Pretreatment method of hot processed food and detection method of acrylamide

A technology of acrylamide and detection method, applied in the field of analysis and detection, can solve the problems of low detection accuracy, large interference of impurities and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

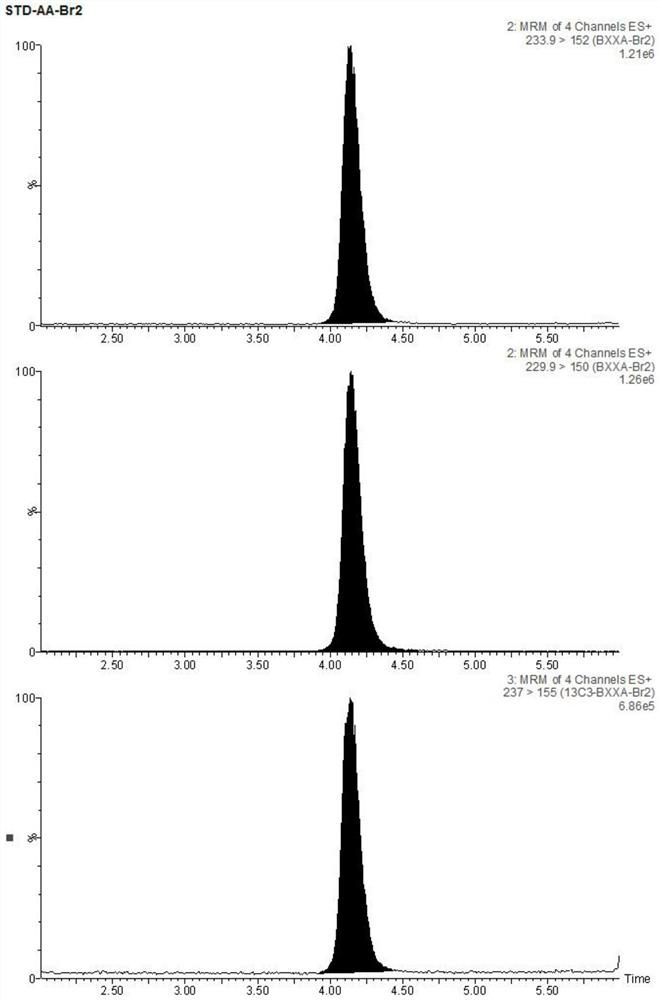

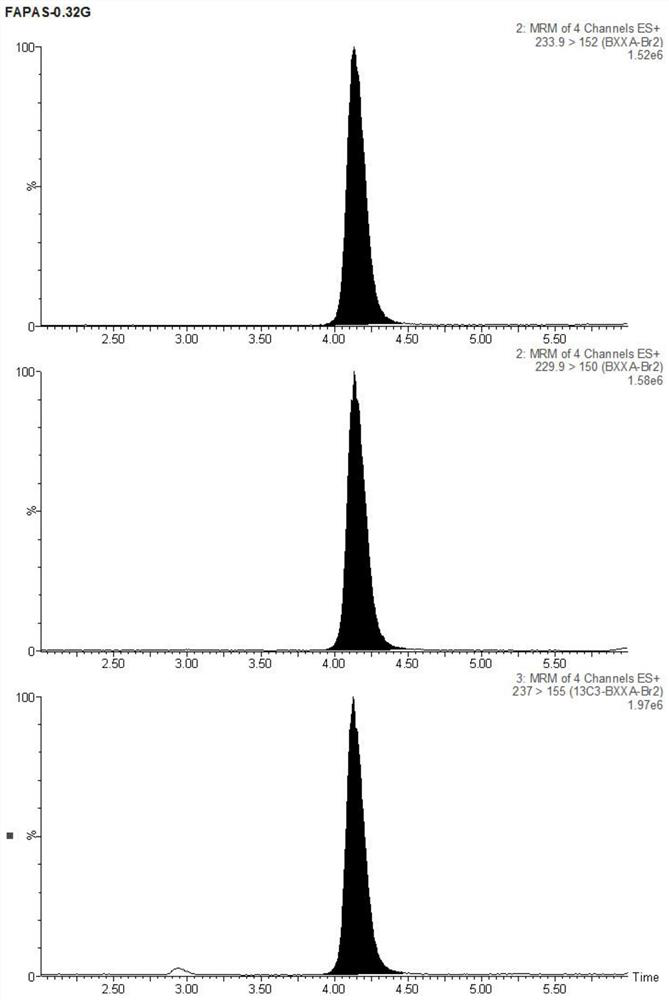

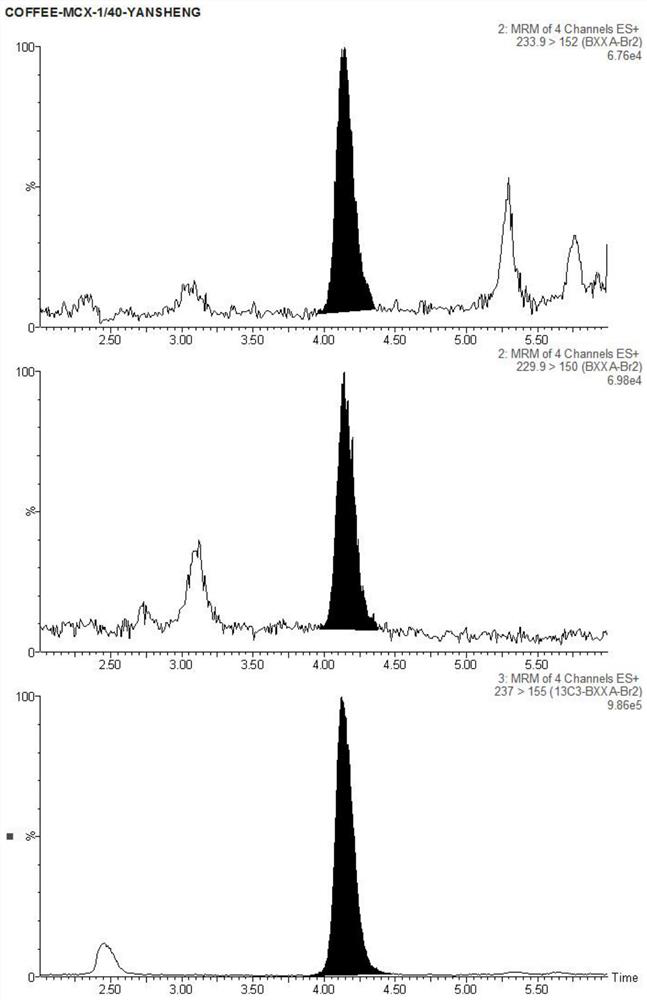

Image

Examples

Embodiment 1

[0121] (1) Preparation of acrylamide series standard working solutions

[0122] (1.1) Prepare 1.0 mg / mL acrylamide standard stock solution

[0123] Accurately weigh 10 mg of acrylamide standard substance (accurate to 0.01 mg), dissolve it in methanol in a 10 mL brown volumetric flask, adjust the volume to the mark, and store in a sealed, dark place at -20°C.

[0124] (1.2) Prepare 10mg / L acrylamide standard stock solution

[0125] Accurately draw 0.25mL of 1.0mg / mL acrylamide standard stock solution into a 25mL brown volumetric flask, dilute to the mark with methanol, and store in a sealed seal at -20°C in the dark.

[0126] (1.3) Prepare 1.0mg / L acrylamide standard solution

[0127] Accurately draw 1.00 mL of 10 mg / L acrylamide standard stock solution into a 10 mL brown volumetric flask, and dilute to the mark with 0.1% formic acid aqueous solution. The 10 mg / L acrylamide standard stock solution is preferably ready-to-use.

