Preparation method of single pure-phase bismuth ferrite material based on ionic compensation

A technology of bismuth ferrite and ions, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve problems such as segregation, volatile components of bismuth oxide, etc., achieve no impurity introduction, clear cubic crystal structure, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

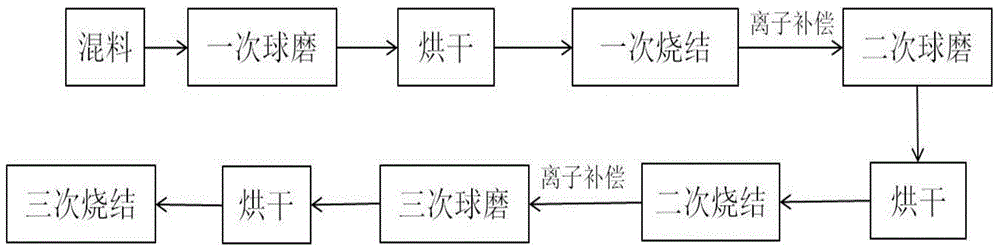

[0030] A preparation method of a single pure phase bismuth ferrite material, specifically comprising the following steps:

[0031] Step 1: Using bismuth oxide and iron oxide as raw materials, according to BiFeO 3 The proportion of metal elements in the mixture is converted into the mass percentage of bismuth oxide and iron oxide, and the materials are weighed and mixed, and then deionized water is used as the grinding medium, and wet ball milled in a planetary ball mill for 18 hours, so that the raw materials are fully mixed and evenly obtained. The mixed powder after ball milling; wherein, the rotating speed of the ball mill is 220 rpm, and the direction is alternated once every 1 hour;

[0032]Step 2: Dry the mixed powder obtained in step 1 after primary ball milling in a blast drying oven at 90°C to obtain a dried powder; then put the dried powder into a sintering furnace for the first Pre-sintering, the pre-sintering temperature is 700°C, the time is 1.5h, and the heating...

Embodiment 2

[0039] A preparation method of a single pure phase bismuth ferrite material, specifically comprising the following steps:

[0040] Step 1: Using bismuth oxide and iron oxide as raw materials, according to BiFeO 3 The proportion of metal elements in the mixture is converted into the mass percentage of bismuth oxide and iron oxide, and the materials are weighed and mixed, and then deionized water is used as the grinding medium, and wet ball milled in a planetary ball mill for 18 hours, so that the raw materials are fully mixed and evenly obtained. The mixed powder after ball milling; wherein, the rotating speed of the ball mill is 220 rpm, and the direction is alternated once every 1 hour;

[0041] Step 2: Dry the mixed powder obtained in step 1 after primary ball milling in a blast drying oven at 100°C to obtain a dried powder; then put the dried powder into a sintering furnace for the first Pre-sintering, the pre-sintering temperature is 700°C, the time is 1.5h, and the heati...

Embodiment 3

[0048] A preparation method of a single pure phase bismuth ferrite material, specifically comprising the following steps:

[0049] Step 1: Using bismuth oxide and iron oxide as raw materials, according to BiFeO 3 The proportion of metal elements in the mixture is converted into the mass percentage of bismuth oxide and iron oxide, and the materials are weighed and mixed, and then deionized water is used as the grinding medium, and wet ball milled in a planetary ball mill for 18 hours, so that the raw materials are fully mixed and evenly obtained. The mixed powder after ball milling; wherein, the rotating speed of the ball mill is 220 rpm, and the direction is alternated once every 1 hour;

[0050] Step 2: Dry the mixed powder obtained in step 1 after primary ball milling in a blast drying oven at 100°C to obtain a dried powder; then put the dried powder into a sintering furnace for the first Pre-sintering, the pre-sintering temperature is 700°C, the time is 1.5h, and the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com