Super-hydrophilic chitosan quaternary ammonium salt hydrogel composite membrane as well as preparation method and application thereof

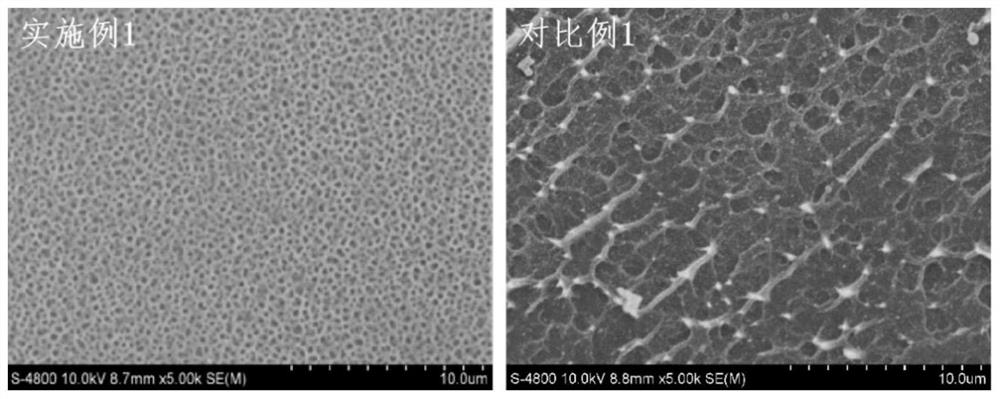

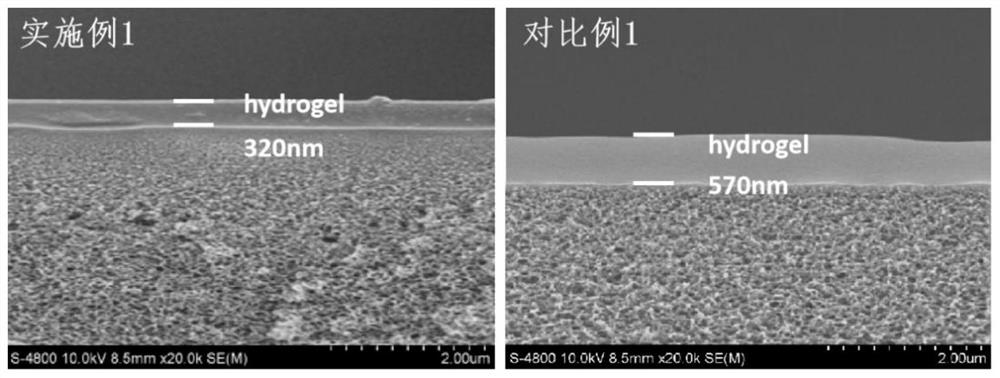

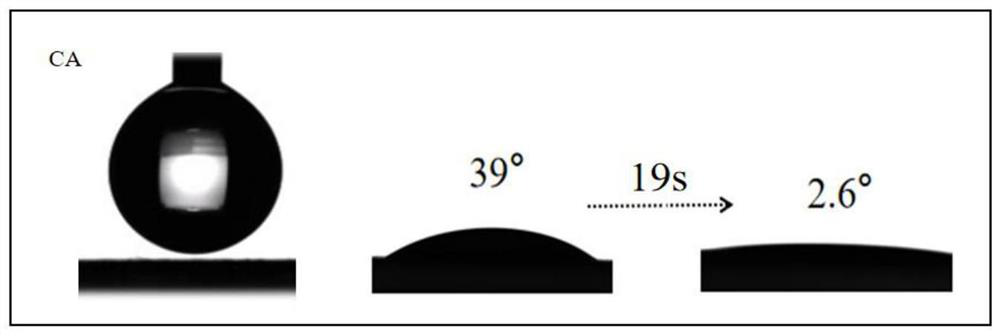

A chitosan quaternary ammonium salt, chitosan technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of shortening and reducing the thickness of the hydrogel layer, to improve flux and effectively intercept , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 2.0g of chitosan quaternary ammonium salt powder (purchased from Nantong Lvshen Bioengineering Co., Ltd., degree of substitution ≥ 90.0) into 58.0g of 2vol% acetic acid aqueous solution at 60°C for 7 hours with magnetic force stirring, and naturally cool to room temperature to obtain Transparent solution A;

[0027] (2) Add 1.5g N, N-methylenebisacrylamide (MBA) and 8.0g acrylamide (AM) to 30.4g 2vol% acetic acid aqueous solution for 1h, then add 0.10g initiator ammonium persulfate (APS) Continue stirring for 15 minutes to obtain solution B;

[0028] (3) Mix solution A and solution B at room temperature, and magnetically stir for 10 minutes to obtain a pregel solution with room temperature self-crosslinking function;

[0029] (4) Dry the polyethersulfone base film soaked in pure water overnight, fix it between the polytetrafluoroethylene plate frame with grooves, place it on a plane, and follow the 0.50g / cm 2 Coat the pre-gel solution prepared in step (3) on t...

Embodiment 2

[0031] (1) Add 2.0 g of chitosan quaternary ammonium salt powder to 58.0 g of 2 vol% acetic acid aqueous solution and stir magnetically at 60° C. for 7 hours, and cool naturally to room temperature to obtain a transparent solution A;

[0032] (2) Add 1.5g N, N-methylenebisacrylamide (MBA) and 8.0g acrylamide (AM) to 30.4g 2vol% acetic acid aqueous solution for 1h, then add 0.10g initiator ammonium persulfate (APS) Continue stirring for 15 minutes to obtain solution B;

[0033] (3) Mix solution A and solution B at room temperature, and mechanically stir for 10 minutes to obtain a pregel solution with room temperature self-crosslinking function;

[0034] (4) Dry the polyethersulfone base film soaked in pure water overnight, fix it between the polytetrafluoroethylene frame with grooves, place it on a plane, and add 0.75g / cm 2 The pre-gel solution is coated on the surface of the PES base film, cured at room temperature for 3 minutes, and this operation is repeated four times, and...

Embodiment 3

[0036] (1) Add 1.0 g of chitosan quaternary ammonium salt powder to 59.0 g of 2 vol% acetic acid aqueous solution, stir magnetically at 60° C. for 6 h, and naturally cool to room temperature to obtain a transparent solution A;

[0037] (2) Add 1.0g of N,N-methylenebisacrylamide (MBA) and 6.0g of acrylamide (AM) to 32.95g of 2vol% acetic acid aqueous solution to dissolve for 1h, then add 0.05g of initiator ammonium persulfate (APS) Continue stirring for 15 minutes to obtain solution B;

[0038] (3) Mix solution A and solution B at room temperature, and magnetically stir for 10 minutes to obtain a pregel solution with room temperature self-crosslinking function;

[0039] (4) Dry the polyethersulfone base film soaked in pure water overnight, fix it between the polytetrafluoroethylene frame with grooves, place it on a plane, and add 0.75g / cm 2 The pre-gel solution is coated on the surface of the PES base film, cured at room temperature for 3 minutes, and this operation is repeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com