Degreaser and preparation method thereof

A degreaser and adsorbent technology, which is applied in the field of degreaser and its preparation, can solve the problems of poor degreasing effect and high corrosiveness of non-metal degreaser, achieve less corrosiveness, reduce corrosion and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

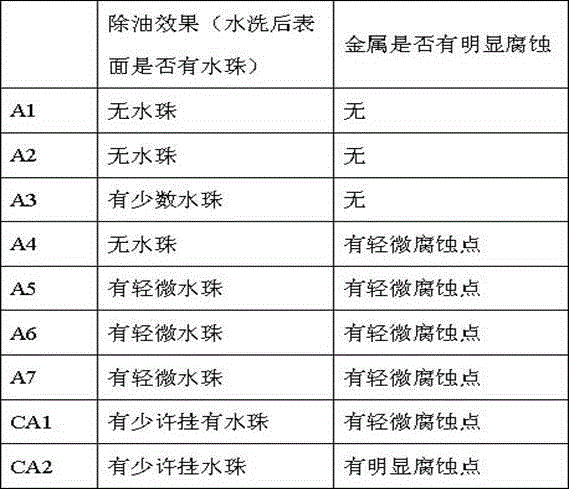

Examples

preparation example Construction

[0016] The invention also provides a preparation method of the degreasing agent, which comprises dissolving the complexing agent in water, adding a surfactant, and adding an emulsifier and an adsorbent after dissolving; the adsorbent is aluminum hydroxide.

[0017] According to the preparation method provided by the present invention, preferably, ethylenediaminetetramethylenephosphonic acid and imidazole are added while adding the adsorbent.

[0018] According to the preparation method provided by the present invention, preferably, the content of the emulsifier is 10-20 g / L, the content of the complexing agent is 10-30 g / L, and the content of the surfactant is 0.5- 3 g / L, the content of the adsorbent is 5-10 g / L, the content of the ethylenediamine tetramethylene phosphonic acid is 1-10 g / L, and the content of the imidazole is 1-5 g / L.

[0019] The degreasing agent of the invention is weakly alkaline, environmentally friendly, easily soluble in water, and has a strong degreas...

Embodiment 1

[0022] Degreaser A1: ethanol 15g / L, sodium citrate 20g / L, aluminum hydroxide 7g / L, sodium lauryl sulfate 1.5g / L, ethylenediamine tetramethylene phosphoric acid 6g / L, imidazole 3g / L L.

Embodiment 2

[0024] Degreaser A2: ethanol 12g / L, sodium citrate 25g / L, aluminum hydroxide 6g / L, sodium lauryl sulfate 2g / L, ethylenediamine tetramethylene phosphoric acid 8g / L, imidazole 4g / L .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com