Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Uniform surface structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

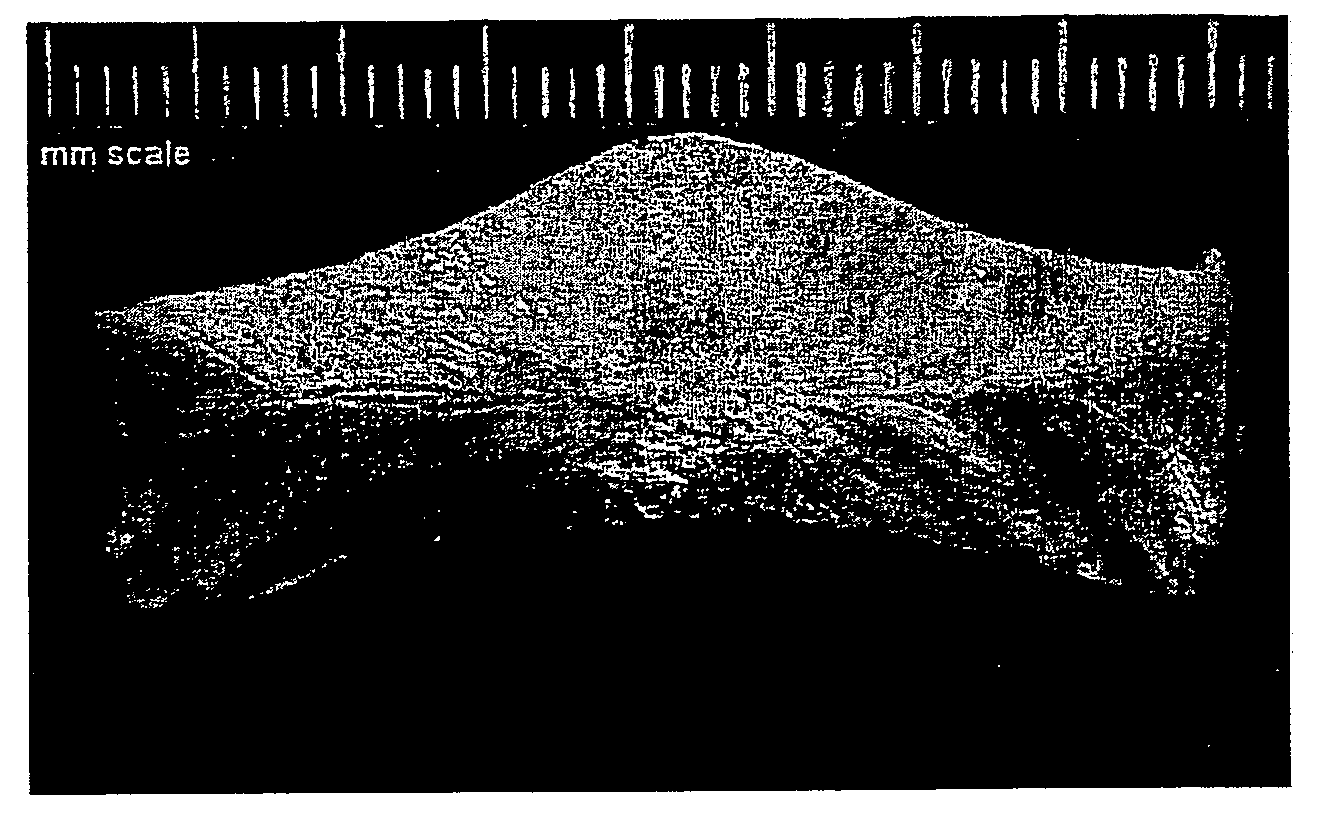

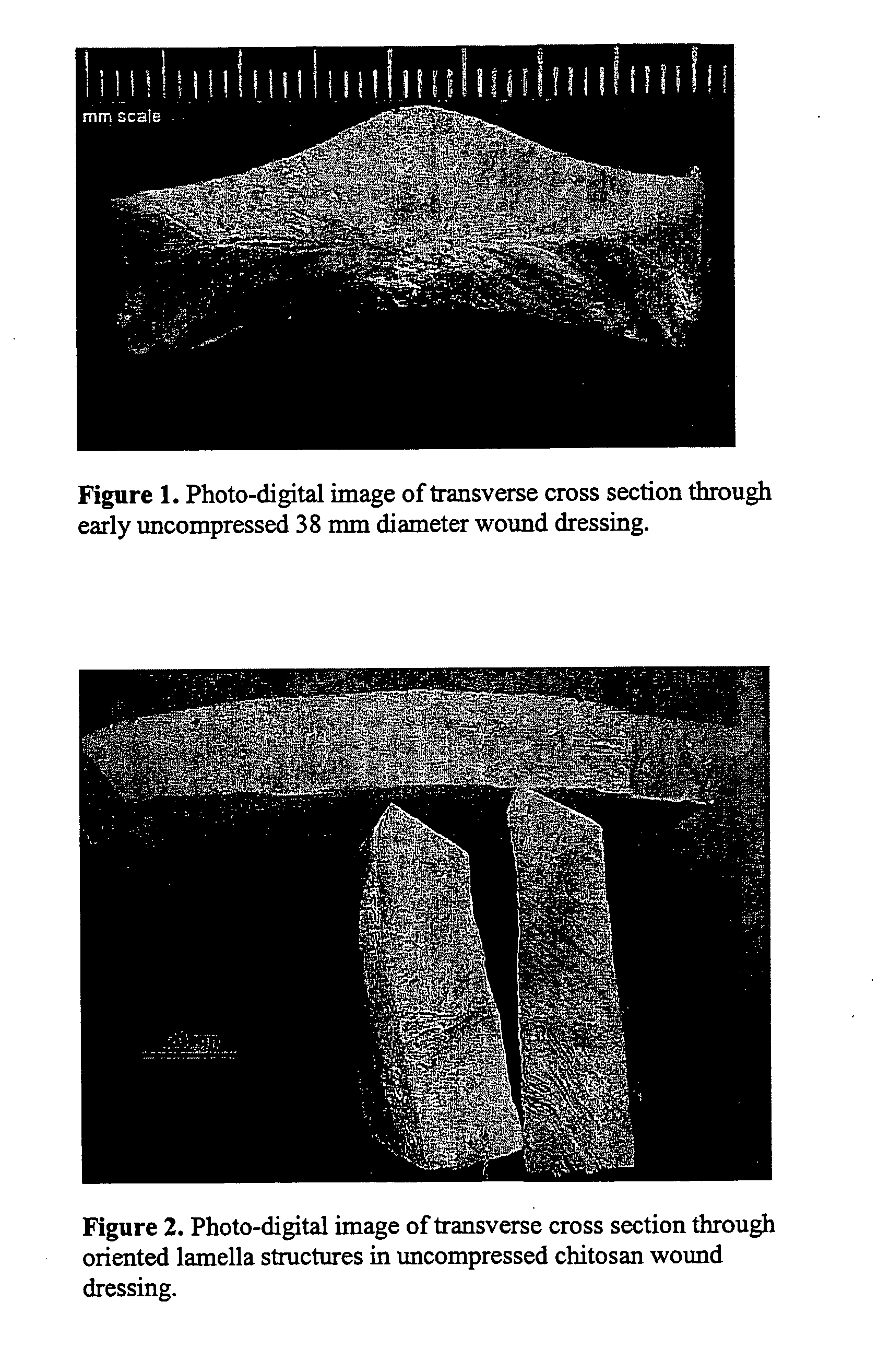

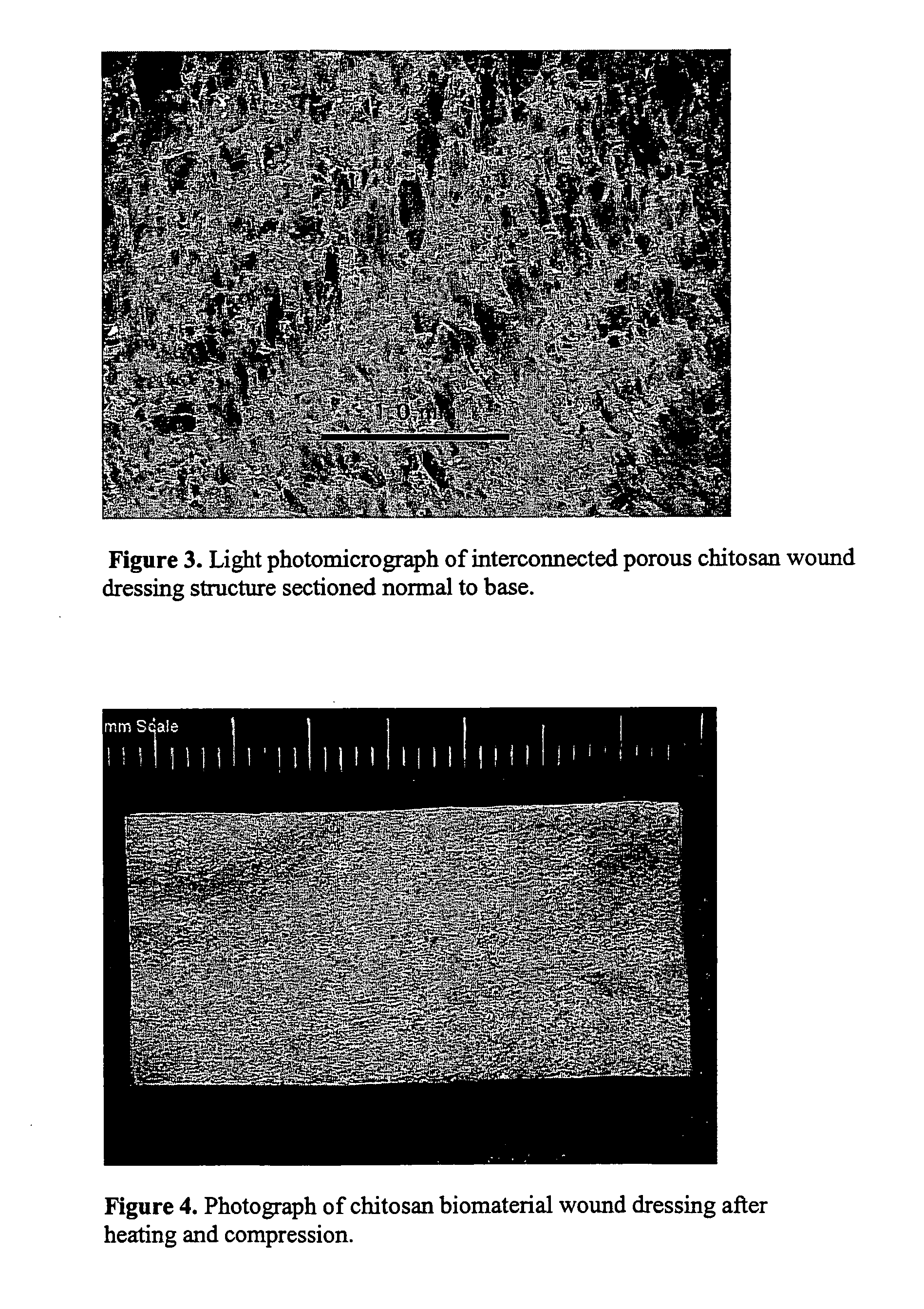

Wound dressing and method for controlling severe, life-threatening bleeding

InactiveUS20050038369A1Stanching flowAvoid bleedingBiocideNon-adhesive dressingsWound dressingClot formation

This invention is directed to advanced hemorrhage control wound dressings, and methods of using a producing same. The subject wound dressing is constructed from a non-mammalian material for control of severe bleeding. The wound dressing is formed of a biomaterial comprising chitosan for controlling severe bleeding. The kind of severe, life-threatening bleeding contemplated by this invention is typically of the type not capable of being stanched when a conventional gauze wound dressing is applied with conventional pressure to the subject wound. The wound dressing being capable of substantially stanching the flow of the severe life-threatening bleeding from the wound by adhering to the wound site, to seal the wound, to accelerate blood clot formation at the wound site, to reinforce clot information at the wound site and prevent bleed out from the wound site, and to substantially prohibit the flow of blood out of the wound site.

