Non-stick oil coating process applied to integrated cooking oil net

A coating process, non-stick oil technology, applied in the field of integrated stoves, can solve the problems of grabbing the oil net, inconvenience, oil net foaming, etc., and achieve the effect of improving the oil removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

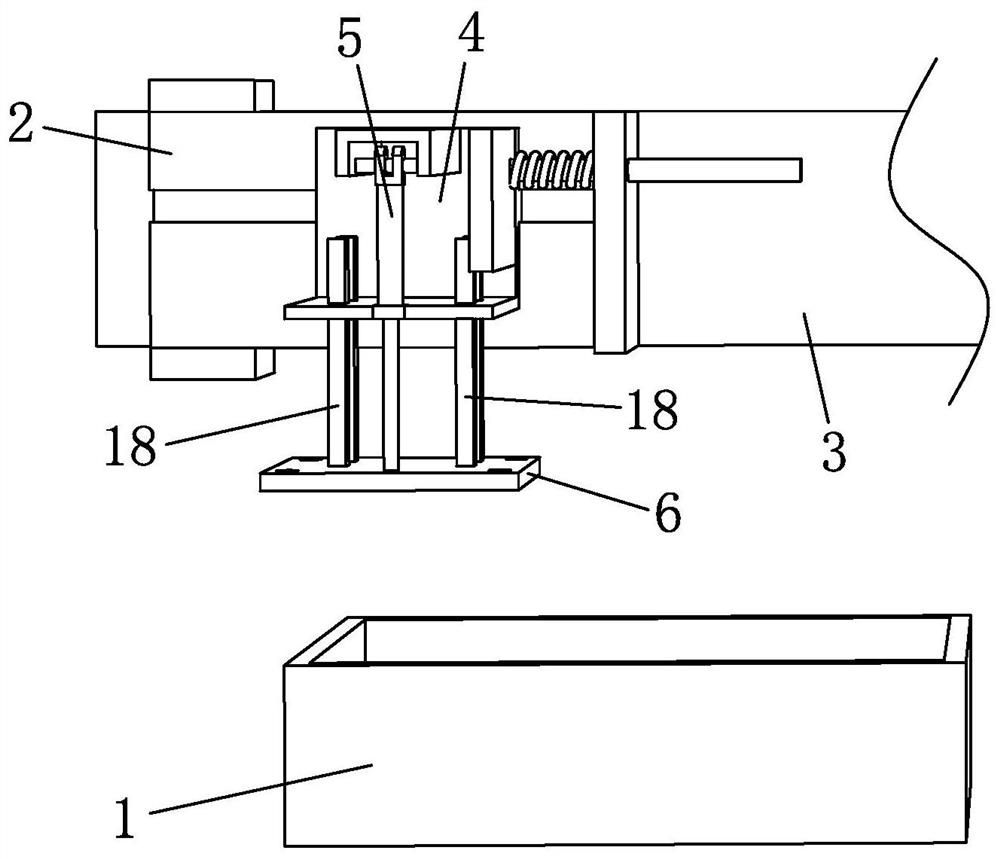

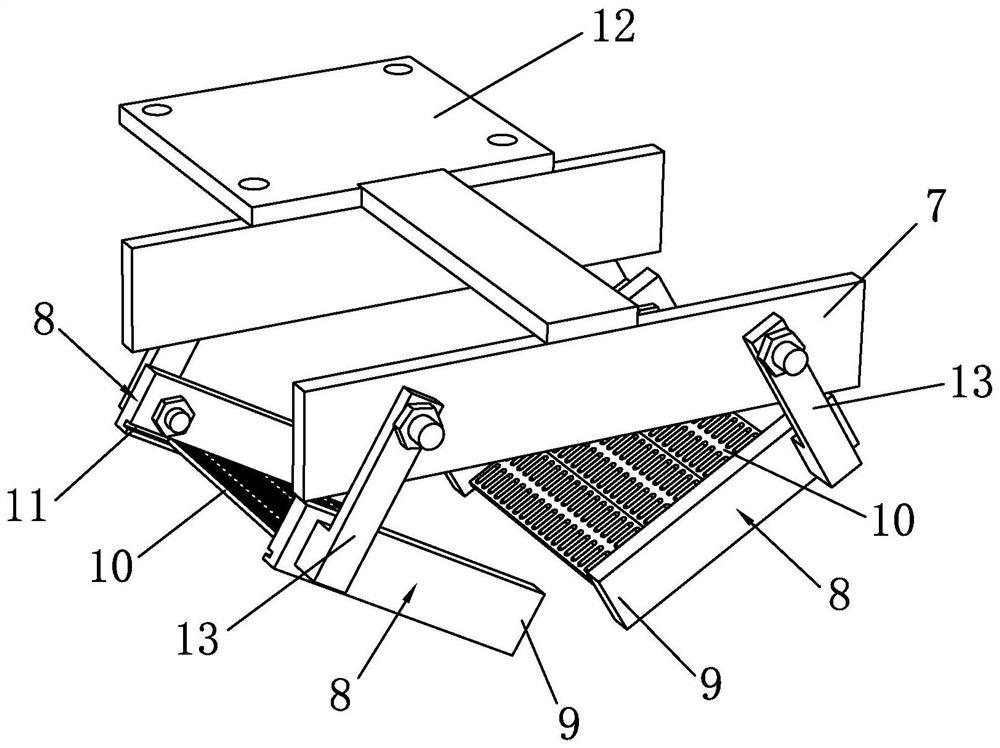

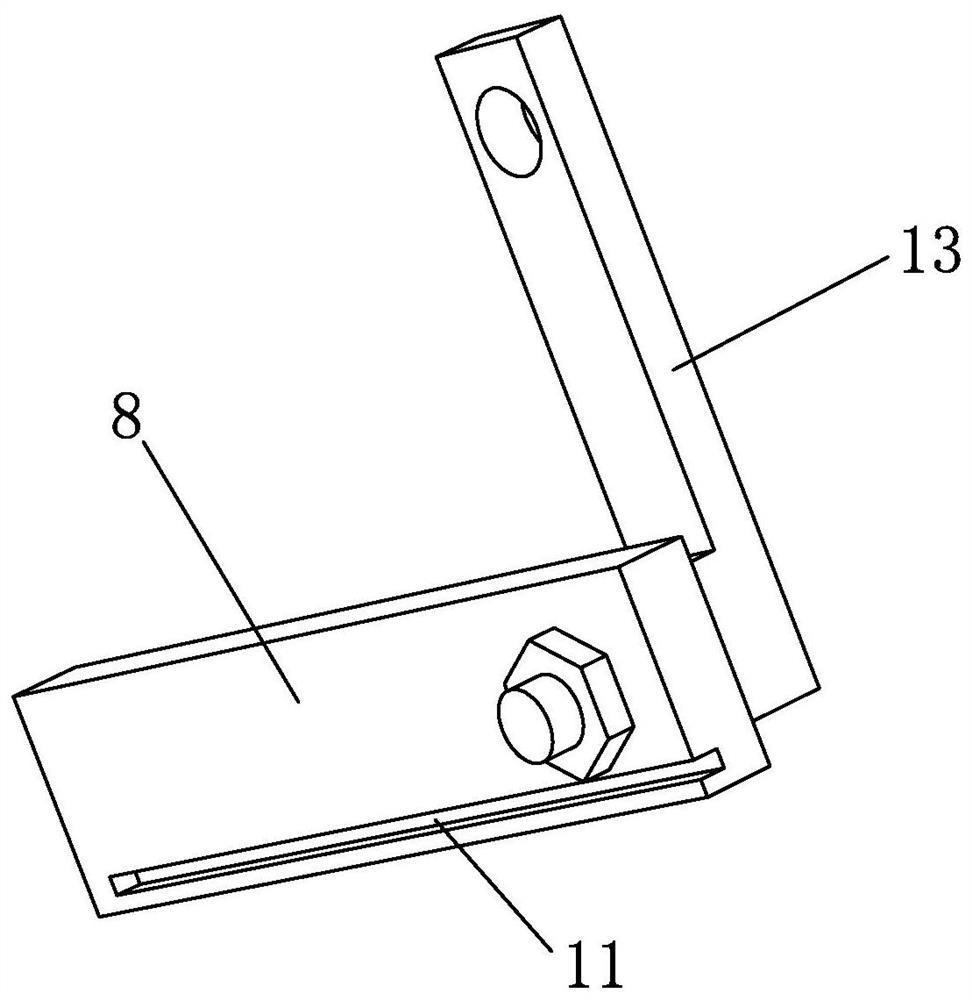

[0040] Such as Figure 1 to Figure 8 Shown, be that the present invention is applied to the non-stick oil coating process of integrated stove oil net, comprises the following steps:

[0041] a. Degreasing treatment:

[0042] (1) In the degreasing tank 1, a degreasing agent composed of an alkaline substance, a surfactant, and a complex capable of softening hard water is placed. It can infiltrate, disperse and emulsify oil stains to achieve the purpose of degreasing.

[0043] (2) Mobile plate 2 is oriented to move on track 3, when mobile plate 2 is arranged on the top of degreasing tank 1, stop mobile plate 2 and move on track 3, open the first hydraulic device 5 on the mounting bracket 4, make The lifting plate 6 fixedly connected to the bottom of the first hydraulic device 5 moves down a set distance, and then measures the vertical distance between the lifting plate 6 and the degreasing tank 1 . Then according to the vertical distance, adjust the inclination angle of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com