Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Small processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Composite insulation material for cable and preparation method thereof

InactiveCN101619148ALittle effect on insulation performanceEffective insulationRubber insulatorsPlasticizerActive agent

The invention discloses a composite insulation material for a cable and a preparation method thereof. The composite insulation material for a cable comprises the following materials by weight part: 30-60 parts of EPDM rubber, 70-40 parts of styrene-butadiene rubber, 1-4 parts of cross linker, 1-6 parts of cross linker addition agent, 4-16 parts of vulcanizing active agent, 1-4 parts of aging inhibitor, 10-40 parts of plasticizer, 1-3 parts of coupling agent and 100-200 parts of reinforcement filling material. The preparation method comprises the following steps: weighing the materials according to the weight parts; mixing; tabletting; cooling; and collecting. The composite insulation material is used for cable low-voltage insulation, has a temperature resistant level capable of reaching 90 DEG C, can resist heat, ozone and weathers and has high tensile strength, good electrical insulating property and mechanical property and cost being far lower than the cost of ethylene propylene rubber, and the preparation method is simple, applicable and easy to operate.

Owner:SICHUAN MINGXING CABLE

Antimony trioxide master batch and preparation method thereof

The invention discloses antimony trioxide master batch and a preparation method thereof. The antimony trioxide master batch comprises the following components by mass percent: 85 to 95 percent of nano antimony trioxide, 3 to 14 percent of carrier, and 0.1 to 5 percent of modified ethylene bis-fatty-acid amide. The high-efficiency antimony trioxide master batch prepared by the invention has the characteristics of easiness in dispersion, high flame-retardant efficiency and low production cost, and has smaller influence on the physical and mechanical properties, the heat resistance, the processability and the surface color of a composite material than the traditional antimony trioxide master batch.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Composition of wear-resistant polyethylene pipe for underground coal mine, and preparation method of composition

InactiveCN102850637AHigh flame retardant efficiencyAdd lessRigid pipesProcedure AgentsWear resistant

The invention relates to a wear-resistant polyethylene pipe for an underground coal mine, belonging to one of polyethylene modified materials. The wear-resistant polyethylene pipe comprises the raw materials by weight percent: 2-5% of super wear-resistant carbon black, 10-20% of superconducting carbon black, 10-20% of decabromodiphenyl ether, 5-10% of antimony trioxide, 5-10% of POE, 0.5-1% of antioxidant, 2-4% of processing agent and the balance of high density polyethylene. The super wear-resistant carbon black has the required particle size of 11-15nm, the iodine absorption value of 145-152g / kg and the dibutyl phthalate (DBP) absorption value of 113-120cm<3> / 100g. The wear-resistant polyethylene pipe has the advantages that excellent flame retardant and antistatic performance is excellent, and wear resistance is high, so that the flame retardant and the antistatic performance and the mechanical property of the pipe are guaranteed not to be reduced due to dragging and friction in the processes of installation and use, and the safety factor of underground coal mine operation can be improved.

Owner:TIANJIN JUNXING PIPE GRP CO LTD

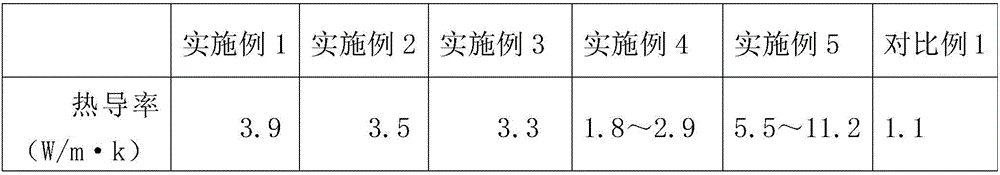

Graphene polymer composite heat-conduction plastic and preparation method

The invention discloses a graphene polymer composite heat-conduction plastic and a preparation method. The graphene polymer composite heat-conduction plastic comprises the following components in parts by weight: 100 parts of polymer matrix resin, 2-10 parts of modified graphene, 0.1-1 part of an antioxidant. The preparation method of the graphene polymer composite heat-conduction plastic comprises the following steps: step 1, preparing modified graphene; and step 2, preparing the graphene polymer composite heat-conduction plastic. Dispersity of the graphene in a resin matrix is improved, graphene agglomeration is reduced, the high-heat-conductivity heat-conduction plastic can be obtained when the content of the graphene is low, high heat conductivity can be achieved by the small content of the graphene only, influence to basic mechanical property and processing property of the material is low, and the technical requirement on modern electronic packaging can be met well.