Owner:PROVIDENCE HEALTH SYST OREGON +1

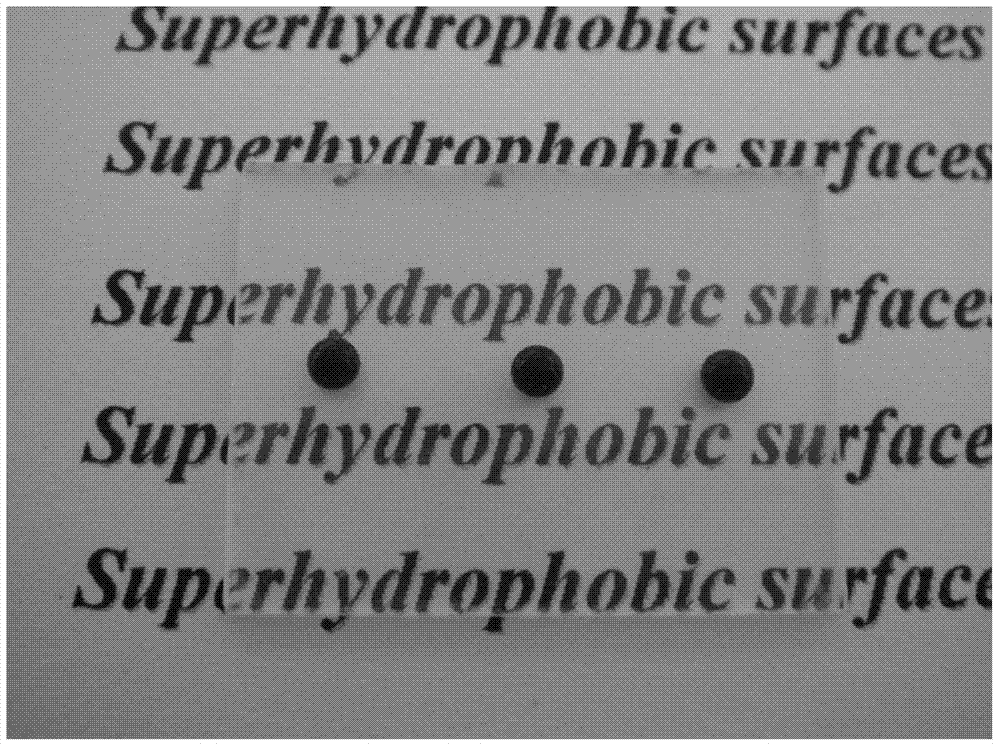

Preparation method of transparent super-hydrophobic zinc oxide coating

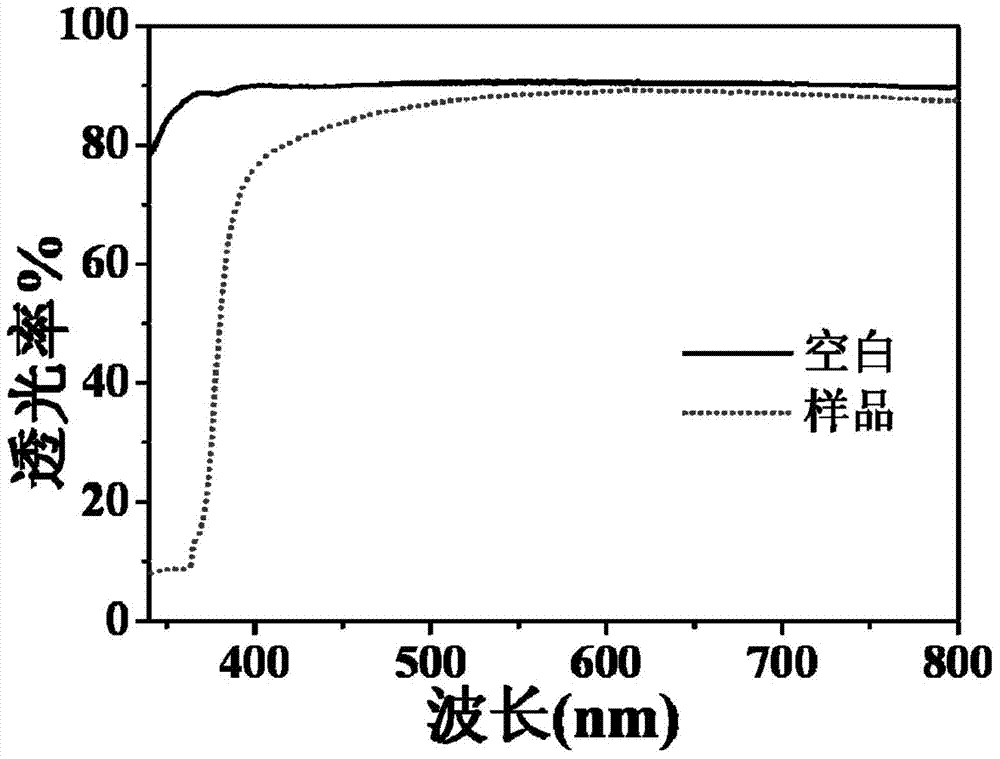

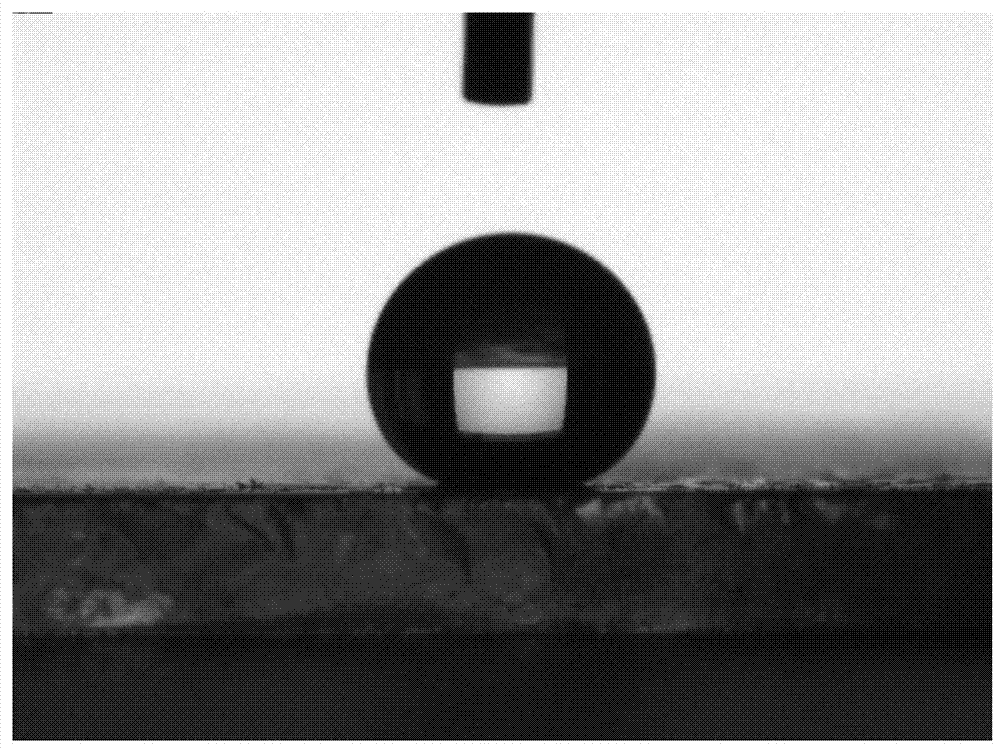

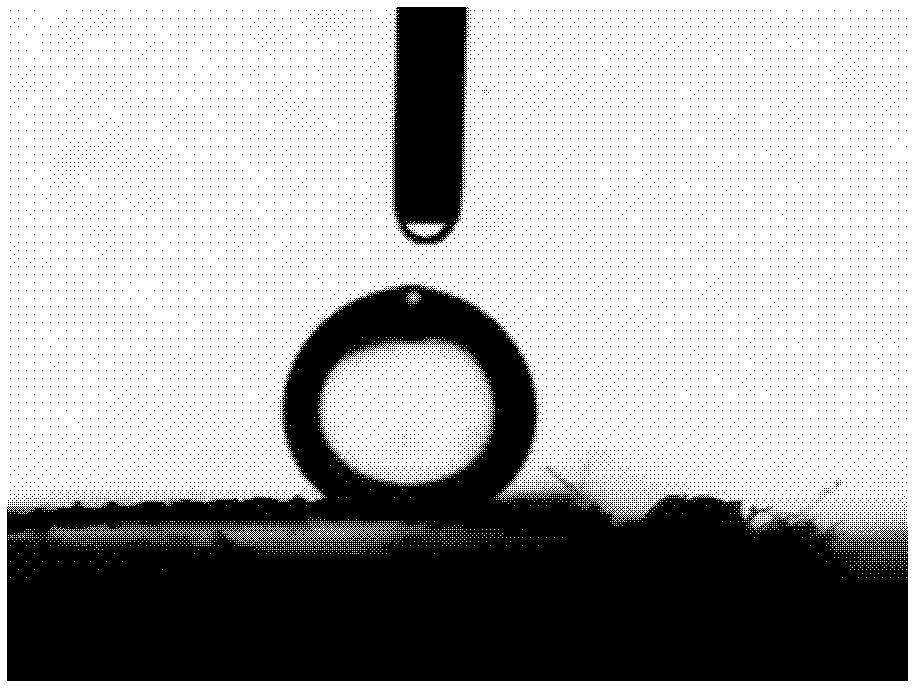

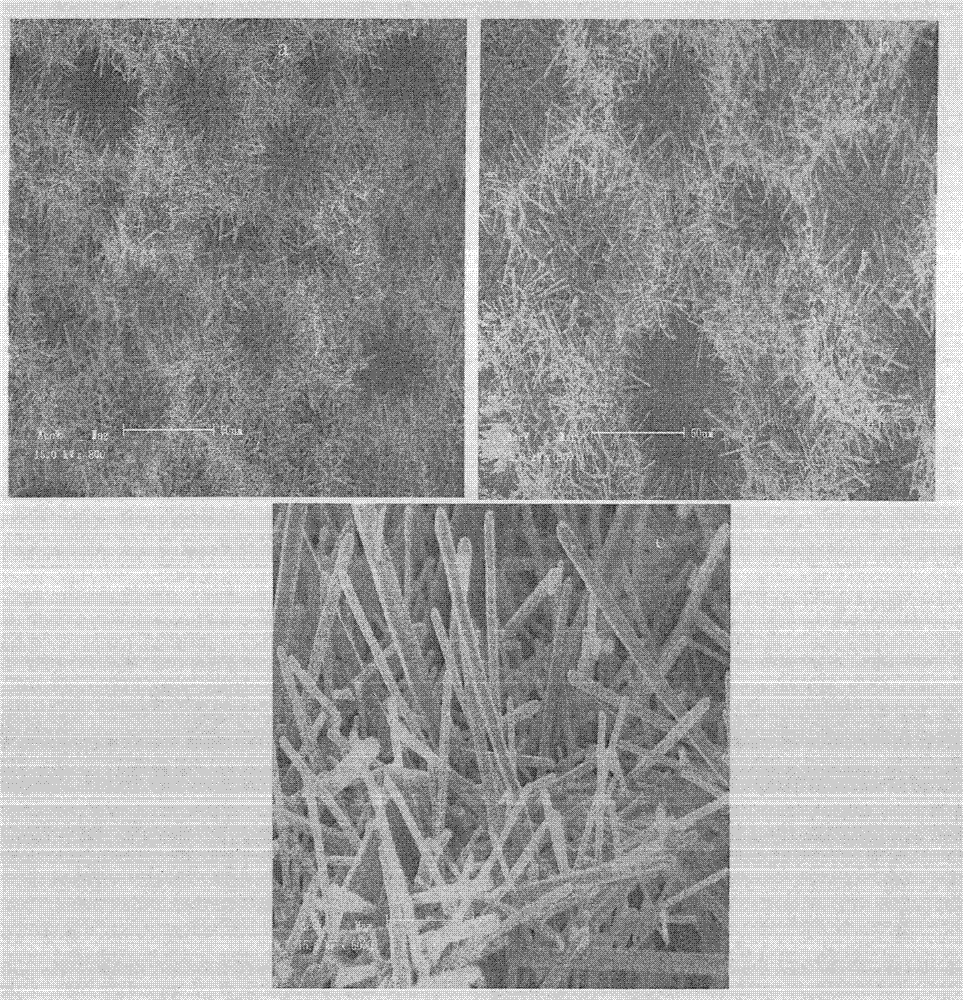

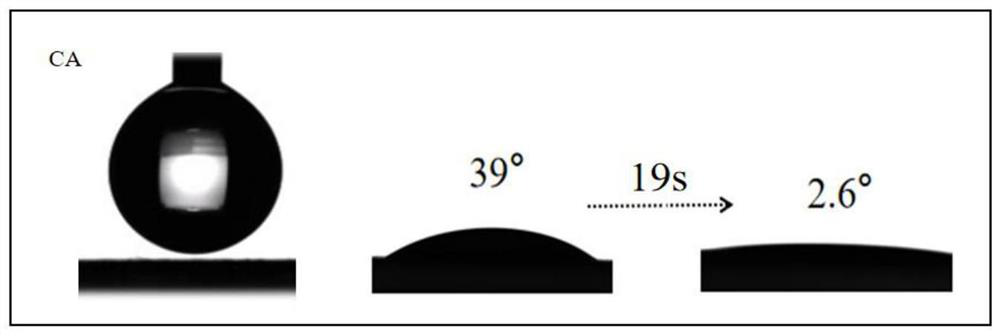

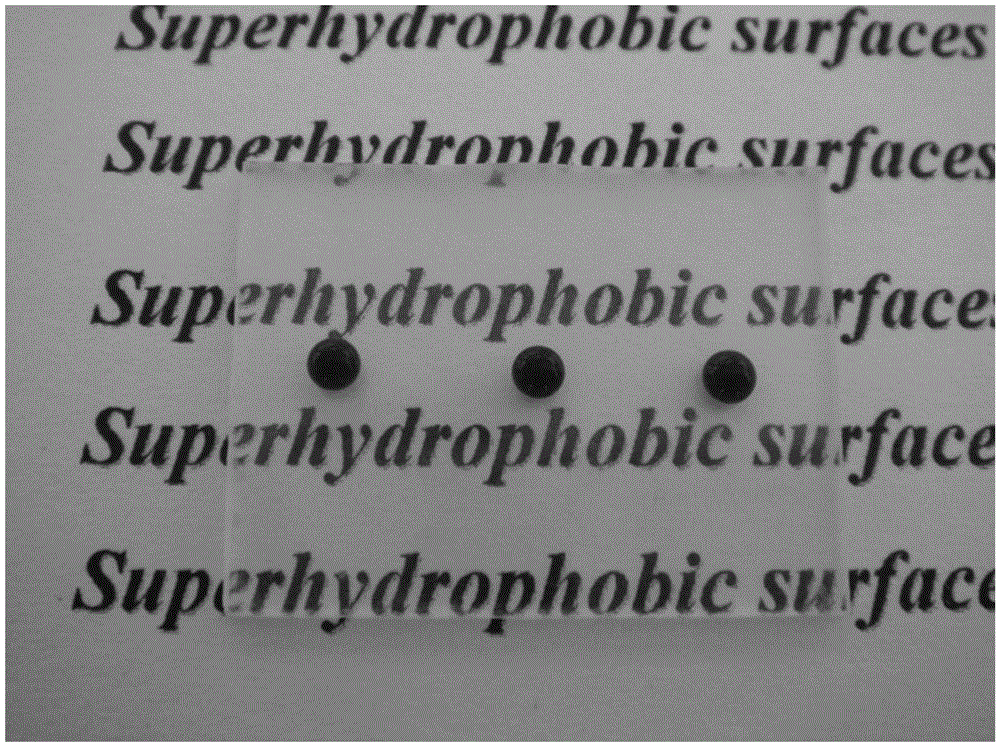

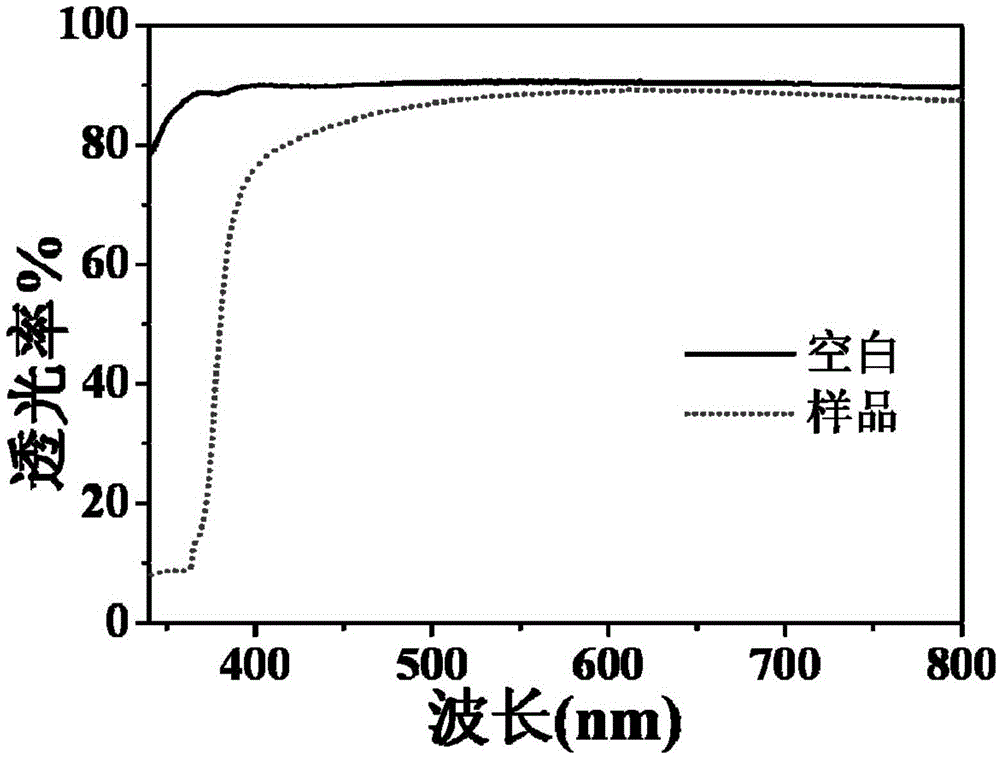

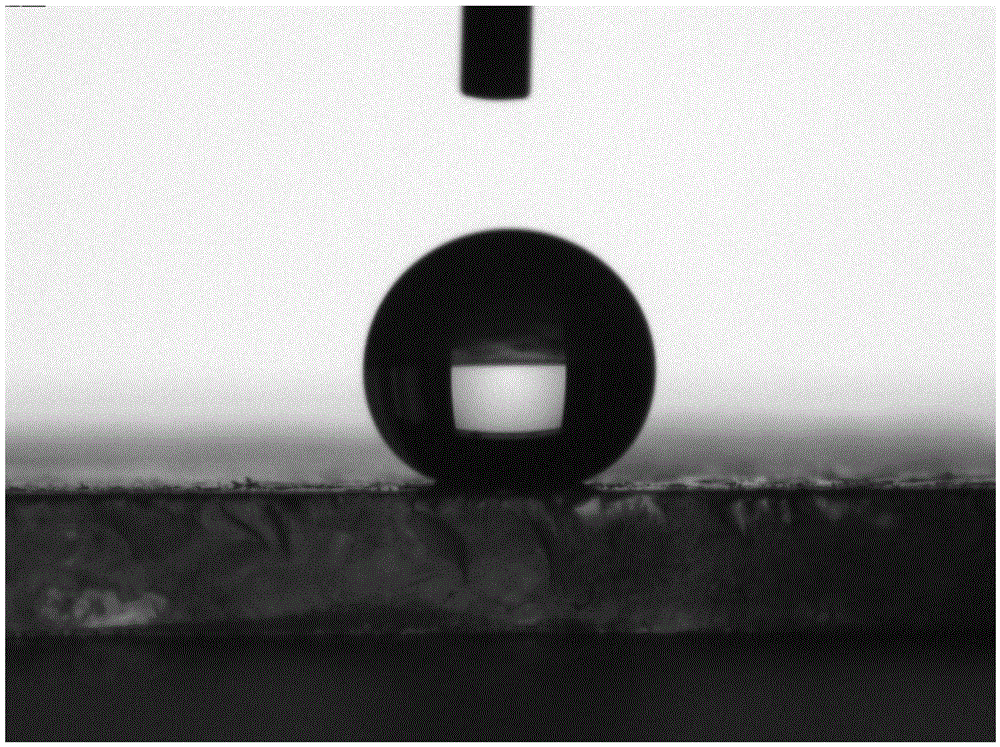

The invention relates to a preparation method of a transparent super-hydrophobic zinc oxide coating on a glass substrate. The preparation method comprises the following steps of a, substrate pretreatment; b, zinc oxide solution preparation; c, zinc oxide coating preparation; and d, zinc oxide coating surface modification. Compared with the prior art, the preparation method has the beneficial effects of simple equipment process, low cost and mild reaction condition and is beneficial to large-scale industrial production. The transparent super-hydrophobic zinc oxide coating prepared by using the method has excellent hydrophobicity and transparency; the contact angle is larger than 160 degrees, the rolling angle is smaller than 8 degrees, and water drops can freely roll on the coating, so that the transparent super-hydrophobic zinc oxide coating has relatively good self-cleaning performance; and the light transmittance is approach to 90% which is close to that of blank glass, so that the transparent super-hydrophobic zinc oxide coating has favorable visible light transmittance. A surface modifier used in the preparation method is an alkyl silane coupling agent instead of a fluorinated compound, so that the cost is low, the environment pollution is relatively low, and the modified coating is relatively stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

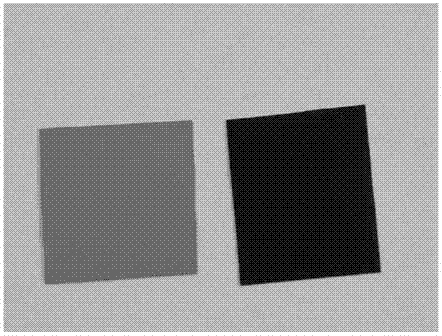

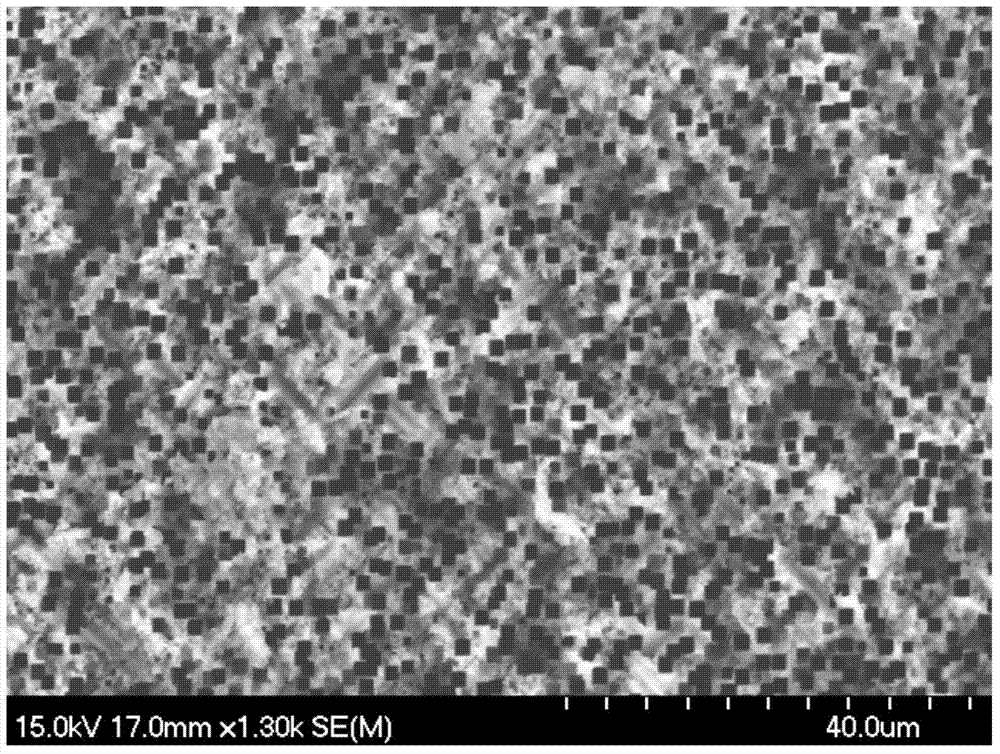

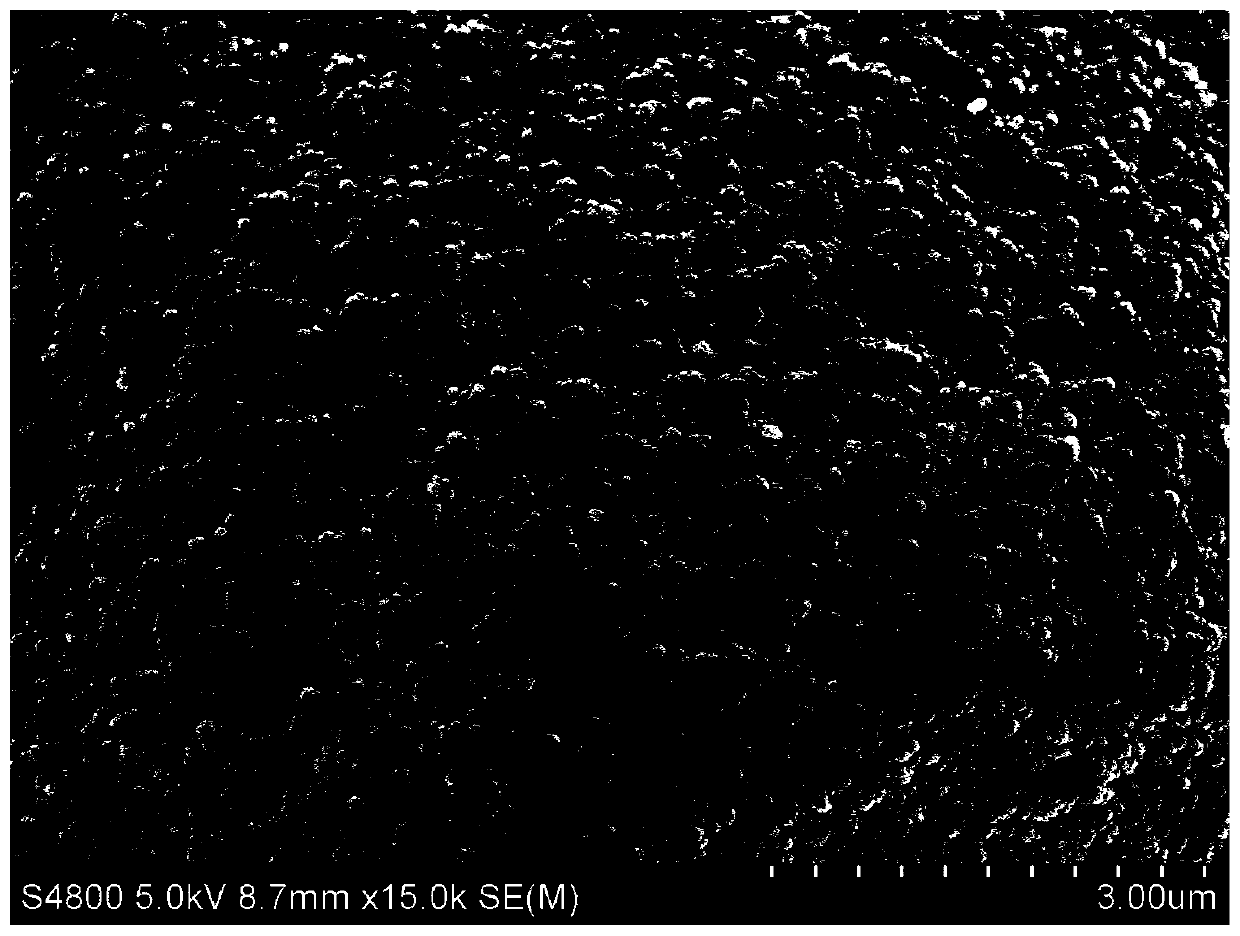

Wet process chemical preparation method for black silicon with pointed-cone-shaped surface

ActiveCN103578966AUniform surface structureUniform colorFinal product manufactureSemiconductor/solid-state device manufacturingIonChemistry

The invention discloses a wet process chemical preparation method for black silicon with a pointed-cone-shaped surface. The preparation method comprises the steps that two kinds of etching liquid are prepared, wherein the first kind of etching liquid is mixing water solution of nitric acid copper, hydrogen peroxide and hydrofluoric acid, and the second kind of etching liquid is mixing water solution of nitric acid copper, ammonium hydrogen fluoride and hydrogen peroxide; a monocrystalline silicon piece is placed into the first kind of etching liquid for initial etching; the monocrystalline silicon piece is placed into the second kind of etching liquid for surface structural ornament; finally, surface metal granule residue is washed, and the black silicon materials with the pointed-cone-shaped surface are obtained. According to the preparation method, two steps of copper ion chemical auxiliary etching is utilized, and a pointed-cone-shaped nanometer structure is prepared on the surface of monocrystalline silicon. The structure has good light trapping performance, and can remarkably improve light absorbing efficiency when applied to a silicon substrate solar cell.

Owner:ZHEJIANG UNIV OF TECH

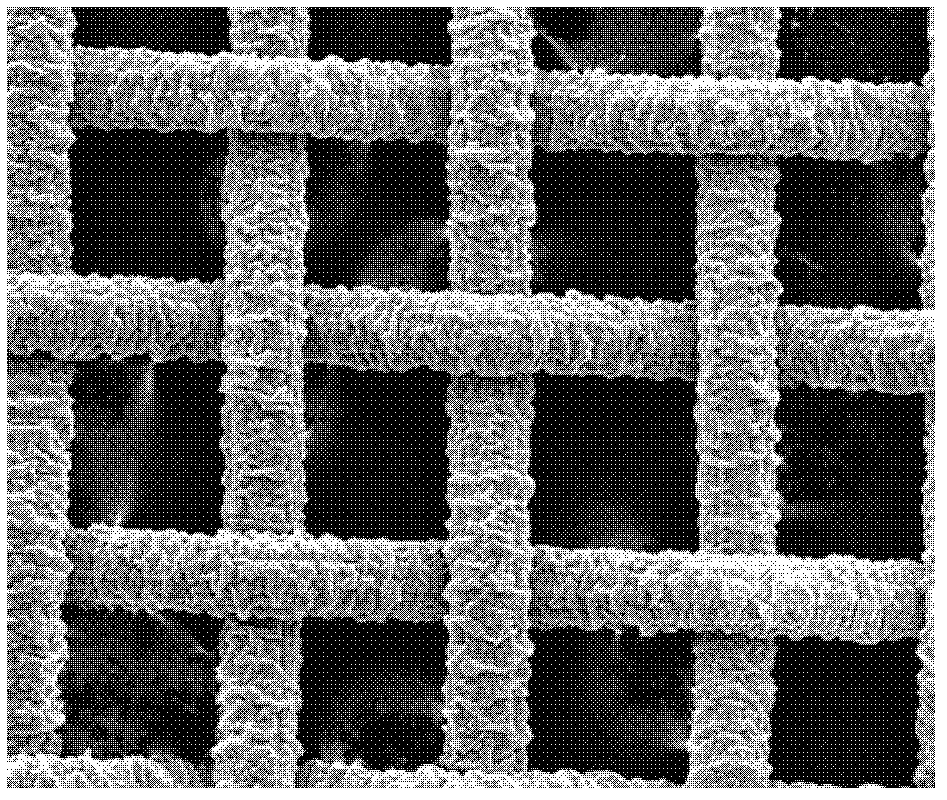

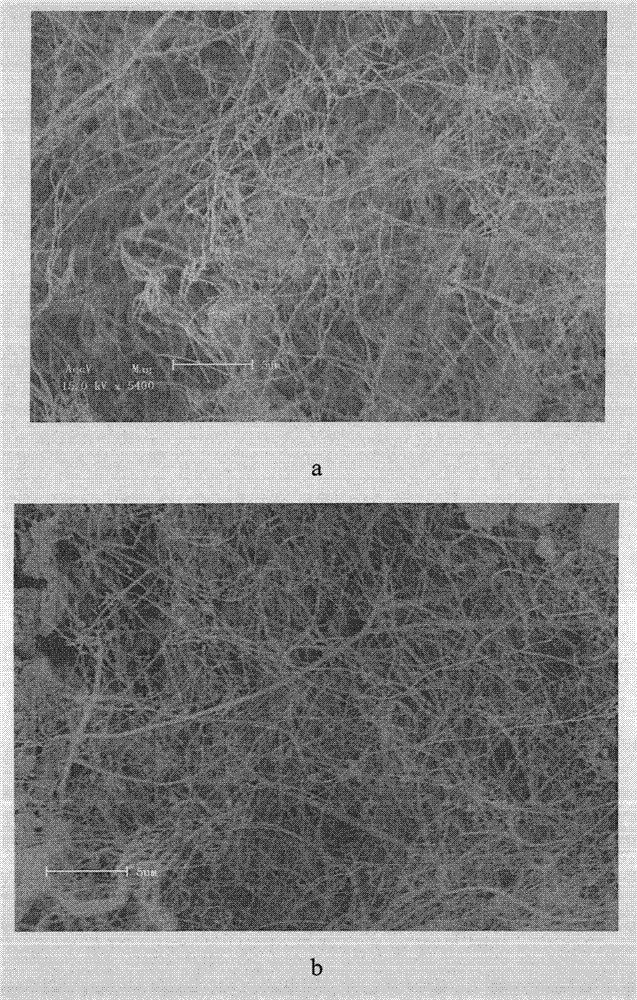

Micro/nano interface separation net as well as preparation method and application thereof

InactiveCN102416269AUniform surface structureGood redox reversibilityLiquid separationOxidation-Reduction AgentConductive polymer

The invention provides a micro / nano interface separation net as well as a preparation method and an application thereof. The micro / nano interface separation net comprises a metal fiber braided net and a conductive polymer layer covering the surface of the metal fiber braided net, wherein the conductive polymer layer is formed by a doped conductive polymer with redox reversibility. The micro / nano interface separation net has a simple manufacturing process, can transform between underwater super oleophobic property and underwater super lipophilic property and is suitable for different oil-water systems, thus realizing intelligent and controllable oil-water separation.

Owner:BEIHANG UNIV

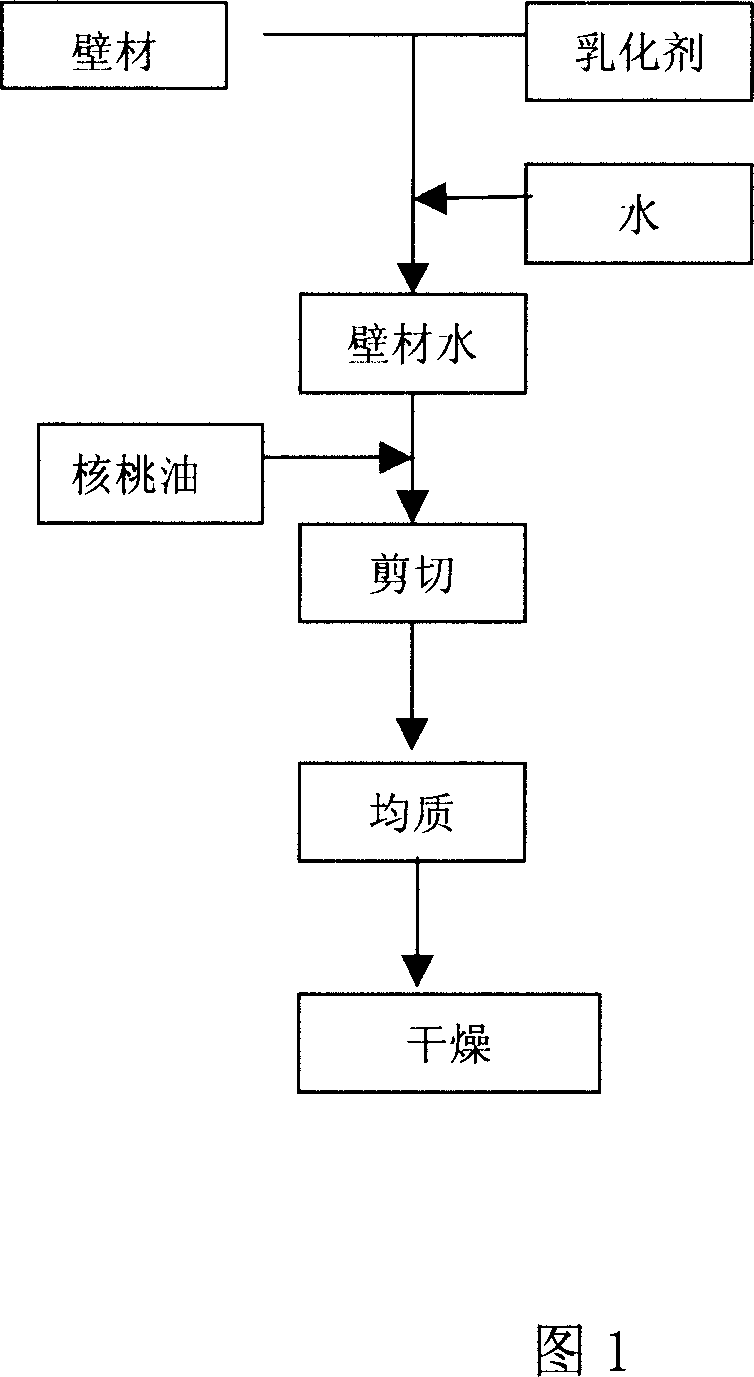

Method for making high-embedding-ratio powder walnut oil

InactiveCN101023763AIncrease contentHigh nutritional valueEdible oils/fatsMonoglycerideSuccinic acid

The present invention discloses a method for preparing powder walnut oil with high embedding rate. Said method includes the following steps: (1), after the monoglyceride, lecithine and Tween-60 as emulsifying agent are dissolved in water, successively adding octylene succinic acid esterified starch HI-CAP100 and maltodextrin as wall material to obtain wall material aqueous solution for stand-by; (2), adding walnut oil into the above-mentioned wall material aqueous solution, shearing and homogenizing to make the walnut oil be uniformly dispersed in the wall material aqueous solution; under the action of emulsifying agent forming O / W (oil-in-water) type emulsion with good emulsification stability; and (3), utilizing drying process to remove water content from emulsion, making wall material be formed into film, then the walnut oil can be uniformly embedded by all material film so as to obtain the invented powder walnut oil with high embedding rate.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

