Strippable semi-conductive shielding material for ethylene propylene rubber cable

An ethylene-propylene rubber, semi-conductive technology, applied in the direction of insulated cables, cables, conductors, etc., can solve the problems that the ethylene-propylene insulating layer cannot be vulcanized simultaneously, the adhesive force of the ethylene-propylene insulating layer is insufficient, and the volume resistance of the shielding material is high. Uniform mixing, solving poor extrusion process performance and good extrusion processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

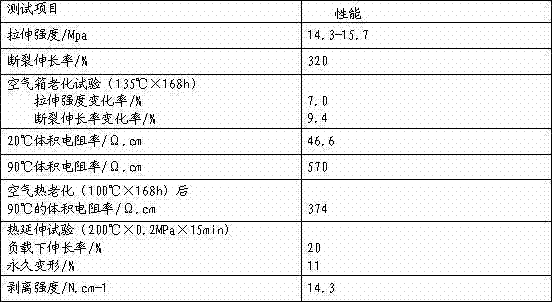

Image

Examples

Embodiment 1

[0032] A strippable semi-conductive shielding material for ethylene-propylene rubber cables, composed of the following raw materials in parts by weight: 70 parts of ethylene vinyl acetate, 30 parts of chlorinated polyethylene, 55 parts of conductive carbon black, and 10 parts of coarse particle carbon black , 8 parts of metal oxide, 30 parts of mineral filler, 3 parts of dispersant, 2 parts of cross-linking agent, 4 parts of auxiliary cross-linking agent, 2 parts of anti-aging agent, 15 parts of plasticizer. The content of vinyl acetate in the selected ethylene vinyl acetate is 50%, the metal oxide is light magnesium oxide, the mineral filling is light calcium carbonate, the dispersant is polyethylene wax, and the crosslinking agent is diisopropyl peroxide. Benzene, trimethylolpropane triacrylate as co-crosslinking agent, 2,2,4-trimethyl-1,2-dihydroquinoline polymer as anti-aging agent, dioctyl sebacate as plasticizer .

[0033] The strippable semi-conductive shielding compou...

Embodiment 2

[0045] A strippable semi-conductive shielding material for ethylene-propylene rubber cables, composed of the following raw materials in parts by weight: 70 parts of ethylene vinyl acetate, 30 parts of chlorinated polyethylene, 50 parts of conductive carbon black, and 5 parts of coarse particle carbon black , 5 parts of metal oxide, 20 parts of mineral filler, 5 parts of dispersant, 3 parts of cross-linking agent, 4 parts of auxiliary cross-linking agent, 3 parts of anti-aging agent, 15 parts of plasticizer. The content of vinyl acetate in the selected ethylene vinyl acetate is 50%, the metal oxide is light magnesium oxide, the mineral filling is light calcium carbonate, the dispersant is polyethylene wax, and the crosslinking agent is diisopropyl peroxide. Benzene, trimethylolpropane triacrylate as co-crosslinking agent, 2,2,4-trimethyl-1,2-dihydroquinoline polymer as anti-aging agent, dioctyl phthalate as plasticizer ester.

[0046] Wherein, the stripped semi-conductive shie...

Embodiment 3

[0049] A peelable semi-conductive shielding material for ethylene-propylene rubber cables, which is composed of the following raw materials in parts by weight: 70 parts of ethylene vinyl acetate, 30 parts of chlorinated polyethylene, 65 parts of conductive carbon black, and 10 parts of coarse particle carbon black , 7 parts of metal oxide, 30 parts of mineral filler, 10 parts of dispersant, 4 parts of crosslinking agent, 5 parts of co-crosslinking agent, 4 parts of anti-aging agent, 17 parts of plasticizer. The content of vinyl acetate in the selected ethylene vinyl acetate is 50%, the metal oxide is light magnesium oxide, the mineral filling is modified kaolin, the dispersant is stearic acid, and the crosslinking agent is dicumyl peroxide The auxiliary cross-linking agent is trimethylolpropane triacrylate, the anti-aging agent is 2,2,4-trimethyl-1,2-dihydroquinoline polymer, and the plasticizer is dibutyl phthalate .

[0050] Wherein, the stripped semi-conductive shielding m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com