High-strength polysaccharide-nano-laponite composite microsphere and preparation method thereof

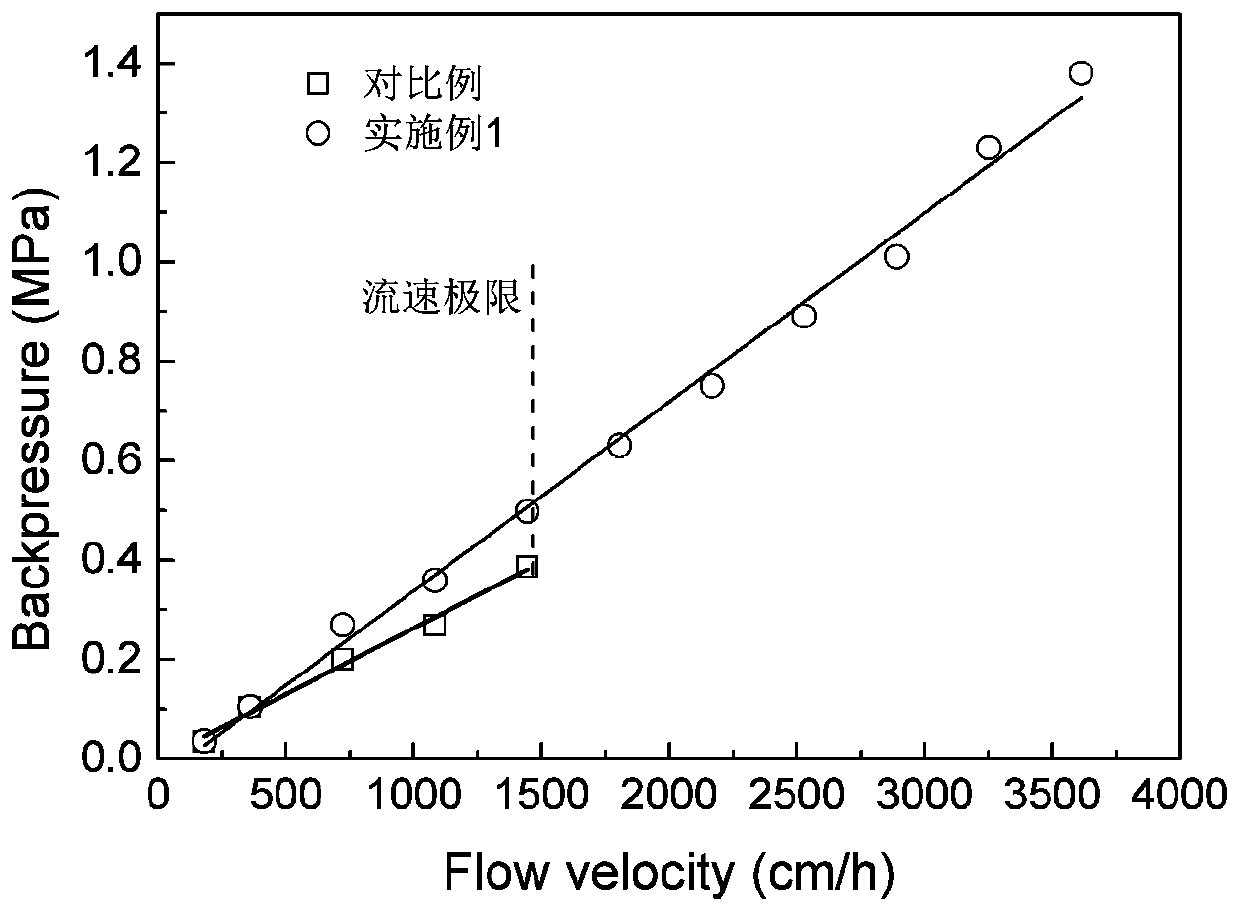

A technology of composite microspheres and lithium algae, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of low mechanical strength, inability to withstand high pressure and can only be operated at low flow rates, etc. Improved mechanical strength, wide application space, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

