Compound oligopeptide capable of improving sexual functions and resisting fatigue, oral preparation of compound oligopeptide and preparation method of oral preparation

A technology of oral preparations and oligopeptides, which is applied in the field of compound oligopeptides, its oral preparations and the preparation of the oral preparations, and can solve problems such as unclear side effects and safety considerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

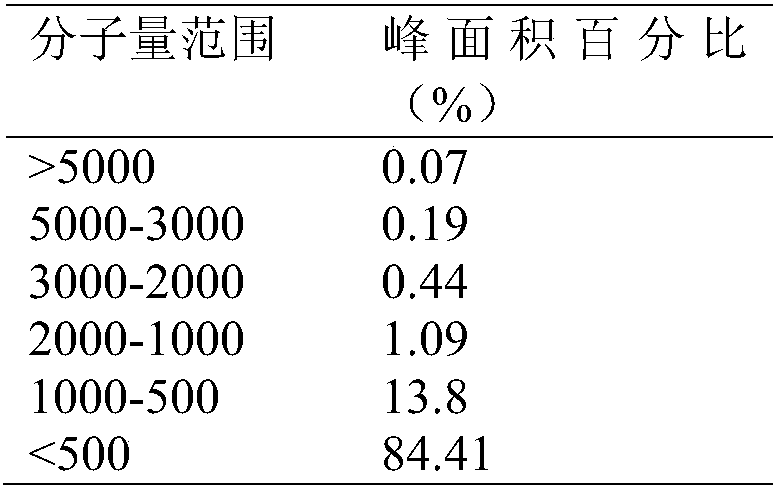

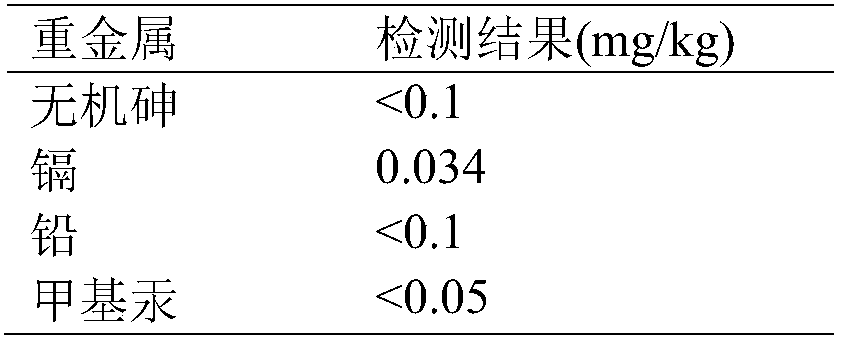

preparation Embodiment 1

[0069] (1) Shelling and beating: take fresh oysters, shell them to get oyster meat, add water, the mass ratio of water to oyster meat is 1:1, and beat into a slurry;

[0070](2) Enzymolysis treatment: adopt biological enzymolysis technology to carry out enzymolysis treatment to the slurry obtained in step (1), the enzyme used is alkaline protease (2.4AU / g, Novozymes, Denmark), and the amount of enzyme added is 1 / 2 of the oyster slurry quality. 2%, the enzymolysis temperature is 50°C, the pH is 8, and the enzymolysis time is 6 hours, the enzymolysis solution is obtained, and the degree of hydrolysis is 20.3%;

[0071] (3) Enzyme-inactivating treatment: the enzymatic hydrolyzate obtained in step (2) was subjected to boiling water to inactivate the enzyme for 10 minutes;

[0072] (4) Clarification treatment: the enzymolysis solution after step (3) deenzyme treatment adopts centrifugation to get the supernatant for subsequent use, centrifugation adopts 10000r / min, centrifugation 1...

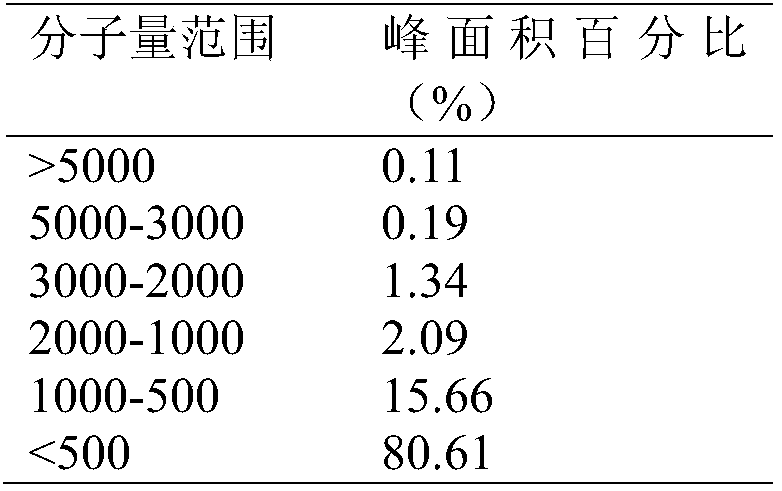

preparation Embodiment 2

[0084] (1) Shelling and beating: take fresh oysters, shell them to get oyster meat, add water, the mass ratio of water and oyster meat is: 2:1, and beat into a slurry;

[0085] (2) Enzymolysis treatment: adopt biological enzymolysis technology to carry out enzymolysis treatment to the slurry obtained in step (1), the enzyme used is selected neutral protease (0.8AU / g, Novozymes, Denmark), and the amount of enzyme added is 1 / 2 of the substrate mass. 2%, the enzymolysis temperature is 40°C, the pH is 7, and the time is 8h, the enzymolysis solution is obtained, and the degree of hydrolysis is 19.4%;

[0086] (3) Enzyme-inactivating treatment: the enzymatic hydrolyzate obtained in step (2) was subjected to boiling water to inactivate the enzyme for 10 minutes;

[0087] (4) Clarification treatment: the enzymolyzed solution after step (3) deenzyme treatment adopts centrifugation to get the supernatant for later use, centrifugation adopts 15000r / min, and centrifuges for 10min;

[008...

preparation Embodiment 3

[0097] (1) Shelling and beating: take fresh oysters, shell them to get oyster meat, add water, the mass ratio of water and oyster meat is: 5:1, and beat into a slurry;

[0098] (2) Enzymolysis treatment: adopt biological enzymolysis technology to carry out enzymolysis treatment to the slurry obtained in step (1), the enzyme used is trypsin (1250USP / mg, Novozymes, Denmark), and the amount of enzyme added is 3% of the substrate mass , the enzymolysis temperature is 50°C, the pH is 7, and the time is 10 hours, the enzymolysis solution is obtained, and the degree of hydrolysis is 40.0%;

[0099] (3) Enzyme-inactivating treatment: the enzymatic hydrolyzate obtained in step (2) was subjected to boiling water to inactivate the enzyme for 10 minutes;

[0100] (4) Clarification treatment: the enzymolysis solution after step (3) deenzyme treatment adopts centrifugation to get the supernatant for subsequent use, centrifugation adopts 15000r / min, centrifugation 20min;

[0101] (5) separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com