Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "To achieve the purpose of degreasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for reducing ash content of pyrolysis carbon black of waste tires and recovering Zn

ActiveCN110760204AEfficient recyclingImprove the performance of pyrolysis carbon blackPigmenting treatmentProcess engineeringResidual oil

The invention relates to a system and a method for reducing the ash content of pyrolysis carbon black of waste tires and recovering Zn. The system comprises a distillation chamber, a first condensation tower and a second condensation tower which are sequentially connected, wherein the first condensation tower is also connected with a zinc collecting tank; the second condensation tower is also connected with an oil collecting tank and a tail gas treatment device; and the distillation chamber is connected with a vacuum pump. According to the method disclosed by the invention, the pyrolysis carbon black is reprocessed by using a vacuum distillation chamber, carbon black and zinc oxide in the pyrolysis carbon black are subjected to a carbothermic reduction reaction under a high-temperature vacuum environment to generate zinc and vaporize at a high temperature, condensation recovery is realized, and residual oil in the carbon black is removed by high-temperature vaporization at the same time; according to the method disclosed by the invention, the ash content of the pyrolysis carbon black can be reduced, the performance of the pyrolysis carbon black is greatly improved, meanwhile, the purposes of recovering zinc and removing excess oil are achieved, the treated carbon black achieves the purposes of deodorization and oil removal, the ash content of the treated carbon black can be obviously reduced, and the recovery rate of crude zinc and oil is high.

Owner:珠海格力绿色再生资源有限公司

Comprehensive treatment agent and use method thereof

InactiveCN103436872AAvoid time costReduce processing costsMetallic material coating processesThioureaPhosphate

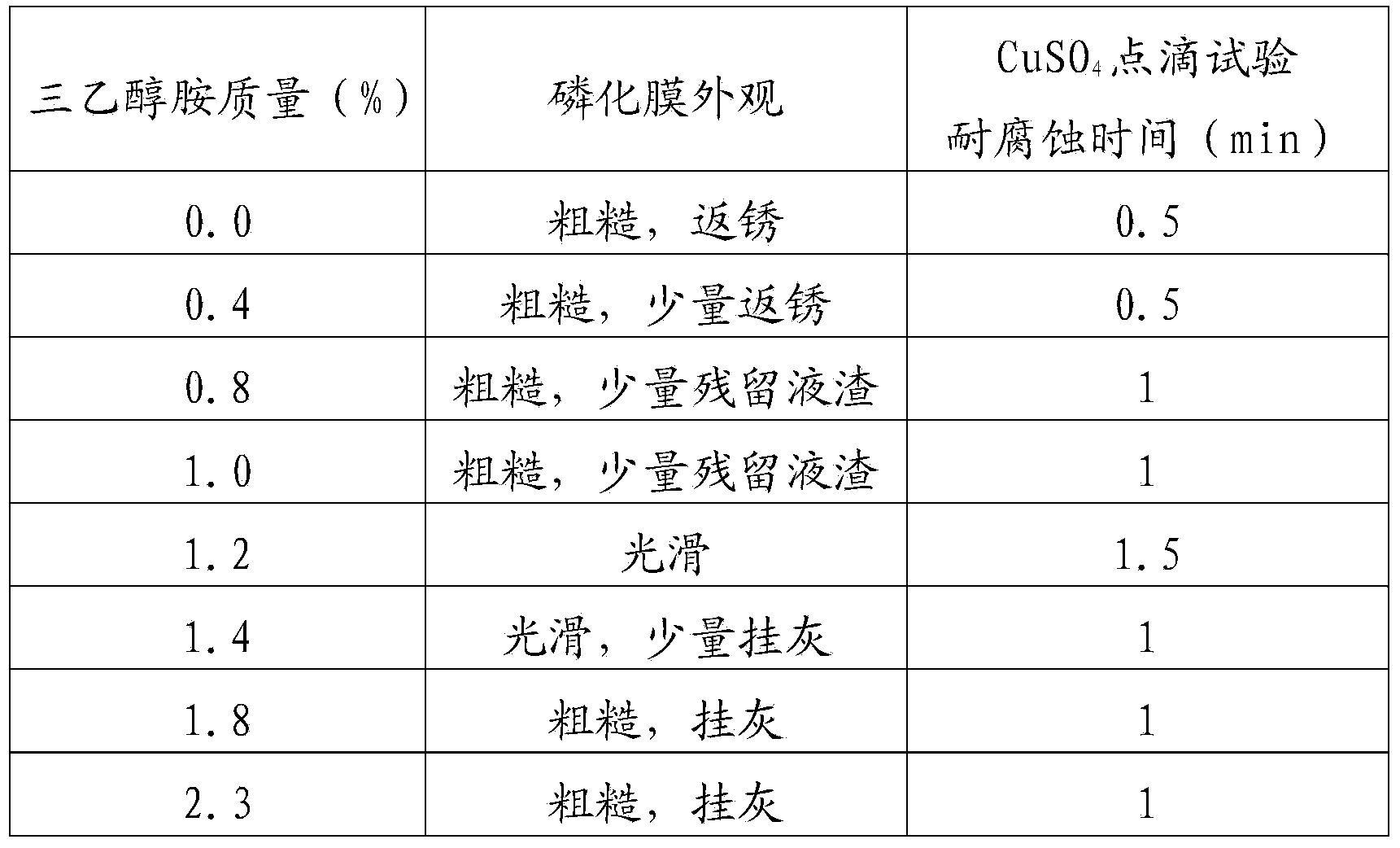

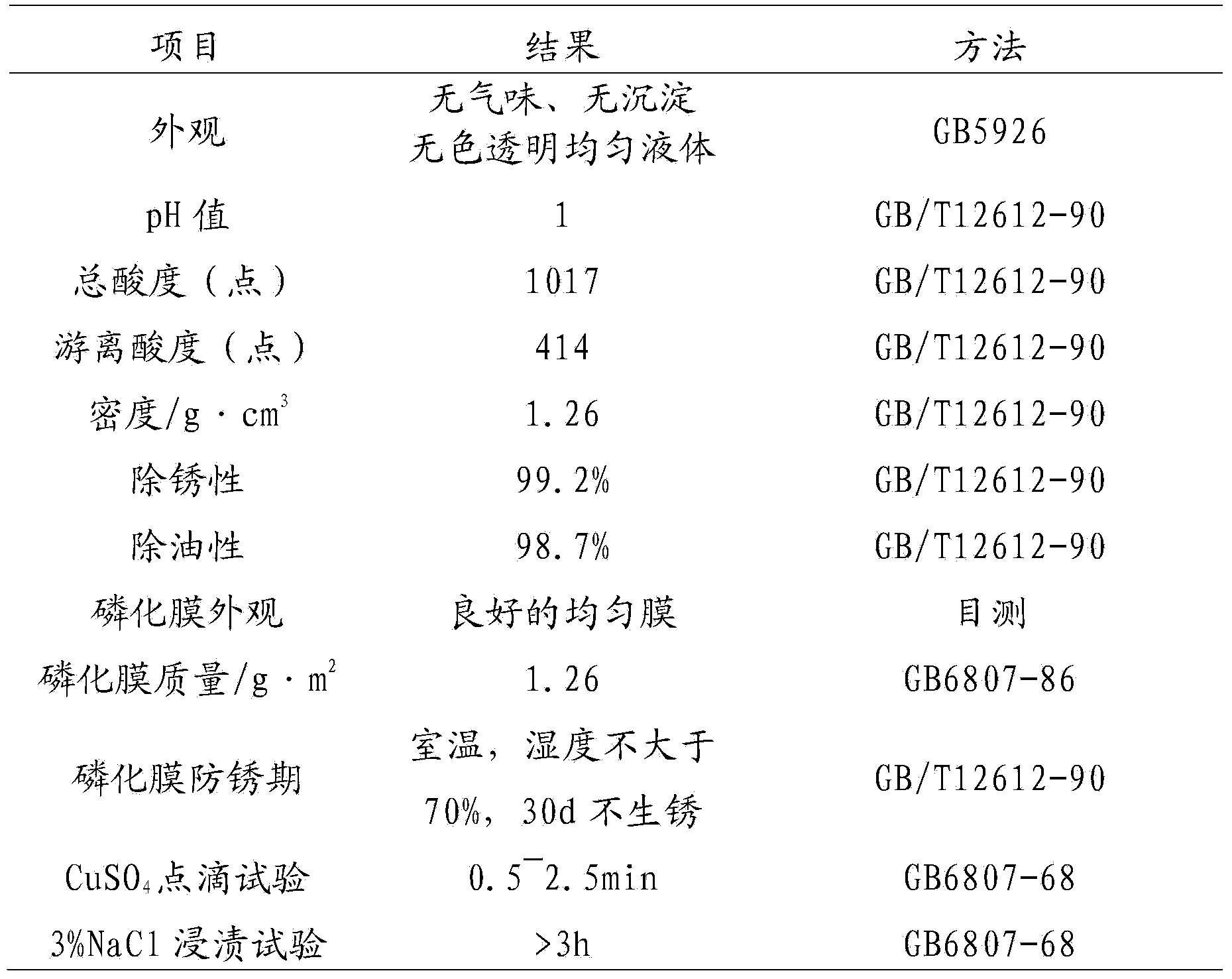

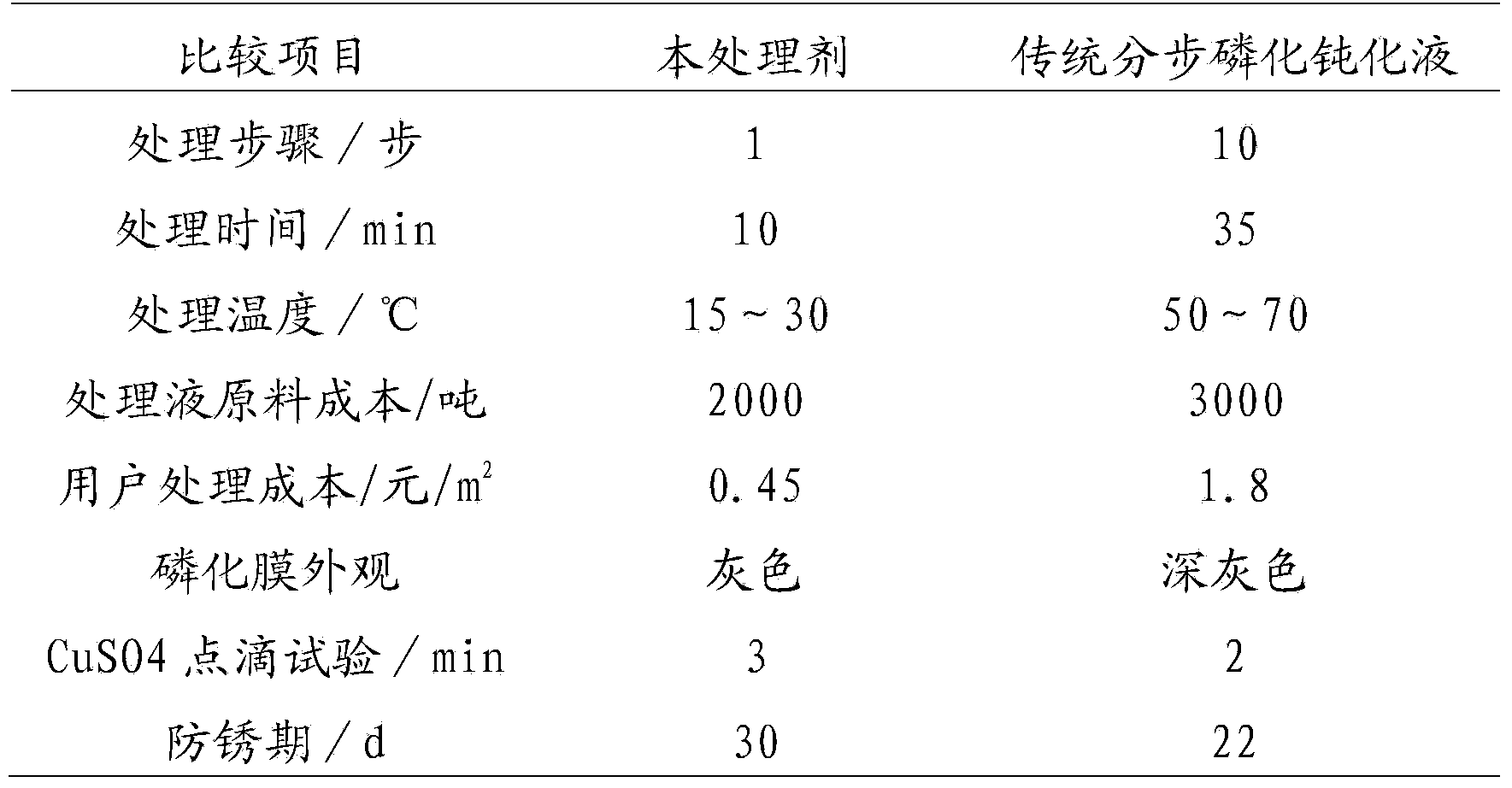

The present invention relates to a comprehensive treatment agent, which comprises, by mass, 25.0-30.0% of phosphoric acid, 1.0-3.0% of zinc oxide, 0.1-0.5% of sodium molybdate, 4.0-7.0% of zinc dihydrogen phosphate, 0.3-1.2% of potassium chlorate, 0.3-1.2% of a surfactant, 0.0-2.3% of triethanolamine, 0.8-2.3% of citric acid, 0.1-0.3% of thiourea, and 58.0-62.6% of water. According to the present invention, the treatment agent can be recycled, a treatment cost is low, and pollution on the environment can not be generated.

Owner:谢俊磊

Fish-skin degreasing method

The invention belongs to the field of aquatic product processing and specifically relates to a fish-skin degreasing method, which comprises the following steps of: immersing fish-skin, cutting into pieces, adding an alkaline lipase enzyme preparation which has pH value of 8.0 and vitality of 50-80U / mL and is 4-6 times as heavy as the fish-skin, carrying out enzymatic hydrolysis at 35+ / -2 DEG C for 25-85 min, heating up to 60-80 DEG C for killing enzyme, cooling to room temperature, filtering, washing off aliphatic acid and residual fat generated from enzymatic hydrolysis by using alkali lye, and washing off alkali lye and other impurities by using deionized water. The invention has advantages of simple technology, mild condition and high degreasing rate, and is suitable for expansion and mass production.

Owner:ZHEJIANG MARINE DEV RES INST

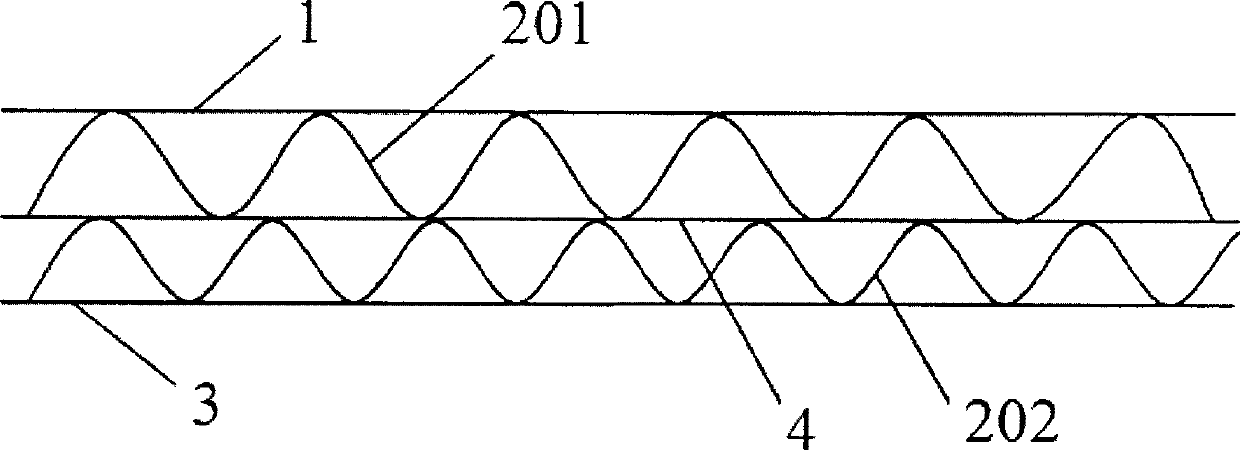

High-intensity water-resistance corrugated board and preparation method thereof

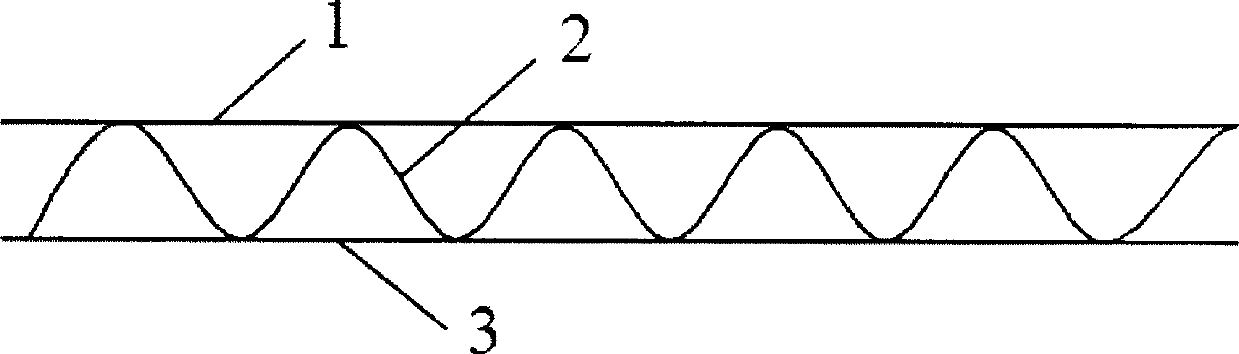

ActiveCN103103891AHigh water resistance strengthStrong water resistanceNon-fibrous pulp additionMechanical working/deformationCardboardAdhesive

The invention discloses a high-intensity water-resistance corrugated board and a preparation method of the high-intensity water-resistance corrugated board according to the national standard GB / T22873-2008. The high-intensity water-resistance corrugated board comprises surface paper and inner paper, wherein a corrugated paper layer is arranged between the surface paper and the inner paper; a high-intensity water-resistance adhesive is coated between the peak surface of the corrugated paper layer and the surface paper as well as the inner paper; a special water-resistance additive is added into the conventional corrugated board adhesive; and various technological parameters of a board automatic line are optimized by an ultrafine particle pulping technology, so that the water resistance of the corrugated board is greatly improved and is much higher than the advanced level of products of the same type in foreign countries.