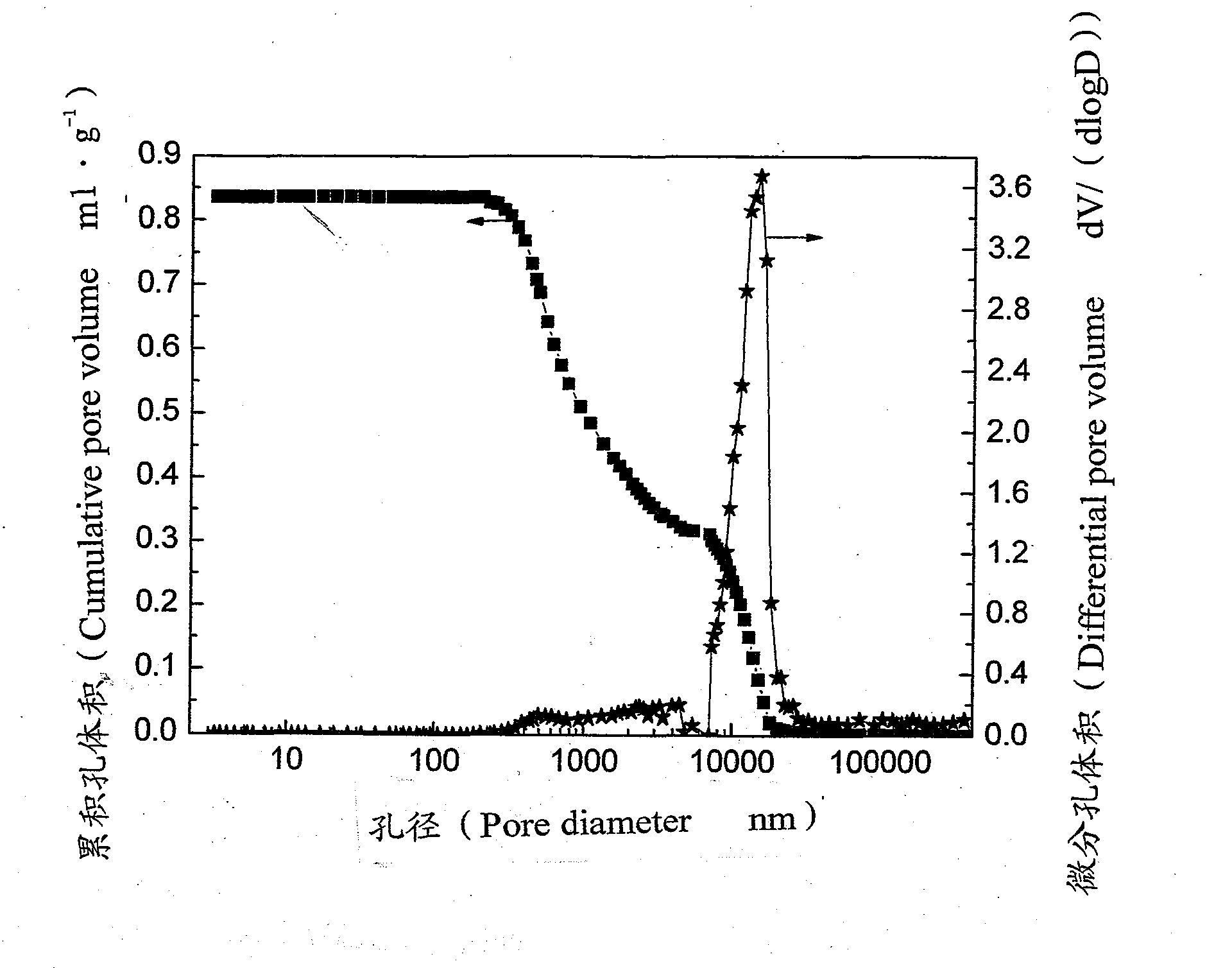

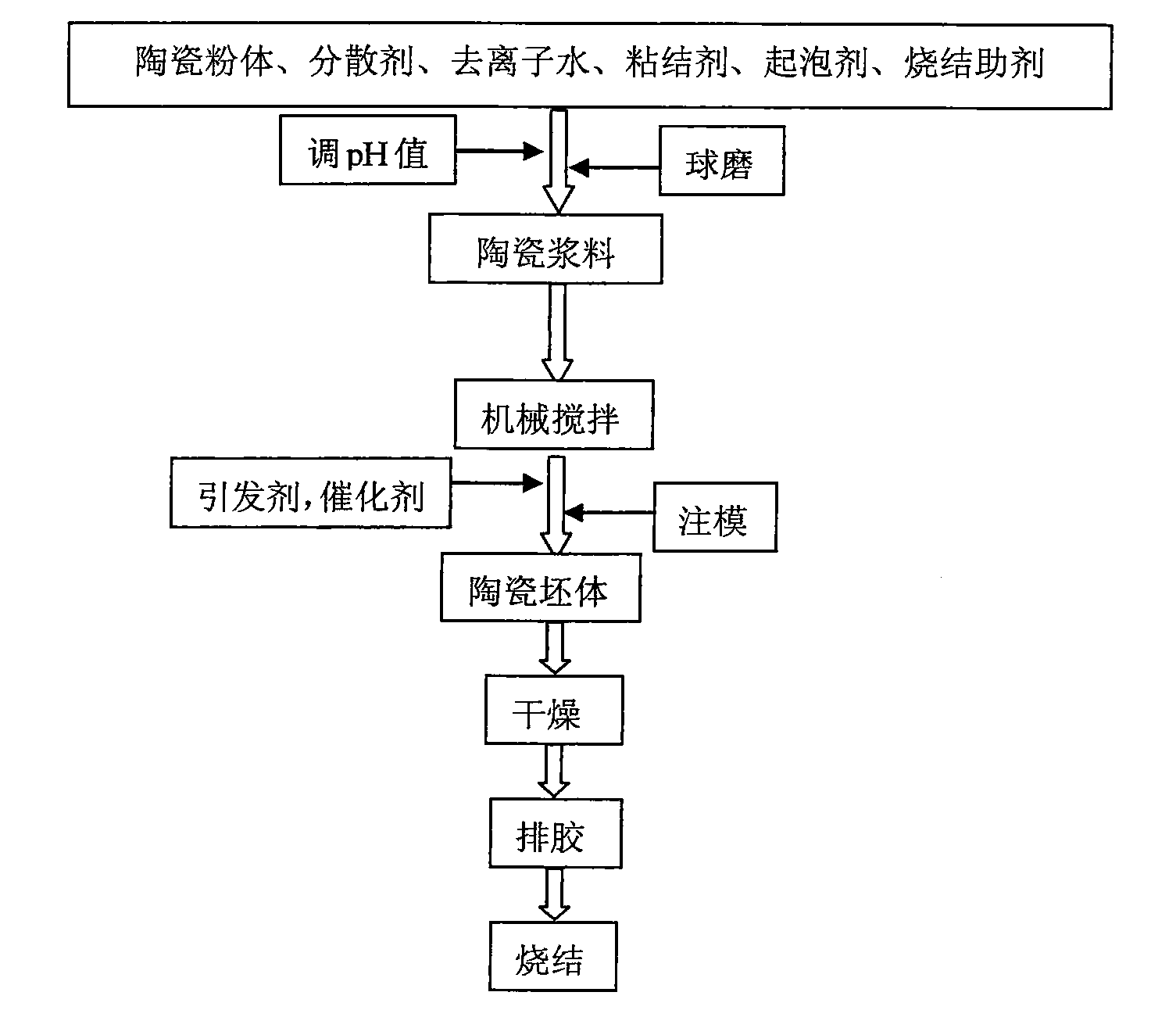

Method for preparing silicon nitride foam ceramic

The invention provides a method for preparing silicon nitride foam ceramic. The method comprises raw material proportioning, raw material blending, pH adjustment, foaming molding curing and sintering. Through utilization of a carboxymethyl cellulose aqueous solution as a binder, foam system surface tension is reduced; slurry viscoelasticity is improved; foam slurry fluidity and stability are improved; a shrinking percentage in foam drying is low; a yield is high; foam stability is good; foam pore sizes are small; sintered body mechanical properties are excellent; and foam pore distribution is uniform. Through a direct mechanical stirring foaming technology, the silicon nitride foam ceramic having good foam stability and excellent mechanical properties is prepared, wherein under the premise of equal porosity, compared with silicon nitride foam ceramic prepared by the prior art, the silicon nitride foam ceramic provided by the invention has bending strength improved by 10 to 30%, and the silicon nitride foam ceramic has porosity more than 60%.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

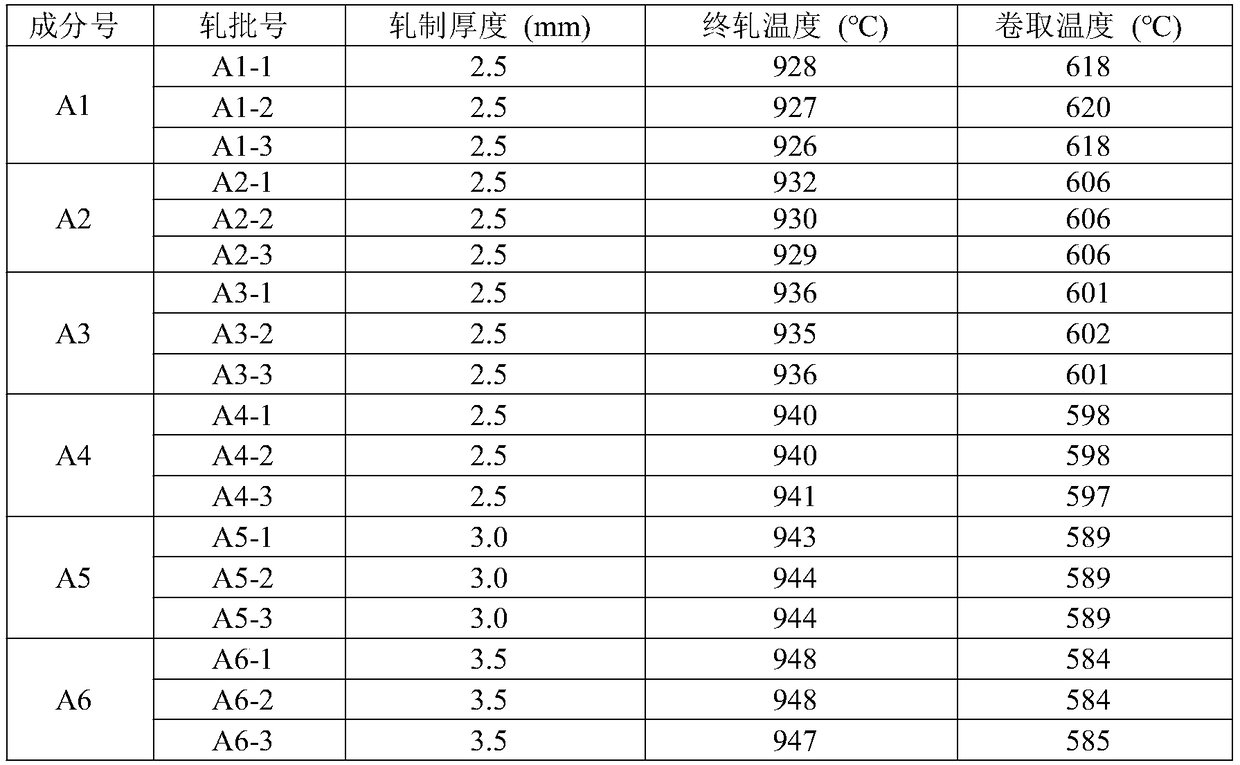

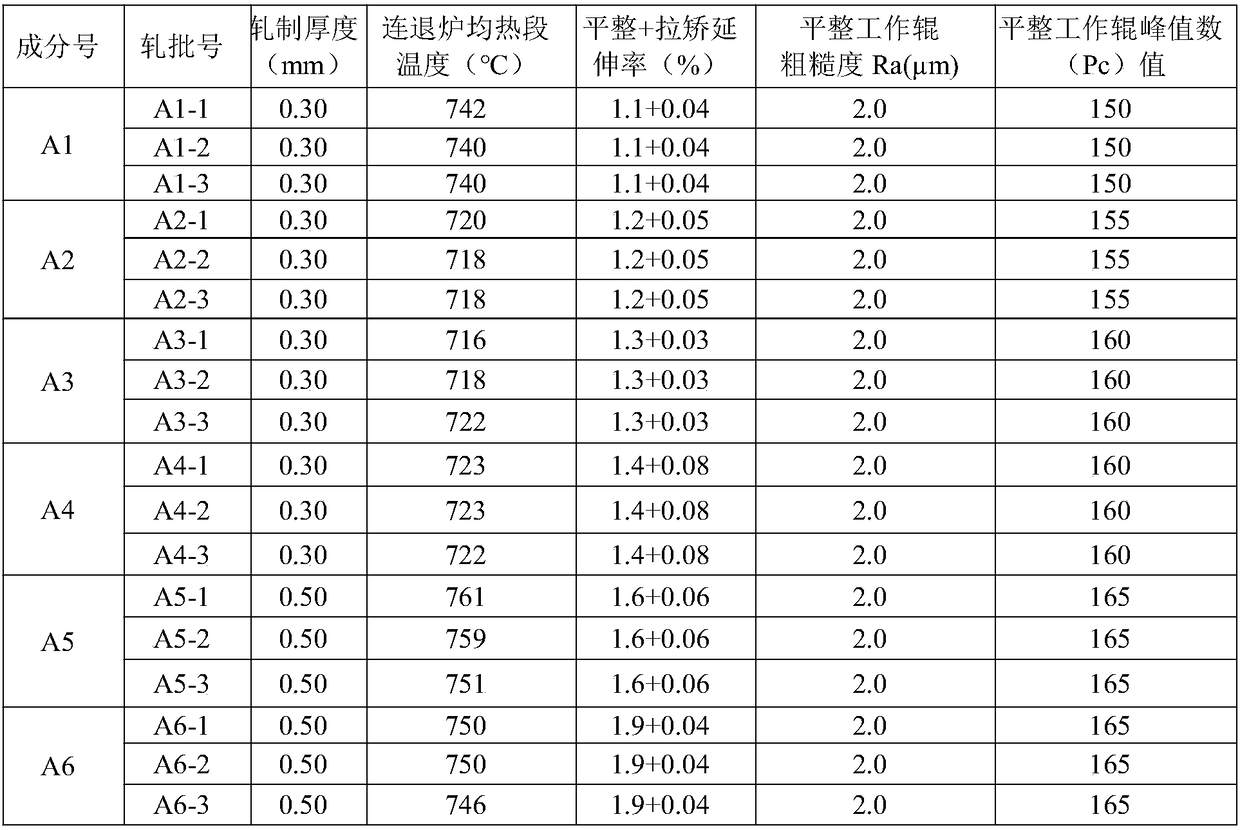

IF isotropic steel with stamping forming improved and manufacturing method thereof

The invention discloses IF isotropic steel with stamping forming improved and a manufacturing method of the IF isotropic steel. The IF isotropic steel is composed of, by weight percent, 0.0012% to 0.0026% of C, not larger than 0.026% of Si, 0.28% to 0.52% of Mn, not larger than 0.015% of P, not larger than 0.010% of S, 0.042% to 0.082% of Al, 0.046% to 0.066% of Ti, not larger than 0.0030% of N and the balance Fe and inevitable impurities. According to the IF isotropic steel, in the subsequent hot rolling, cold rolling, continuous annealing, flattening and bridging production processes, the rolling temperature is controlled to range from 580 DEG C to 620 DEG C, the cold rolling reduction rate is controlled to range from 85% to 95%, the annealing temperature is controlled to range from 708DEG C to 742 DEG C, the flattening ductility is controlled to range from 1.0% to 2.0%, and the bridging ductility is controlled to range from 0.03% to 0.10%; and according to the obtained IF isotropicsteel, the surface roughness Ra ranges from 0.36 micrometer to 0.56 micrometer, the peak concurrent Pc is larger than or equal to 126, the hardness ranges from 95 HV to 110 HV, the plastic strain ratio r90 value is larger than or equal to 1.8, the work-hardening exponent n90 value is larger than or equal to 0.18, and the delta r value is smaller than or equal to 0.20. The beneficial effect that when a round component is deeply stamped, no earing or galling defect is generated is achieved.

Owner:新余钢铁股份有限公司

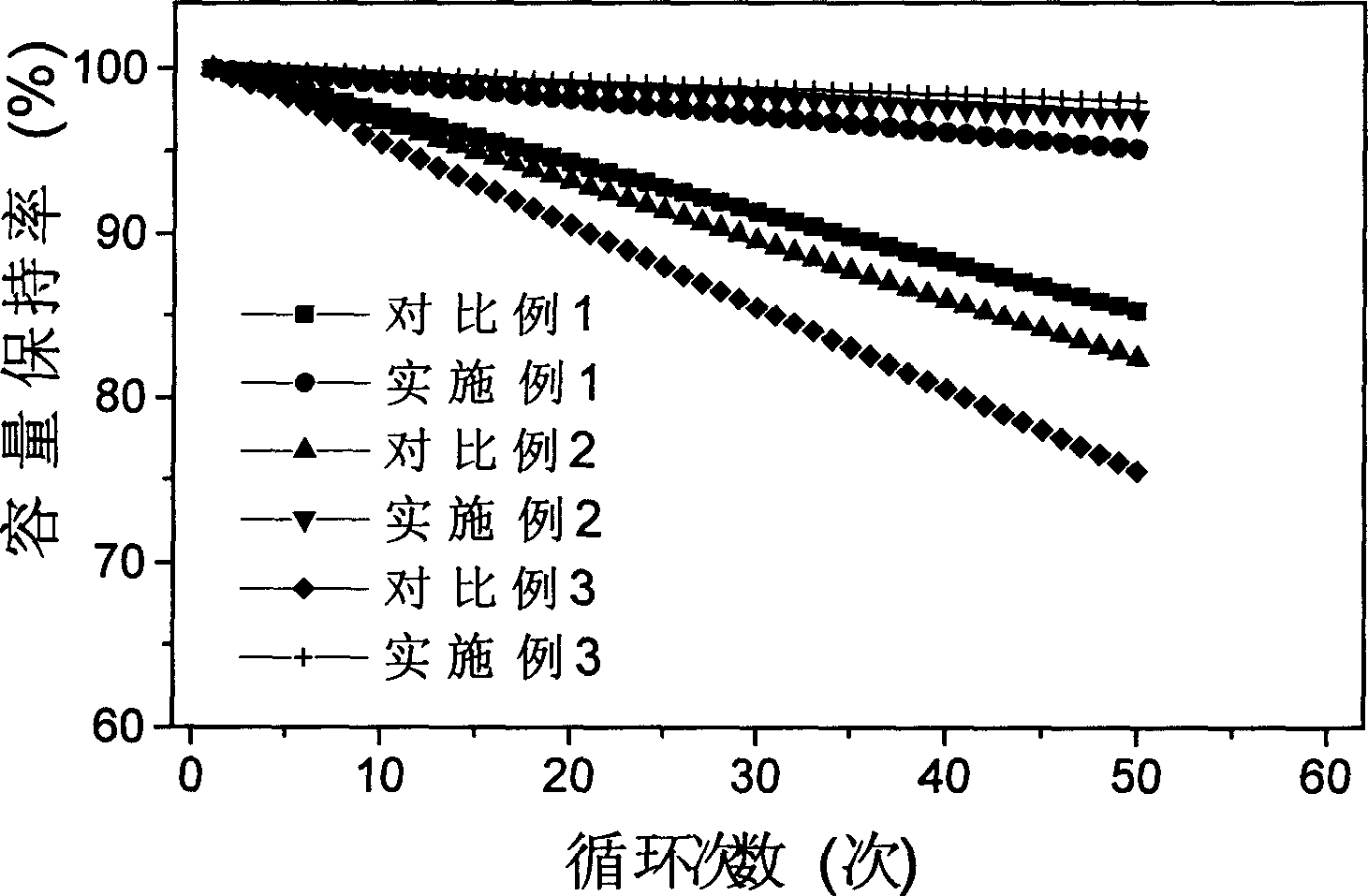

Method for modifying carbon negative polar material

InactiveCN1710734APromote circulationUniform surface structureElectrode manufacturing processesOperabilityLithium compound

The method modifies surface of material of carbon cathode by using compound of containing lithium so as to obtain material of carbon cathode of lithium ion cell. The material of carbon cathode produced according to the disclosed method possesses full even surface structure. Favorable cohesiveness and cycle performance is possessed between cathodes prepared from the material and afflux body of cathode. Advantages of the invention are: good operability and repeatability, and stable product quality.

Owner:FUDAN UNIV

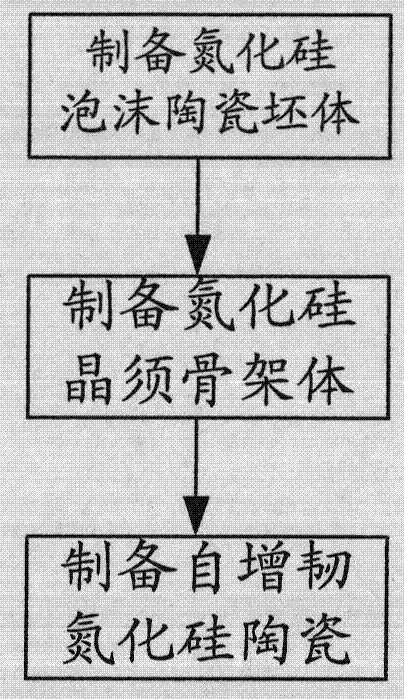

Method for preparing self-toughening silicon nitride ceramics

The invention provides a method for preparing self-toughening silicon nitride ceramics, and the method comprises the following steps that first a silicon nitride foam ceramic billet is prepared, then sintered to prepare a silicon nitride crystal whisker skeleton body, and finally a silicon nitride organic precursor is dipped, cracked and made into ceramics and the self-toughening silicon nitride ceramics is prepared. According to the method for preparing self-toughening silicon nitride ceramics, the silicon nitride ceramic foam body is obtained by directly foaming; then the silicon nitride ceramic foam body is sintered; a long column-shaped beta-silicon nitride crystal bar is fully grown through the special structure of a large number of pore spaces of the ceramic foam when in sintering; the grown long column-shaped beta-silicon nitride (Si3N4) crystal bar is nearly fully filled in each foam pore in the silicon nitride foam ceramic body; the average slenderness ratio of the beta-Si3N4 crystal bar is 20, and the maximum slenderness ratio can reach about 30; and the silicon nitride crystal whisker skeleton body which is obtained by sintering the silicon nitride foam ceramic billet is dipped and cracked to obtain the self-toughening silicon nitride ceramics, and the toughening effect is good.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Fe/Co/N/MWCNTs catalyst

A Fe / Co / N / MWCNTs catalyst is obtained as follows: an iron-ion-doped polyaniline (PANI) and carbon nanotube (MWCNT) compound is heated at 900DEG C to obtain an iron-containing catalyst FeNC; and the FeNC containing a cobalt salt is calcined at different temperatures to obtain the composite catalyst FeCoNC. With the increase of calcination temperature, the surface structure of the catalyst tends tobe uniform. The surface structure of the catalyst with the calcination temperature of 500DEG C is most even and smooth, and sintering occurs when the temperature is above 500DEG C. A higher nitrogen content can improve the ORR electroactivity of the catalyst. The catalyst with the calcination temperature of 500 DEG C has highest ORR electrocatalytic activity. ORR initial potentials in acidic and alkaline solutions are 0.63 and-0.12V (vsSCE), respectively, current densities are 11.67 and 9. 83mAmg-1@-0.3V(vsSCE) respectively, and the catalyst has good thermal stability and catalytic activity stability. The catalyst obtained by stepwise adding Fe and Co and calcining at 500 DEG C after addition of the Co has excellent ORR electrocatalytic activity.

Owner:韩会义

Biodegradable composite material

ActiveCN104039367AExtraordinary ease of useHigh X-ray opacityBone implantTissue regenerationBone defectBiodegradable composites

The invention relates to a biodegradable composite material and to a method for producing same. The biodegradable composite material according to the invention is preferably a bone-building material that can be used in the field of regenerative medicine, particularly as a temporary bone defect filler for bone regeneration.

