Electrostatic oil removal type range hood

A range hood and static electricity technology, which is applied in the fields of oil fume removal, heating method, household stove/stove, etc., can solve the problems of causing danger, troublesome cleaning and maintenance, discount of oil removal effect, etc. trapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

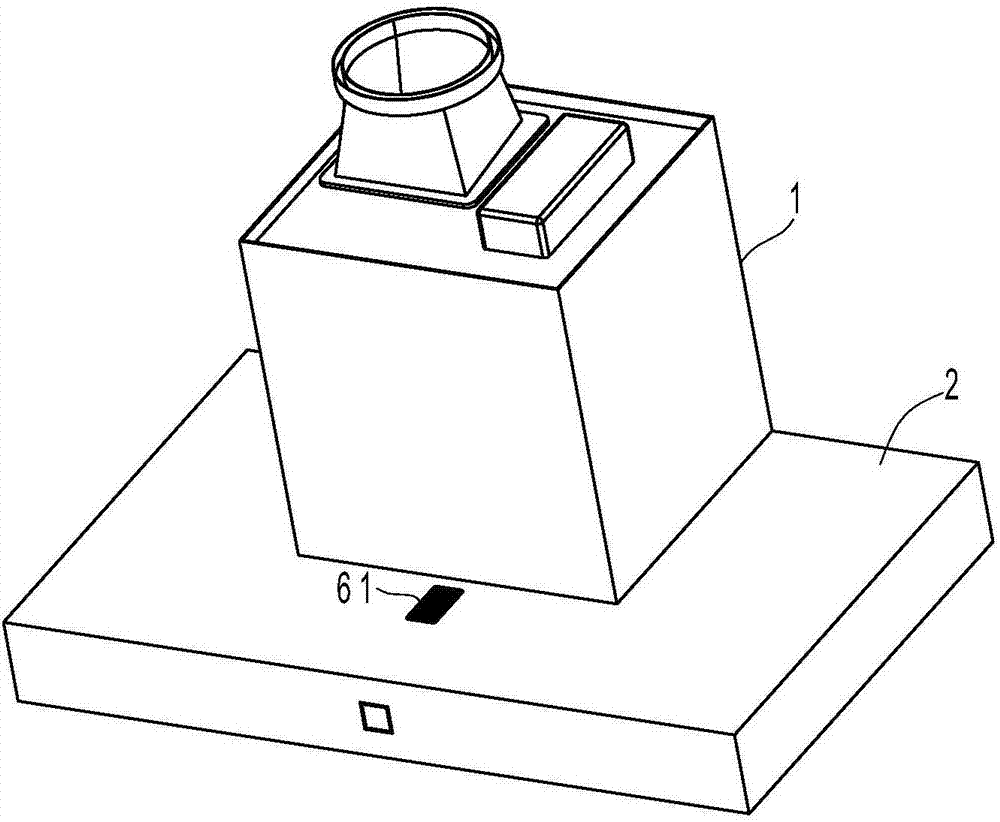

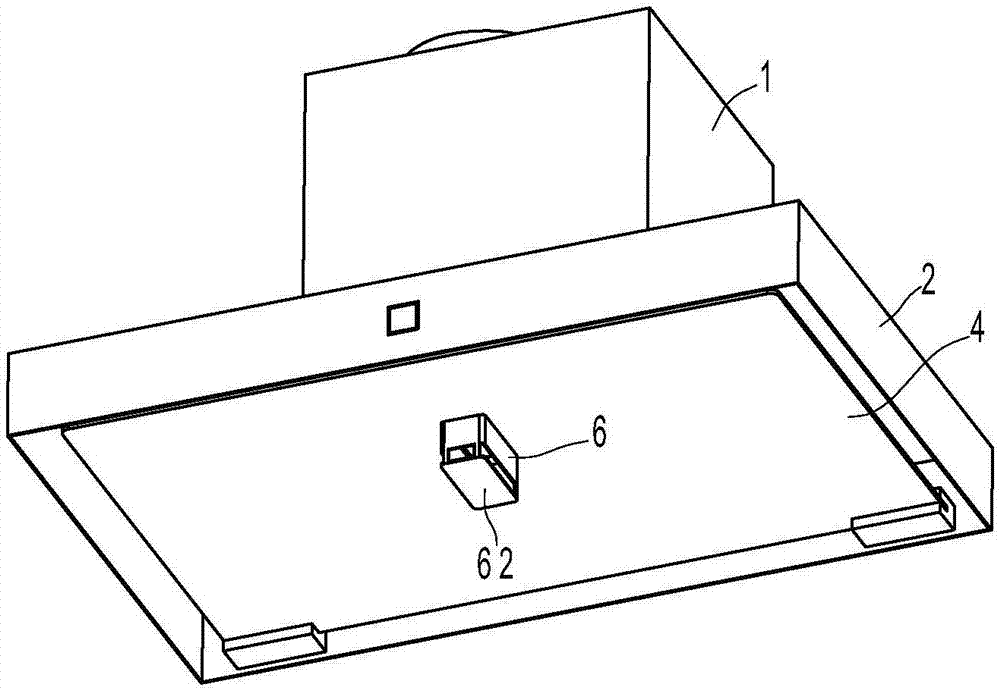

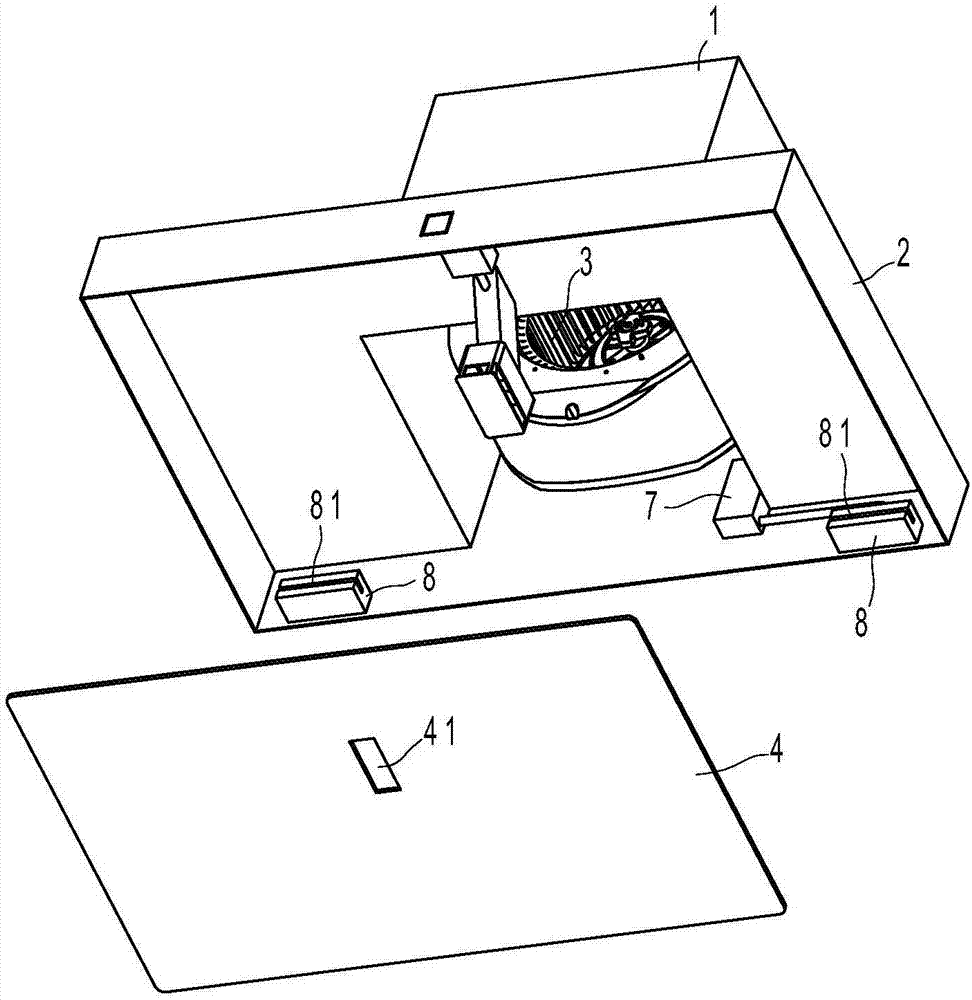

[0020] Such as figure 1 , figure 2 , image 3 As shown, the electrostatic degreasing type range hood summarized in this embodiment includes a casing 1, a smoke collecting hood 2 arranged at the lower port of the casing 1, a fan 3 arranged in the casing, an anion generator 5, an anion channel 6 and a DC positive high voltage The generator 7 and the front port of the fume collecting hood 2 are provided with a rectifying plate 4 for guiding the smoke, and there is a gap between the rectifying plate 4 and the front end of the fume collecting hood 2 for the oil fume to enter. An oil cup (not shown in the figure) is provided at the inner lower end of the smoke collecting hood 2, and the oil cup can receive the oil dripping from the rectifying plate 4.

[0021] An anion generator 5 and an anion channel 6 are arranged in the fume collecting hood 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com