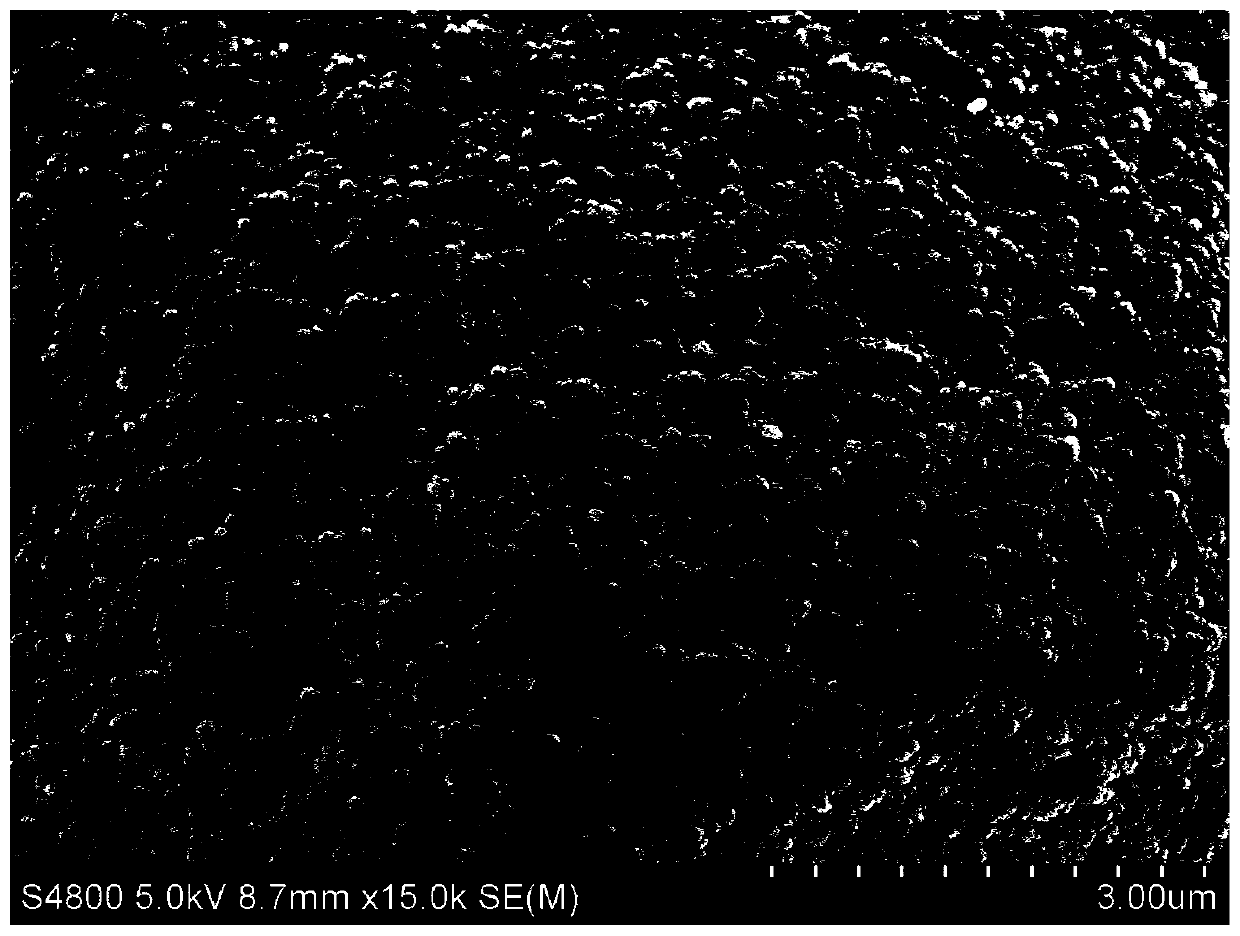

[0027] 1) Weigh agarose (0.6g), lepidolite (0.06g) and 10ml of ultrapure water into a 100ml round bottom flask as the water phase, and heat with magnetic stirring at 90°C until the solution is clear and transparent. In a 500ml three-neck flask equipped with mechanical stirring, add liquid paraffin (150ml), petroleum ether (50ml), Span 80 (7.2g) and Tween (0.8g) and heat up to 80°C as the oil phase. Add the above-prepared water phase into the oil phase for emulsification at 350 rpm for 40 min to obtain a white W / O emulsion.

[0028] 2) Slowly add a mixed solution of 4ml of crosslinking agent epichlorohydrin and 2ml of 45% NaOH dropwise to the above emulsion, further carry out crosslinking reaction at 80°C, and wash microspheres with petroleum ether, ethanol and deionized water successively after reacting for 8h. spheres to obtain agarose-nanometer lithium composite microspheres with an average particle size of 85 μm. After crosslinking, the composite microspheres were stored i...

Embodiment 2

[0030] 1) Weigh dextran T20 (1.0g), lepidolite (0.03g) and 25ml of ultrapure water into a 100ml round bottom flask as the water phase, and magnetically stir until the solution is clear and transparent. In a 250ml three-neck flask equipped with mechanical stirring, add olive oil (75ml) and PO 500 (2.25g) and heat up to 20°C as the oil phase. Add the above-prepared water phase into the oil phase for emulsification at 1000 rpm for 10 min to obtain a white W / O emulsion.

[0031] 2) Slowly add a mixed solution of 5ml of cross-linking agent ethylene glycol diglycidyl ether and 3ml of 65% KOH dropwise to the above-mentioned emulsion, and further carry out cross-linking reaction at 10°C. After 24 hours of reaction, use petroleum ether, ethanol and deionized The microspheres are washed with water to obtain dextran-nanometer lithium composite microspheres with an average particle size of 23 μm. After crosslinking, the composite microspheres were stored in 20% ethanol at 4°C.

Embodiment 3

[0033] 1) Weigh agarose (1.0g), lithium diatomaceous earth (0.1g) and 25ml of ultrapure water into a 100ml round bottom flask as the water phase, and heat with magnetic stirring at 90°C until the solution is clear and transparent. In a 250ml three-neck flask equipped with mechanical stirring, add chlorobenzene (75ml) and Span 80 (3g) and heat up to 60°C as an oil phase. Add the above-prepared water phase into the oil phase for emulsification at 450 rpm for 100 min to obtain a white W / O emulsion.

[0034] 2) Slowly add a mixed solution of 6ml of cross-linking agent epichlorohydrin and 3ml of 40% NaOH dropwise to the above emulsion, further carry out cross-linking reaction at 60°C, and wash the microgel with petroleum ether, ethanol and deionized water successively after reacting for 2 hours. spheres to obtain agarose-nanometer lithium composite microspheres with an average particle size of 125 μm. After crosslinking, the composite microspheres were stored in 20% ethanol at 4°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com