Owner:DACHENG PACKAGING PROD SUZHOU

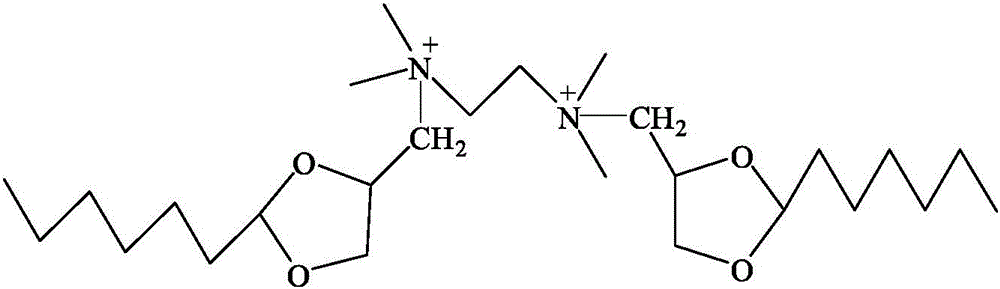

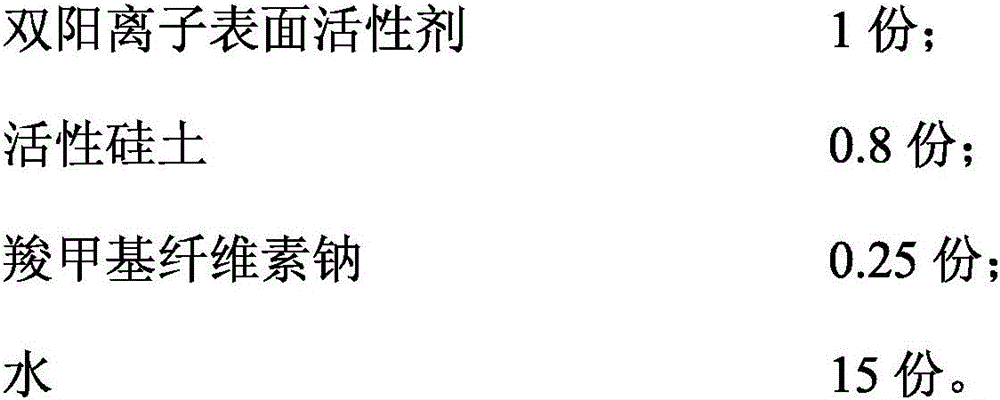

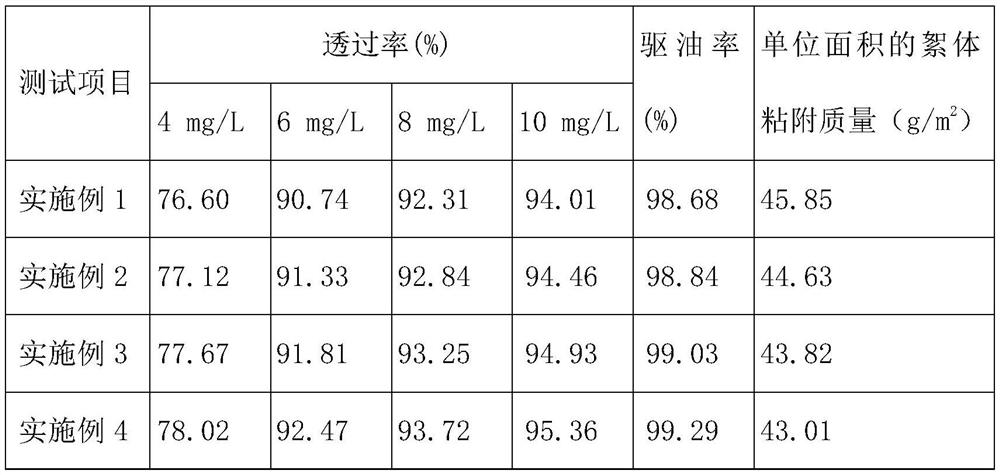

High-temperature high-salt resistant thick oil thermal recovery sewage degreasing agent and preparation method thereof

ActiveCN106348362AGood flocculation effectHigh activityWaste water treatment from quariesWater treatment compoundsSalt resistanceSewage

The invention belongs to the technical filed of oil field sewage treatment, and in particular relates to a high-temperature high-salt resistant thick oil thermal recovery sewage degreasing agent which is compounded from a dication surfactant, activated silica, sodium carboxymethylcellulose and water, wherein the dication surfactant is a symmetric molecule with long-carbon-chain alkyl and biquaternary ammonium salt cation polar groups. The degreasing agent provided by the invention has the characteristics of simple preparation process, low cost and good temperature and salt resistance, the mineralization resistance degree of the degreasing agent can be up to 250000mg / L, the temperature resistance of the degreasing agent is up to 250 DEG C, and a good degreasing effect can be achieved; the degreasing rate of thick oil thermal recovery sewage can be greater than 96%, and compared with that of a conventional agent, the degreasing rate of the degreasing agent is increased by more than 40%. Therefore, the degreasing agent can be widely applied to degreasing processes of thick oil thermal recovery sewage.

Owner:深圳市亿歌润滑科技有限公司

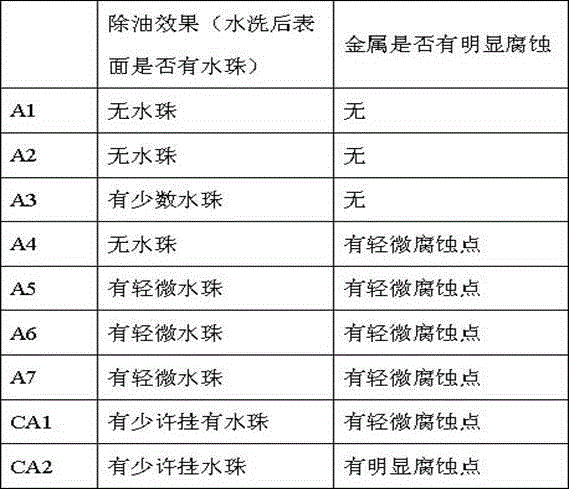

Environment-friendly type metal surface degreasant and manufacturing method thereof

The invention provides an environment-friendly type metal surface degreasant. The environment-friendly type metal surface degreasant is composed, by weight, ten percent to 30 percent of saponin, five percent to 15 percent of fatty acid amide, five percent to 15 percent of sodium hydroxide, two percent to ten percent of sodium phytate, and the balance water. The environment-friendly type metal surface degreasant is efficient, economical and environmentally friendly. According to the environment-friendly type metal surface degreasant, the metal surface can be rapidly degreased, short-term interprocess corrosion can be carried out on the metal surface, and the environment-friendly type metal surface degreasant is easy to use, safe, efficient, free of peculiar smell and low in foam. The environment-friendly type metal surface degreasant has the advantages of being simple in waste liquid treatment and the like, and the degreasant is an ideal product which is green and clean in production. The invention further provides a manufacturing method of the environment-friendly type metal surface degreasant. The production process is simple, and the cost is low. In addition, the invention provides a method for using the environment-friendly type metal surface degreasant. Degreasing can be rapidly carried out at the using temperature from the normal temperature to the high temperature, the environment-friendly type metal surface degreasant can be suitable for scrubbing and flushing large-scale equipment and ultrasonically cleaning a small-type workpiece, and the environment-friendly type metal surface degreasant has the effect of rapidly removing various kinds of grease on the metal surface.

Owner:HUAINAN TIANLI BIOLOGIC TECH

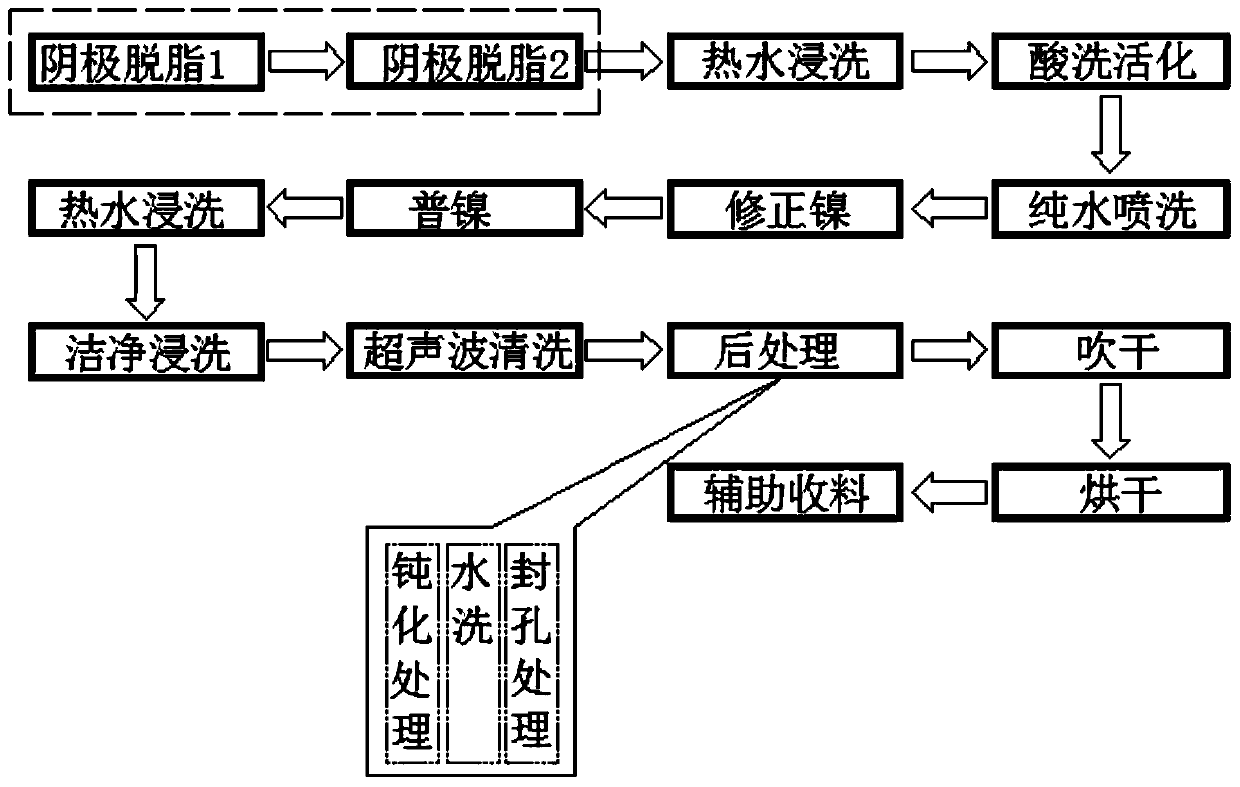

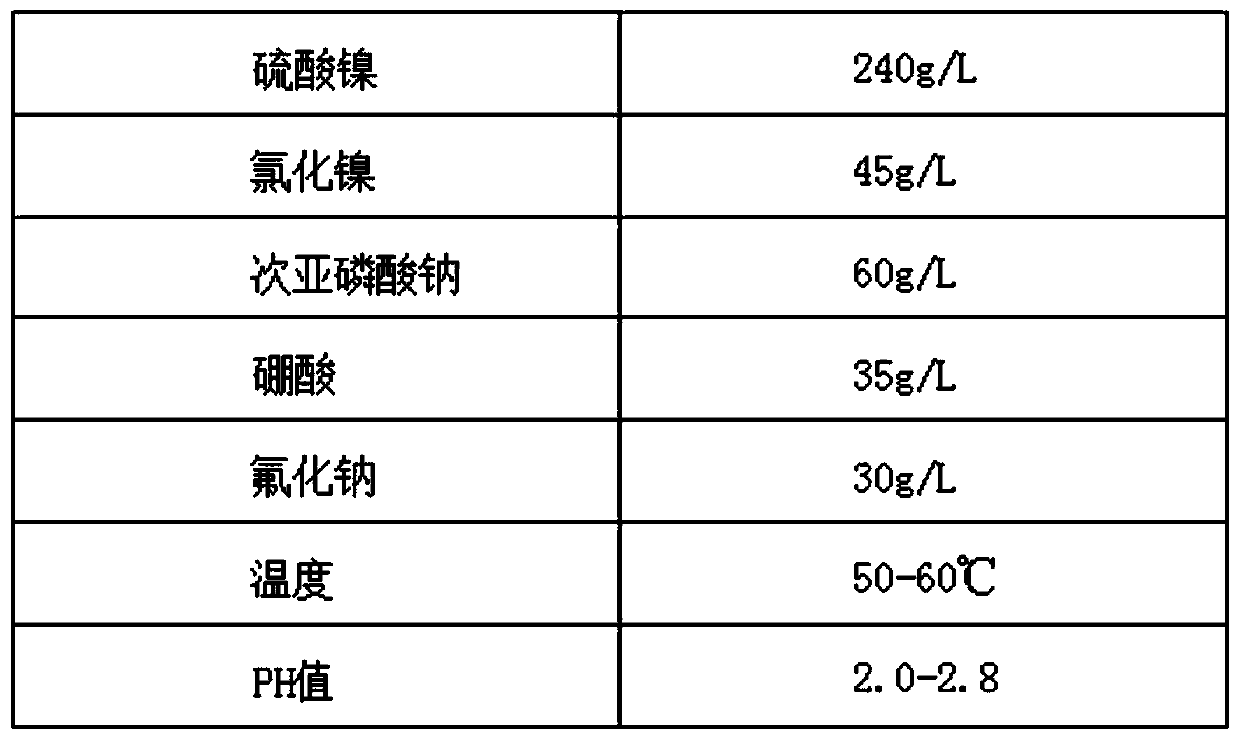

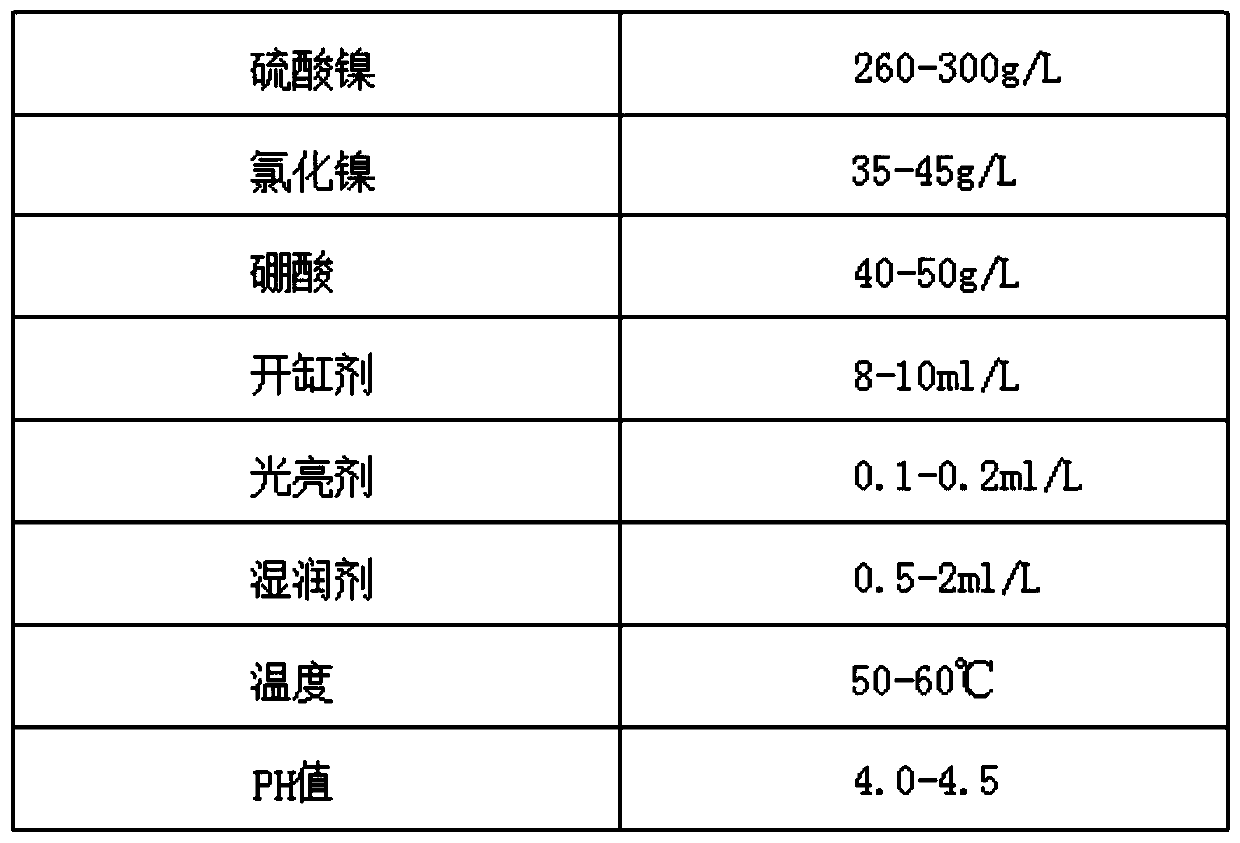

Copper alloy electroplating technology

ActiveCN109957822AImprove appearance cohesionReduce porosityMetallic material coating processesPorosityWater immersion

The invention discloses a copper alloy electroplating technology, and belongs to the technical field of electroplating. The copper alloy electroplating technology comprises the following steps of: step one. degreasing; step two. carrying out hot water immersion; step three. carrying out pickling activation; step four. carrying out spray rinsing by using pure water; step five. correcting nickel; step six. common nickel; step seven. carrying out hot water immersion; step eight. carrying out cleaning immersion; step nine. carrying out ultrasonic cleaning; step ten. carrying out post-processing; step eleven. drying; step twelve. drying; and step thirteen. carrying out auxiliary receiving. By extending and optimizing the pre-treatment process line, the copper alloy electroplating technology canprovide an electroplating plane of follow-up coating deposition and increases the appearance binding force of a coating. Crystal lattices of the nickel coating are significantly improved by using thecorrecting nickel for priming in the electroplating process, so that the structure is tight, the crystal lattices are refined, the porosity of the coating is reduced, thus, the uniformity and glossiness of the common nickel layer appearance are ensured; and a perfect cleaning process is developed and led to cooperate with passivation treatment and hole sealing treatment, so that the corrosion resistance of the coating is greatly enhanced.