Owner:CURASAN

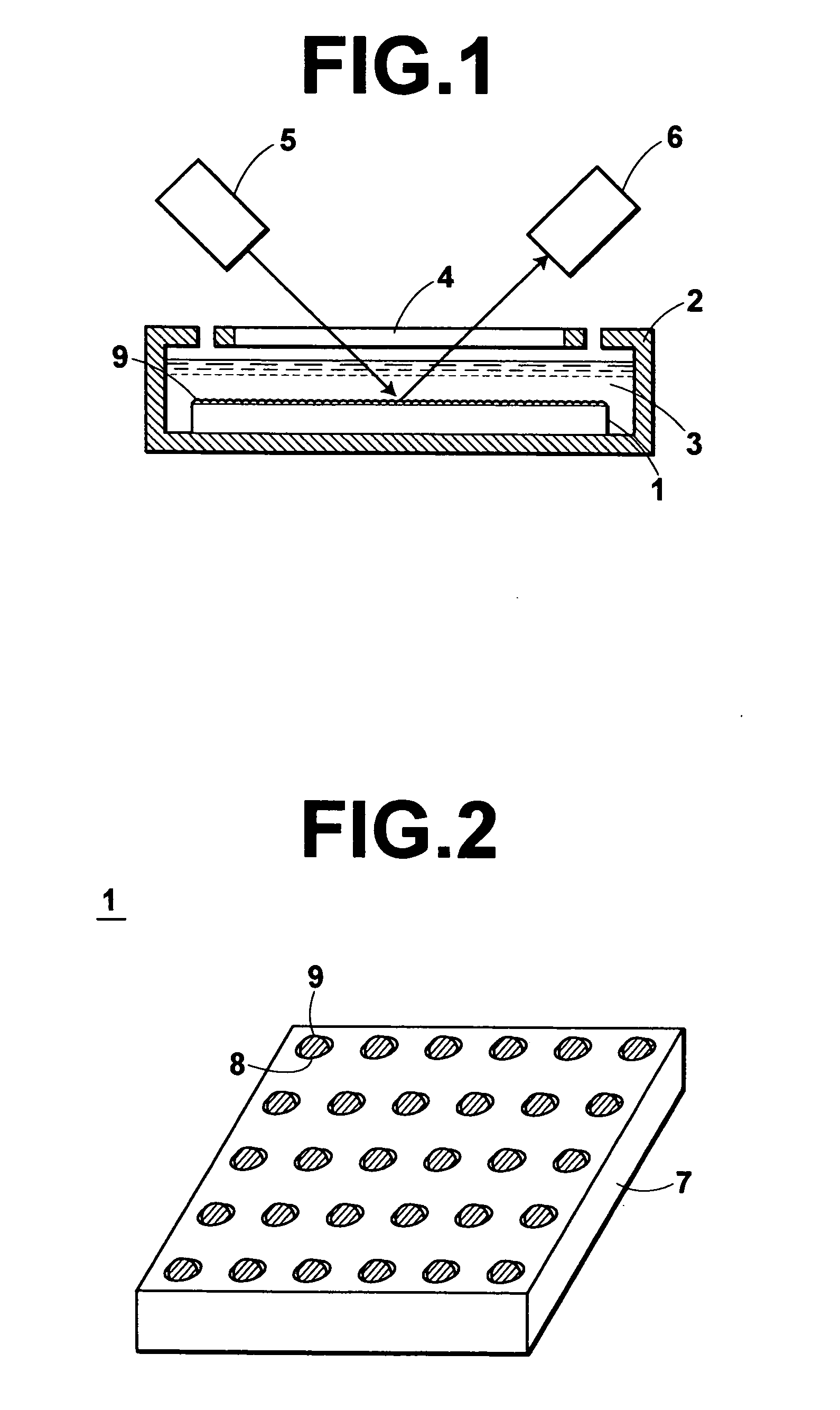

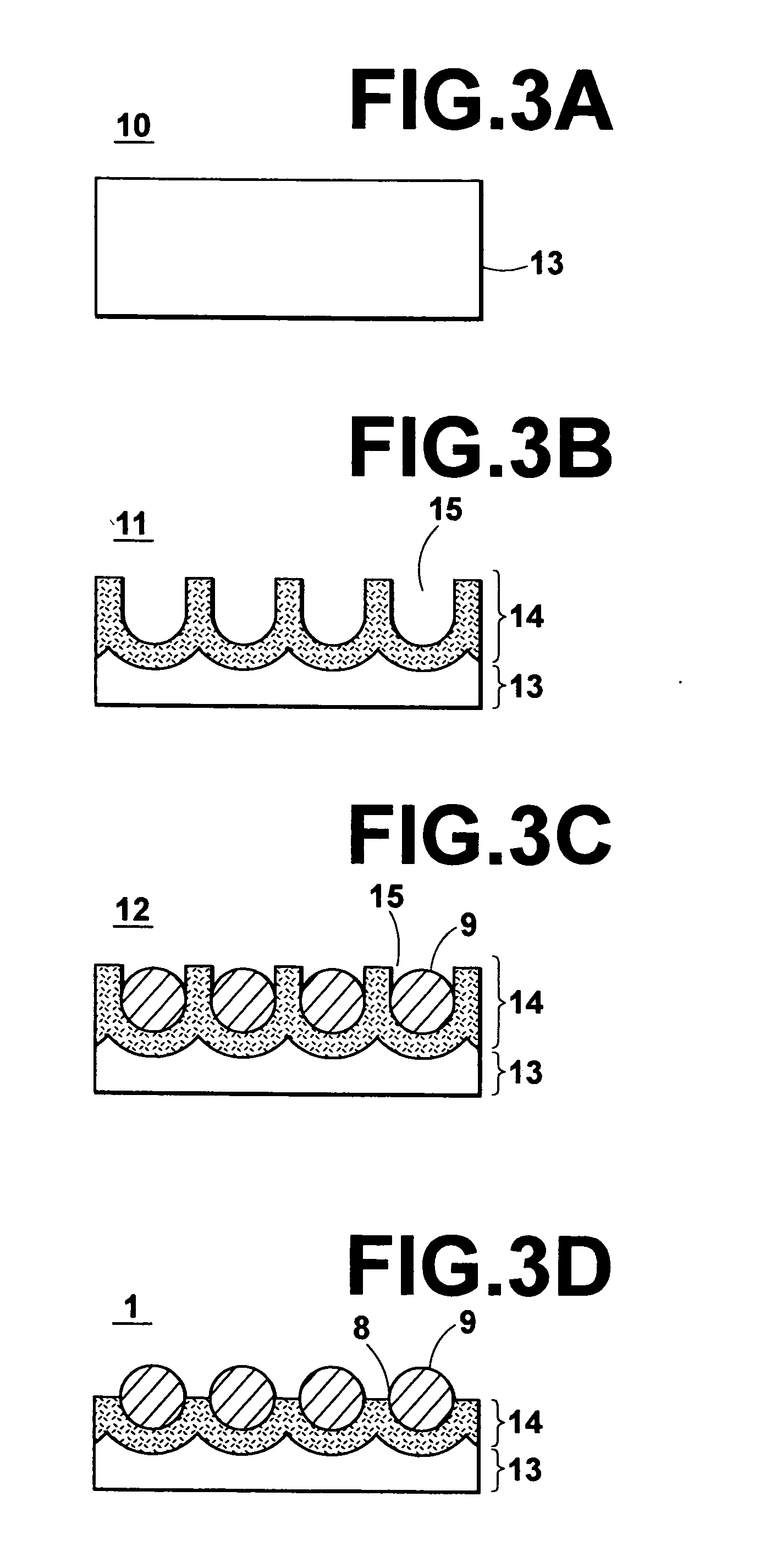

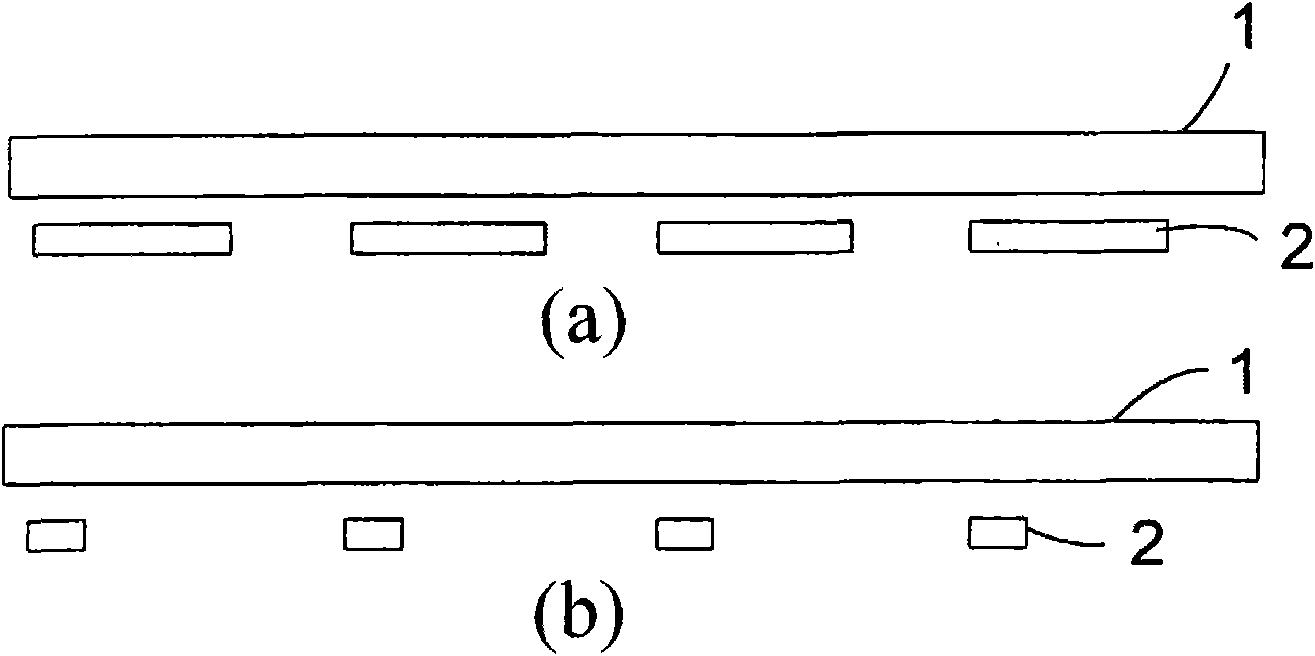

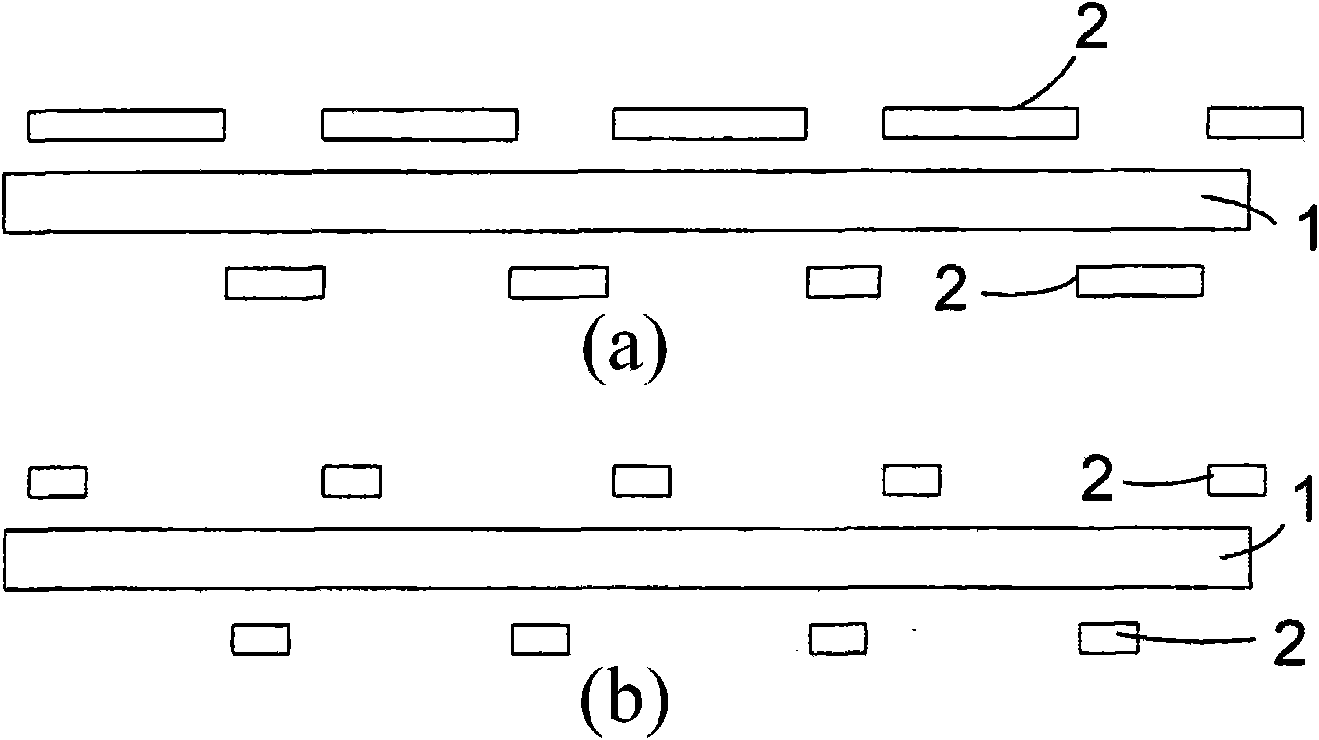

Method of detecting test bodies

InactiveUS7307731B2Uniform sizeUniform surface structurePhase-affecting property measurementsScattering properties measurementsFine structureResonance wavelength

Owner:FUJIFILM HLDG CORP +1

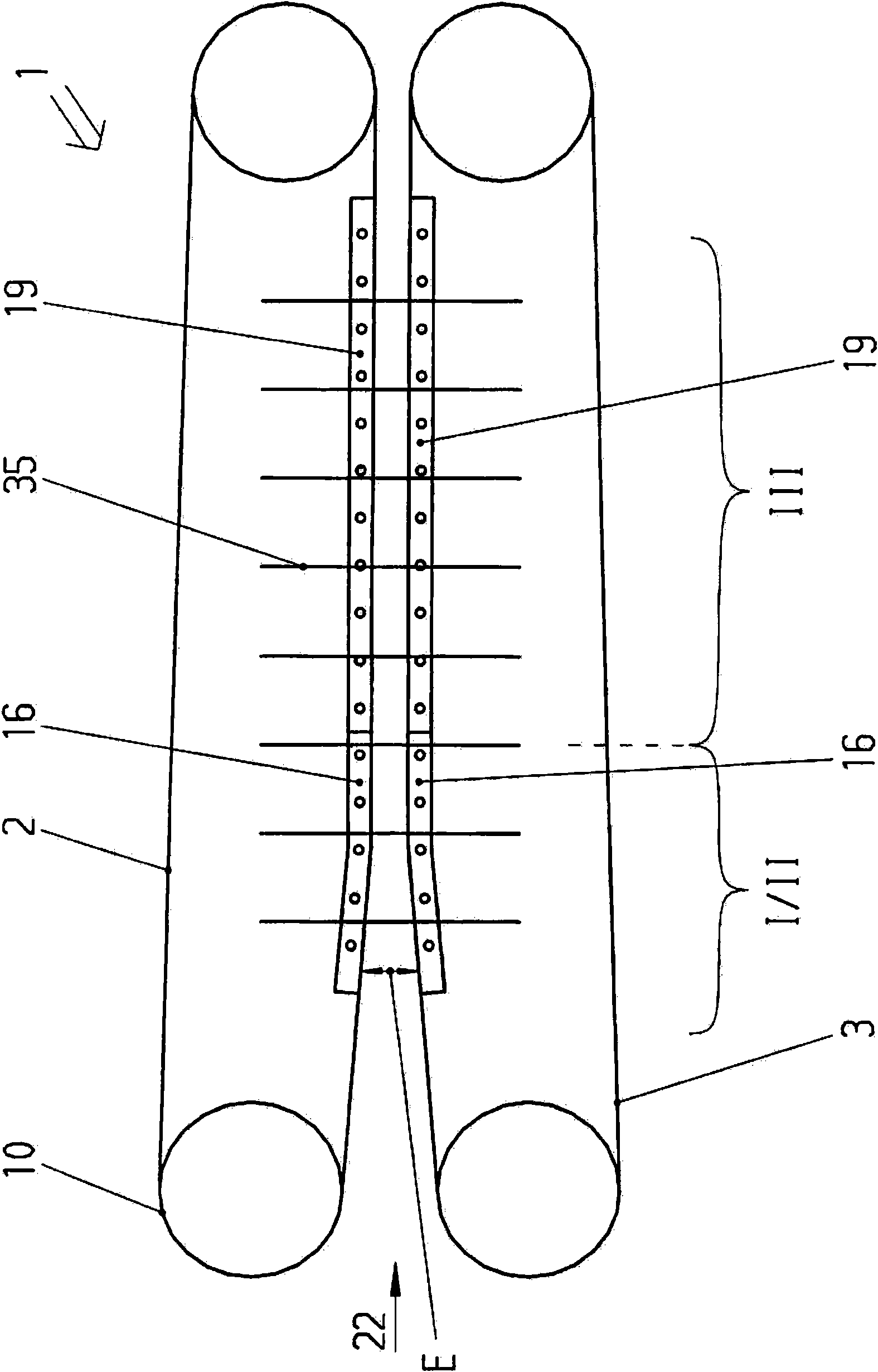

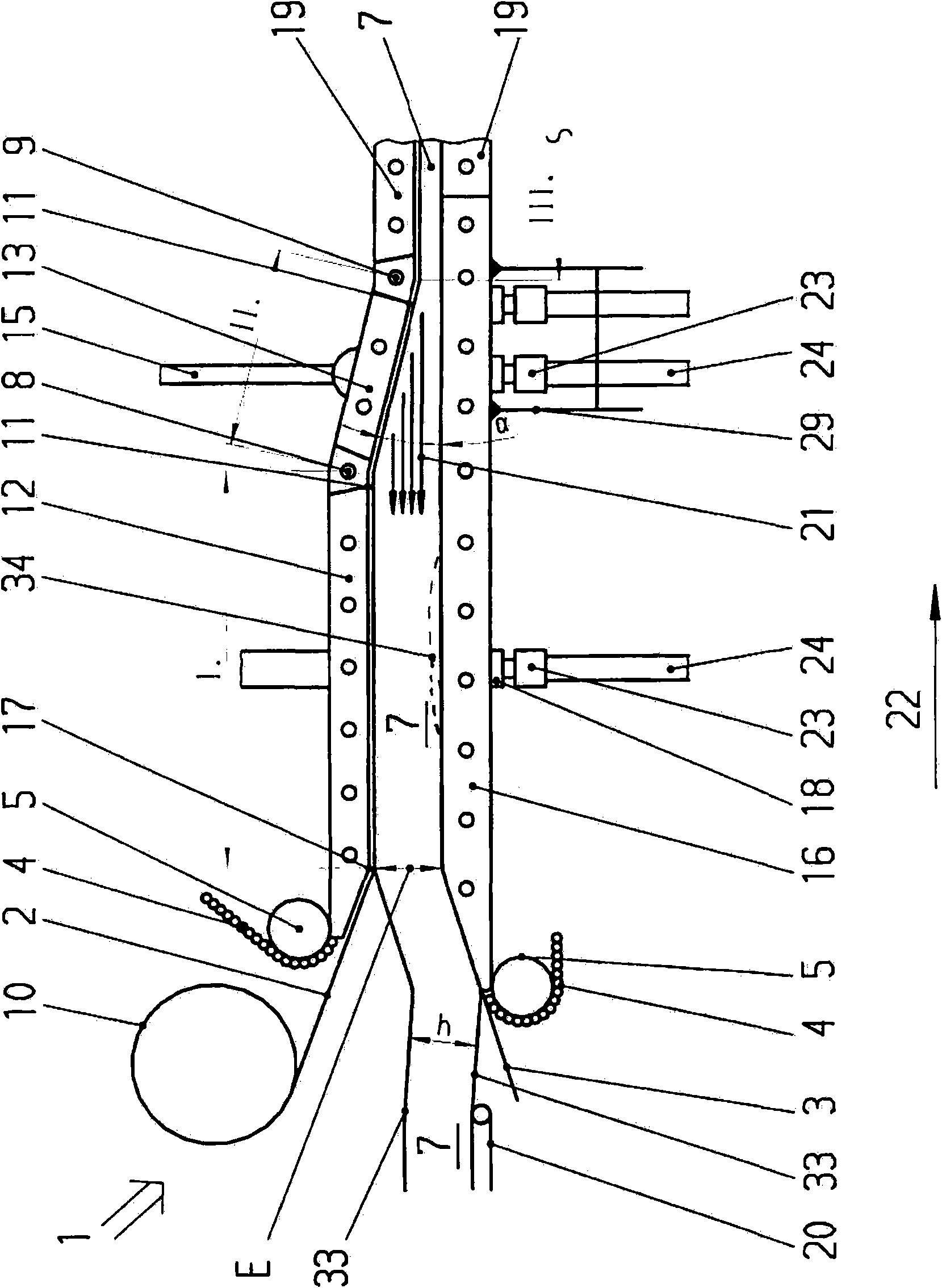

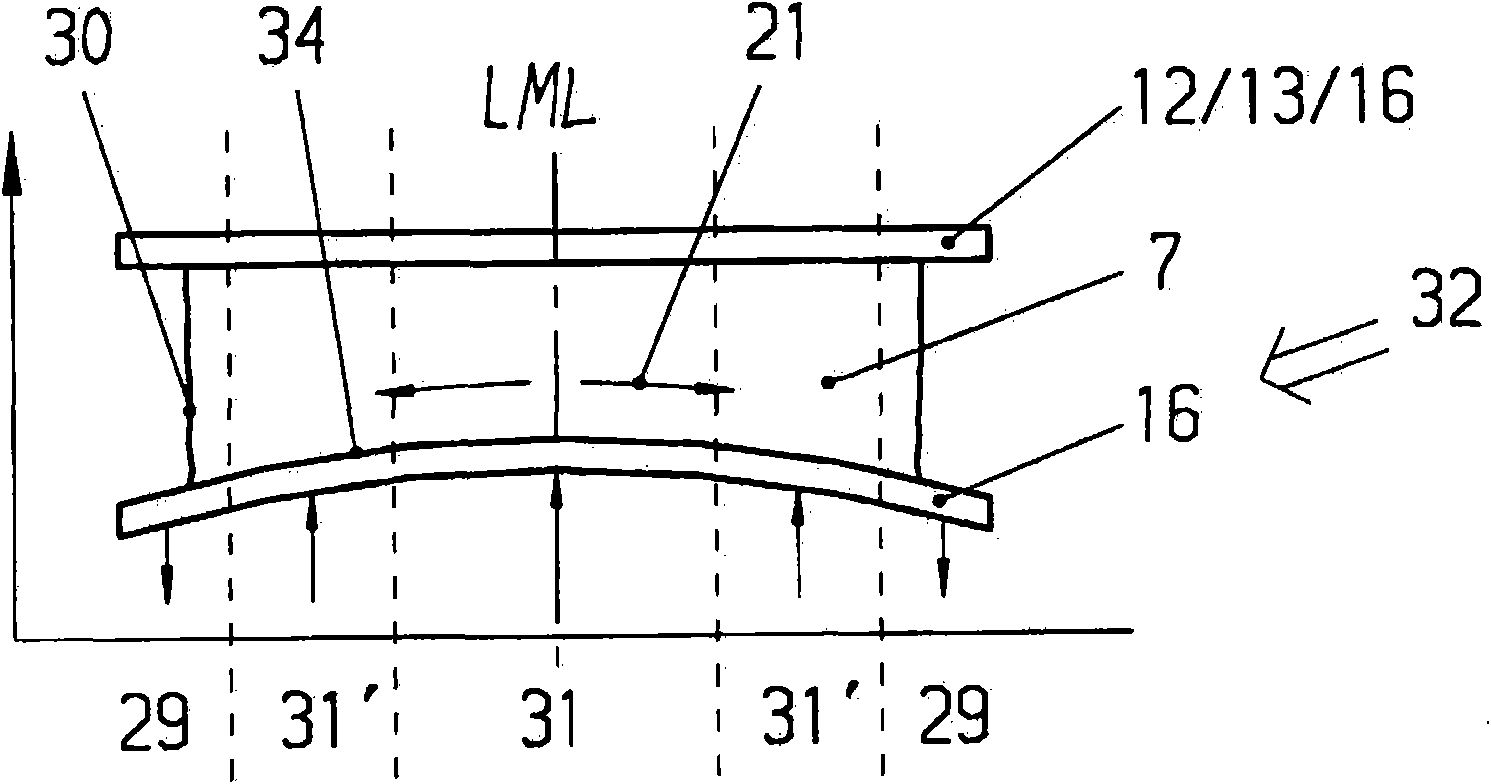

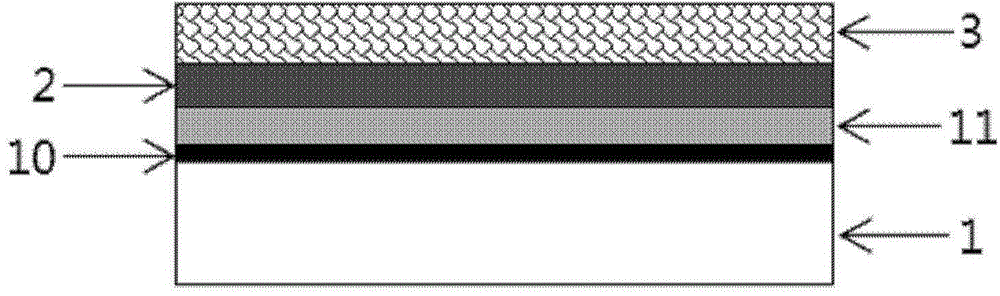

Method for producing composite panels in a continuously operating press and continuously operating press

InactiveCN101856835AAvoid dischargeReduce the risk of fireWood working apparatusDomestic articlesMiddle lineSteel belt

The present invention relates to a method for producing composite panels in a continuously operating press (1). In the continuously operating press (1), the pressing blanks (7) are clamped and / or pressed in an area of material feeding segment before a main pressing area along a production direction (22) through steel strips (2,3) which operate around a bending roller (10) and are supported through a rolling rod (4), wherein in the area of material feeding segment, a material feeding segment heating plate (16) and / or hinging plate (12,13) which are used for regulating the geometric dimension of the material feeding segment clearance (E) along the production direction can adjust the clearance of the material feeding segment heating plate (16) and / or the hinging plates (12,13) and / or can be bended. The settlement solution of the utility model is characterized in that: in passing the areas (I,II) of the material feeding segment, the basically linear material feeding segment heating plate (16) which is perpendicular with the production direction (22) and at least two basically linear hinging plates (12,13) that are perpendicular with the production direction (22) are used on a surface side (33) in at least one segment along the production direction (22); and the bended material feeding segment heating plate (16) which is bended perpendicularly with the production direction (22) at least in the area along a longitudinal middle line (LML) along the direction of the pressing blank (7) from the opposite surface side (33). Additionally, the invention also relates to a continuously operating press.

Owner:DIEFFENBACHER GMBH & CO KG

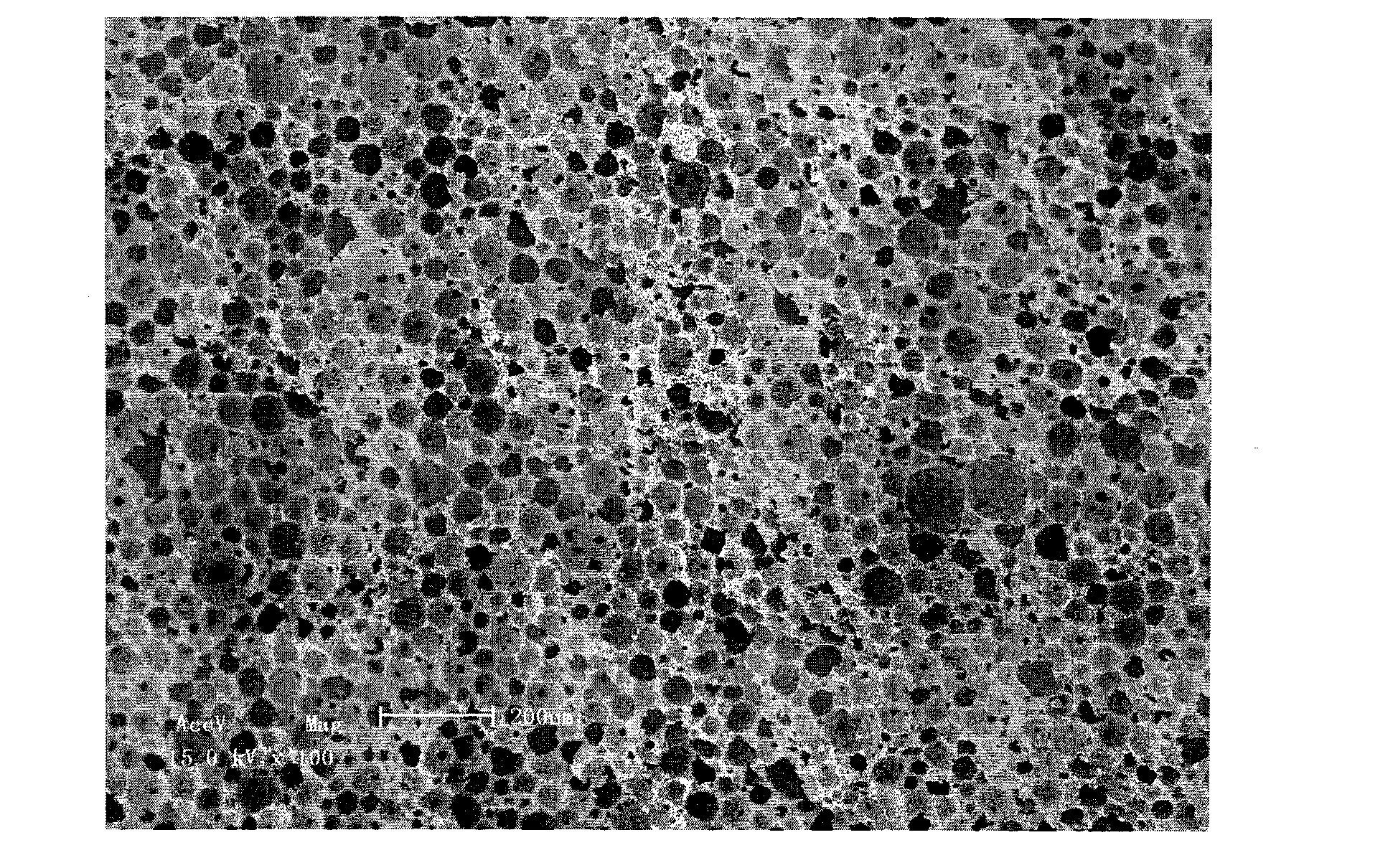

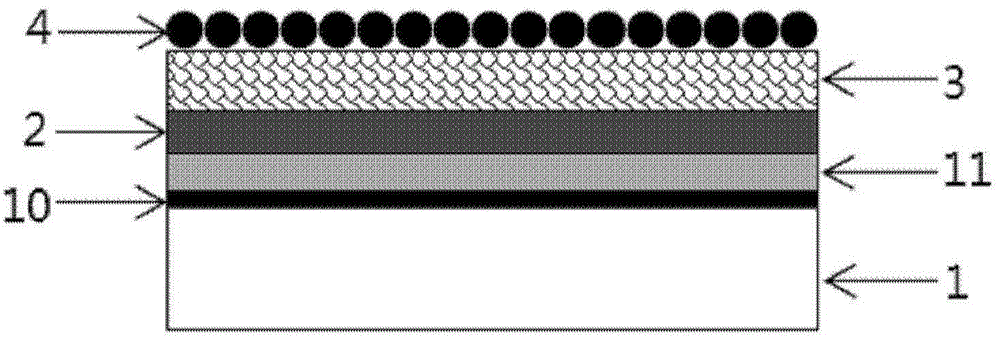

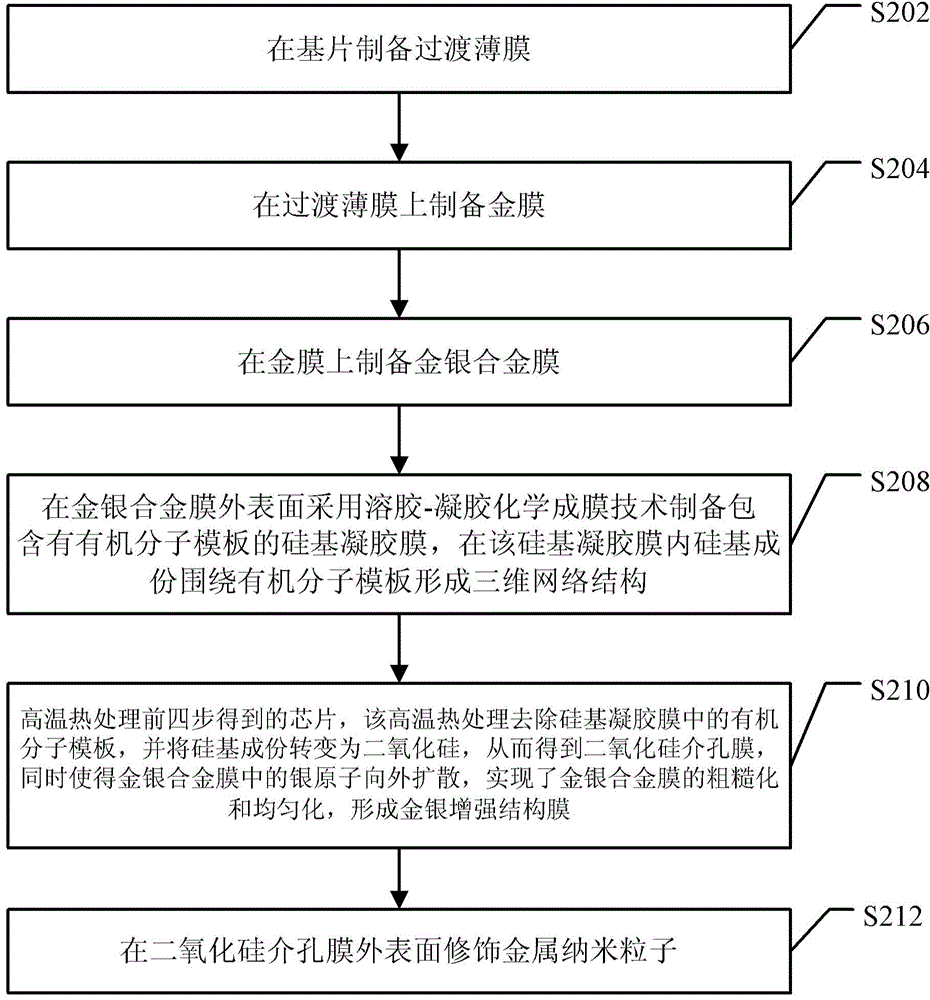

Large-area uniform raman detection chip for porous membrane sensitivity enhancing and preparation method for large-area uniform raman detection chip