[0128] (1.4) Prepare 0.5mg / mL 13 C 3 -Acrylamide...

Embodiment 2

[0144] (1) Sample pretreatment

[0145] (1.1) First crush the potato chips with a pulverizer, accurately weigh 0.5 g (accurate to 0.0001 g) of the crushed potato chips sample into a 25 mL graduated centrifuge tube, add 40 μL of 5.0 μg / L 13 C 3 -Acrylamide internal standard application solution and 10mL ultrapure water, ultrasonically extract for 10min, add 5mL of dichloromethane to degrease, vortex for 5min, centrifuge at 10000r / min for 3min, take out, and the supernatant is the extract;

[0146] (1.2) Put 5.0mL of the sample extraction solution into a GCB / PSA column for purification, wherein the flow rate of the sample extraction solution is 2mL / min, and collect the sample purification solution into a 15mL graduated centrifuge tube;

[0147] (1.3) Add 0.75g potassium bromide to 5mL sample purification solution and vortex to dissolve, add 0.3mL sulfuric acid solution with a concentration of 0.3mol / L, 0.5mL potassium bromate solution with a mass volume percent concentration of...

Embodiment 3

[0157] Detect according to the method of Example 2, the difference from Example 2 is: the concentration of acrylamide in the sample liquid to be tested is 100 μg / kg, and the test result is the average value of 6 experiments, and the test results are shown in Table 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com