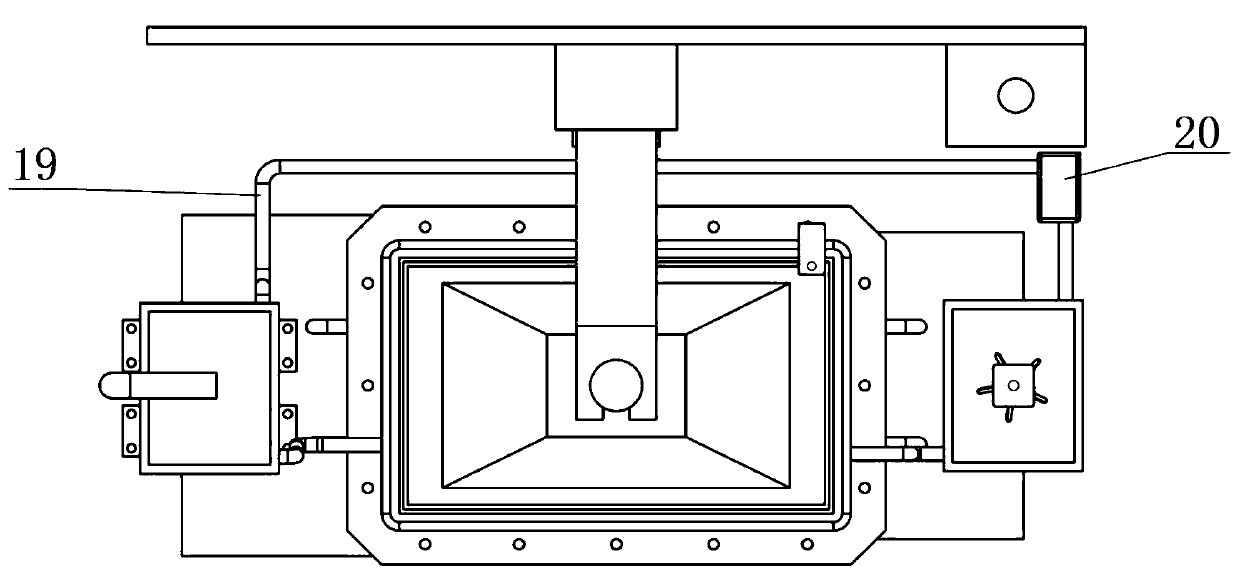

[0061] Such as figure 2 ...

Embodiment 2

[0081] Step 1: Modification of ceramic powder. First prepare a mixed solution of 5% concentration with absolute ethanol and silane coupling agent KH-570, then add alumina ceramic powder with an average particle size of 3 μm to the mixed solution at a volume ratio of 5:1. Magnetic stirring at a temperature of 8 h, filtered and dried to obtain surface-modified alumina ceramic powder;

[0082] Step 2: Configure ceramic slurry. The free radical photosensitive premix solution and PAA were used as raw materials to prepare an organic mixture solution, and the mixture was used as a solvent, and the surface-modified alumina ceramic powder (adding ratio of 4o%) produced by the above process was added in batches to it, and at the same time, the Stir at high speed (2200r / min) for 8h until the powder is evenly dispersed, then stir at low speed (500r / min) to remove foam for 2h. The free radical type resin-based alumina ceramic slurry can be obtained, and finally added to the raw material ...

Embodiment 3

[0088] Step 1: Modification of ceramic powder. First prepare a mixed solution with a concentration of 5% with absolute ethanol and silane coupling agent KH-570, then add zirconia ceramic powder with an average particle size of 20 μm to the mixed solution at a volume ratio of 4:1, at 48 ° C Stir magnetically for 9 hours at a temperature above 100°F, filter and dry to obtain surface-modified zirconia ceramic powder;

[0089] Step 2: Configure ceramic slurry. The radical photosensitive premix solution and PAA were used as raw materials to prepare an organic mixture solution, and the mixture was used as a solvent, and the surface-modified zirconia ceramic powder (addition ratio: 5o%) produced by the above-mentioned process was added in small amounts in batches, and the auxiliary Stir at high speed (2300r / min) for 9h until the powder is evenly dispersed, then stir at low speed (500r / min) to remove foam for 2h. The free radical type resin-based zirconia ceramic slurry can be obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com