ActiveCN104406953AImprove Raman detection sensitivityIncrease the number of molecules to be testedRaman scatteringNanoporous membranePorous membrane

The invention provides a large-area uniform raman detection chip for porous membrane sensitivity enhancing and a preparation method for the large-area uniform raman detection chip. The raman detection chip comprises a substrate, a gold-based enhanced structural membrane which is formed on the substrate and is used as an electromagnetic enhancement layer of the raman detection chip, and a nano porous membrane which is formed on the outer surface of the gold-based enhanced structural membrane so as to enrich molecules to be detected. According to the large-area uniform raman detection chip for porous membrane sensitivity enhancing, the nano porous membrane serving as a molecule enriching layer can obviously increase the quantity of the molecules to be detected within a local enhanced electric field working range, so that the raman detection sensitivity of the chip is improved; the large-area uniform raman detection chip is particularly suitable for detection on small-molecular substances with ultralow concentration. The raman detection chip disclosed by the invention has the advantages of low preparation cost, high large-area uniformity and the like, and can suppress interference on a raman fingerprint diagram of the molecules to be detected due to metals.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

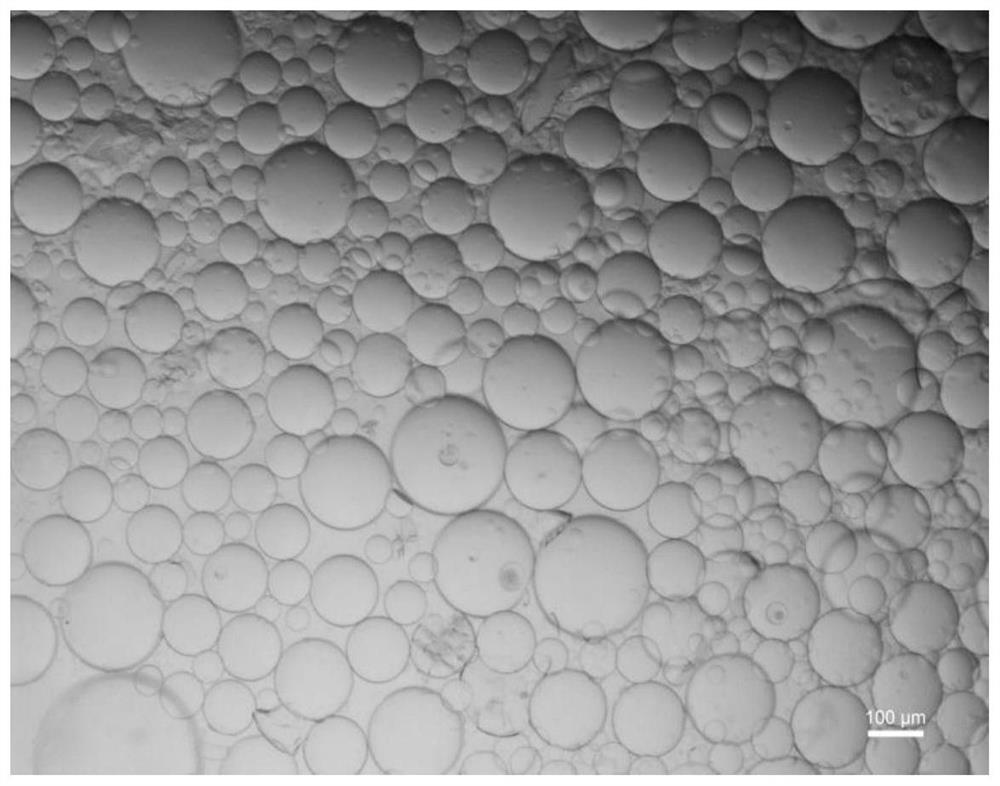

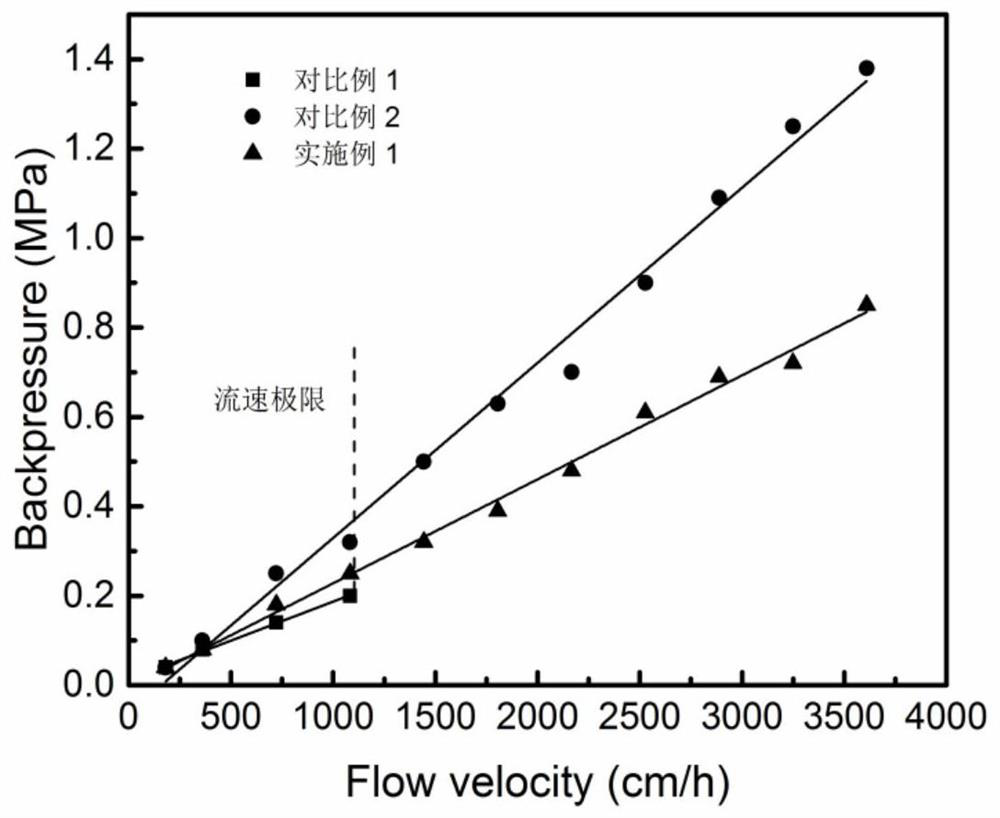

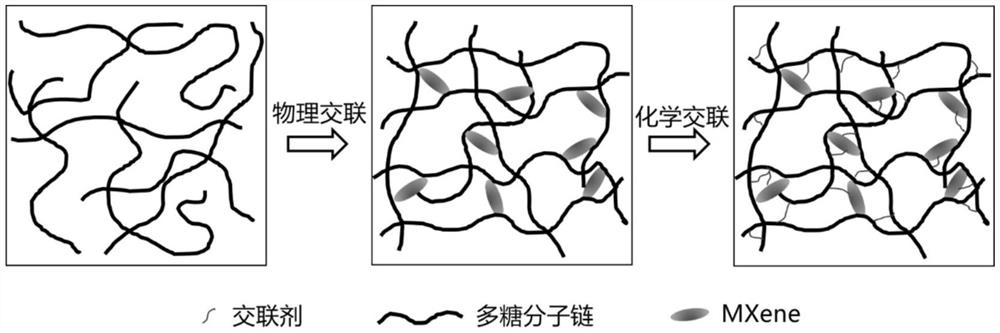

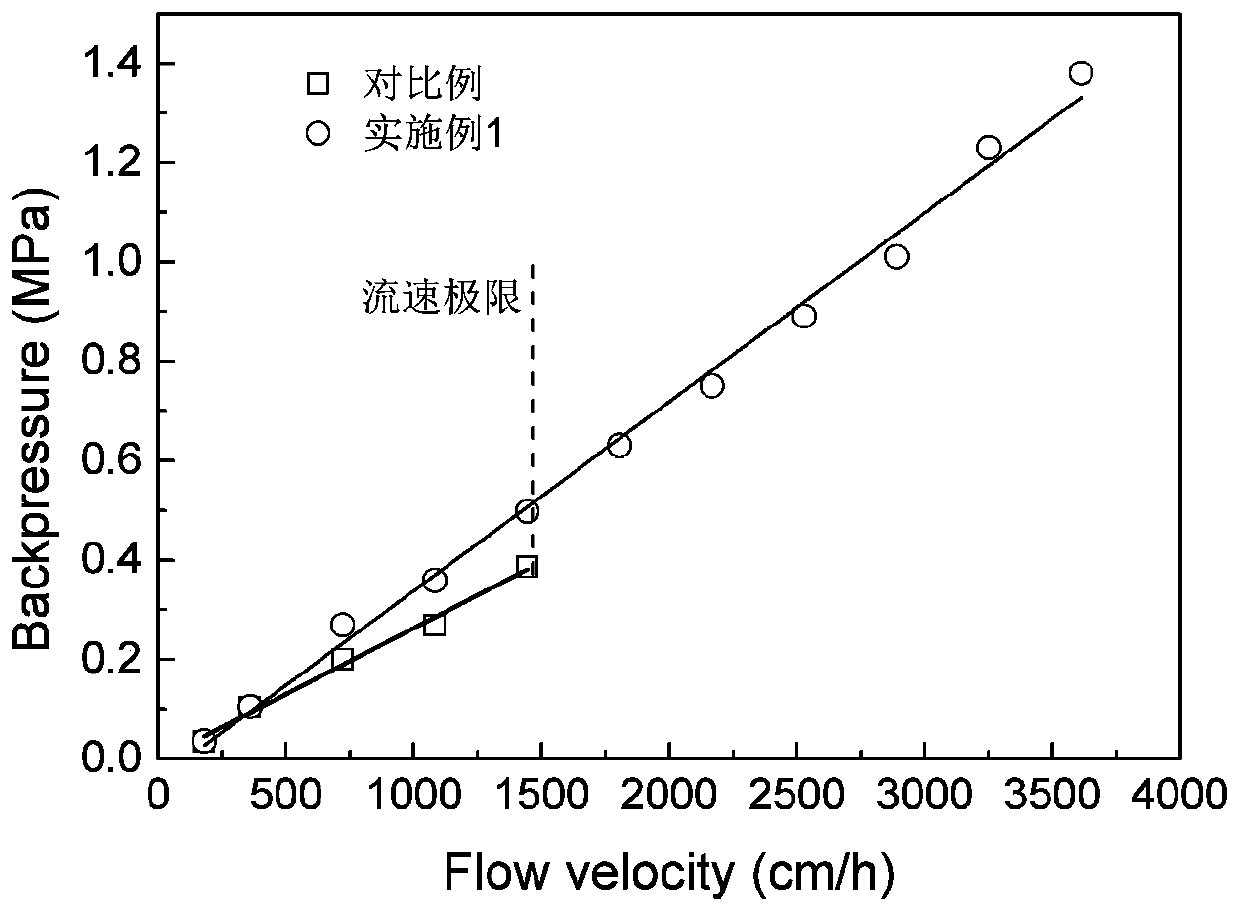

High-strength polysaccharide-MXene composite microsphere and preparation method thereof

PendingCN113368792AUniform surface structureHigh mechanical strengthMicroballoon preparationMicrocapsule preparationPolymer scienceMicrosphere

The invention relates to the field of preparation of natural polymer / inorganic nanosheet composite materials, and especially relates to a high-strength polysaccharide-MXene composite microsphere and a preparation method thereof. The surface of MXene is rich in hydroxyl groups, hydrogen bonds can be formed through -OH / -O- and -O- / -OH on a polysaccharide molecular chain, an additional physical cross-linking point effect is achieved, subsequent chemical cross-linking is assisted, and the high-strength polysaccharide-MXene composite microsphere is prepared. Protein adsorption and pressure flow velocity curve experiments show that the composite microsphere is good in biocompatibility, the operation flow velocity is greatly improved compared with that of a pure polysaccharide microsphere, and the composite microsphere has great application potential in the fields of biological catalysis and high-flow-velocity egg white spectrum separation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

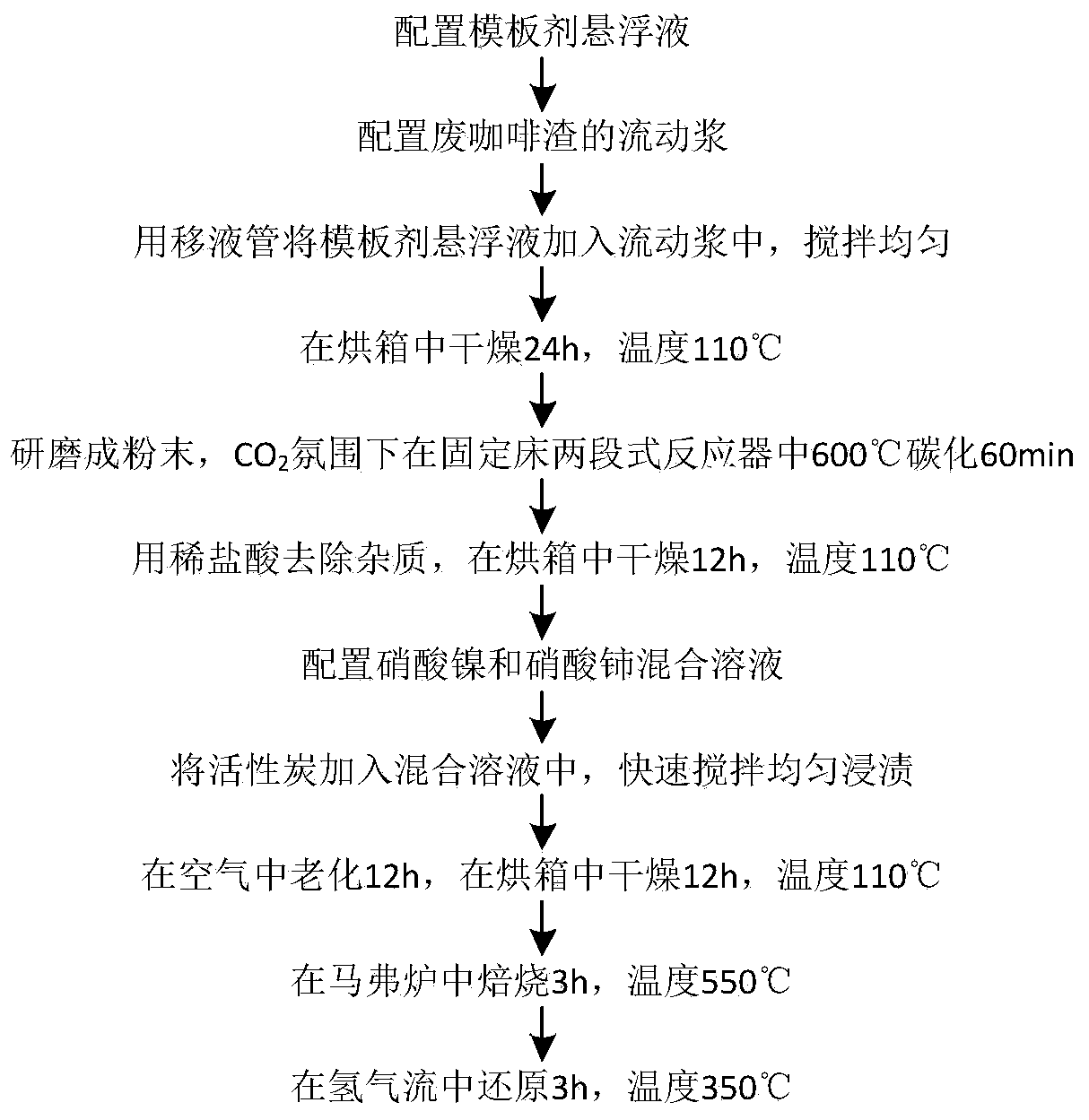

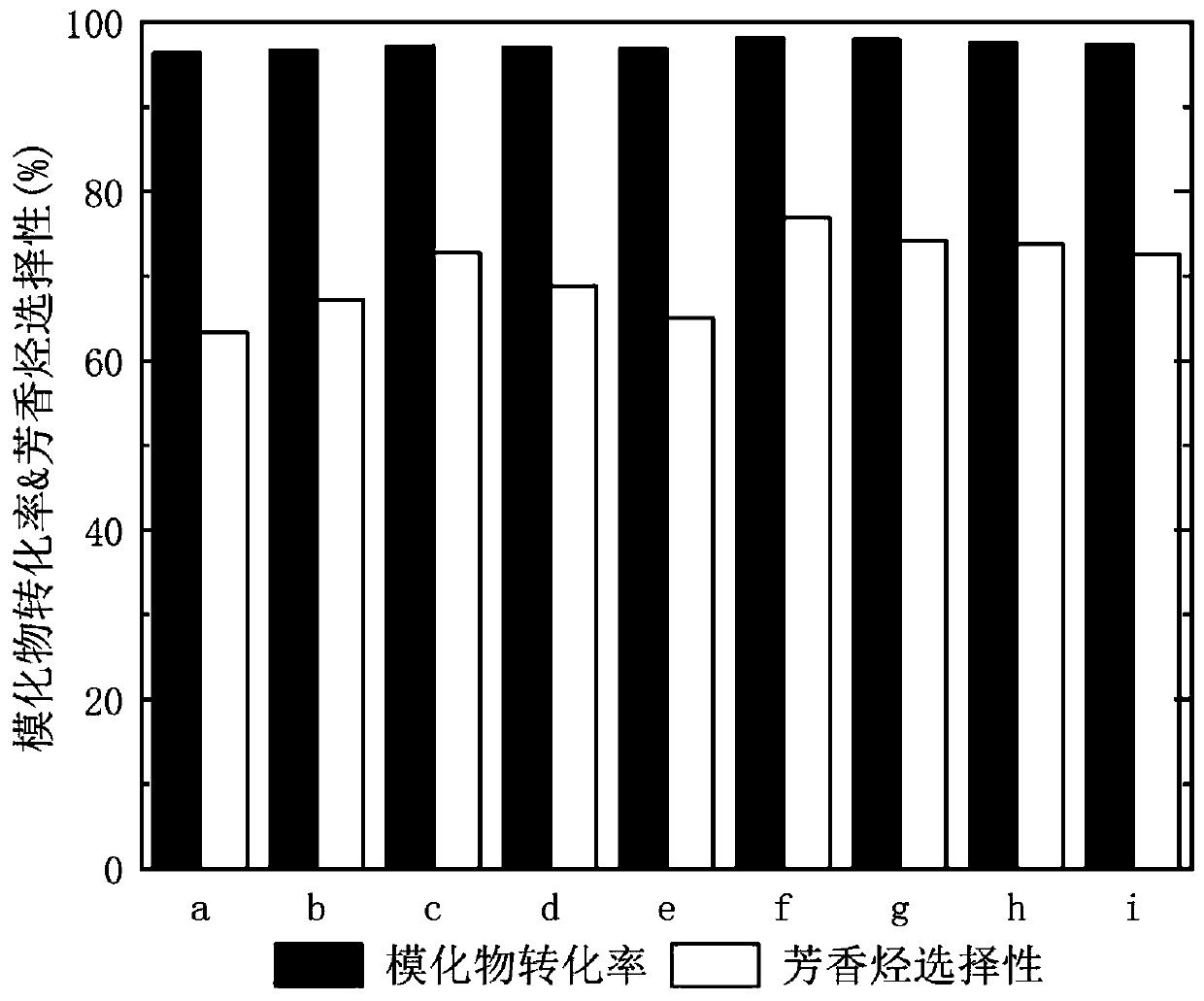

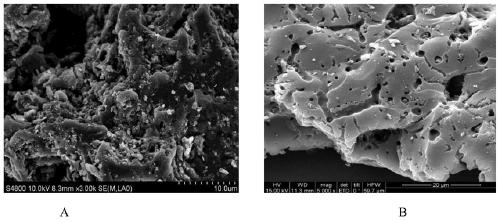

Preparation method of novel metal-biochar-based hydrogenation catalyst and application thereof

ActiveCN111229237AIncrease the number ofUniform surface structureBio-feedstockMetal/metal-oxides/metal-hydroxide catalystsCerium nitratePtru catalyst

The invention belongs to the field of preparation of liquid fuel and chemical products through catalytic conversion of biomass, and relates to a preparation method of a novel metal-biochar-based hydrogenation catalyst and an application thereof. The method comprises the following steps: preparing a template agent suspension; then introducing coffee residue slurry, stirring, drying, grinding into powder, and carrying out high-temperature carbonization to obtain biochar; washing with diluted hydrochloric acid and drying to obtain activated carbon; mixing the metal-biochar-based hydrogenation catalyst with nickel nitrate, cerium nitrate and deionized water, then aging, drying and roasting in air, and finally reducing in hydrogen flow to obtain the metal-biochar-based hydrogenation catalyst. The biochar obtained by carbonizing the waste coffee grounds at a high temperature in a CO2 atmosphere has larger specific surface area and specific pore volume and extremely high mesoporous rate, so that the number of active sites of the catalyst is effectively increased, and the problem that the catalyst is easy to block and inactivate pore passages is solved; meanwhile, the yield of aromatic hydrocarbon after deoxidation and hydrogenation of a biomass pyrolysis product is increased, and the method is low in cost, safe, environmentally friendly and suitable for large-scale production.

