A color-coated cold-rolled substrate for home appliance panels and its manufacturing method

A manufacturing method and color coating technology, which is applied in the field of metal material manufacturing, can solve the problems of edge defects, poor deep drawing performance, and excessive height of color-coated plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

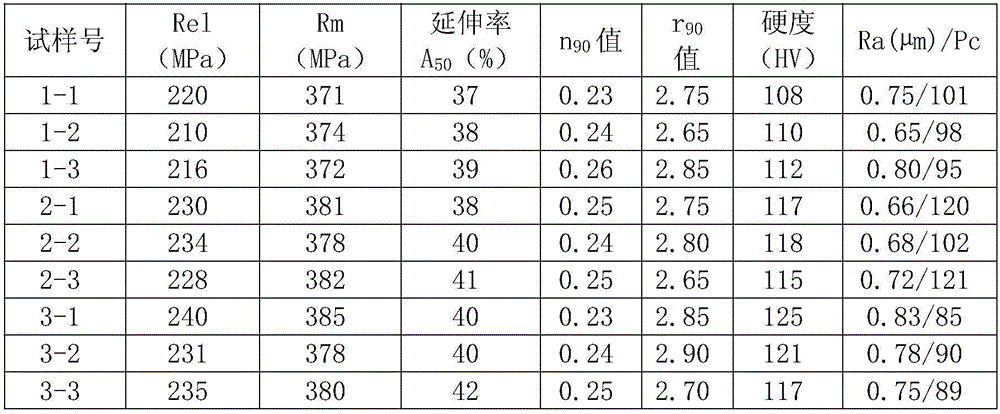

[0060] Embodiment 1: A color-coated cold-rolled substrate for a home appliance panel, the cold-rolled substrate:

[0061] 1) Smelting in a converter, refining in an RH furnace, and continuous casting into the slab described in component number 1;

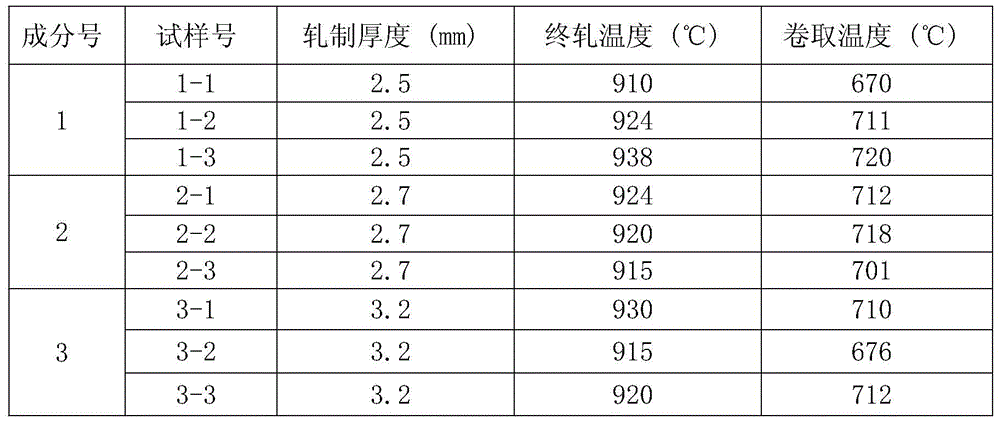

[0062] 2) Hot rolling: heat the slab with the component number 1, the target hot rolling thickness is 2.5mm, the billet is rough rolled and finished rolled to obtain a hot rolled plate, the final rolling temperature is 910 ° C ~ 938 ° C, and then the The hot-rolled sheet is cooled by laminar flow, and coiled into a hot-rolled coil after cooling. The coiling temperature is 670-720°C;

[0063] 3) cold rolling: the target cold rolling thickness is 0.40 mm, and the hot rolled plate is rolled after pickling;

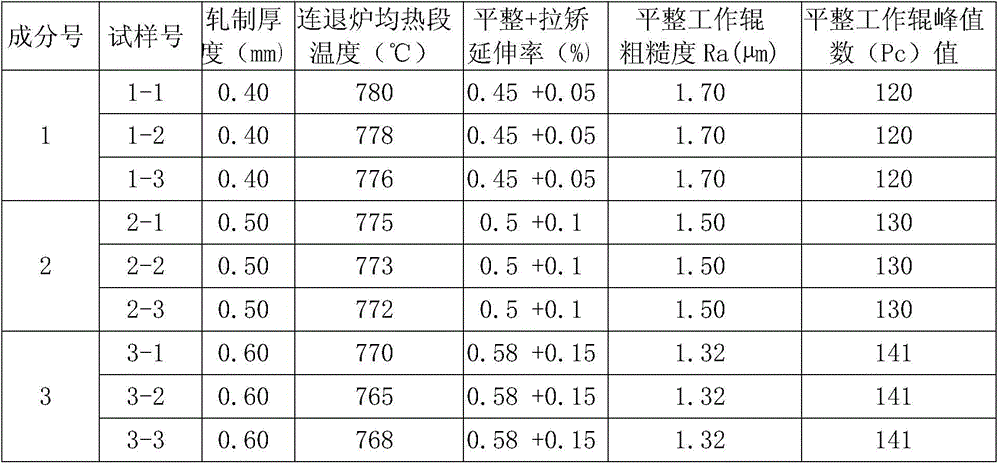

[0064] 4) Annealing treatment: the temperature of the soaking section of the continuous annealing furnace is 776-780°C;

[0065] 5) Leveling and tension bridge: leveling elongation 0.45% + tension leveling elongation 0.05%, level...

Embodiment 2

[0067] Embodiment 2: A color-coated cold-rolled substrate for a home appliance panel, the cold-rolled substrate:

[0068] 1) The slab described in component number 2 is formed through converter smelting, RH furnace refining, and continuous casting;

[0069] 2) Hot rolling: heat the slab of component number 2, the target hot rolling thickness is 2.7mm, the billet is rough rolled and finished rolled to obtain a hot rolled plate, the final rolling temperature is 915 ° C ~ 924 ° C, and then the The hot-rolled sheet is cooled by laminar flow, and coiled into a hot-rolled coil after cooling. The coiling temperature is 701-718°C;

[0070] 3) Cold rolling: the target cold rolling thickness is 0.50mm, and the hot-rolled plate is rolled after pickling;

[0071] 4) Annealing treatment: the temperature of the soaking section of the continuous annealing furnace is 772-775°C;

[0072] 5) Leveling and tension bridge: leveling elongation 0.50% + tension leveling elongation 0.10%, leveling w...

Embodiment 3

[0074] Embodiment 3: A color-coated cold-rolled substrate for a home appliance panel, the cold-rolled substrate:

[0075] 1) The slab described in component number 2 is formed through converter smelting, RH furnace refining, and continuous casting;

[0076] 2) Hot rolling: heat the slab of component number 2, the target hot rolling thickness is 3.2mm, rough rolling and finishing rolling of the slab to obtain a hot rolled plate, the final rolling temperature is 915°C to 930°C, and then the The hot-rolled sheet is cooled by laminar flow, and coiled into a hot-rolled coil after cooling. The coiling temperature is 676-712°C;

[0077] 3) cold rolling: the target cold rolling thickness is 0.60 mm, and the hot rolled plate is rolled after pickling;

[0078] 4) Annealing treatment: the temperature of the soaking section of the continuous annealing furnace is 765-770°C;

[0079] 5) Leveling and tension bridge: leveling elongation 0.58% + tension leveling elongation 0.15%, leveling wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com