Owner:东莞市康圣精密合金材料有限公司

Preparation method of dried salted large yellow croakers

InactiveCN108739968AIncrease contact surfaceFully infiltratedMeat/fish preservation by heatingFood ultrasonic treatmentUltrasonic assistedCold storage

The present invention provides a preparation method of dried salted large yellow croakers. The dried salted large yellow croakers are prepared by pre-treating, fish flesh perforating, ultrasonic assisted pickling, low-temperature dehydrating, quantifying, vacuum packaging and mild sterilizing. The prepared instant dried salted large yellow croakers can also be preserved for a long term; the quality of the product is improved; and the dried salted large yellow croakers have a shelf life of 30-60 days at a normal temperature and a shelf life of 300-360 days at a cold storage, and overcome problems that the processed dried salted large yellow croakers by using the prior art are high in oil content, need cold storage, are hard in texture, poor in mouthfeel, short in time, etc.

Owner:NINGDE CITY YUEHAI AQUATIC PROD

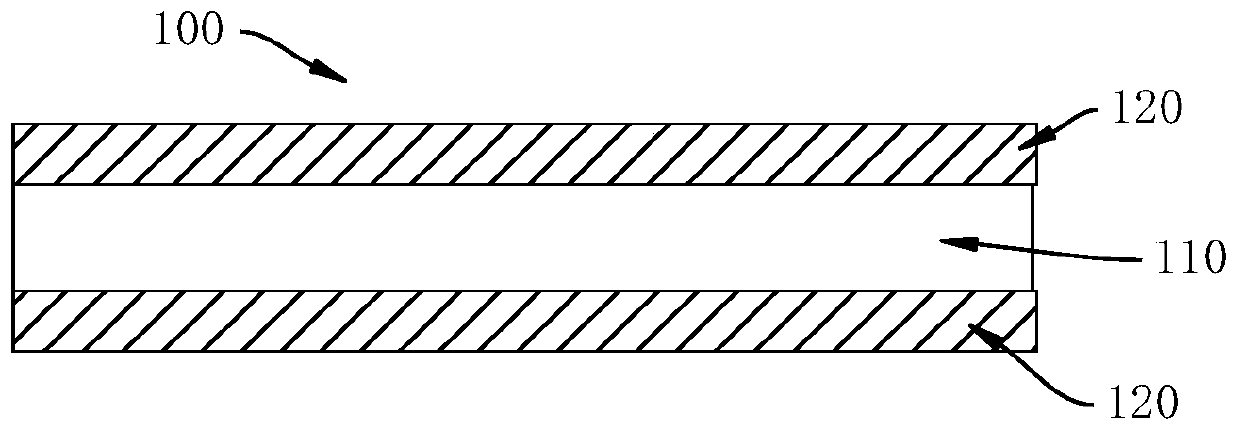

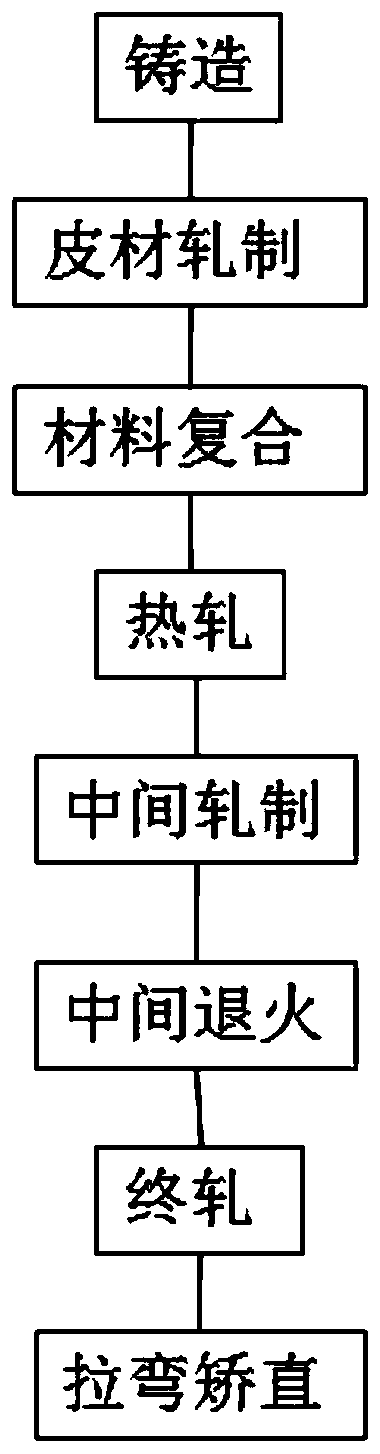

Preparation method for brazing aluminum alloy material and brazing aluminum alloy material

InactiveCN111299322AReduce usageTo achieve the purpose of degreasingWork heating devicesMetal rolling arrangementsAluminium alloyBrazing

The invention provides a preparation method for a brazing aluminum alloy material and the brazing aluminum alloy material. The preparation method for the brazing aluminum alloy material comprises thesteps that material compositing is carried out, specifically, a core material and a skin material are composited to obtain a composite material; hot rolling is carried out, specifically, the compositematerial is preheated, and the preheated composite material is subjected to hot rolling until the thickness is 5-10 mm to obtain a hot-rolled plate strip; intermediate rolling is carried out, specifically, the hot-rolled plate strip is subjected to intermediate cold rolling to obtain a cold-rolled strip foil; intermediate annealing is carried out, specifically, the cold-rolled strip foil is subjected to recrystallization annealing to obtain an O-state strip foil; final rolling is carried out, specifically, the O-state strip foil is subjected to final cold rolling until the thickness is 0.4-3.0 mm to obtain a finally-rolled strip foil; and stretch bending and straightening are carried out, specifically, the finally-rolled strip foil is corrected, and the corrected strip foil is baked through a roaster at a preset speed. According to the method, a plate is baked through the roaster, and the no-clean brazing aluminum alloy material is obtained.

Owner:YINBANG CLAD MATERIAL

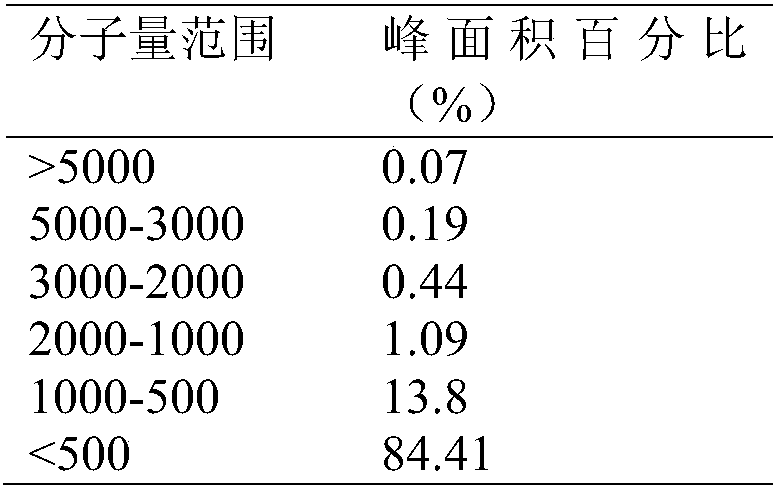

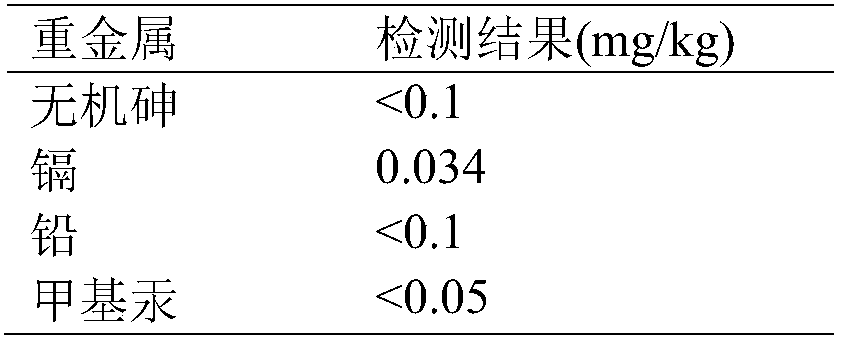

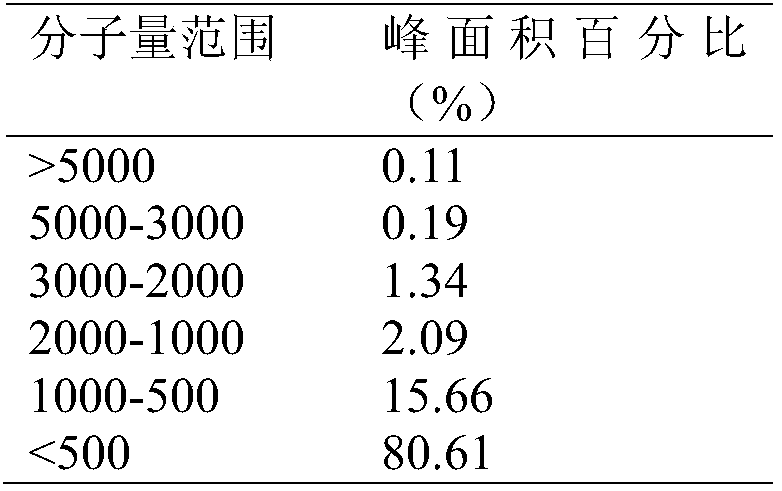

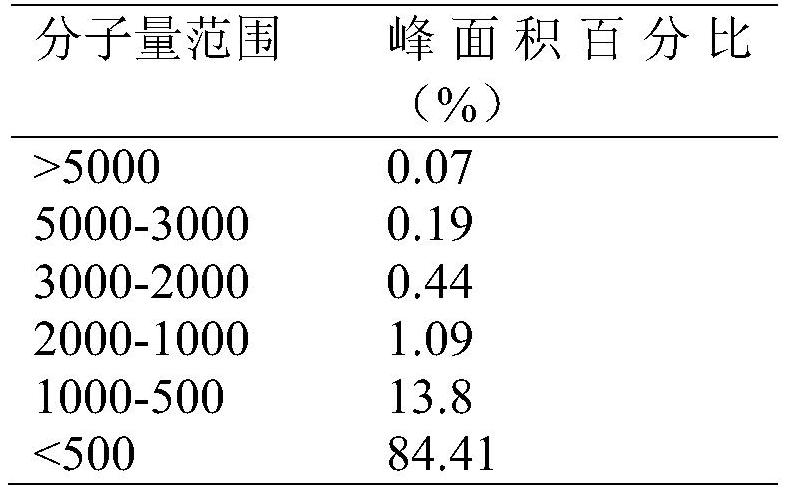

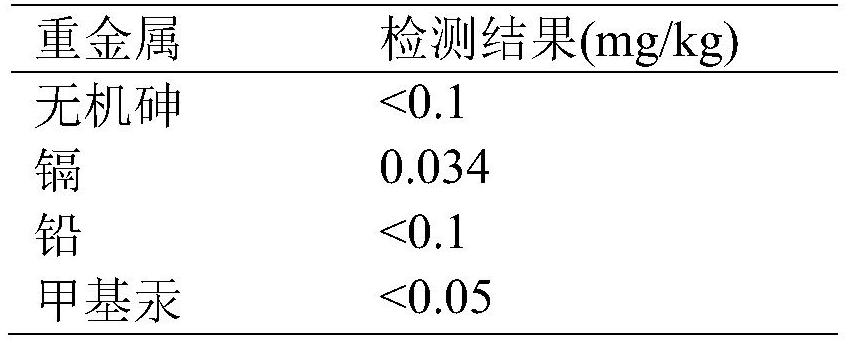

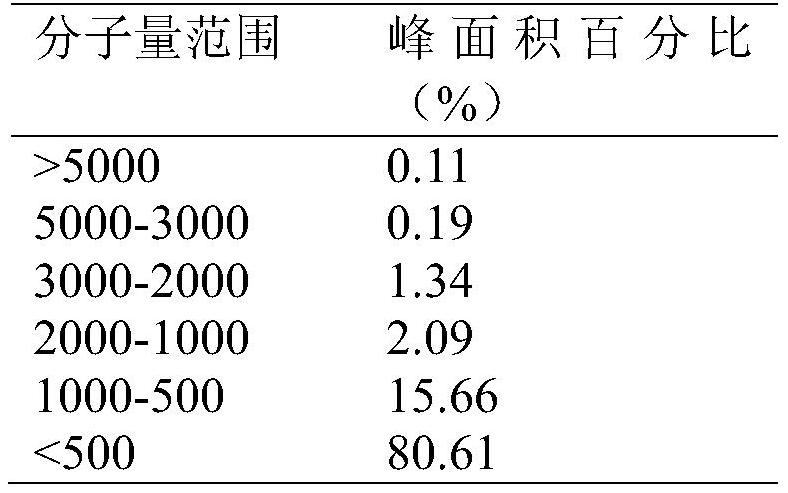

Compound oligopeptide capable of improving sexual functions and resisting fatigue, oral preparation of compound oligopeptide and preparation method of oral preparation

ActiveCN109007848AIncrease varietyIncrease ratingsProtein composition from fishFood shapingSexual functionMedicine

The invention provides compound oligopeptide capable of improving sexual functions and resisting fatigue, an oral preparation of the compound oligopeptide and a preparation method of the oral preparation to overcome the defects of Chinese herbal medicines in improvement of the sexual function in the prior art. The compound oligopeptide is prepared from main raw materials including oyster oligopeptide and walnut oligopeptide and Chinese yam polysaccharide used as an auxiliary material. The compound oligopeptide is prepared from main raw materials including oyster oligopeptide and walnut oligopeptide which are extracted from purely natural and edible biomaterials and the Chinese yam polysaccharide used as the auxiliary material, the oral preparation in different dosage forms is prepared fordifferent application conditions, and the oral preparation can effectively relieve fatigue and improve the sexual functions.

Owner:河南东肽生物有限公司

Degreaser and preparation method thereof

InactiveCN104673505AExtended service lifeLess corrosiveInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSURFACTANT BLENDMetal

The invention provides a degreaser and a preparation method thereof. The degreaser comprises an emulsifier, a complexing agent, a surfactant and an adsorbent; and the adsorbent is aluminum hydroxide. The invention also provides a preparation method of the degreaser. The degreaser has an excellent degreasing effect, and has an extremely good protection effect on metals in a degreasing solution.

