Preparation method of a double-layer composite self-assembled lubricating film

A self-assembly, lubricating film technology, applied in the directions of lubricating compositions, coatings, devices for coating liquids on surfaces, etc., can solve the problems of limited practical application, cannot be maintained for a long time, low bearing capacity, etc., and is easy to implement and popularize. , the effect of low energy consumption and cost, low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

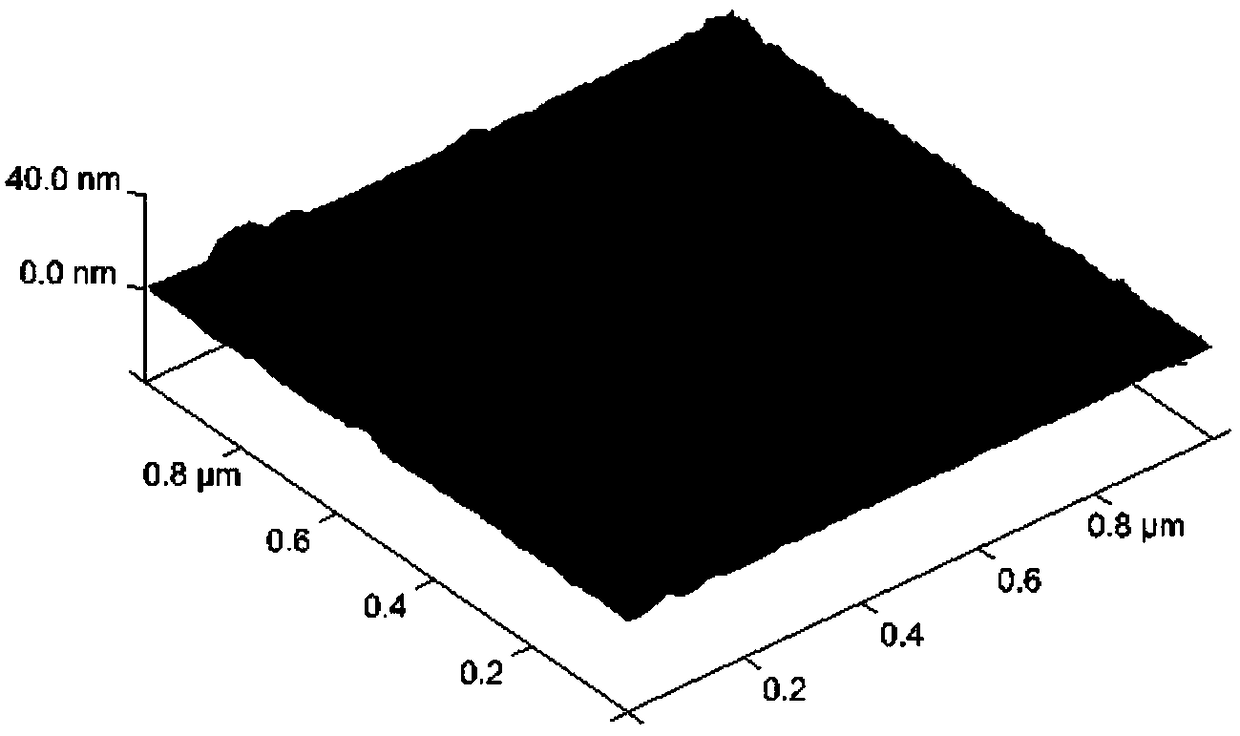

[0025] The preparation method of the double-layer self-assembled lubricating film of the present invention uses 1,2-bis(triethoxysilyl)ethane and a low surface energy silane coupling agent as raw materials, and is prepared by conventional self-assembly technology with stable , uniform and orderly microstructured double-layer film surface; the preparation method comprises the following steps:

[0026] (1) After the monocrystalline silicon wafer is cut into regular sizes, it is sequentially washed with organic solvent and water ultrasonically;

[0027] (2) At a temperature of 90°C, 98% concentrated H with a volume ratio of 7:3 is used. 2 SO 4 and 30%H 2 o 2 Composed of Piranha solution, oxidize the surface of single crystal silicon for 30 minutes to make the surface hydroxylated, and finally fully wash with deionized water and dry carefully;

[0028] (3) Fully hydrolyze 1,2-bis(triethoxysilyl)ethane in methanol / water mixed solvent; The fully hydrolyzed concentration in the ...

Embodiment 1

[0031] Example 1: Cut the monocrystalline silicon wafer into small pieces of 1cm × 1cm size, then immerse in acetone, chloroform, and isopropanol in order to ultrasonically clean for 10 minutes, then fully clean with deionized water, take it out and dry it carefully; The final monocrystalline silicon wafer is immersed in a 90°C Piranha solution for oxidation treatment to make the surface hydroxylated. The Piranha solution is 98% concentrated H 2 SO 4 and 30%H 2 o 2 The mixed solution, the volume ratio is 7:3; the monocrystalline silicon wafer is taken out after 30min treatment, fully cleaned with deionized water and carefully blown dry. Take a certain amount of 1,2-bis(triethoxysilyl)ethane and add it to methanol / water mixed solvent (16 / 1 by volume), control the pH of the system to 4.5, and make it hydrolyze at room temperature for 2 day; immerse the oxidized monocrystalline silicon wafer in the hydrolyzed solution of 1,2-bis(triethoxysilyl)ethane for 2 minutes; take out t...