Owner:JIANGSU UNIV

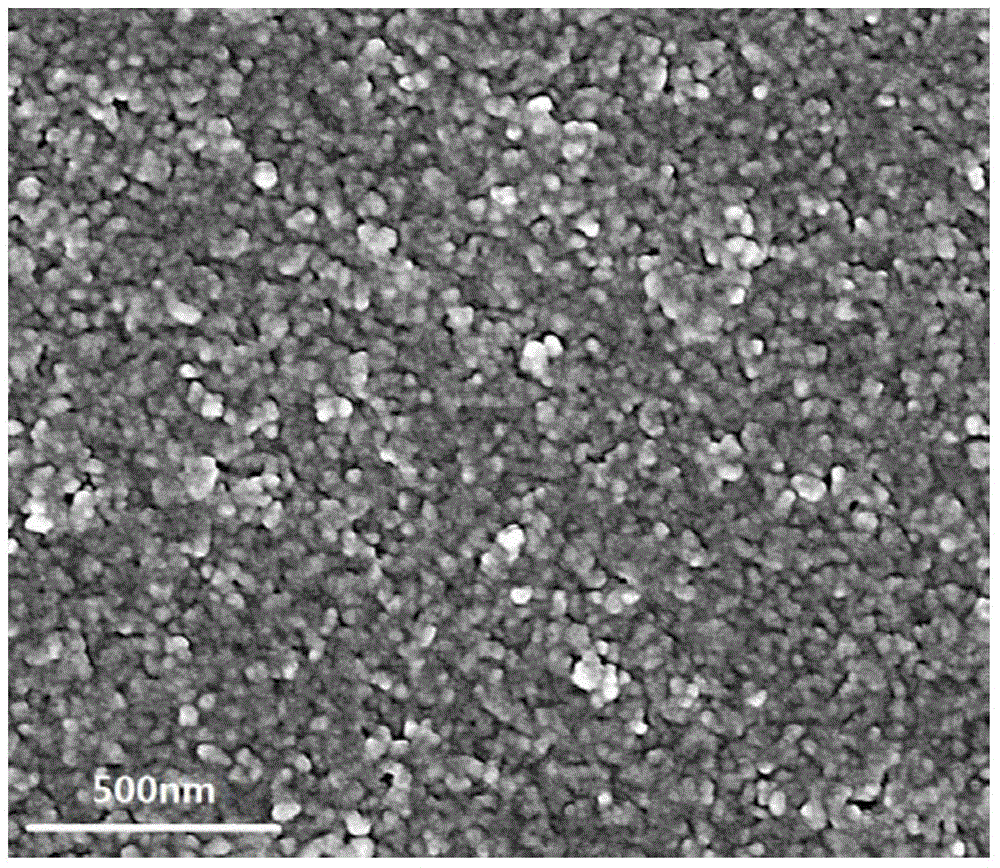

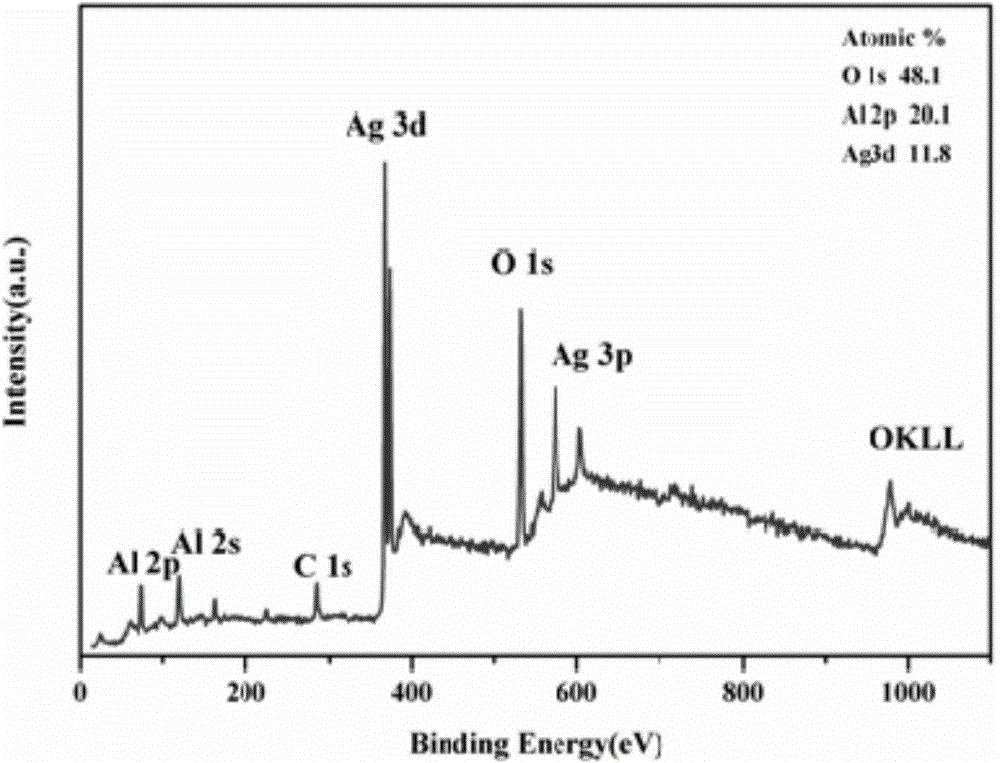

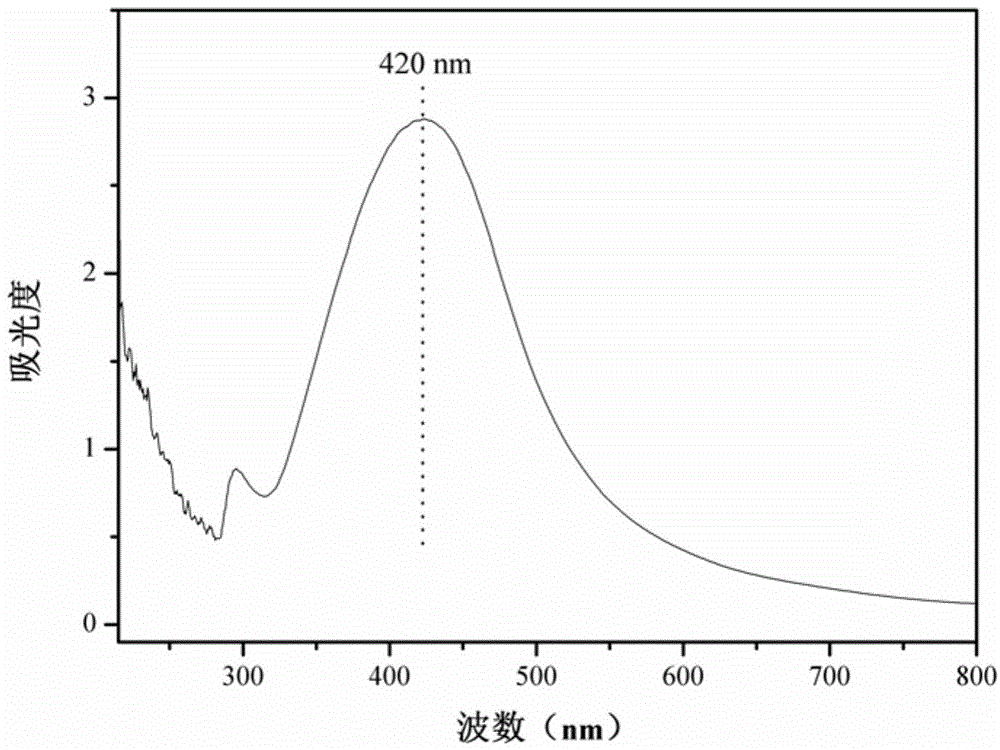

SERS substrate material and preparation method thereof

InactiveCN105986268AContribute to the loadSave raw materialsRaman scatteringMetallic material coating processesSurface-enhanced Raman spectroscopyNano al2o3

The invention provides a SERS substrate material and a preparation method thereof. The preparation method comprises the following steps: preparing a nanometer alumina coating with a certain thickness and uniform pore size distribution from boehmite; impregnating the coating in a precious metal precursor solution; and carrying out deposition and immobilization of precious metal nanoparticles by using a method employing a combination of a reducing agent and irradiation by a high-pressure mercury lamp. The method uses cheap raw materials, is simple in process and has easily controllable process conditions; and the obtained SERS substrate material has good stability and uniform hot spot distribution and shows high sensitivity and repeatability in ultralow-concentration detection.

Owner:NANJING UNIV OF SCI & TECH

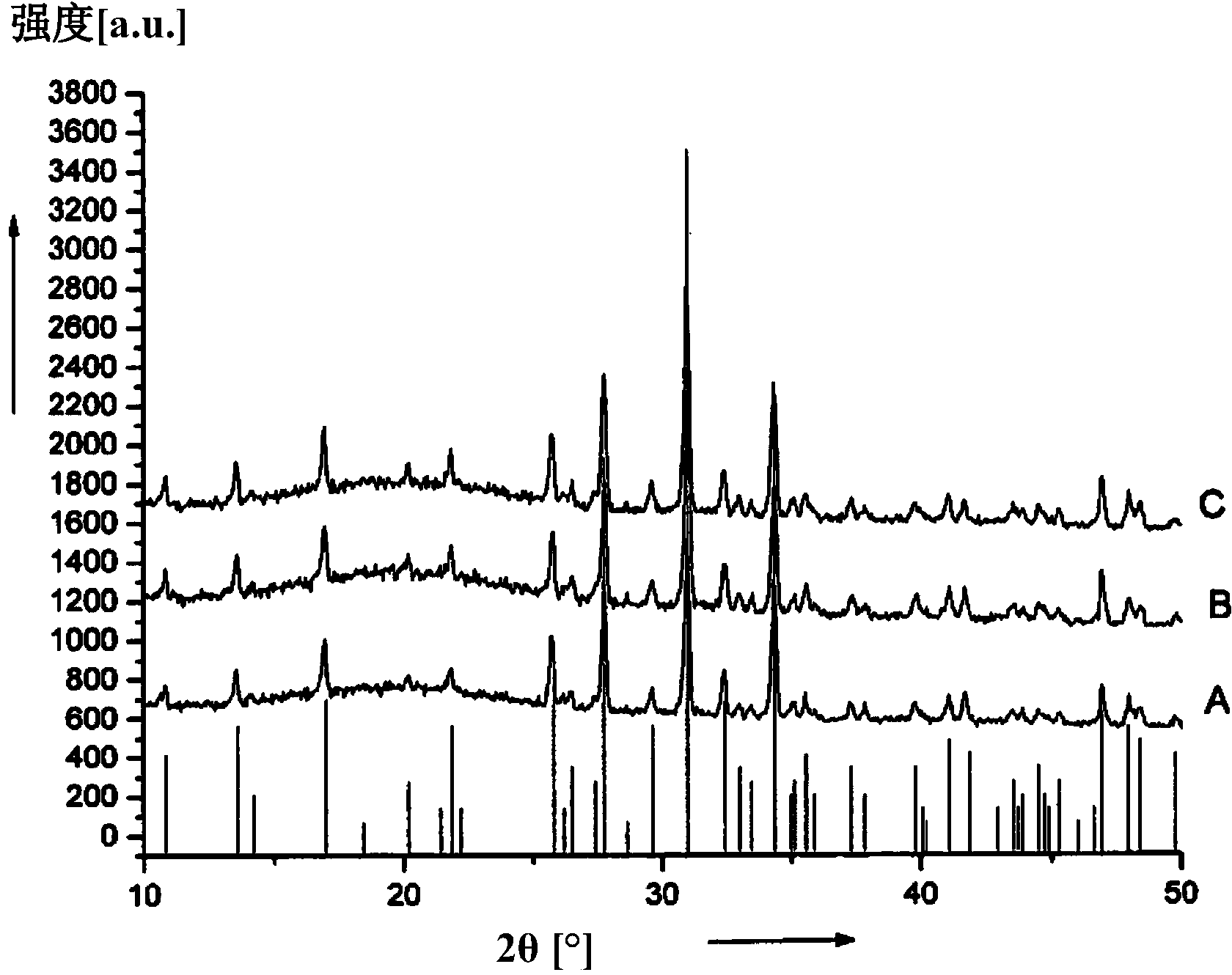

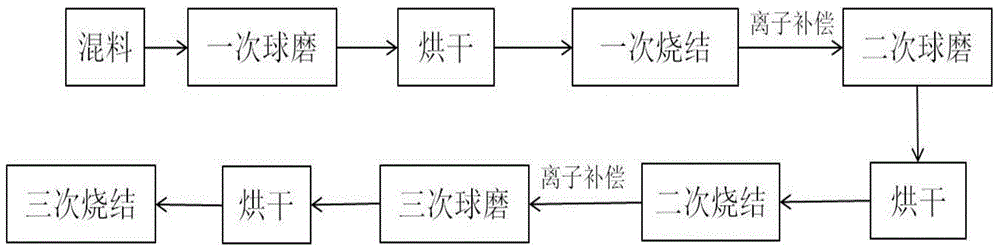

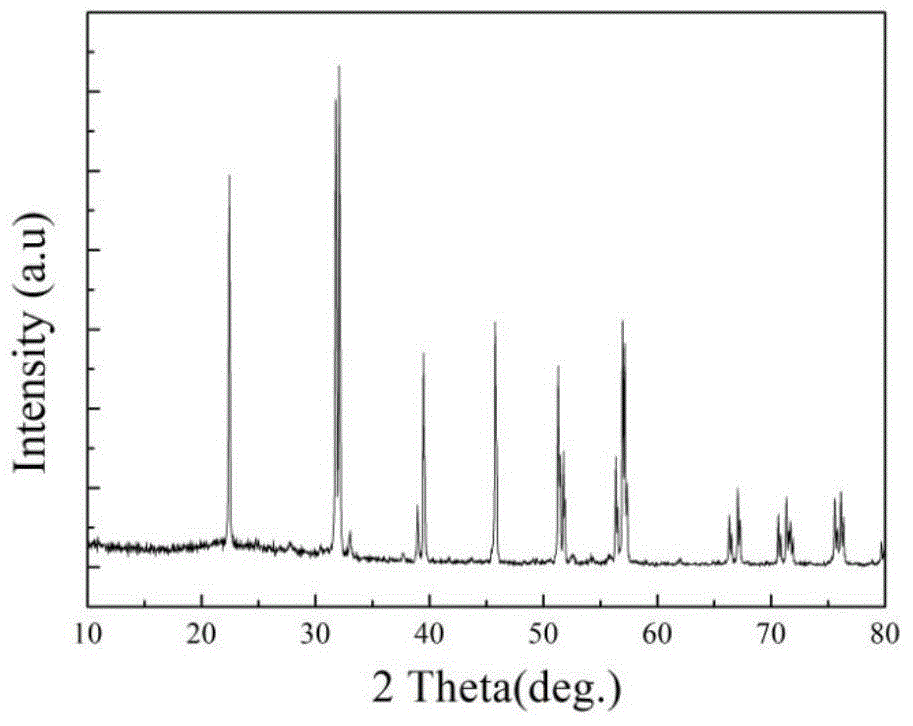

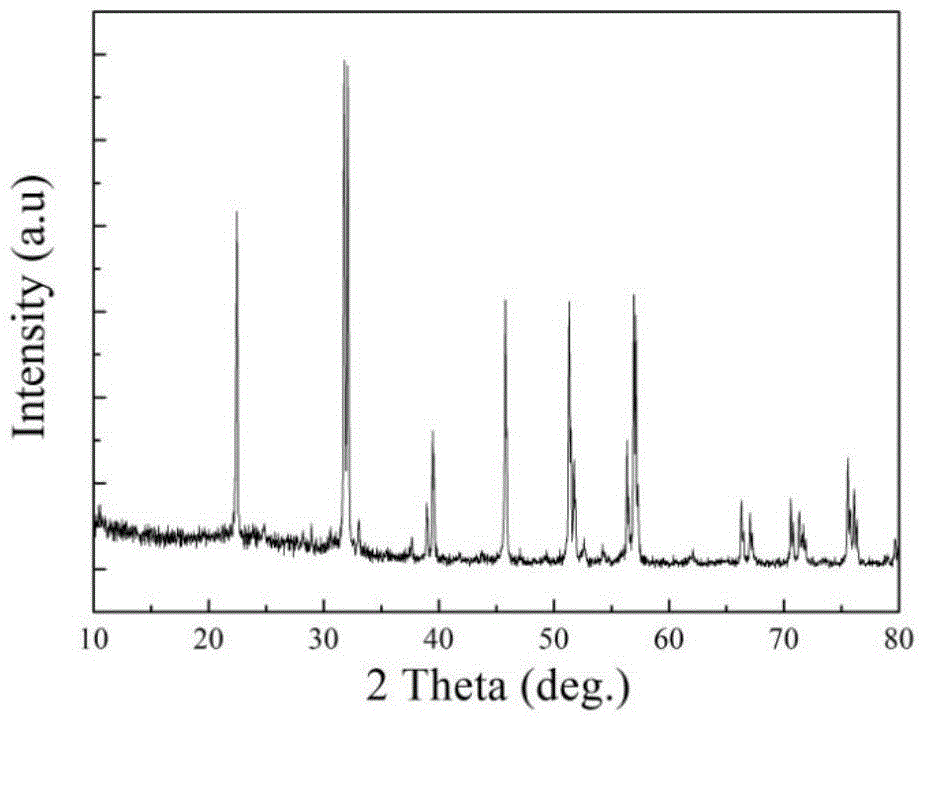

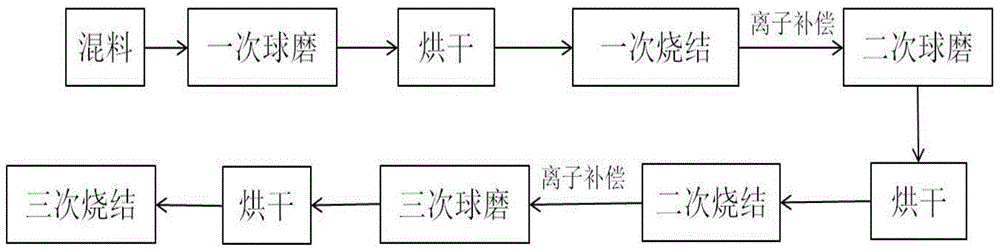

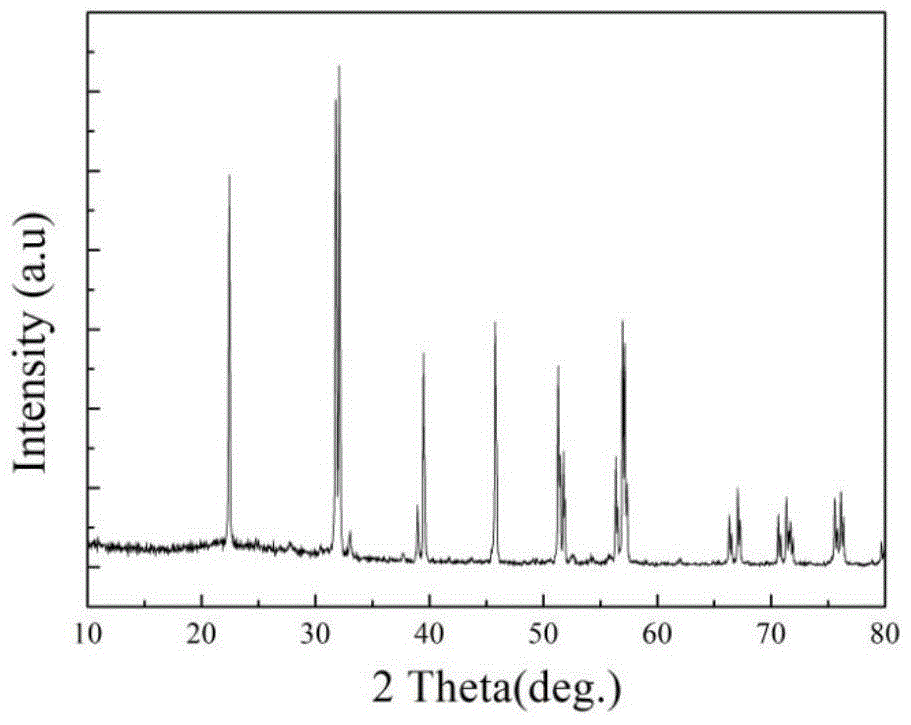

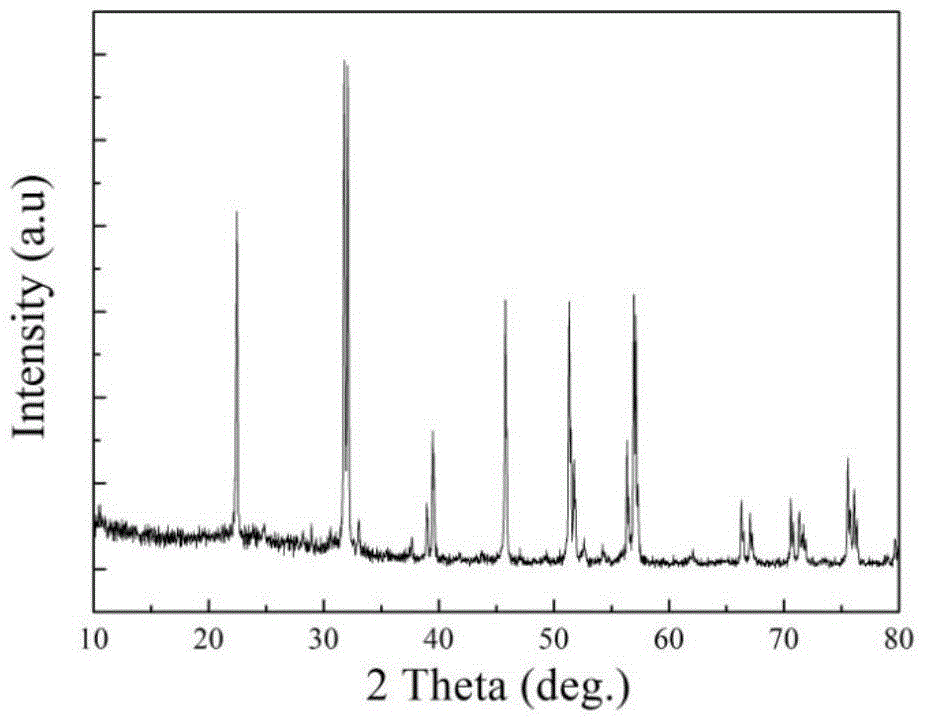

Preparation method of single pure-phase bismuth ferrite material based on ionic compensation

InactiveCN104961162ASolve technical problems of composition segregationReduce the ratioIron compoundsRoom temperatureIron oxide

The invention provides a preparation method of a single pure-phase bismuth ferrite material based on ionic compensation, which belongs to the field of ceramic material preparation. Firstly, a bismuth ferrite ceramic reaction mixture is prepared and then is dried for presintering for the first time; then 0.3 to 0.7wt percent of bismuth oxide is added through secondary ball milling for ionic compensation, and drying is performed for presintering for the second time; 0.2 to 0.4wt percent of bismuth oxide is added through third ball milling for ionic compensation, drying is performed for presintering for 0.5 to 1.5 h at 810 to 835 DEG C, and natural cooling is performed to room temperature along with a furnace, so as to obtain the single pure-phase bismuth ferrite material. According to the preparation method, the bismuth oxide and ferric oxide are used as raw materials, and three-step sintering and twice ionic compensation are adopted to prepare the single pure-phase bismuth ferrite material, so as to solve the technical problem of composition segregation caused by volatile bismuth oxide in the preparation process of bismuth ferrite and prepare the single pure-phase bismuth ferrite material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