Owner:BYD CO LTD

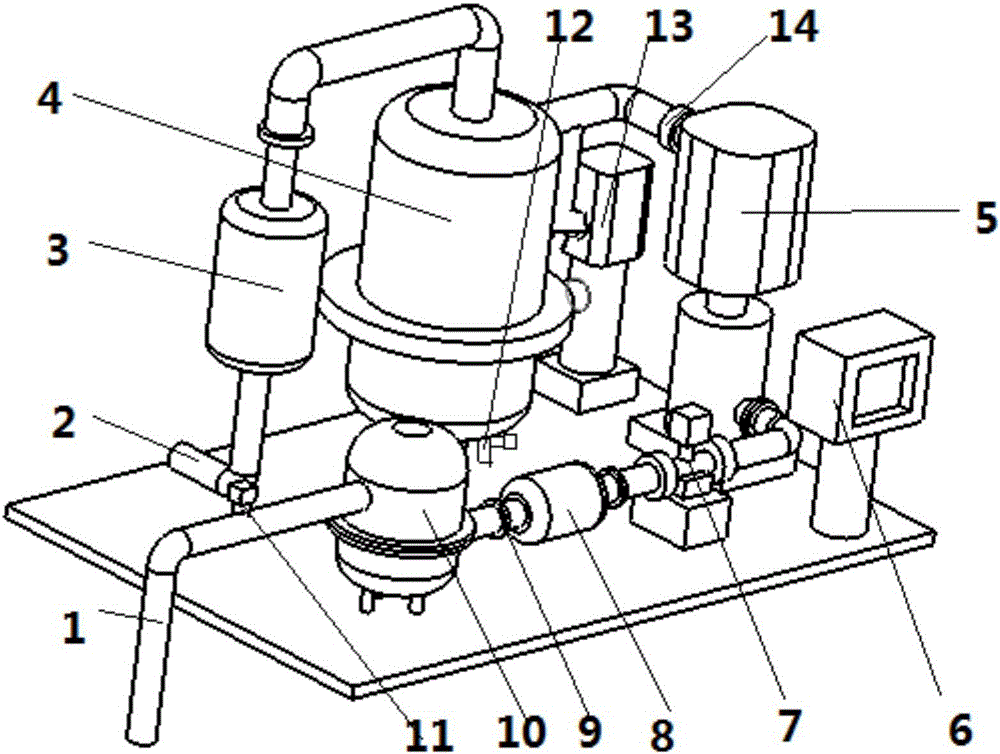

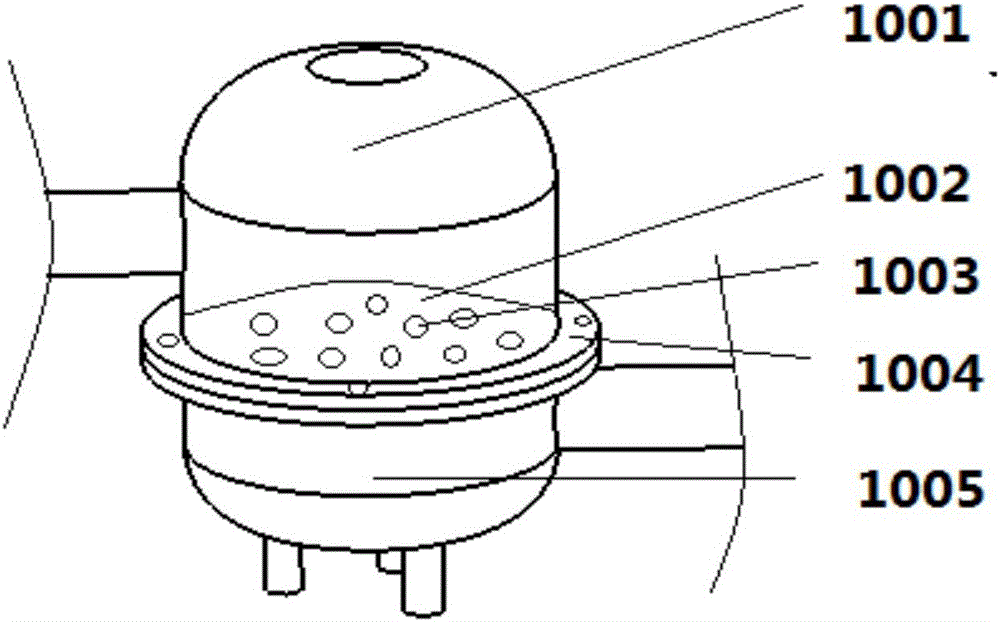

Wastewater treatment apparatus allowing recycling

InactiveCN106145495AEfficient separationSave energyFatty/oily/floating substances removal devicesWater contaminantsElectromagnetic valveWater pipe

The invention provides a recyclable waste water treatment equipment, comprising a base and a crude oil filter device, a fine oil filter device, a solenoid valve, a first water pump, an evaporator and a condenser placed on the base and connected sequentially through pipelines, The first water pump is controlled by the solenoid valve to suck out the waste water and pass through the coarse oil filter device and the fine oil filter device in turn, and the deoiled waste water enters the evaporator through the first water pump, and the evaporator passes through the second water pump and the outlet of the first water pump End connection, the coarse oil filter device includes the first filter device and the second filter device placed below it through flange connection, and a filter plate is arranged between the two, the water inlet pipeline is placed on the first filter device, and the outlet pipe The road is placed on the second filter device. The recyclable wastewater treatment equipment of the present invention enables industrial wastewater to be recycled, reduces the discharge of industrial wastewater, optimizes the surrounding environment and reduces the production and processing costs of enterprises.

Owner:TIANJIN XINYUE JINZHAO TECH DEV

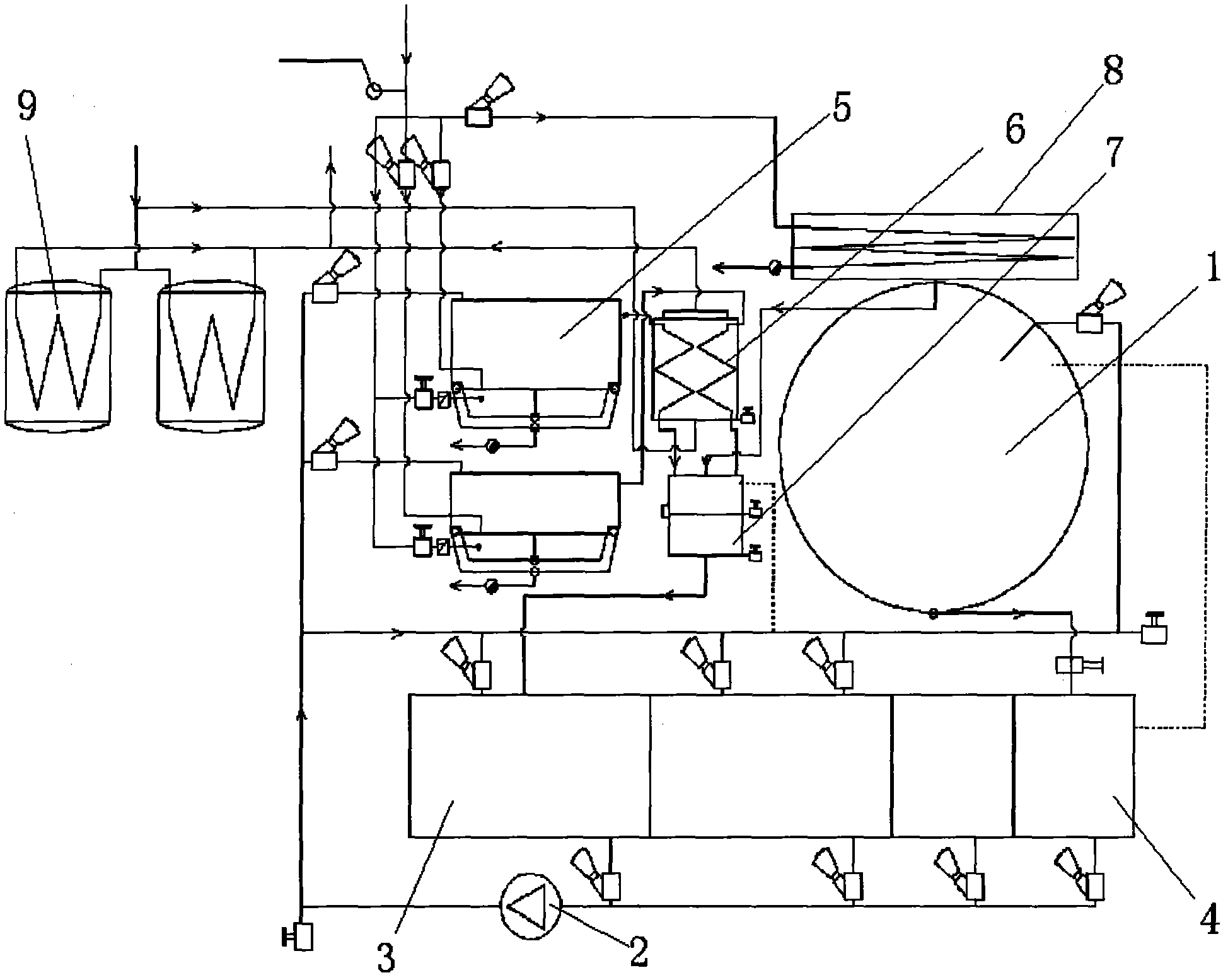

Environment-purifying and pollution-preventing method and device for manufacturing fur coats from goose down fur

InactiveCN101982548AQuality improvementNo toxicityTanning treatmentPre-tanning chemical treatmentAcetic acidMildew

The invention relates to an environment-purifying and pollution-preventing method and device for manufacturing fur coats from goose down fur, which can effectively purify the environment and prevent pollution. The method of the invention comprises the following steps: firstly, carrying out hydrophilic softening on the goose down fur by a formula of adding 1g of Eusapon S, 10g of industrial salt, 2g of anti-mildew agent 3 and 1g of sodium carbonate to 1 liter of water; then carrying out manual grease pressing and mechanical grease pressing; pickling by a formula of adding 3g of Bascal S, 20g of industrial salt, 2g of formic acid and 2g of acetic acid to 1 liter of water; then tanning by a formula of adding 10-15g of 781 tanning agent, 20g of industrial salt, 25g-30g of glauber salt, 2g of penetrating agent JFC and 3g of sodium carbonate to 1 liter of water; and finally carrying out solvent degreasing by an environment-friendly full-closed goose down fur degreasing machine. The invention can effectively improve the product quality of the fur coats of goose down fur, and can purify the environment and prevent pollution.

Owner:陈仲仁 +2

A method for color retention and degreasing of wood

ActiveCN107214800BImprove permeabilityGood degreasing effectPressure wood treatmentWood treatment detailsPre treatmentLiquid nitrogen

The invention relates to a method for wood color preserving and degreasing and belongs to the technical field of wood treatment. According to the method, to-be-degreased wood is soaked with water, sprayed with liquid nitrogen, frozen and dried to obtain dry wood; the dry wood is subjected to micro-blasting to obtain pre-treated wood; tea bran is ground, mixed with water, subjected to heating boiling and centrifugal treatment, and separated to obtain upper layer liquid, the upper layer liquid is concentrated to obtain concentrated liquid, and then the concentrated liquid, a sodium bicarbonate solution, potassium permanganate and the like are evenly stirred to obtain self-prepared degreasing color preserving liquid; and then the self-prepared degreasing color preserving liquid is put into a steam generator, the pre-treated wood is treated through steaming, and wood degreasing can be finished. Wood permeability is effectively improved, the wood degreasing rate is remarkably increased, and meanwhile the good color preserving effect is achieved.

Owner:安徽嘉美工艺品有限公司

Preparation method for extracting saponin powder by using camellia seed cake

InactiveCN104892718ATo achieve the purpose of degreasingKeep drySugar derivativesSteroidsLiquid ratioTon

The invention discloses a preparation method for extracting a saponin powder by using a camellia seed cake. The preparation method comprises the steps: drying and crushing the camellia seed cake, adding into a proper amount of a methanol solution according to the material-liquid ratio of 1:(4-8), leaching for 1-2 h at the temperature of 55 DEG C-75 DEG C, concentrating, and precipitating to obtain the product. Compared with a conventional extraction method, the method has the advantages of short extraction time, high extraction rate of the saponin powder, high purity, comprehensive utilization of the camellia seed cake resource and the like. The extraction rate of the saponin powder can reach 93.5% or more, the purity of the saponin powder is 80.7% or more, and 28 kg of proteins can be extracted from per ton of the camellia seed cake.

Owner:HUNAN TIANJIN TECH

Ultrasonic oil-water separation device

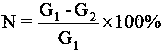

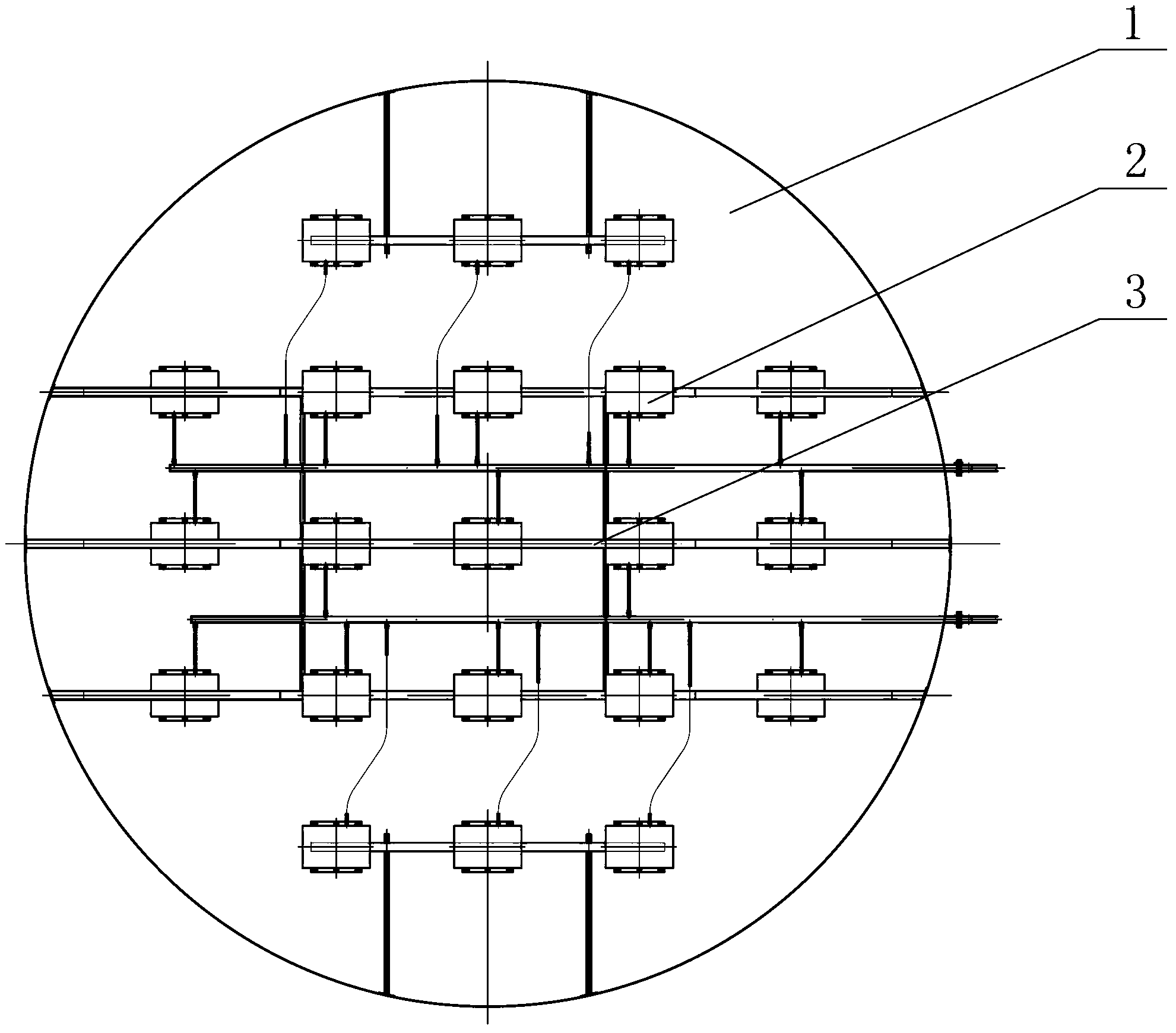

InactiveCN102698472AEvenly dispersedLow mechanical strengthEnergy based chemical/physical/physico-chemical processesLiquid separationUltrasound - actionWater storage tank

The invention discloses an ultrasonic oil-water separation device, which comprises a water storage tank. The device is characterized in that a plurality of ultrasonic transmitting vibrating plates are arranged in the water storage tank. The device has the advantages that ultrasonic acts on oil-containing wastewater, so that the oil-water separation effect is good, the recovery rate of oil is high, the consumption of energy required when the device works is low, economic benefits are ensured, and energy conservation and emission reduction are realized at the same time.