Embodiment 2

[0033]Embodiment 2: After cutting, cleaning and oxidizing the monocrystalline silicon wafer according to the steps of Embodiment 1, fully clean it with deionized water and dry it carefully; take a certain amount of 1,2-bis(triethoxy silicon Base) ethane is added in the methanol / water mixed solvent, the volume ratio of methanol / water mixed solvent is 9 / 1, the pH of the control system is 5.0, and it is hydrolyzed at normal temperature for 3 days; The slice was immersed in the hydrolyzed solution of 1,2-bis(triethoxysilyl)ethane for 1min; the sample was taken out to be cleaned and dried, and then immersed in 1mM 3-aminopropyltriethoxysilane Self-assembled in a toluene solution for 0.5 h under a nitrogen-protected environment; the silicon wafer was taken out, washed and dried to obtain a self-assembled lubricating film with a double-layer structure.

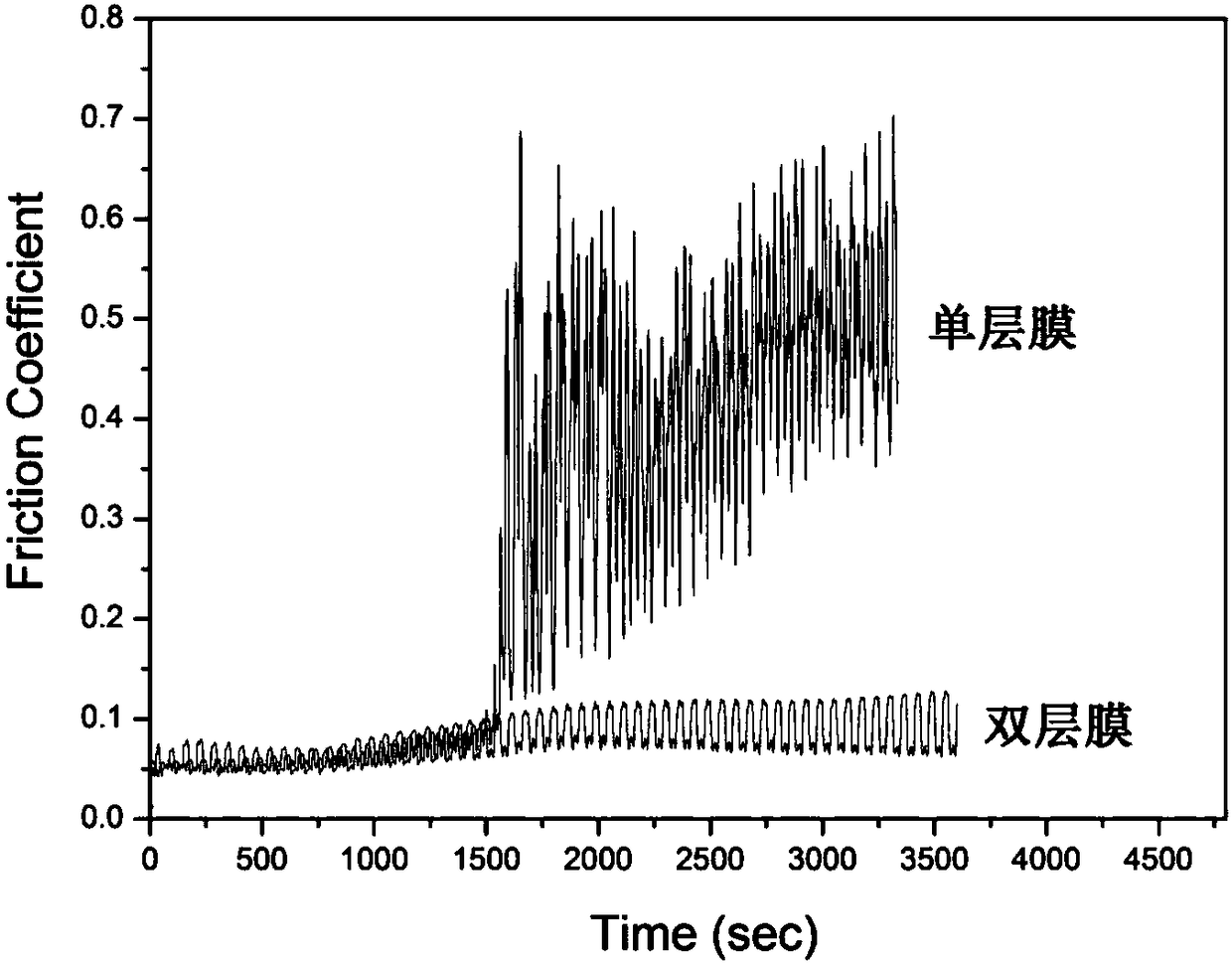

[0034] The oxidized single crystal silicon wafer was directly immersed in a toluene solution of 1mM 3-aminopropyltriethoxysilane, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com