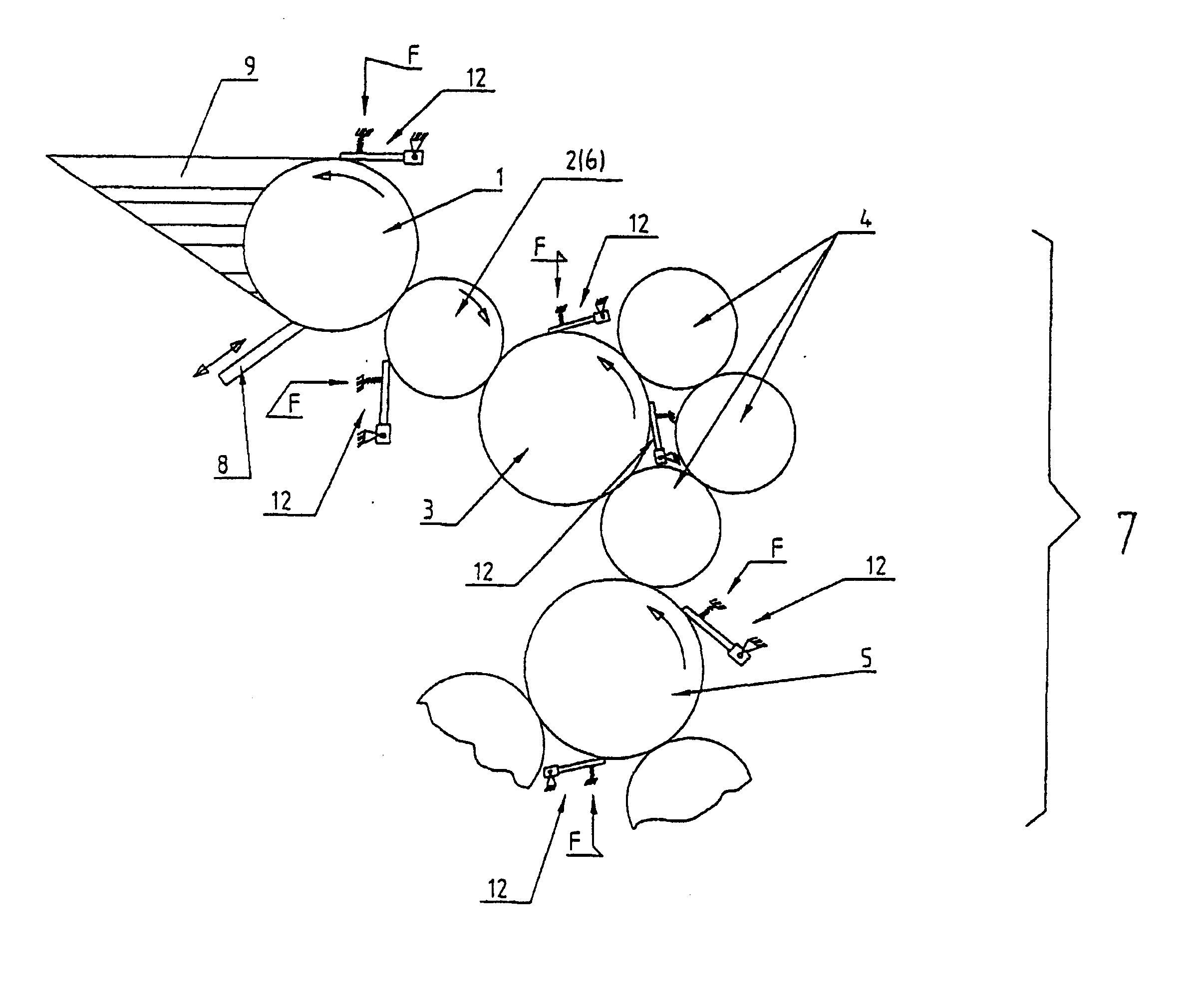

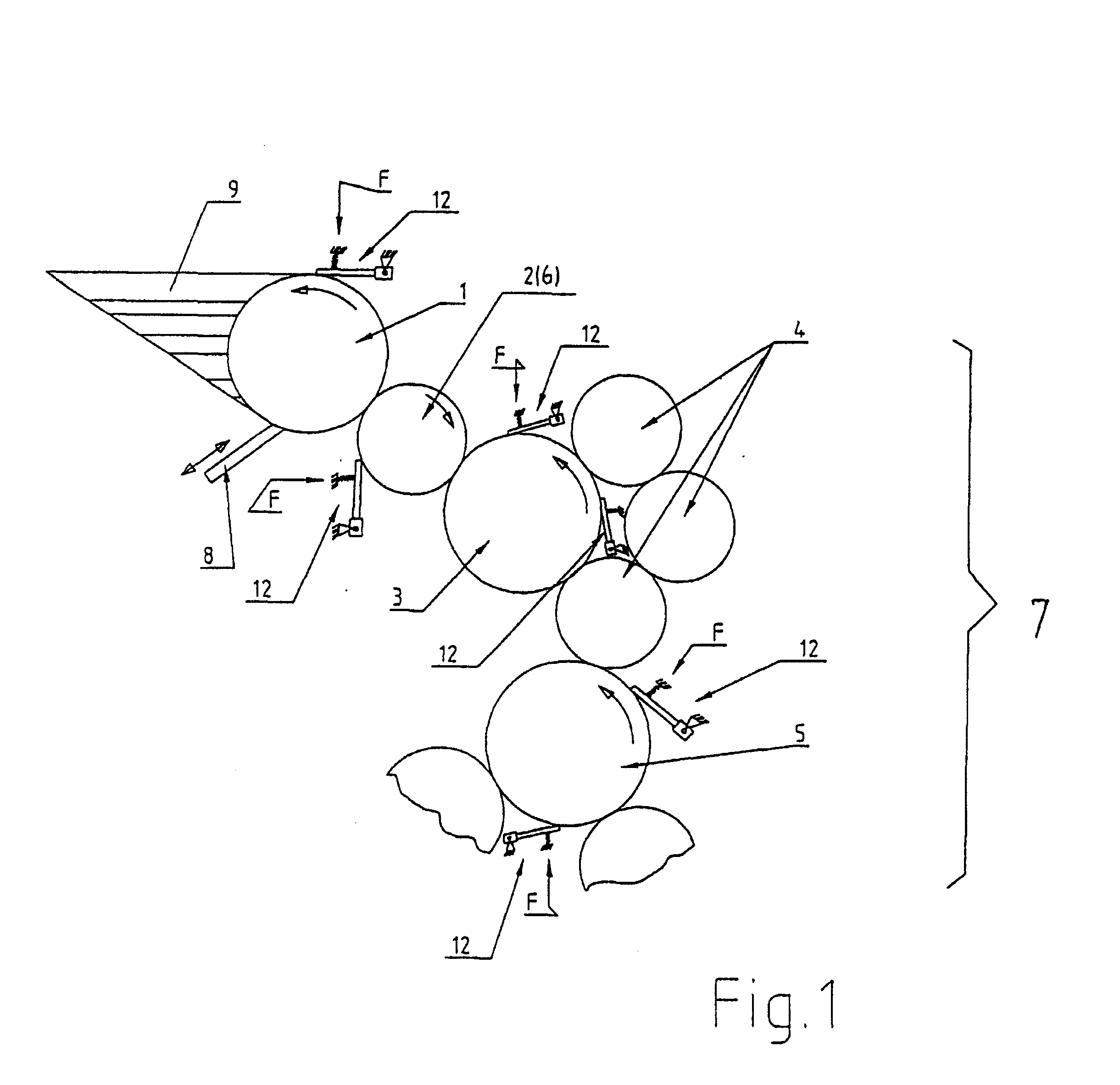

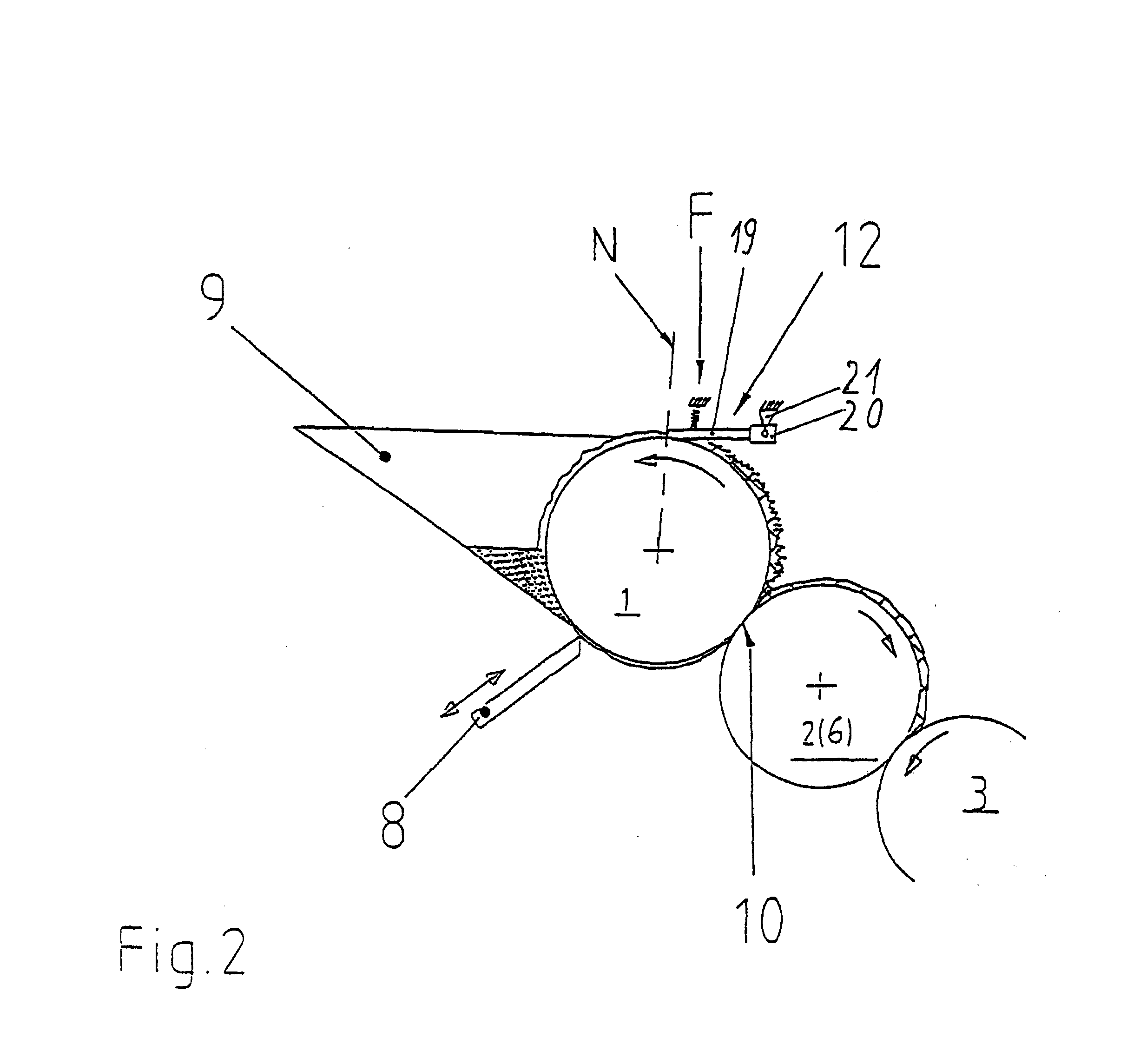

Dosing system for inking up rollers in a printing machine

InactiveUS20030192442A1Good body shapeReduce in quantityPrinting press partsEngineeringPrinting press

The invention concerns a metering system for the inking of rollers in a printing machine. The task of the invention is based on creating a metering system that achieves, with minimum expense, a uniform, stable ink guidance on a roller surface and noticeably improves the print quality. The task is solved in that, in the direction of rotation of a roller <bold>1, < / highlight>preferably after a contact zone <bold>10, < / highlight>where ink separation occurs, a plating device <bold>12 < / highlight>is adjustable to the outer surface of the roller <bold>1. < / highlight>

Owner:MANROLANAD AG

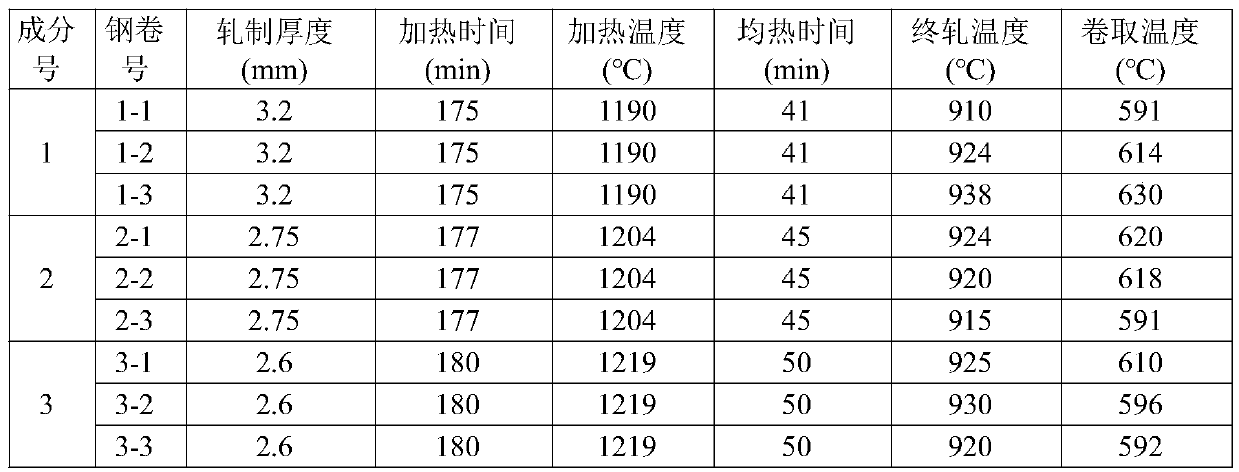

Ultra-low carbon steel coil plate for ultra-thin shell of oil filter and manufacturing method thereof

The invention discloses an ultra-low carbon steel coil plate for an ultra-thin shell of an oil filter and a manufacturing method thereof. The ultra-low carbon steel coil plate comprises the followingchemical components according to the weight percentage: 0.0028 to 0.0050% of C, less than or equal to 0.030% of Si, 0.45 to 0.55% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008%of S, 0. 045-0.080% of Al, 0.065-0.085% of Ti, and less than or equal to 0.0030% of N. The manufacturing method comprises the following steps of: heating a plate blank, and carrying out rough rollingand finish rolling to obtain a hot rolled plate, wherein the coiling temperature is 590-630 DEG C; and carrying out cold rolling on the hot rolled plate to obtain the ultra-low carbon steel coil plate with the thickness of 0.30 to 0.44 mm, wherein the reduction ratio of cold rolling is 80 to 90%, the annealing temperature is 700 to 760 DEG C, the elongation of temper rolling is 1.0 to 2.0% , andthe elongation of straightening and withdrawal is 0.03 to 0.10%. The ultra-low carbon steel coil plate has the Rel of 220-270MPa, Rm of 330-390MPa, hardness of 54-60HR30T, and elongation A80 of greater than or equal to 40%. The ultra-low carbon steel coil plate has relatively high hardness, relatively good ductility, uniform structure property, good isotropic homogeneity and good deep-drawing property, does not generate earing, can completely replace the traditional 0.50-0.70mm thick material, and meets the requirements on thinning and weight reduction of automotive parts.

Owner:新余钢铁股份有限公司 +1

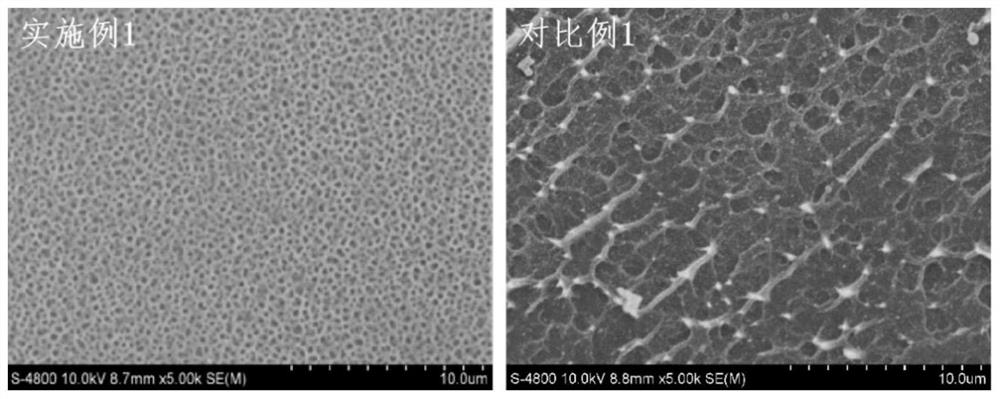

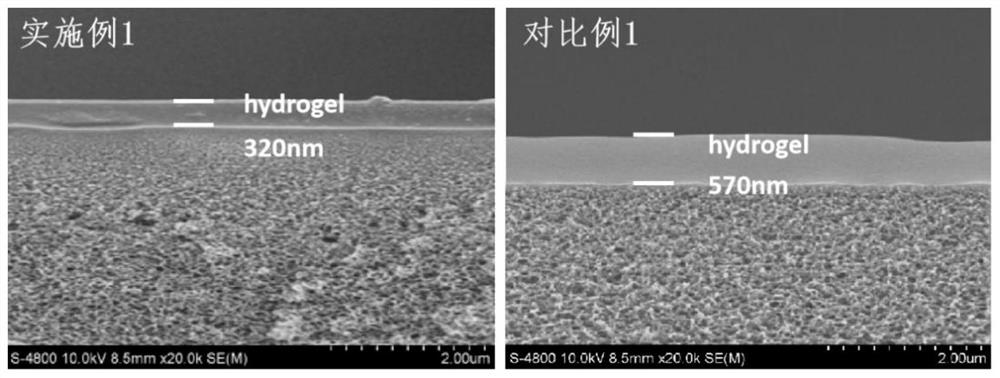

Super-hydrophilic chitosan quaternary ammonium salt hydrogel composite membrane as well as preparation method and application thereof

ActiveCN114042383AHydrophilicStrong antibacterialSemi-permeable membranesMembranesAceric acidUltrafiltration

The invention discloses a super-hydrophilic chitosan quaternary ammonium salt hydrogel composite membrane and a preparation method and application thereof. The preparation method comprises the following steps of: adding chitosan quaternary ammonium salt powder into an acetic acid aqueous solution, and heating and stirring to obtain a transparent solution A; adding and dissolving a reinforcing agent acrylamide and a cross-linking agent into an acetic acid aqueous solution, then adding an initiator, and stirring until the initiator is completely dissolved to obtain a solution B; mixing the solution A and the solution B, and stirring well to obtain pre-gelled liquid with a room-temperature self-crosslinking function; and by taking an ultrafiltration membrane as a base membrane, transferring the pre-gelled liquid to the surface of the base membrane by adopting a surface multi-time coating method, and after cross-linking and curing at room temperature, putting the pre-gelled liquid into a blast oven for heat treatment to obtain the super-hydrophilic chitosan quaternary ammonium salt hydrogel composite membrane. The preparation method disclosed by the invention is simple. The surface of the obtained composite membrane is super-hydrophilic, the flux of the composite membrane is higher than that of a membrane prepared by a traditional single loading method, the anti-pollution performance is remarkably enhanced, and the composite membrane has a relatively high rejection rate on divalent cations.

Owner:OCEAN UNIV OF CHINA

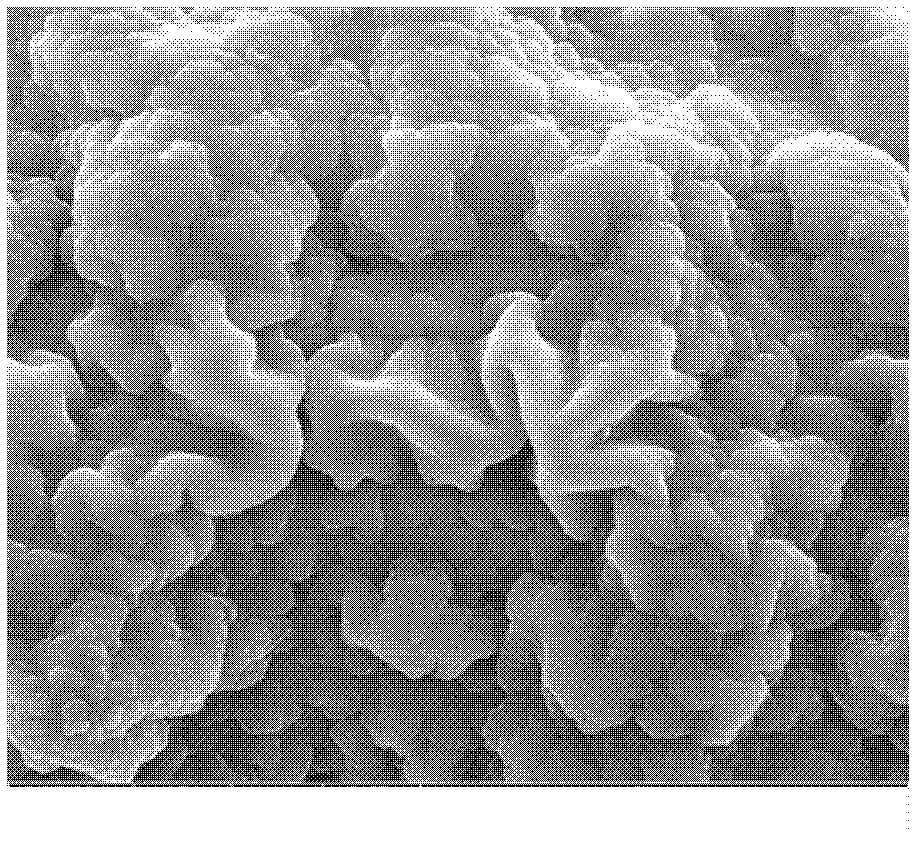

A kind of preparation method of transparent superhydrophobic zinc oxide coating

The invention relates to a preparation method of a transparent super-hydrophobic zinc oxide coating on a glass substrate. The preparation method comprises the following steps of a, substrate pretreatment; b, zinc oxide solution preparation; c, zinc oxide coating preparation; and d, zinc oxide coating surface modification. Compared with the prior art, the preparation method has the beneficial effects of simple equipment process, low cost and mild reaction condition and is beneficial to large-scale industrial production. The transparent super-hydrophobic zinc oxide coating prepared by using the method has excellent hydrophobicity and transparency; the contact angle is larger than 160 degrees, the rolling angle is smaller than 8 degrees, and water drops can freely roll on the coating, so that the transparent super-hydrophobic zinc oxide coating has relatively good self-cleaning performance; and the light transmittance is approach to 90% which is close to that of blank glass, so that the transparent super-hydrophobic zinc oxide coating has favorable visible light transmittance. A surface modifier used in the preparation method is an alkyl silane coupling agent instead of a fluorinated compound, so that the cost is low, the environment pollution is relatively low, and the modified coating is relatively stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

High-strength polysaccharide-nano-laponite composite microsphere and preparation method thereof

ActiveCN110935406AUniform surface structureHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceMicrosphere

The invention relates to the field of organic-inorganic composite material preparation and especially relates to a high-strength polysaccharide-nano-laponite composite microsphere and preparation method thereof. The nano-laponite has abundant hydroxyl on the surface, so that through the hydrogen bonds, the nano-laponite and the polysaccharide macromolecules are combined to achieve great physical crosslinking effect; and with following chemical crosslinking, the polysaccharide-nano-laponite composite microsphere with excellent performances is prepared. A protein adsorption test and a pressure-flow speed curve test prove that the composite microsphere has good biocompatibility, wherein operation flow speed is increased by more than two times than that of single polysaccharide microspheres. The composite microsphere has extensive application potential in the field of enzyme immobilization, cell culture, and quick separation and purification of biomacromolecules.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

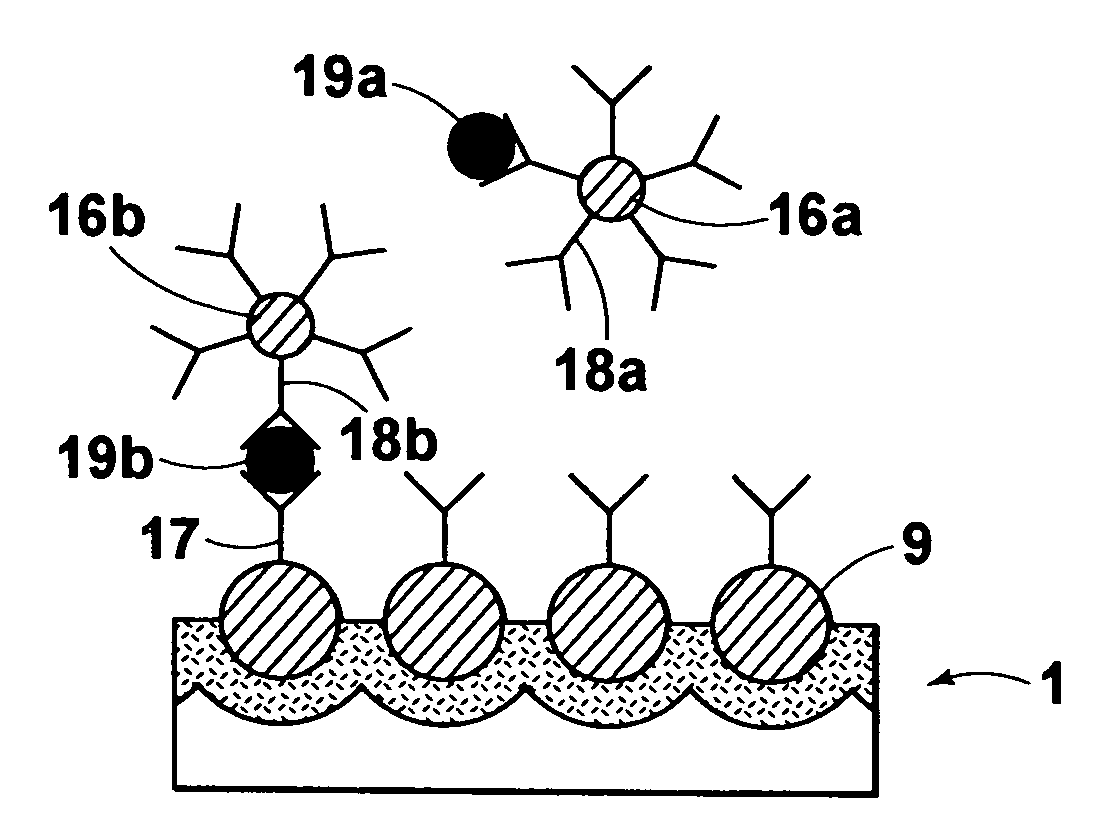

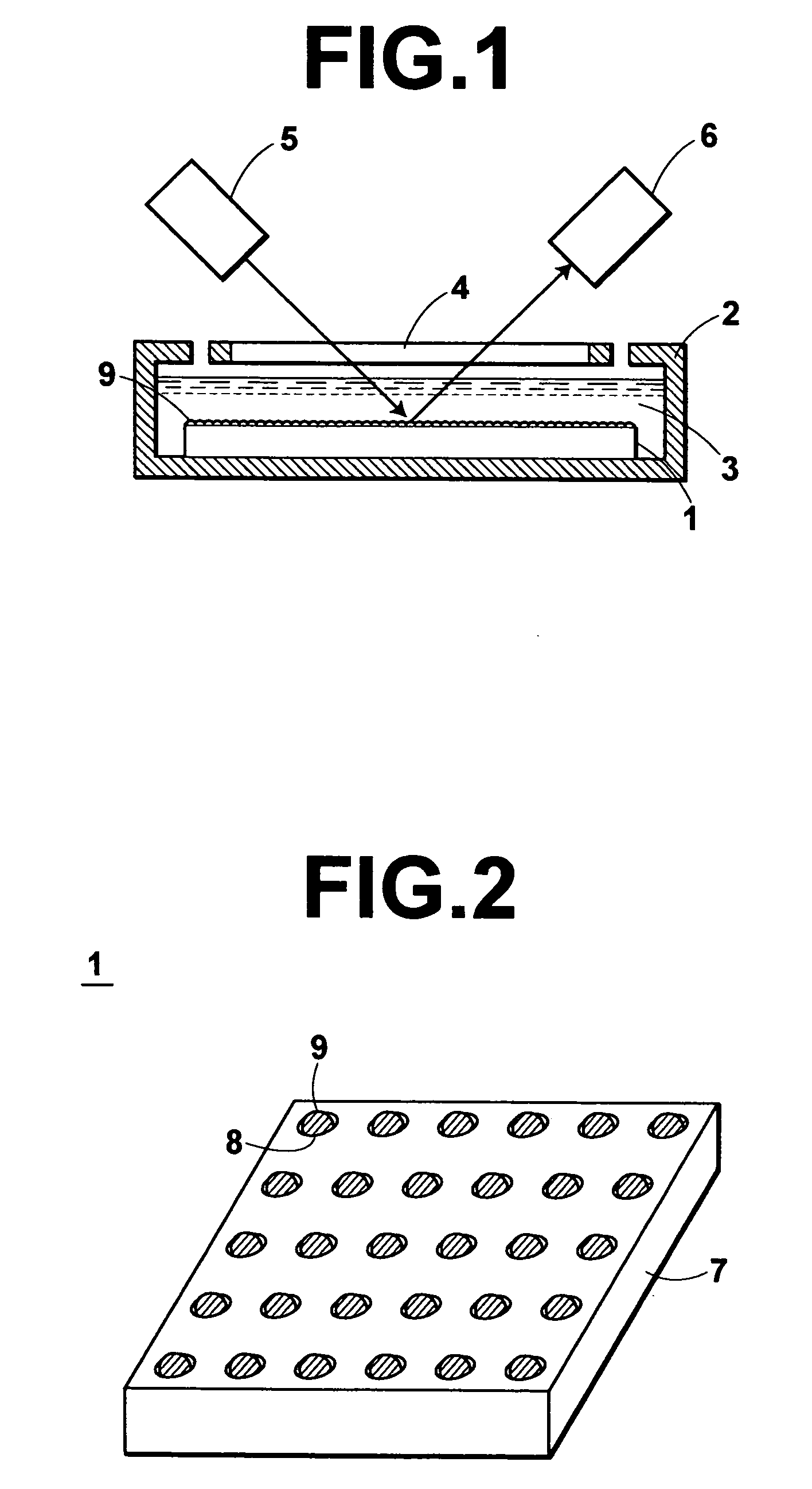

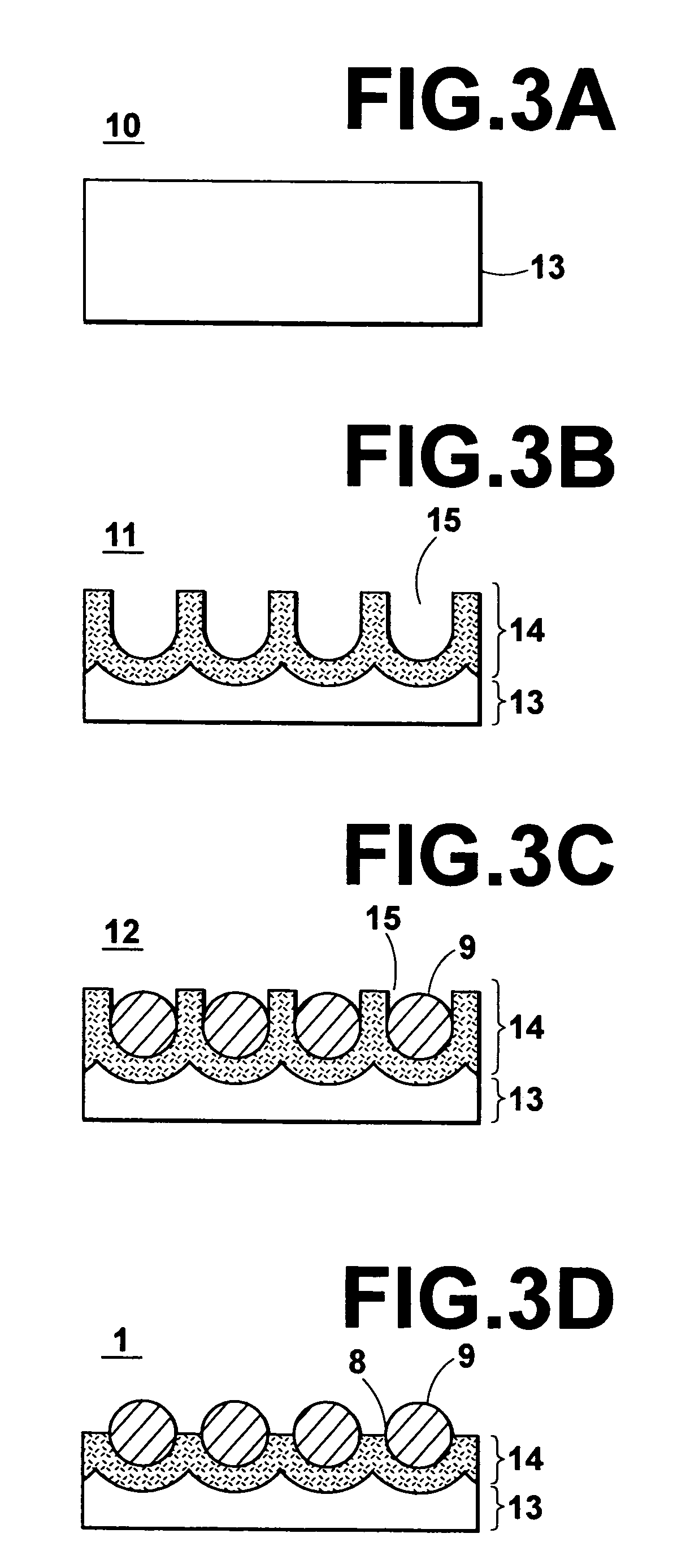

Method of detecting test bodies

InactiveUS20050168745A1Uniform sizeUniform surface structurePhase-affecting property measurementsScattering properties measurementsFine structureResonance wavelength

A fine structure body comprising first fine metal particles, which have head regions projected upwardly from a surface of a base body, is utilized. A substance capable of undergoing specific binding with a test body is fixed to the head regions of the first fine metal particles. Second fine metal particles, to which a substance capable of undergoing specific binding with the test body has been fixed, are dispersed in a sample liquid. The test body is detected from variation of a resonance wavelength of localized plasmon resonance, which variation occurs when the test body is adsorbed to the surface of the fine structure body by being sandwiched between the substance fixed to the first fine metal particle and the substance fixed to the second fine metal particle.