Owner:NINGBO SCIENTZ BIOTECH

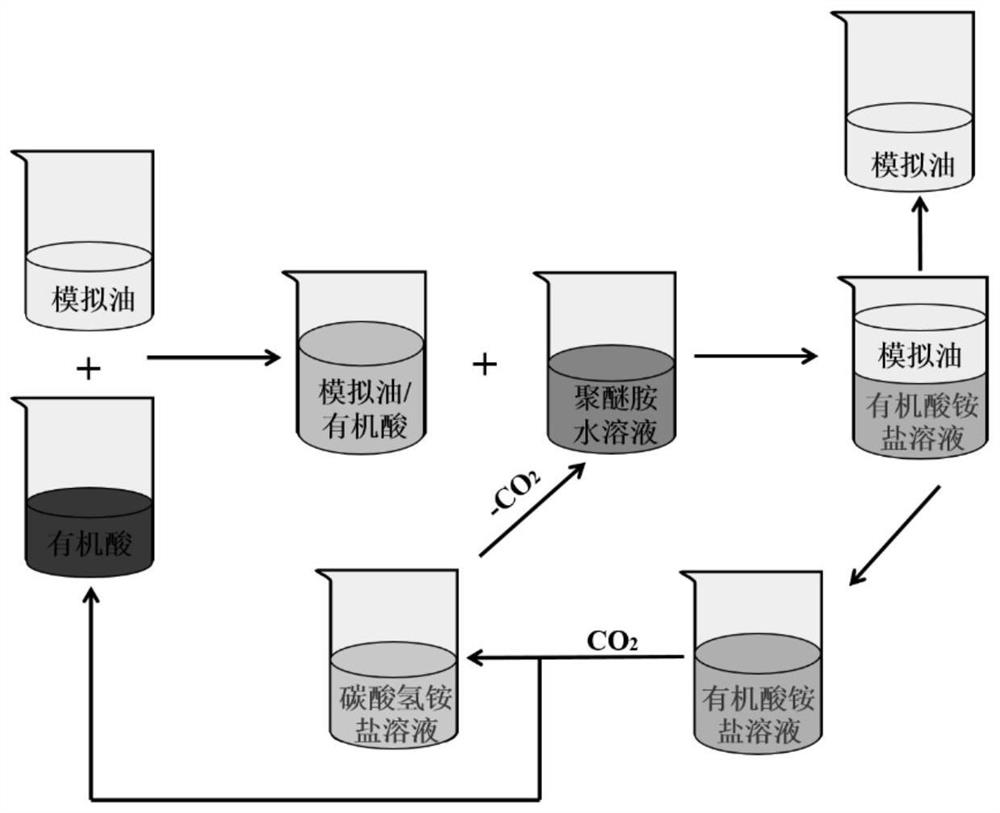

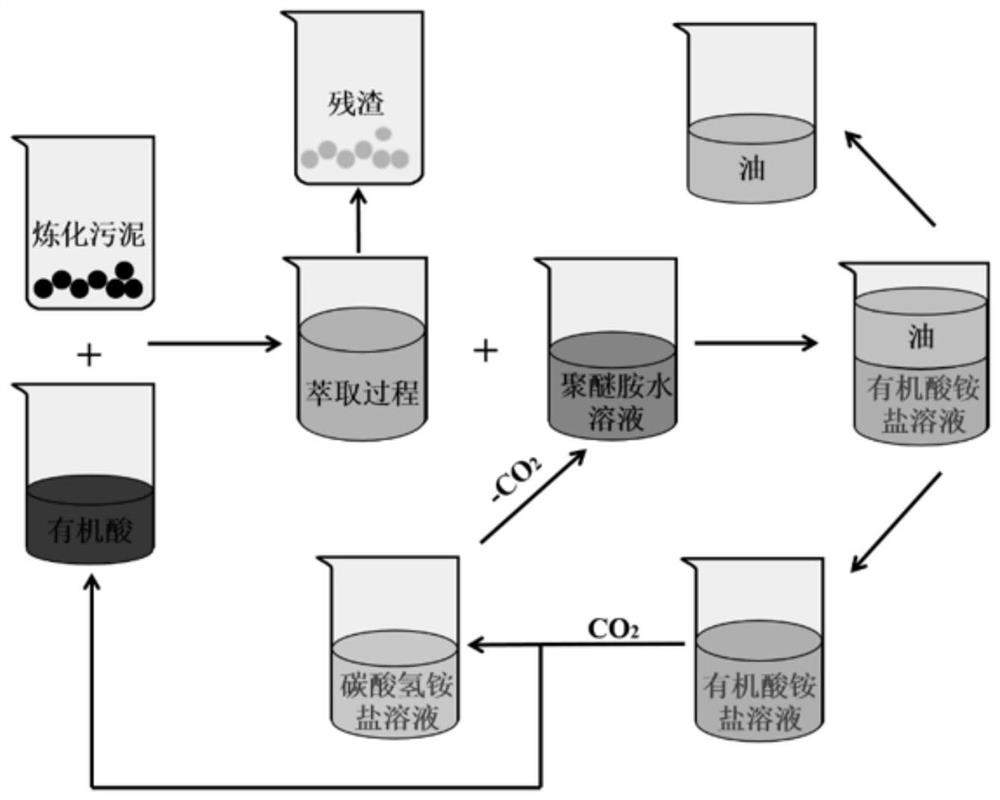

CO2/N2 switching type double-circulation extraction process and application thereof

ActiveCN112391190ANothing producedReduce usageSludge treatmentLiquid hydrocarbon mixture productionOrganic acidProcess engineering

The invention discloses a CO2 / N2 switching type double-circulation extraction process. The process comprises: mixing oil-containing solid waste and organic acid, separating to obtain mixed liquid A and solid waste, adding a polyetheramine aqueous solution into the mixed solution A, separating to obtain an oil phase and a mixed solution B, introducing CO2 into the mixed solution B, protonating, separating to obtain an organic acid and a mixed solution C, returning the organic acid to the oily solid waste, introducing N2 into the mixed solution C, deprotonating to obtain CO2 and a polyetheramineaqueous solution, returning the polyetheramine aqueous solution to the mixed solution A, and returning CO2 to the mixed solution B, wherein the temperature control range of the whole extraction process is 30-70 DEG C. The method has the advantages that (1) the organic acid aqueous solution and the polyether amine aqueous solution are combined for use, so that the purpose of oil removal is achieved, the organic acid aqueous solution and the polyether amine aqueous solution are recycled, the method is environment-friendly and safe to operate, and the oil removal cost is saved, the recovery rateof oil products is high, other impurities are not introduced, and the recovery rate of conventional oil products, especially heavy oil products, can reach 90% or above.

Owner:SOUTHWEST PETROLEUM UNIV

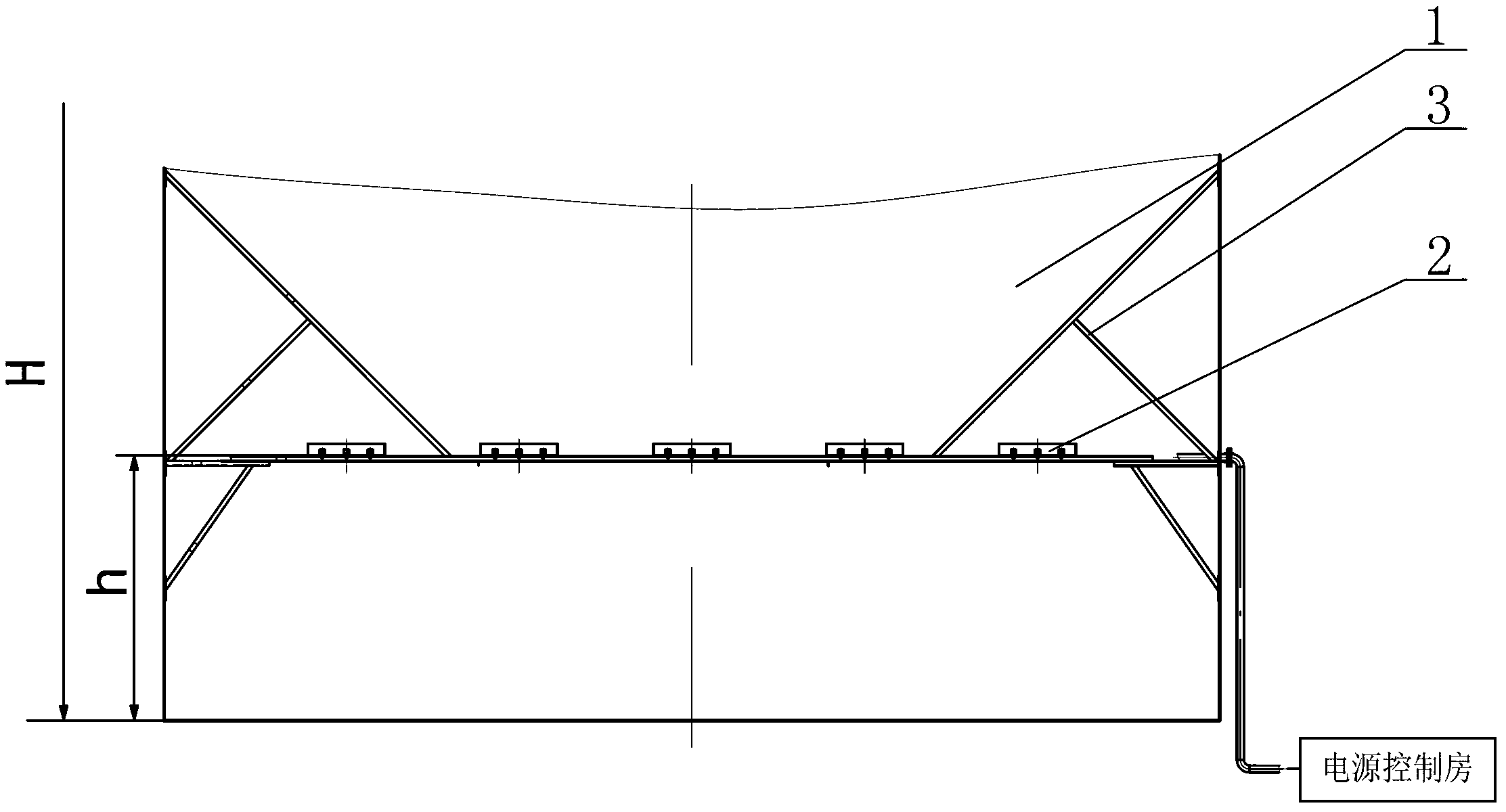

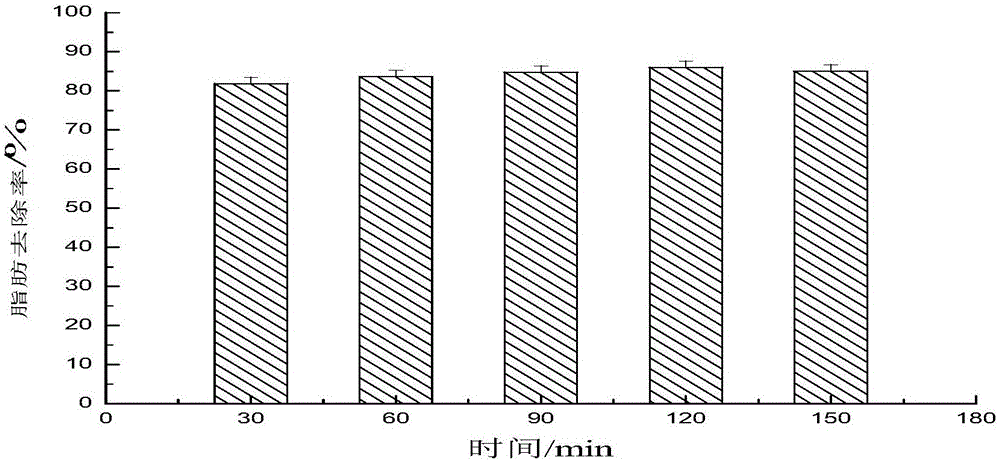

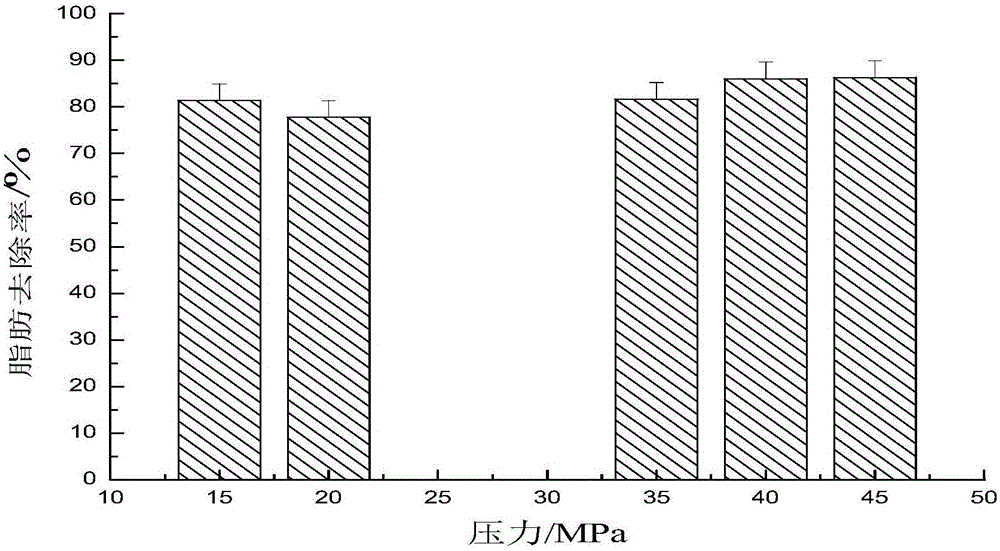

Method for degreasing pigskin with supercritical CO2 extraction technique

InactiveCN106244740AHigh degreasing efficiencyMild extraction conditionsPre-tanning chemical treatmentLeather degreasingEconomic benefitsChemistry

The invention provides a method for degreasing pigskin with a supercritical CO2 extraction technique. The method comprises steps as follows: firstly, fresh pigskin is crushed; and then extraction treatment is performed on the treated pigskin by using CO2 as a supercritical fluid at the temperature ranging from 35 DEG C to 45 DEG C and under the pressure ranging from 35 MPa to 45 MPa with the supercritical extraction technique. With the method, grease in the pigskin is removed with the supercritical CO2 method, the degreasing limitation of a traditional method is broken through, the simple, efficient and environment-friendly extraction purpose is achieved, the cost is saved, and the economic benefit is increased. The whole process is easy to regulate and control due to the mildness of the supercritical CO2 condition, an experimental project meets the efficient degreasing development tendency, the characteristic is obvious, and the feasibility is high.

Owner:张玉斌

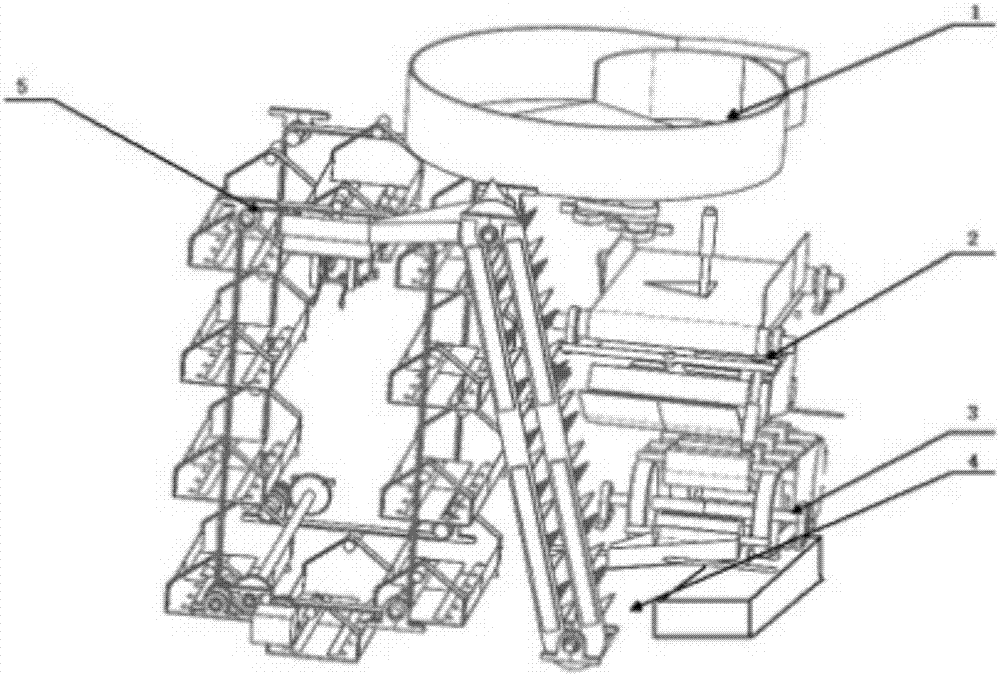

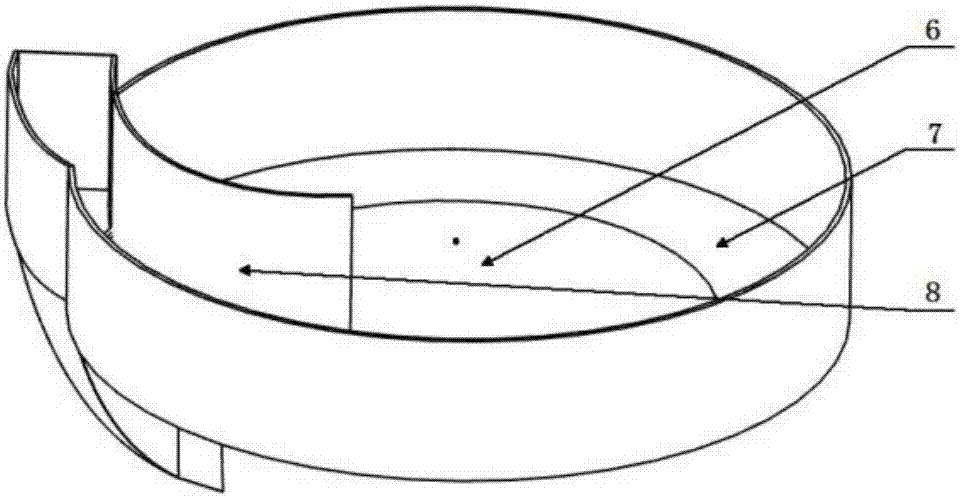

Retracting and folding multifunctional integrated machine for spectacles

InactiveCN106927199AEasy to cleanEffective disinfectionSpectales/gogglesMechanical conveyorsEyewearEngineering

The invention discloses a retracting and folding multifunctional integrated machine for spectacles, which solves the problem of heavy manual workload in the prior art, and has the advantages of high automation degree and good cleaning effect. The scheme is as follows: the retracting and folding multifunctional integrated machine for spectacles comprises a rotary separation mechanism and a spectacles leg folding mechanism, wherein the rotary separation mechanism comprises a rotary separation disk which is used for receiving spectacles and a conical whirling separation part which is arranged on the inner circumference of the rotary separation mechanism, the conical whirling separation part and the rotary separation disk do differential rotation motion, and the end part of the conical whirling separation part is provided with an outlet for delivering the spectacles out of the outlet; the spectacles leg folding mechanism comprises a second conveying slideway and folding units, the second conveying slideway is inclined downwards to receive the spectacles, and lug sides are arranged on the two sides of the second conveying slideway; and the folding units are arranged on the middle lower part of the second conveying slideway, the spectacles enter the folding units through the second conveying slideway, and each folding unit comprises a first arc flexible push plate and a second arc flexible push plate.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Oil field sewage flocculant and preparation method thereof

PendingCN112978890AImprove hydrophobicityGood hydrophobic association propertiesWaste water treatment from quariesFatty/oily/floating substances removal devicesMeth-Diethylenetriamine

The invention belongs to the technical field of oil field chemicals, and particularly relates to an oil field sewage flocculant which is characterized by comprising the following components in percentage by mass: 88-92% of a polymer and 8-12% of silicon oxide aerogel / diethylenetriamine propyl trimethoxy silane / glycidyl trimethyl ammonium chloride. The polymer is prepared by polymerizing sunflower seed oil-based pyridine quaternary ammonium salt / ethylenediamine modified oxidized walnut powder, vinyl (trifluoromethyl) dimethylsilane and 2-acrylamido-methylpropanesulfonic acid. The invention also provides a preparation method of the oil field sewage flocculant. The invention develops the oil field sewage flocculant which is salt-resistant, not easy to generate oil-containing flocs, good in oil displacement and flocculation effect, wide in raw material source, low in price, easy to biodegrade, safe and non-toxic.

Owner:西安威弗莱环境控制技术有限责任公司

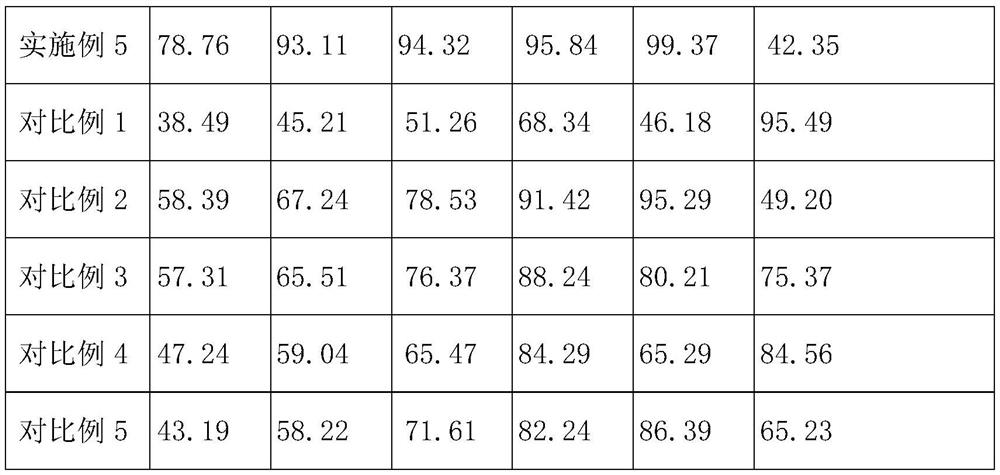

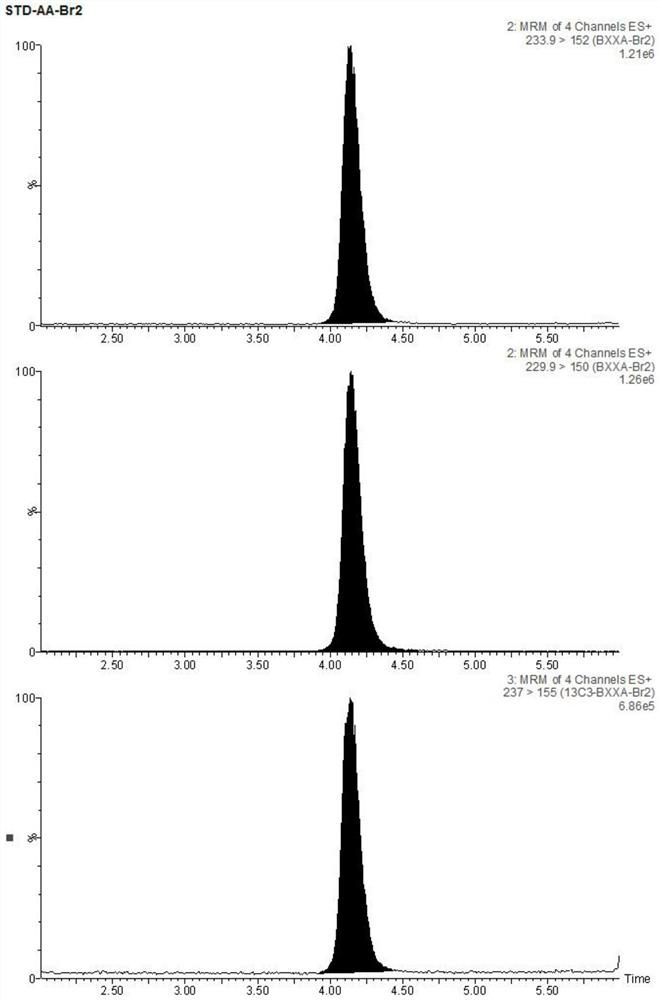

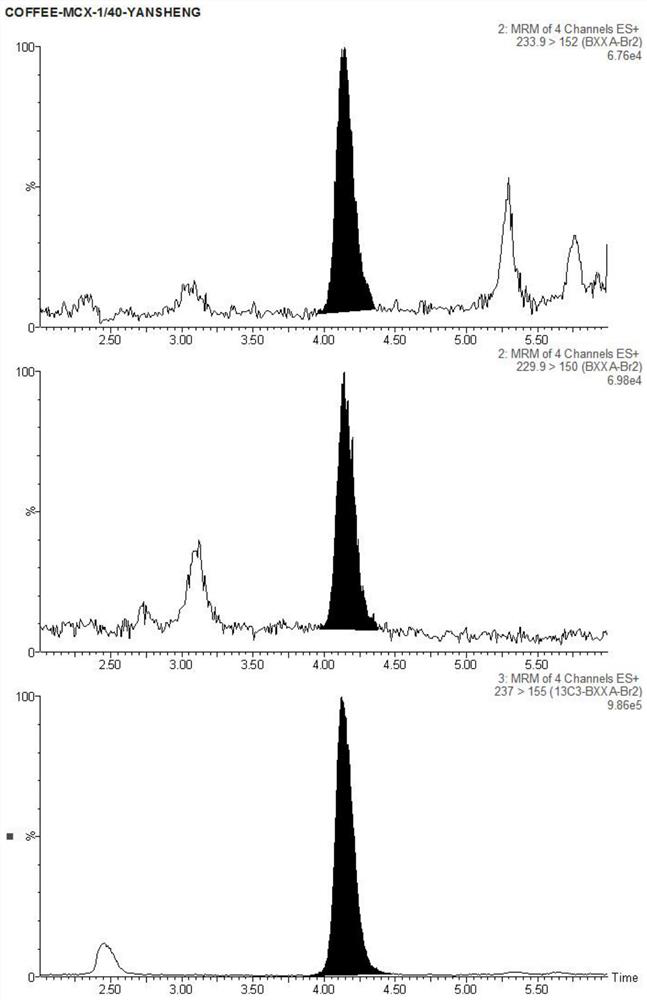

Pretreatment method of hot processed food and detection method of acrylamide

ActiveCN111735886AHigh extraction rateImprove retentionComponent separationDichloromethaneSulfuric acid

The invention relates to the technical field of analysis and detection, in particular to a pretreatment method of hot processed food and a detection method of acrylamide. The pretreatment method comprises the following steps: crushing hot processed food, adding 13C3-acrylamide internal standard application liquid and water, mixing, extracting, mixing an obtained extraction system with dichloromethane, degreasing, purifying an obtained sample extraction liquid by adopting a GCB / PSA column, adding potassium bromide, a sulfuric acid solution and a potassium bromate solution, mixing, and deriving.The invention provides the pretreatment method. After pure water extraction, dichloromethane degreasing, GCB / PSA column purification and potassium bromate and potassium bromide derivation are adoptedto convert acrylamide into 2, 3-dibromoacrylamide, the molecular weight is increased, the polarity is weakened, the chromatographic retention capacity is enhanced, the matrix interference phenomenonin LC-MS / MS detection is greatly reduced, and the detection accuracy is high.