Owner:FUJIFILM HLDG CORP +1

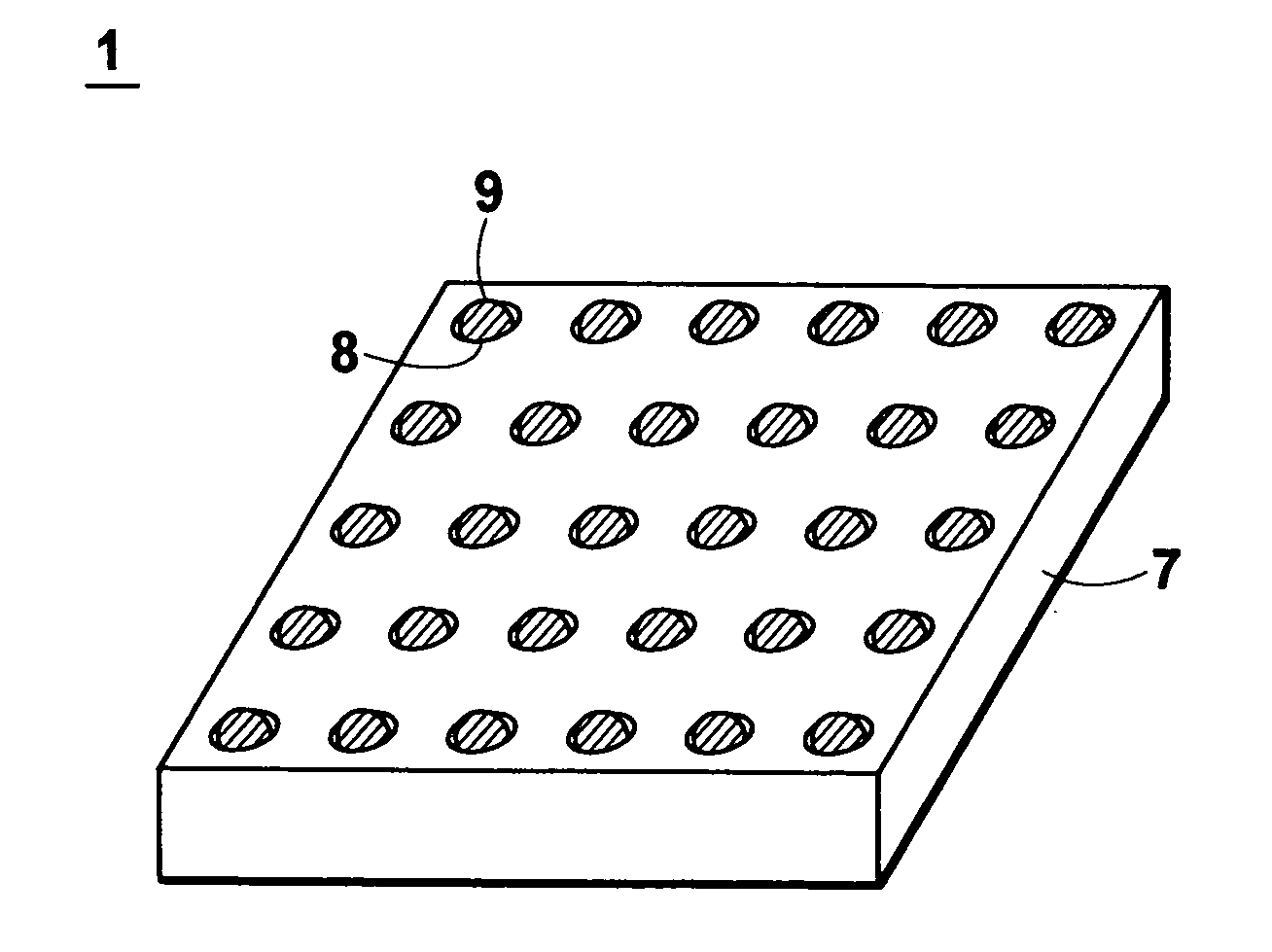

Master device

InactiveCN101802914AUniform surface structureChange heightRecord information storageAuxillary data arrangementEngineeringSurface structure

Owner:麦沃姆&博辛地产有限公司

Double-sided heat-sealing matt film and preparation method thereof

PendingCN114771063ALow flatnessReduce uniformitySynthetic resin layered productsFlat articlesPolymer scienceHigh density

The invention discloses a double-sided heat-sealing matt film which is sequentially composed of an upper surface layer, a core layer and a lower surface layer. The upper surface layer is prepared from the following raw materials in parts by mass: 44-50 parts of polypropylene, 35-40 parts of high-density polyethylene, 25-30 parts of an ethylene-1-octylene copolymer, 5-8 parts of matting powder and 1-3 parts of lanthanum-doped nano silicon dioxide. The invention also discloses a preparation method of the double-sided heat-sealing matt film. The double-sided heat-sealing matt film disclosed by the invention has excellent matting performance and heat-sealing performance, and has a good application prospect in the field of food packaging.

Owner:GETTEL GRP TONGCHENG PLASTIC IND

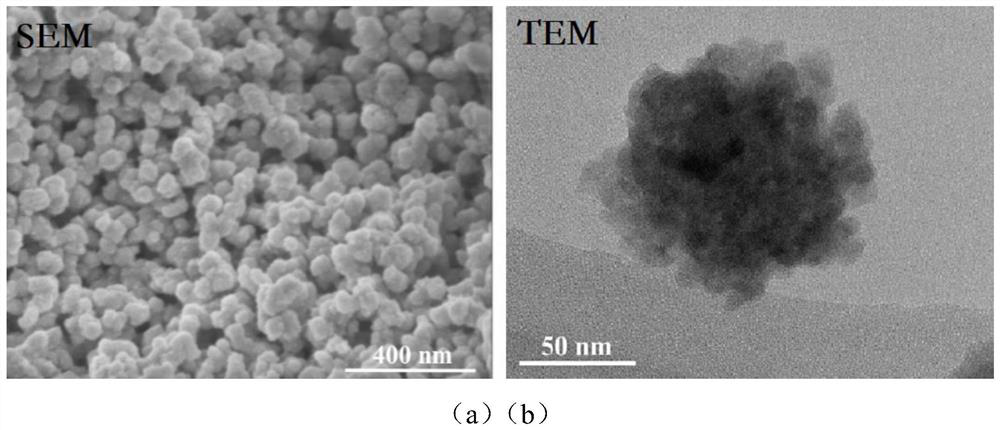

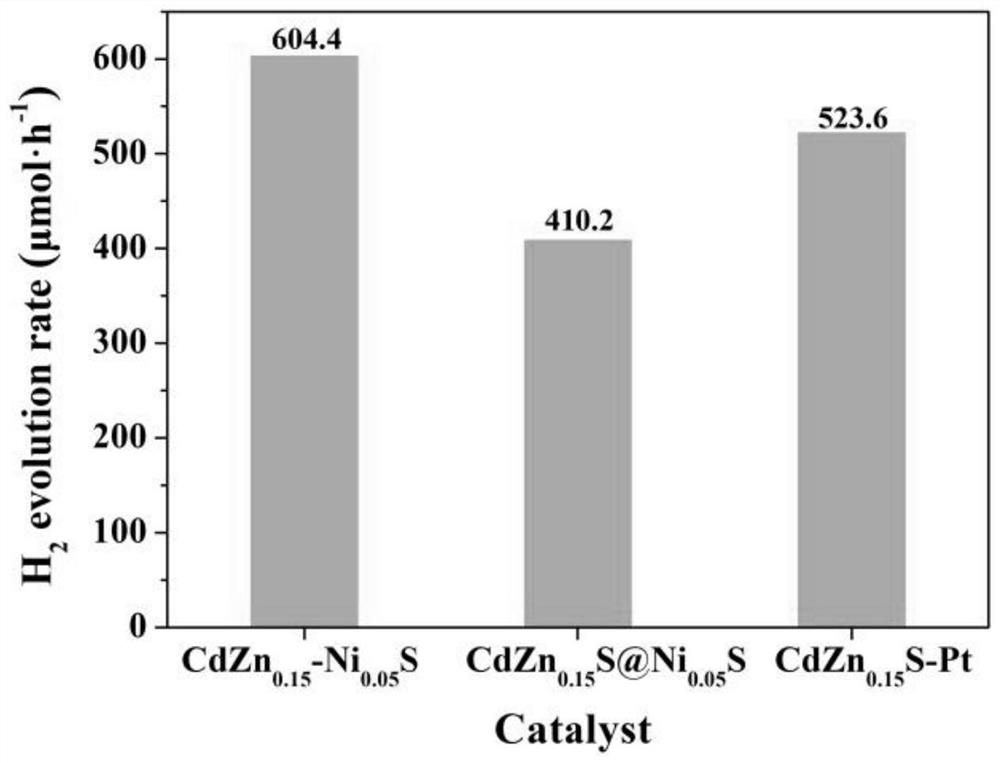

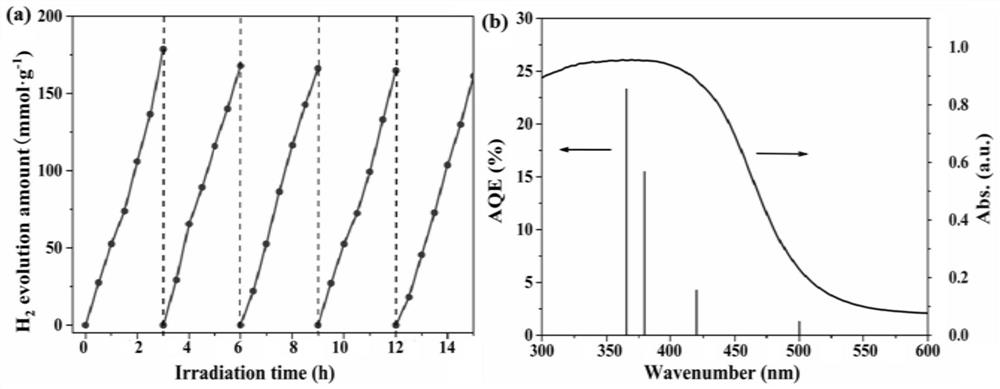

CdS/ZnS-NiS nano-cluster photocatalyst and preparation method and application thereof

ActiveCN113634267AImprove hydrogen production performanceSimple manufacturing processPhysical/chemical process catalystsEnergy inputPtru catalystCadmium acetate

The invention discloses a CdS / ZnS-NiS nano-cluster photocatalyst and a preparation method and application thereof, and belongs to the technical field of photocatalysis. In the CdS / ZnS-NiS nano-cluster photocatalyst, semiconductors CdS and ZnS and a non-metal cocatalyst NiS are uniformly distributed in the nanoscale, and a nano-cluster with a porous structure is formed by self-assembly while a close contact interface is formed. The preparation method comprises the following steps: taking cadmium acetate, zinc acetate and nickel acetate as precursors, obtaining the CdS / ZnS-NiS nano-cluster photocatalyst which is composed of non-noble metals and has a nanoscale close contact interface through a one-step hydrothermal method. The catalyst system has a nanoscale close contact interface and excellent photocatalytic activity, so that the catalyst system can be applied to hydrogen production by photocatalytic decomposition of water.

Owner:XI AN JIAOTONG UNIV

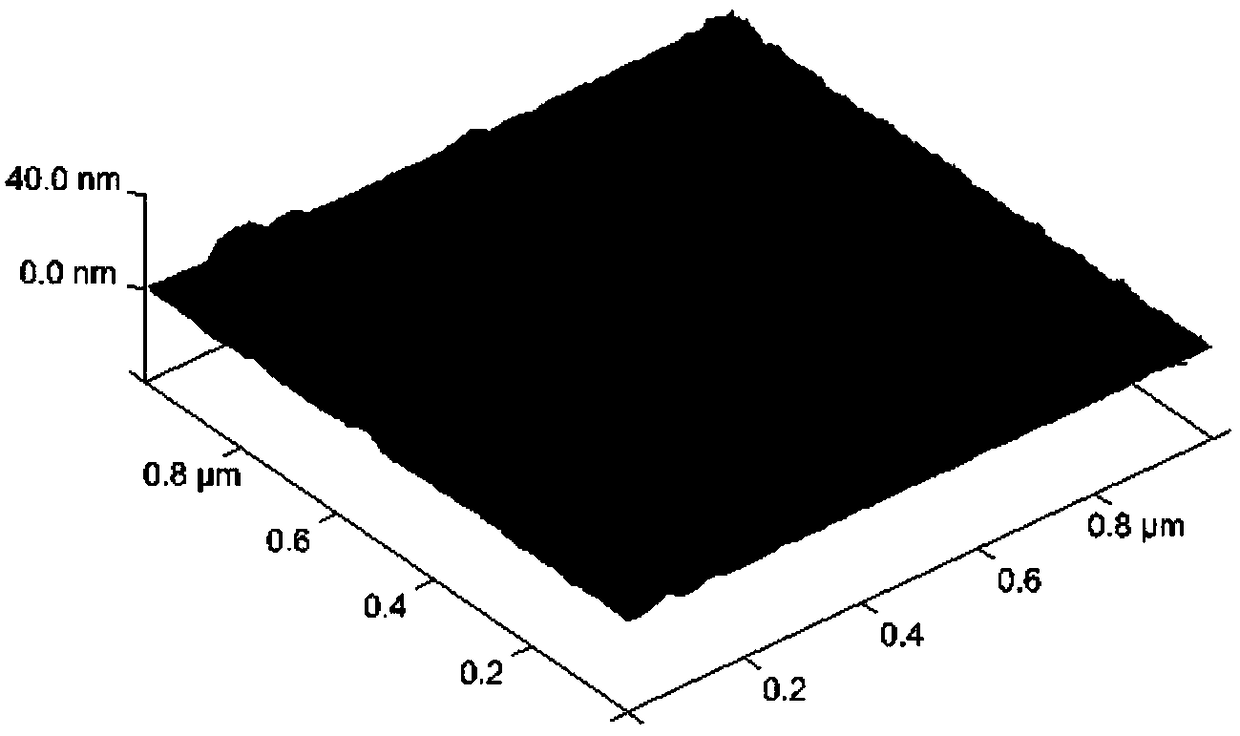

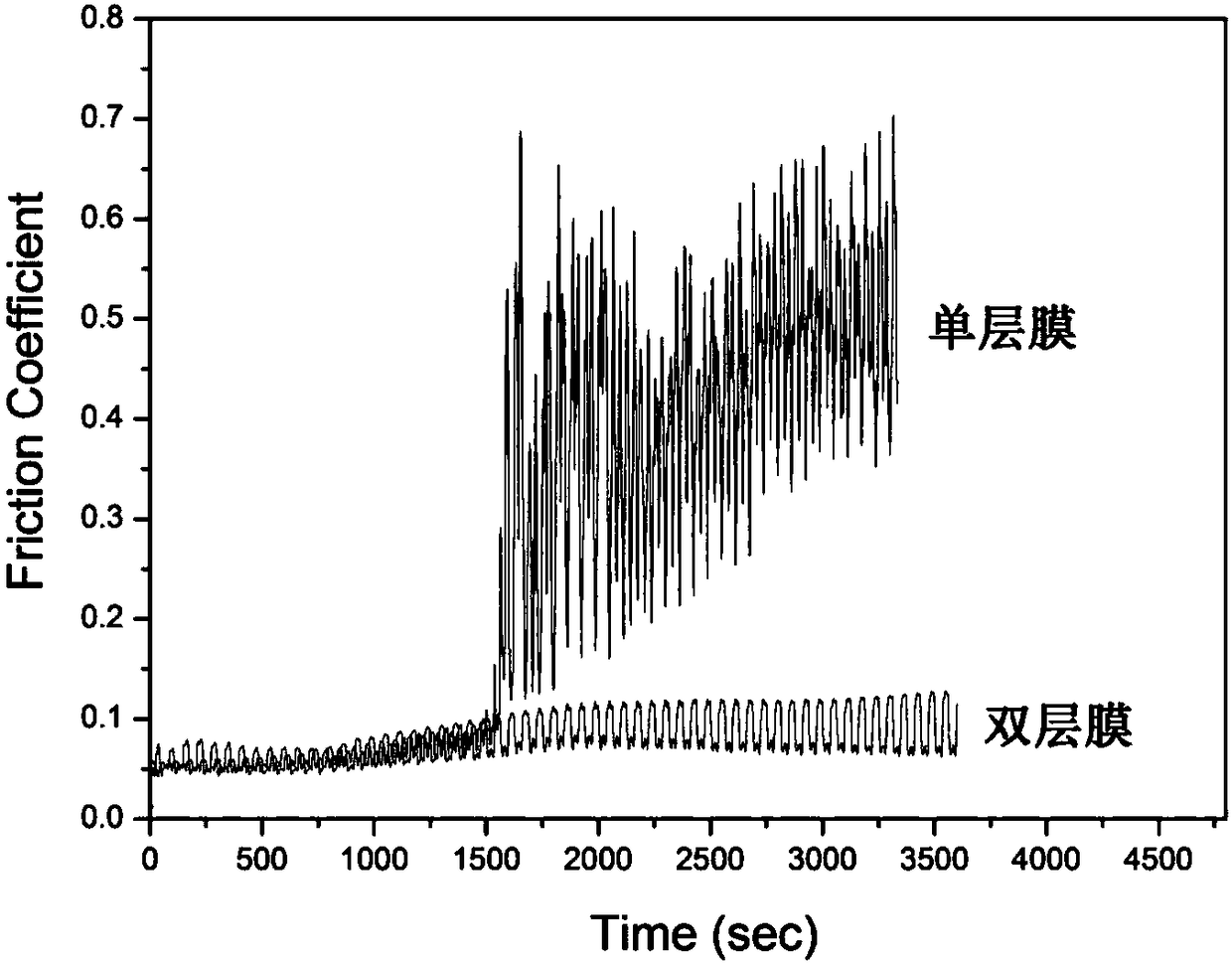

Preparation method of a double-layer composite self-assembled lubricating film

InactiveCN105772373BReduce coefficient of frictionGood anti-adhesionAdditivesCoatingsHydrolysateLubrication

The invention provides a preparation method of a double-layer self-assembly lubricating film and relates to a preparation method of a novel double-layer self-assembly film formed by 1,2-Bis(triethoxysilyl)ethane and a low-surface-energy silane coupling agent. The method comprises the steps that single crystal silicon wafers are cut and cleaned and then are subjected to oxidation treatment; and the processed silicon wafers are immersed into 1,2-Bis(triethoxysilyl)ethane hydrolysate, and a first-layer film is prepared; and the obtained film is immersed into a low-surface-energy silane coupling agent solution again after being cleaned and dried, and deposition of a second-layer film is carried out through active groups on the surface of the first-layer film. Instruments and equipment involved in the preparation method are simple, operation is easy during the process, and the obtained double-layer films are of a stable and ordered structure. Compared with a single-layer film of the low-surface-energy silane coupling agent, the double-layer films can maintain a low friction coefficient, and the adhesion resistance and abrasion resistance of the double-layer self-assembly lubricating film can be effectively improved. The double-layer film is expected to become an effective means of solving the problems of lubrication and protection of the surfaces of devices in micro electro-mechanical systems.

Owner:CHINA UNIV OF MINING & TECH

A method for preparing single pure phase bismuth ferrite material based on ion compensation

InactiveCN104961162BSolve technical problems of composition segregationReduce the ratioIron compoundsMaterials preparationRoom temperature

The invention provides a method for preparing a single pure-phase bismuth ferrite material based on ion compensation, which belongs to the field of ceramic material preparation. First prepare the bismuth ferrite ceramic reaction mixture, and perform the first pre-sintering after drying; then add 0.3-0.7wt% bismuth oxide through the second ball mill for ion compensation, and perform the second pre-sintering after drying; Add 0.2-0.4wt% bismuth oxide for ion compensation by ball milling, sinter at 810-835°C for 0.5-1.5h after drying, and naturally cool to room temperature with the furnace to obtain a single-phase pure-phase bismuth ferrite material. The present invention uses bismuth oxide and iron oxide as raw materials, and adopts three-step sintering and two ion compensations to prepare a single pure-phase bismuth ferrite material, so as to solve the technical problem that bismuth oxide is volatile and causes component segregation in the process of preparing bismuth ferrite. A single pure phase bismuth ferrite material was prepared.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

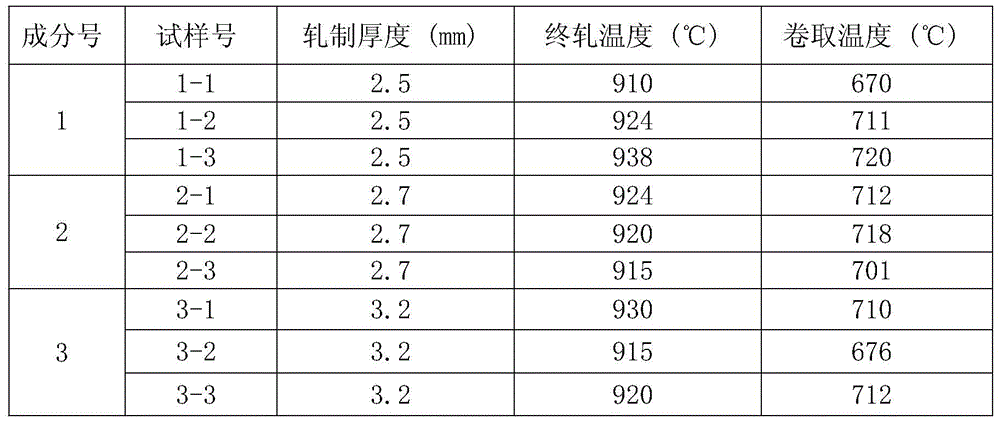

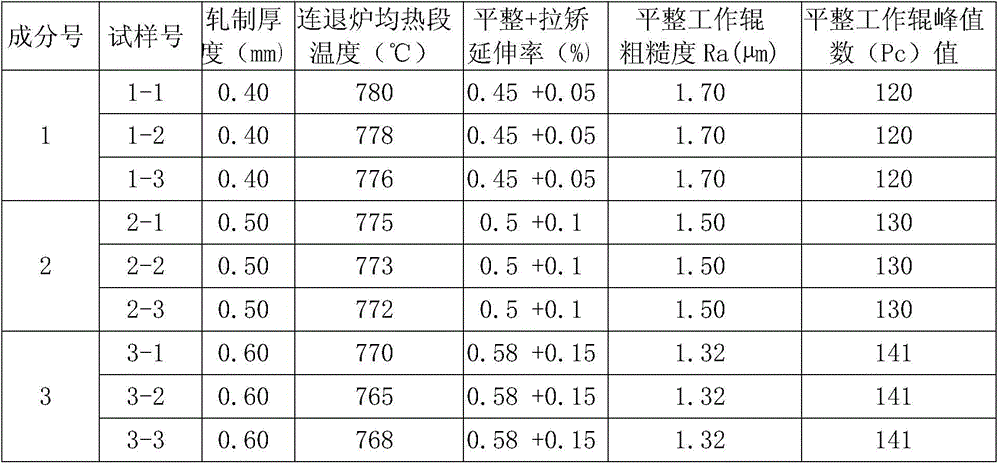

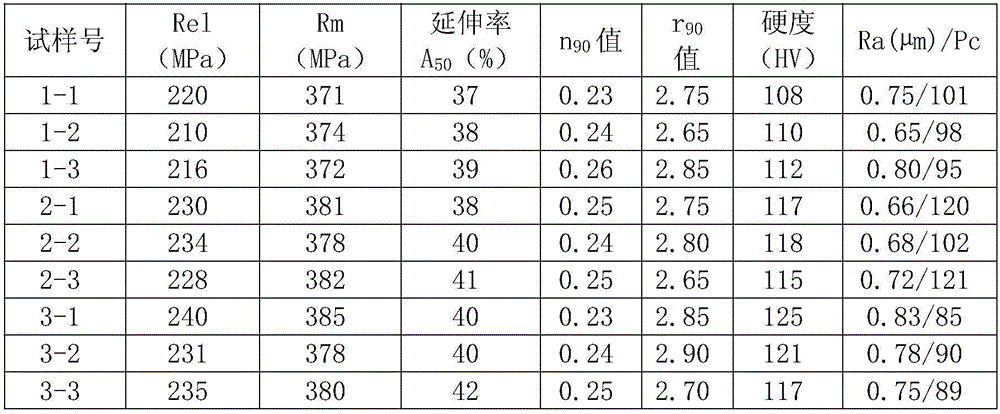

A color-coated cold-rolled substrate for home appliance panels and its manufacturing method

The invention discloses a color-coated cold-rolled baseplate used for a household appliance panel and a manufacturing method of the color-coated cold-rolled baseplate. The cold-rolled baseplate is manufactured by a plate blank consisting of the following ingredients by weight percentage: 0.0035-0.0065% of C, less than or equal to 0.009% of Si, 0.38-0.48% of Mn, 0.040-0.056% of P, less than or equal to 0.009% of S, 0.035-0.055% of Al, 0.045-0.055% of Ti, less than or equal to 0.0036% of N, and the balance being Fe. The method is characterized in that the plate blank is heated, and subjected to rough rolling and precision rolling to form a hot-rolled plate; a coiling temperature is 670-720 degrees; a hot-rolled coil is subjected to cold rolling; the temperature of a soaking zone of a continuous annealing furnace is 765-780 degrees; the elongation of temper rolling is 0.45-0.58%; the withdrawal and straightening elongation is 0.05-0.15%; the roughness of a working roll for the temper rolling is 1.3-1.7 micrometers; and a peak count (Pc) of the working roll for the temper rolling is greater than or equal to 120. With the adoption of the design ingredients and the manufacturing method, the color-coated cold-rolled baseplate with good deep drawability, low cost, ageing resistance and excellent dent resistance is obtained, and higher requirements of the household appliance panel are met.

Owner:XINYU IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com