Owner:ZHEJIANG CENT FOR DISEASE CONTROL & PREVENTION

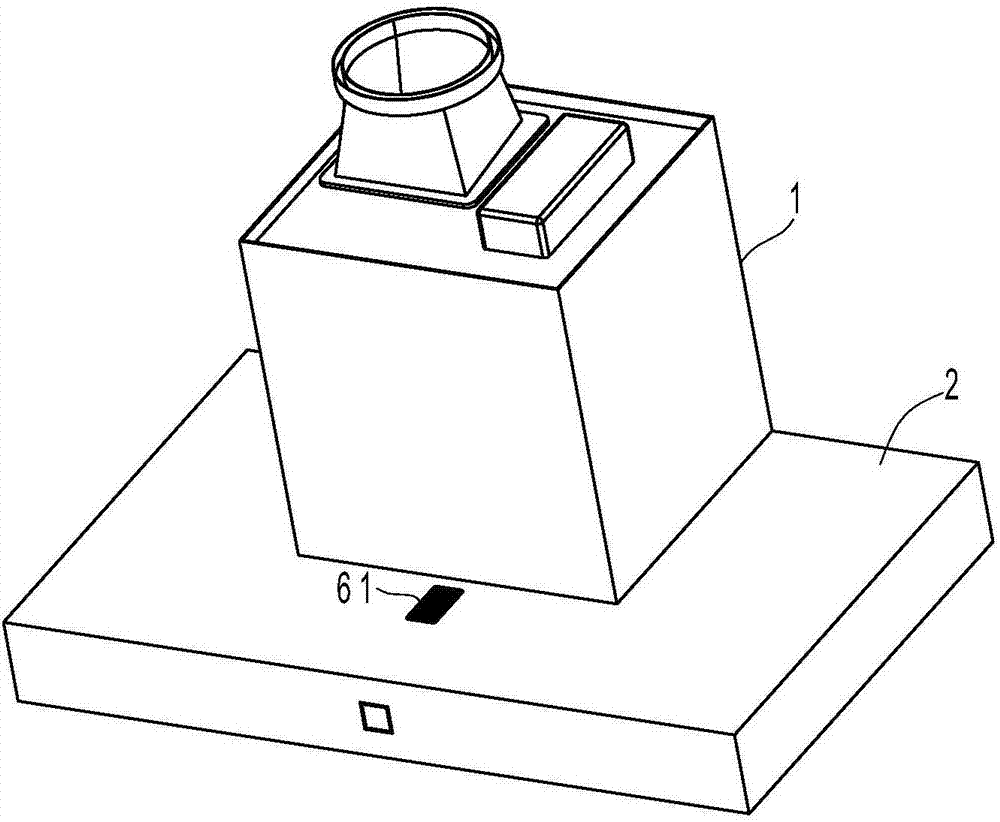

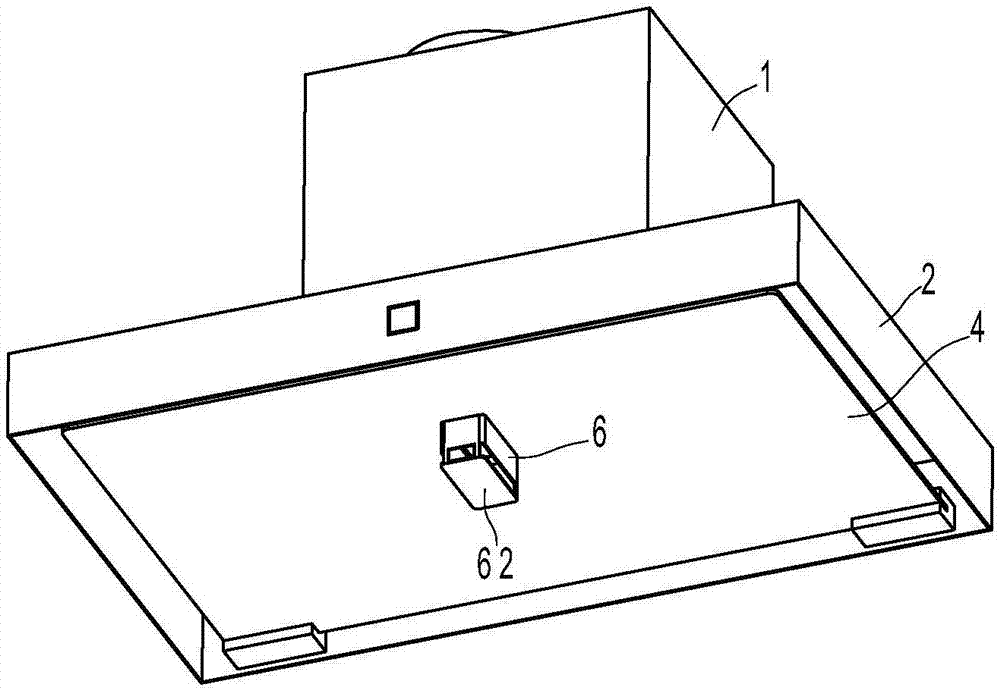

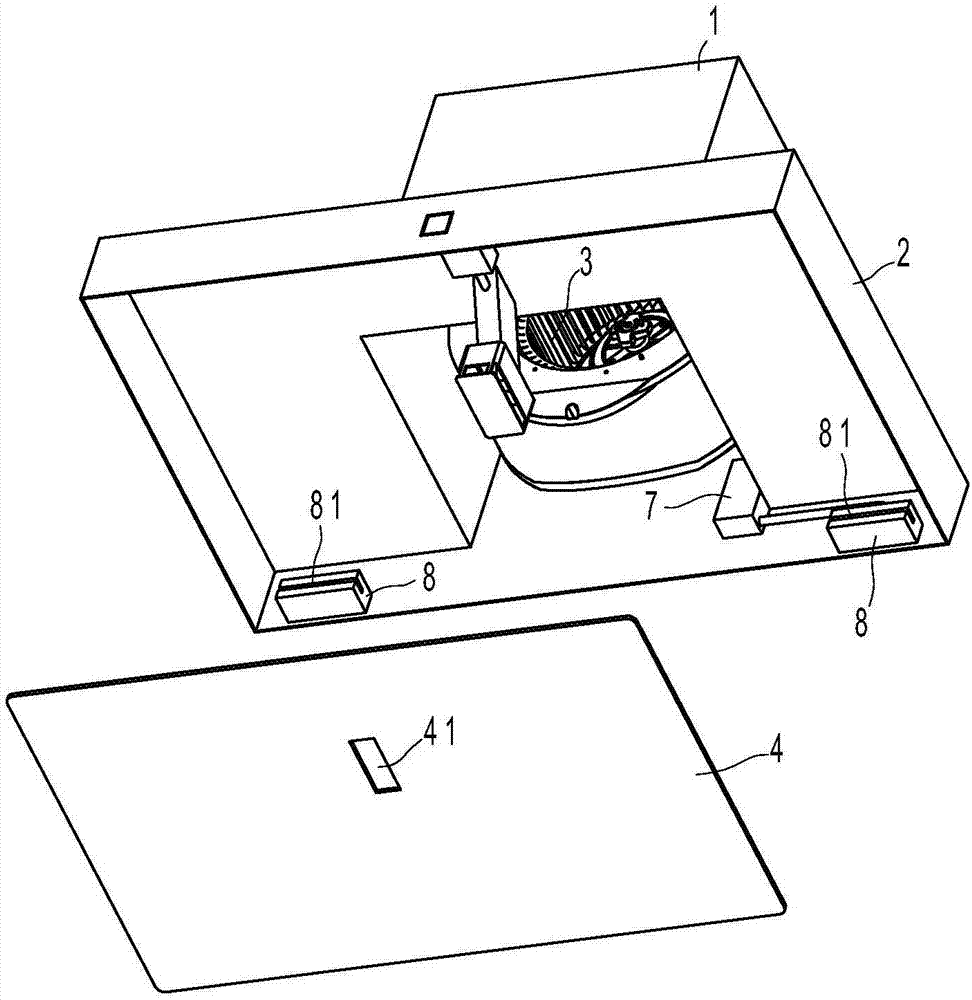

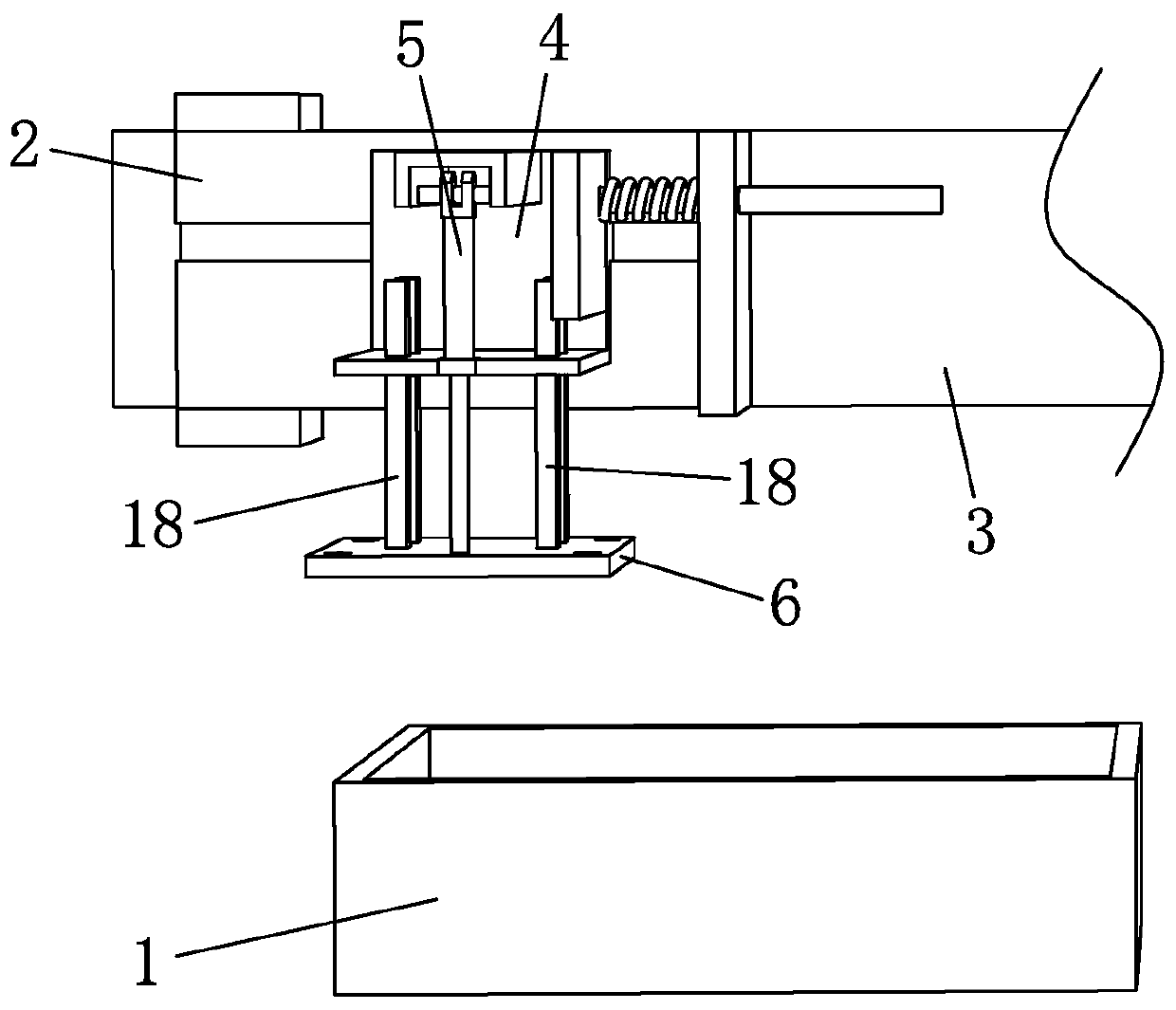

Electrostatic oil removal type range hood

ActiveCN107339724ASpeed upReduce haphazard diffusionDomestic stoves or rangesLighting and heating apparatusPhysicsExhaust fumes

The invention provides an electrostatic oil removal type range hood. The electrostatic oil removal type range hood comprises a shell (1), an exhaust fume collecting hood (2) arranged at a lower end opening of the shell (1) and a draught fan (3) arranged in the shell, wherein a commutation plate (4) for guiding fume is arranged at a front end opening of the exhaust fume collecting hood (2); a gap through which lampblack passes is formed between front end faces of the commutation plate (4) and the exhaust fume collecting hood (2); the electrostatic oil removal type range hood is characterized in that the exhaust fume collecting hood (2) is internally provided with a negative ion generator (5) and a negative ion channel (6); a transmitting end (51) of the negative ion generator (5) is located in the negative ion channel (6); an outlet of the negative ion channel (6) stretches out of the commutation plate (4); the shell (1) is internally provided with a direct-current positive high-voltage generator (7); and an output positive electrode of the direct-current positive high-voltage generator (7) is electrically connected with the commutation plate (4). The commutation plate has the effects of flow guide, oil collection and electrode plates and integrates various functions. The electrode plate does not need to be additionally arranged in the range hood, so that the whole structure is more compact and is very convenient to mount, dismount, wash and maintain.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A compound oligopeptide for improving sexual function and anti-fatigue, its oral preparation and the preparation method of the oral preparation

ActiveCN109007848BIncrease varietyIncrease ratingsProtein composition from fishFood shapingSexual functioningMedicine

The present invention aims at the defects of Chinese herbal medicines in the prior art in improving sexual function, and provides a compound oligopeptide for improving sexual function and anti-fatigue, its oral preparation and a preparation method of the oral preparation. The compound oligopeptide is based on Oyster oligopeptide and walnut oligopeptide are the main raw materials, supplemented by yam polysaccharide. The composite oligopeptide uses oyster oligopeptide and walnut oligopeptide extracted from pure natural edible biological materials as main raw materials, supplemented with yam polysaccharide, and prepares oral preparations in different dosage forms for different application conditions, which can effectively relieve fatigue and improve sexual function.

Owner:河南东肽生物有限公司

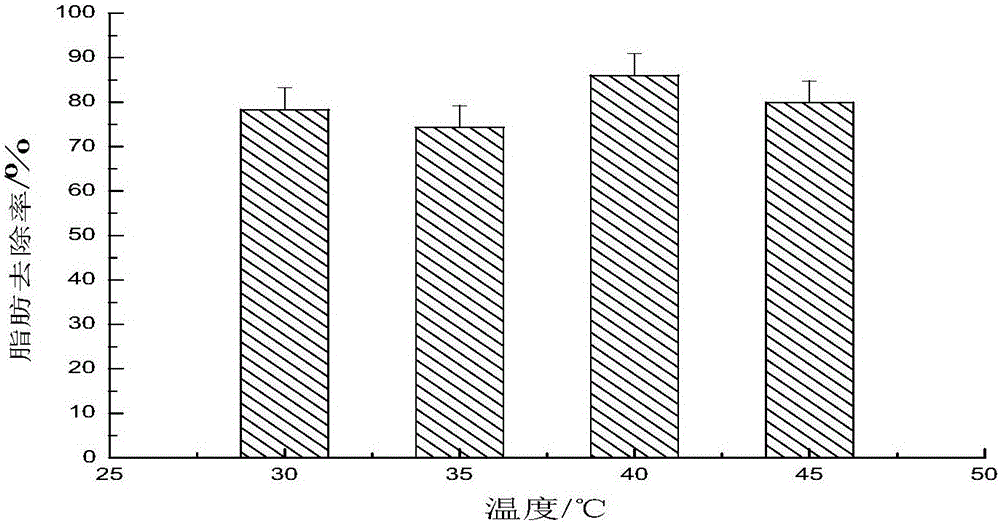

Method for quickly removing lipid compounds in tobaccos by utilizing accelerated solvent extraction device and degreasing remaining rate calculation method

InactiveCN106198300AThe extraction process is highly automatedReduce consumptionWeighing by removing componentPreparing sample for investigationBenzeneAlcohol

The invention provides a method for quickly removing lipid compounds in tobaccos by utilizing an accelerated solvent extraction device. The method is characterized in that a mixed solution of alcohol, benzene and diethyl ether is used as an extracting solvent, a tobacco raw material is extracted and degreased with an accelerated solvent extraction device and is washed and dried to obtain a degreased tobacco powder sample. The tobacco powder sample can be used for analyzing and detecting cellulose, hemicellulose and lignin in tobaccos. The method for calculating the degreasing remaining rate is convenient and quick, and has high accuracy. The method for quickly removing lipid compounds in tobaccos by utilizing the accelerated solvent extraction device can be established by sufficiently utilizing the advantages including high automatic degree, small reagent consumption and the like of the accelerated solvent extraction device, is simple and convenient in experiment operation, can be used for improving working efficiency, can meet the requirement for YC / T 347-2010, and achieves the aim of degreasing tobaccos.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

co2/n2 switch-type double-circulation extraction process and its application

ActiveCN112391190BReduce usageHigh puritySludge treatmentLiquid hydrocarbon mixture productionOrganic acidOil phase

The invention discloses a CO 2 / N 2 Switch-type double-cycle extraction process, oily solid waste and organic acid are mixed and separated to obtain mixed liquid A and solid waste; polyetheramine aqueous solution is added to mixed liquid A to separate oil phase and mixed liquid B, and CO is introduced into mixed liquid B 2 After protonation, the organic acid and the mixed solution C are separated, the organic acid is returned to the oily solid waste, and N is passed into the mixed solution C 2 CO is obtained after deprotonation 2 And polyetheramine aqueous solution, polyetheramine aqueous solution returns in the mixed solution A, CO 2 Returning to the mixed solution B, the temperature control range of the whole extraction process is 30-70°C; (1) The combination of organic acid and polyether amine aqueous solution not only achieves the purpose of oil removal but also realizes the separation of organic acid and polyether amine. The recycling of amine aqueous solution is environmentally friendly, safe in operation and saves oil removal costs; the recovery rate of oil products is high, and no other impurities are introduced. The recovery rate of conventional oil products, especially heavy oil products, can reach 90%. above.

Owner:SOUTHWEST PETROLEUM UNIV

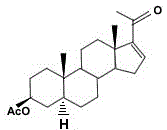

A kind of production method of monoenolone acetate synthesized by sisal saponin

ActiveCN103113448BEnsure the stability of the ring-opening cleavage reactionTo achieve the purpose of degreasingSteroidsAcetic acidAcetic anhydride

Owner:湖北民生生物医药有限公司

A kind of preparation method of bone glue

ActiveCN110218522BTo achieve the purpose of degreasingImprove the efficiency of subsequent bone rubbingFatty-oils/fats separationGlue/gelatin preparationMedicineEngineering

The invention belongs to the technical field of bone glue preparation, and specifically relates to a preparation method of bone glue, which includes sorting collected miscellaneous bones and removing impurities; crushing the sorted aggregates to obtain bone blocks; Carry out an oil extraction operation; the oil extraction operation includes immersing the bone block in hot water containing a degreasing compound, and then performing multi-layer filtration to obtain bone blocks of different particle size ranges; wherein, the preparation of the degreasing compound The raw materials include chitosan, silicon source precursor and povidone; in the present invention, the broken bone is soaked in hot water containing a degreasing compound, and the degreasing compound wraps the fat separated from the bone Cover and precipitate in hot water to achieve the purpose of degreasing, and then use multi-layer filtration to distinguish the bone blocks into different particle size ranges, thereby improving the efficiency of subsequent bone rubbing.

Owner:安徽省淮河制胶有限公司

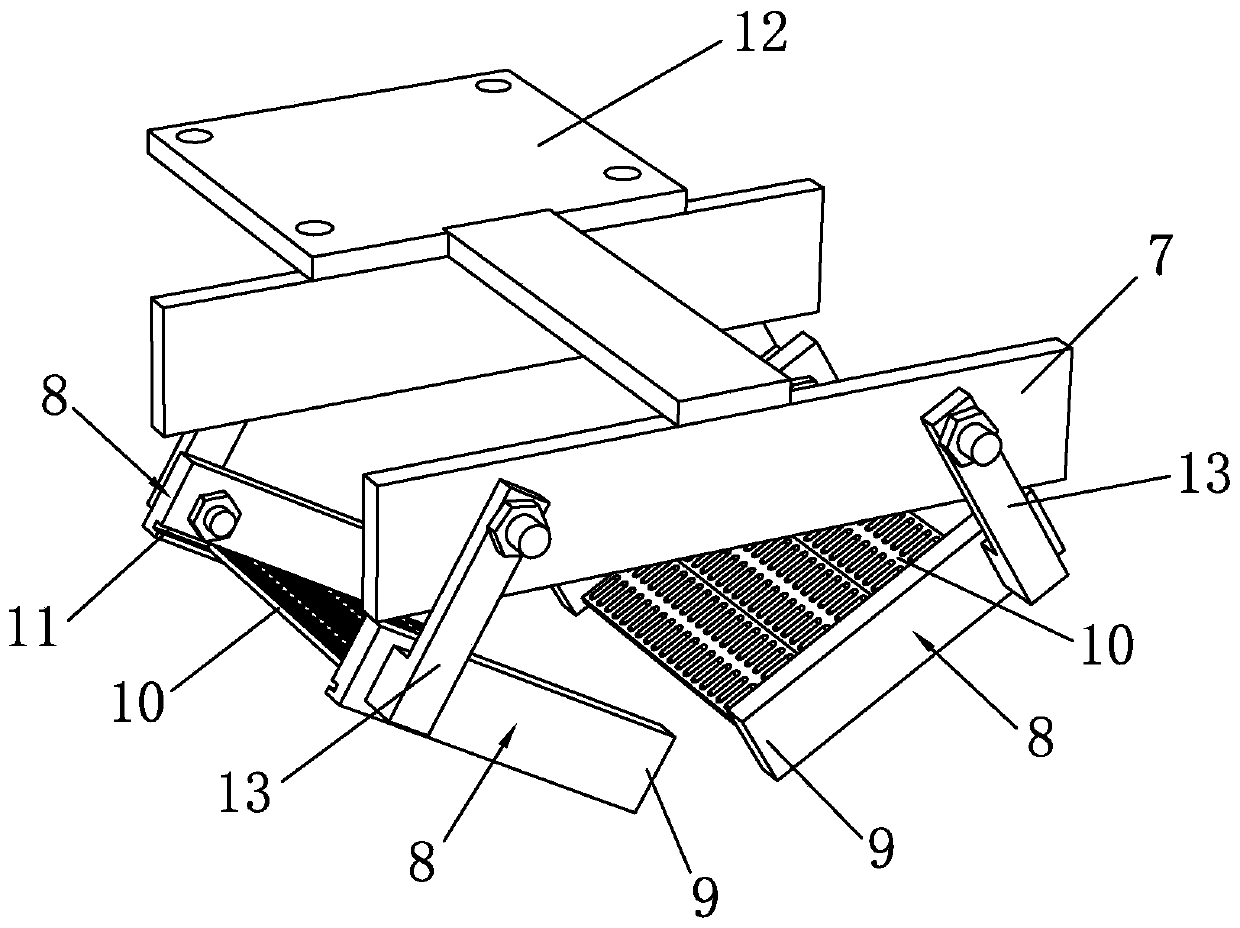

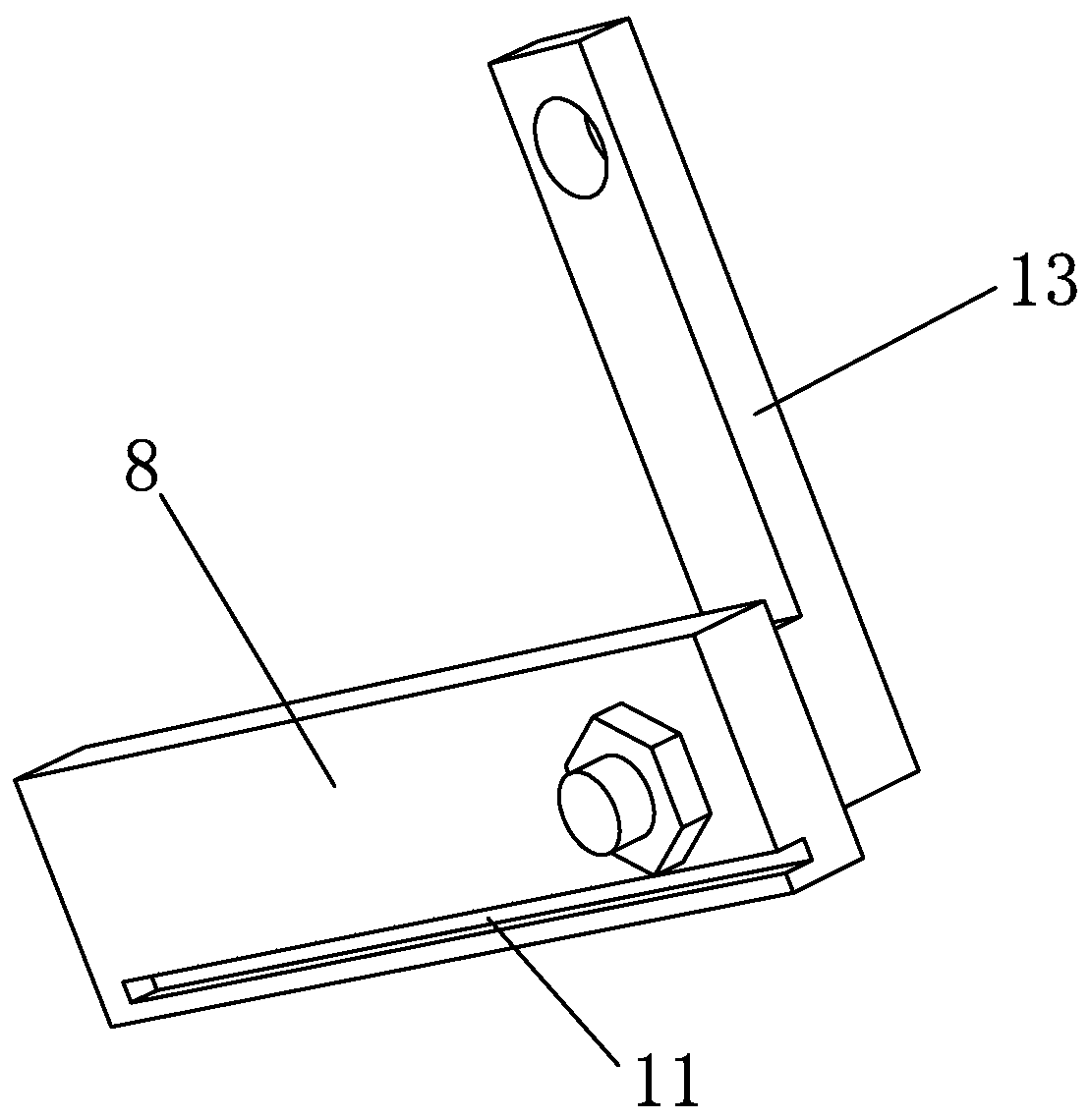

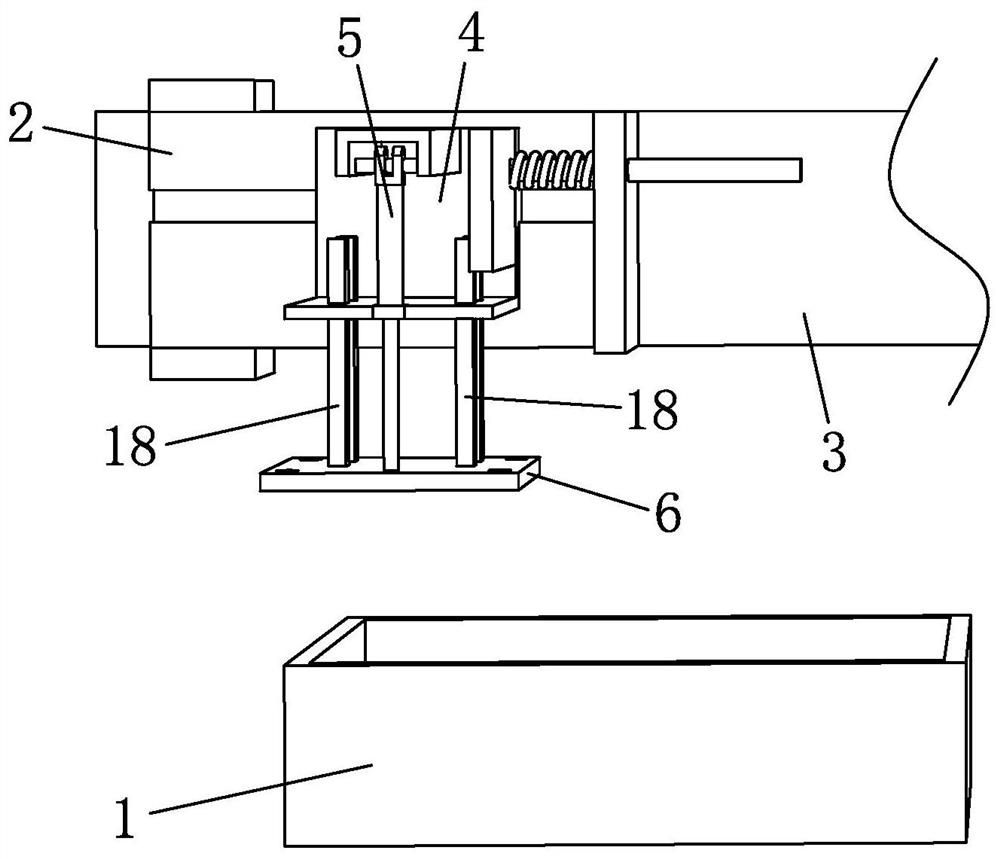

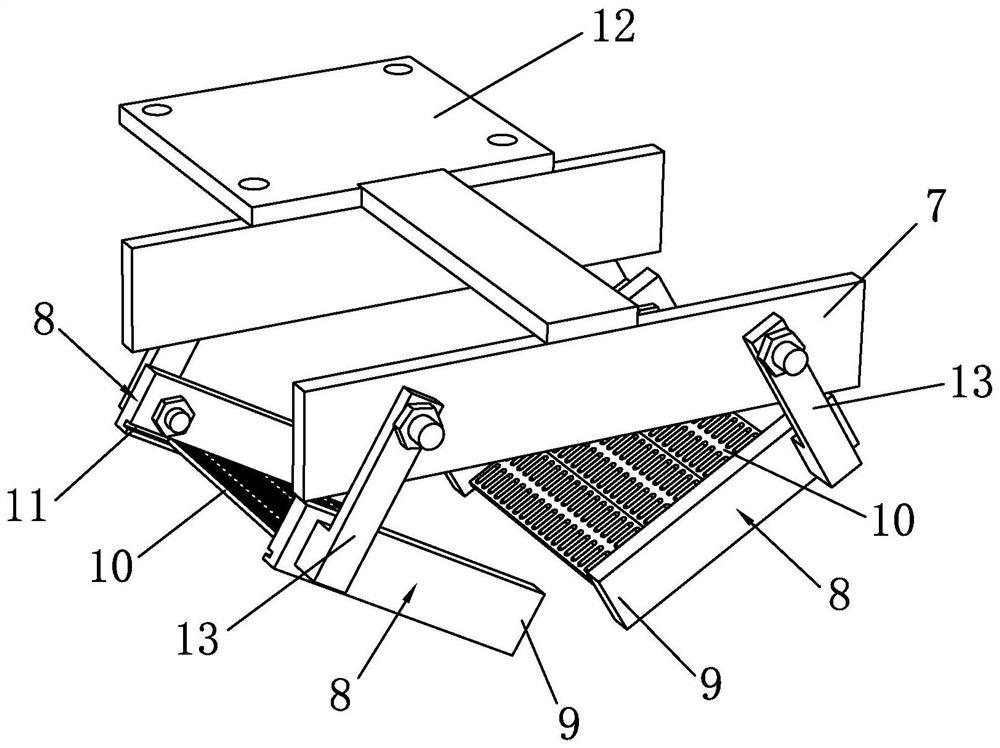

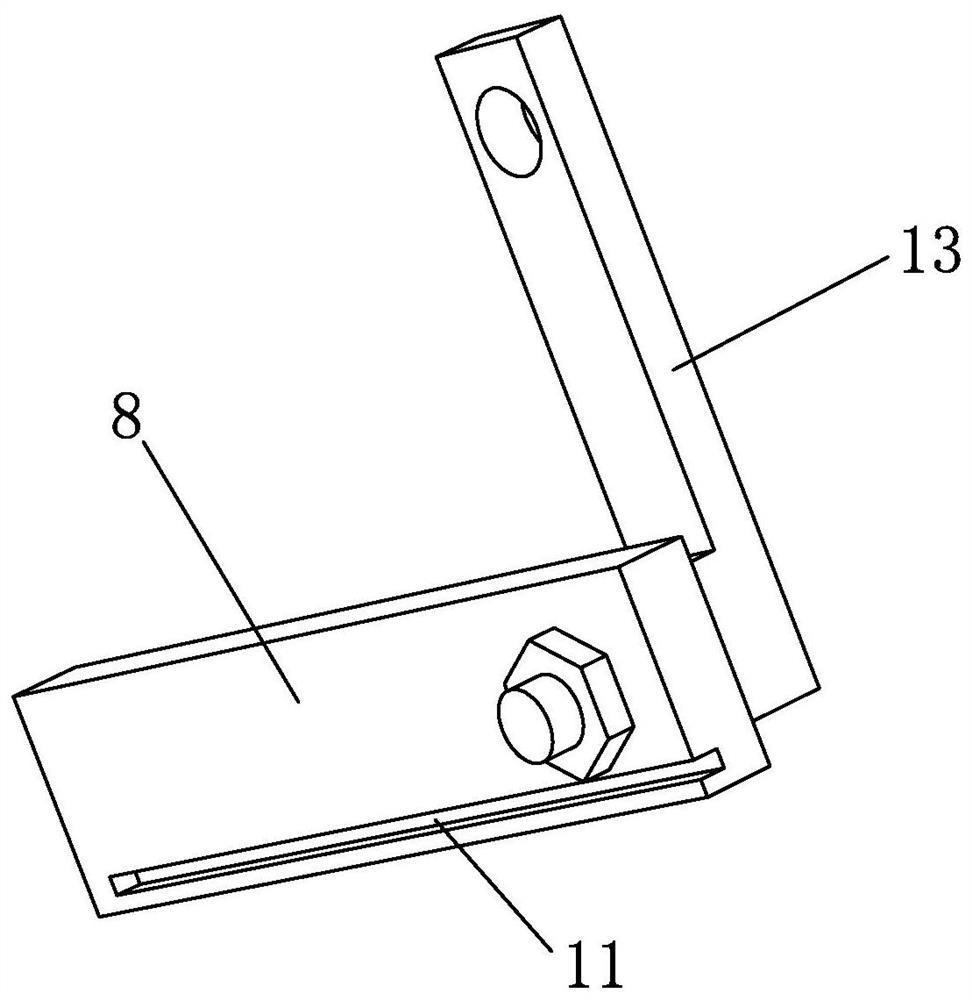

Oil sticking-free coating process applied to integrated cooker oil screens

ActiveCN110835776AConvenient for centralized placementIncrease contact areaElectrophoretic coatingsElectrophoresesThermodynamics

The invention discloses an oil sticking-free coating process applied to an integrated cooker oil screens. The process comprises the following steps of a, carrying out degreasing treatment; b, carryingout pure water spraying; c, carrying out cathode electrophoresis coating; d, carrying out ultrafiltration circulating water washing; and e, putting a frame body provided with oil screens into a drying system to be dried. According to the oil sticking-free coating process applied to the integrated cooker oil screens, the oil screens can be centrally stored, and when the degreasing treatment is carried out, the oil screens keep inclined states and abut against with one another, so that the up-down stacking phenomenon does not occur; the oil screens are completely exposed to a degreasing agent for the degreasing treatment, so that the oil removing effect is improved; meanwhile, generated dirt can fall down to the bottom of a degreasing tank along the oil screens keeping the inclined states,so that the blistering phenomena of the surfaces of the oil screens caused by the deposited dirt on the surfaces of the oil screens are avoided; and oil screen placement plates reciprocate left and right in the degreasing tank through the deformation effect on springs, so that the dirt on the inner walls of through holes of the oil screens is washed off under the action of degreasing agent, and the blistering phenomena of the inner walls of the through hole of the oil screens caused by the deposited dirt on the inner walls of the through hole of the oil screens are avoided.

Owner:浙江森歌智能厨电股份有限公司

Non-stick oil coating process applied to integrated cooking oil net

ActiveCN110835776BTo achieve the purpose of degreasingConvenient for centralized placementElectrophoretic coatingsElectrophoresesProcess engineering

Owner:浙江森歌智能厨电股份有限公司

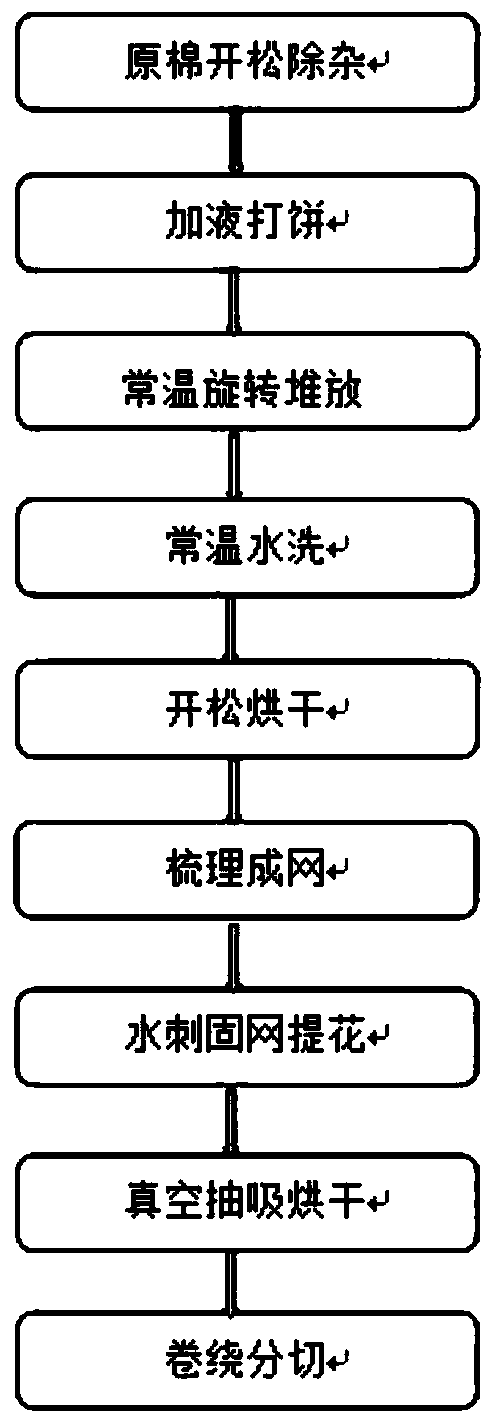

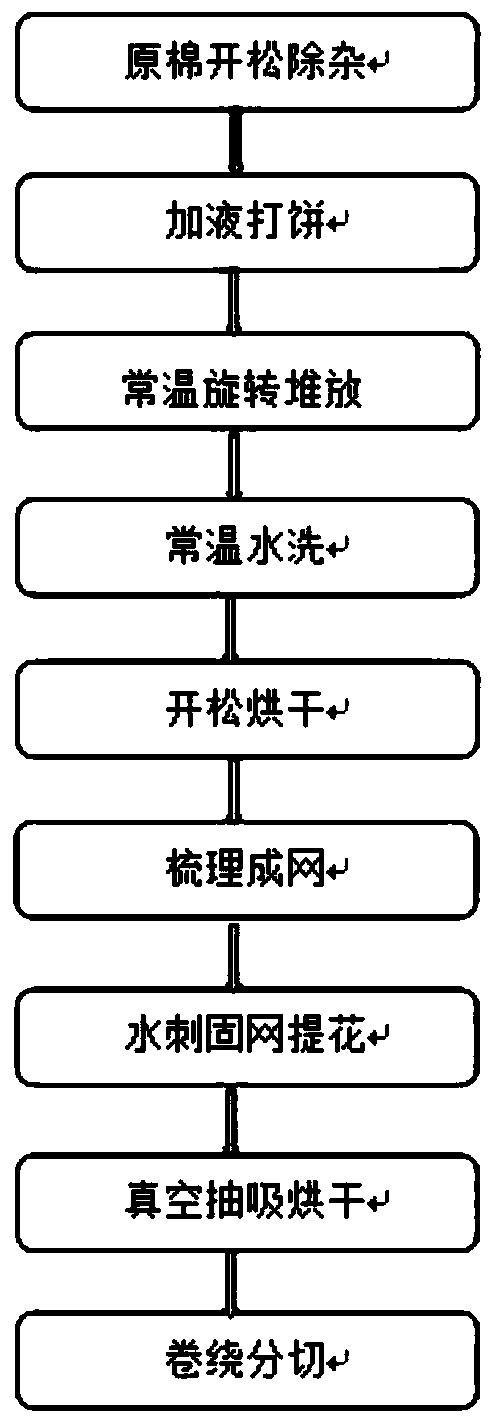

Raw cotton cold stack skilled water spin -free woven production process

ActiveCN107326533BTo achieve the purpose of degreasingReduce intermediate transfer linksNon-woven fabricsVegetal fibresYarnProcess engineering

The invention discloses a spunlace non-woven fabric production process for degreasing cold piles of raw cotton. The spunlace non-woven fabric production process includes steps of 1), opening the raw cotton and removing impurities from the raw cotton; 2), filling the raw cotton with liquid and caking the raw cotton; 3), rotationally piling up the raw cotton at the normal temperature; 4), washing the raw cotton at the normal temperature; 5), opening and drying the raw cotton; 6), carding the raw cotton and forming nets; 7), carrying out spunlace fixed net jacquard; 8), vacuumizing and drying the nets; 9), winding and slitting the nets. The spunlace non-woven fabric production process has the advantages that the cold piles of the raw cotton are directly degreased, dried degreased cotton and pure cotton spunlace yarns are produced in an online manner, and accordingly the purposes of saving energy and energy sources, reducing emission and intermediate transfer links, improving production environments, quickly carrying out circulation and enhancing the product manufacturing control ability can be achieved; the problem that pure cotton spunlace non-woven fabrics only can be degreased at required high temperatures in liquid immersion press-rolling working procedures by existing cold piling pure cotton spunlace non-woven fabric production processes can be solved.

Owner:AOMEI MEDICAL SUPPLIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com