Owner:金华碳力新材料科技有限公司

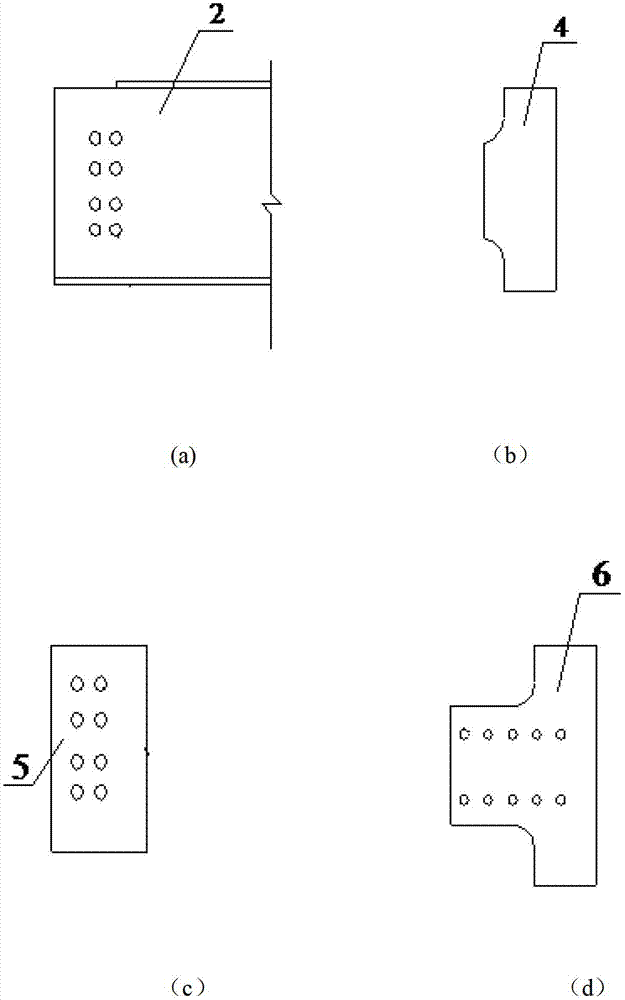

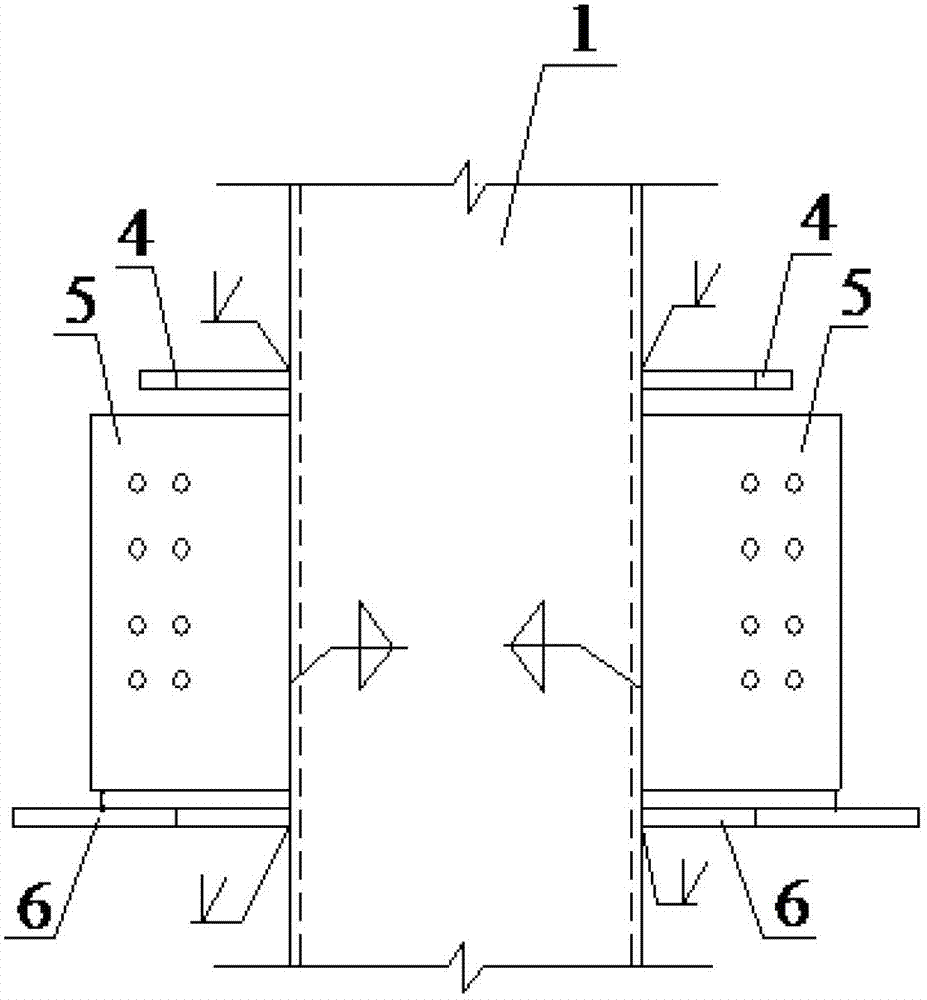

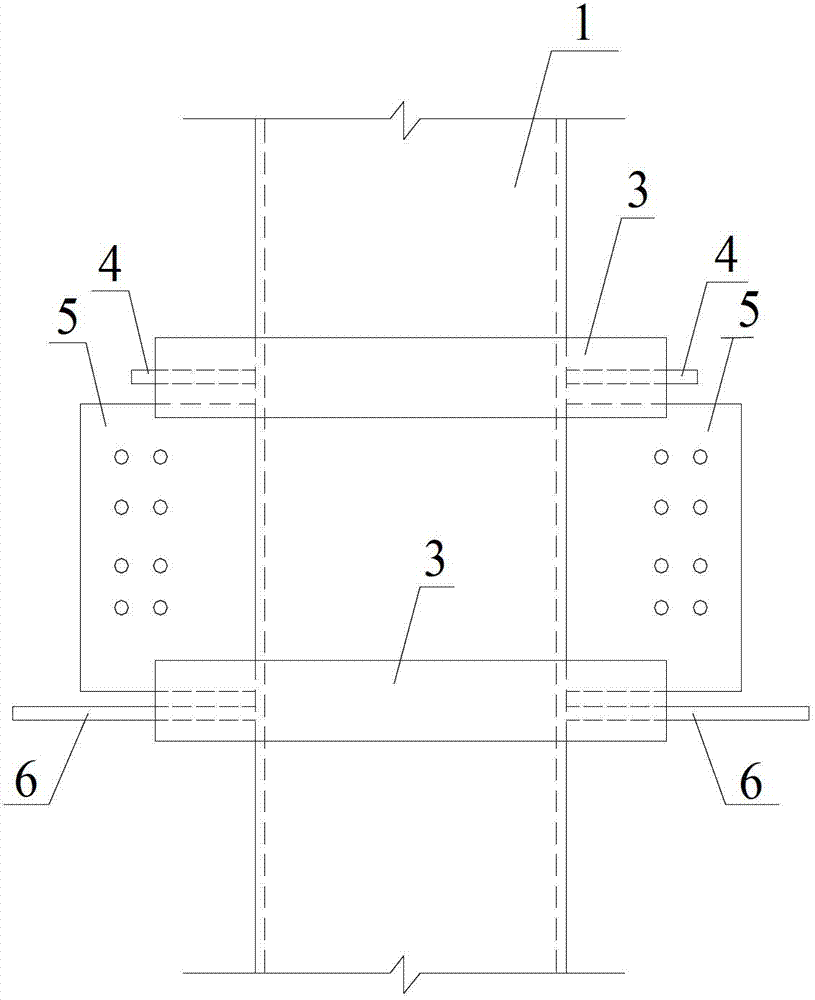

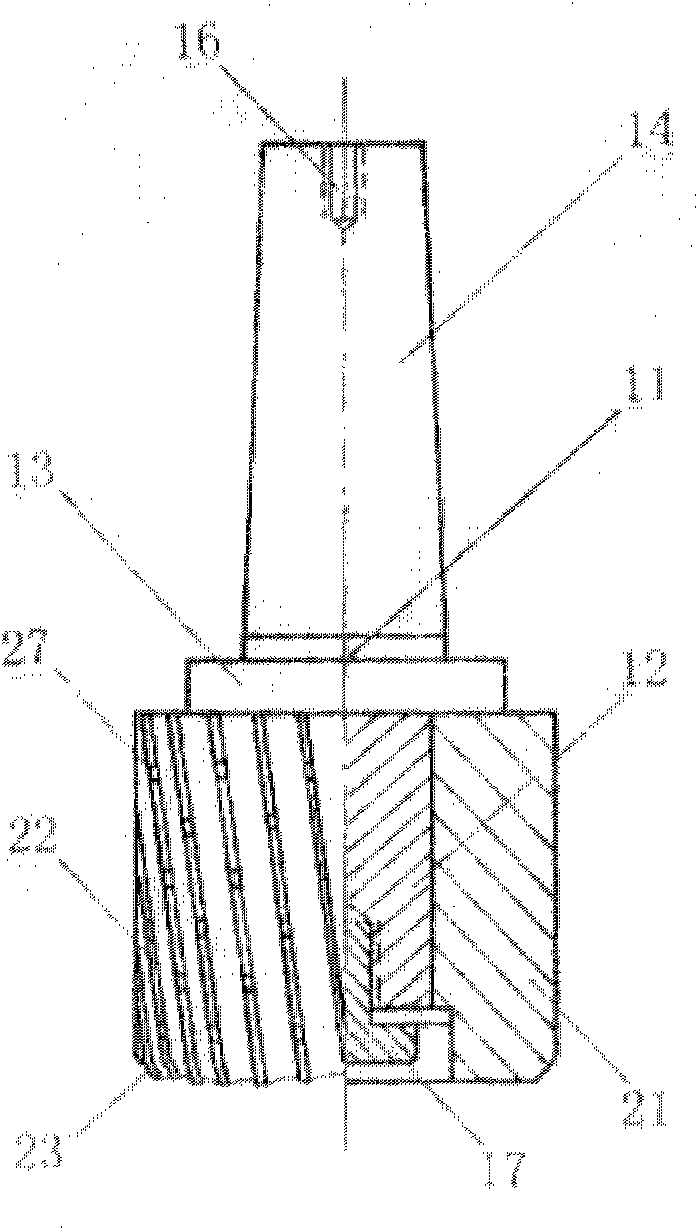

Rectangular steel pipe concrete column steel beam lower bolt upper welding outer rib annular plate node construction method

The invention belongs to the technical field of engineering construction, and relates to a rectangular steel pipe concrete column steel beam lower bolt upper welding outer rib annular plate node construction method. The rectangular steel pipe concrete column steel beam lower bolt upper welding outer rib annular plate node construction method is applied to two occasions, one occasion is an occasion with a single beam: an upper outer annular plate and a lower outer annular plate are welded by groove welding at the corresponding heights of the wall of a rectangular steel pipe concrete column, a web connecting board is welded between the upper outer annular plate and the lower outer annular plate through a fillet weld, and a clearance for the lower wing edge of the steel beam to be inserted into is reversed in advance on the lower portion of the web connecting board. An upper vertical rib board and a lower vertical rib board which are arranged at two sides are closely attached on the upper outer annular plate and the lower outer annular plate to be connected with the steel pipe concrete column in a welding mode, wherein the vertical rib plates are connected with the steel pipe concrete column through the fillet weld, the vertical rib plates are connected with the upper outer annular plate and the lower outer annular plate through the groove weld. After the mentioned processing is achieved, the mentioned components are installed as a whole on site. The invention further provides a construction method of beams at two directions. The rectangular steel pipe concrete column steel beam lower bolt upper welding outer rib annular plate node construction method has the advantages of being more reasonable in stress tolerance, convenient and fast to construct.

Owner:TIANJIN UNIV

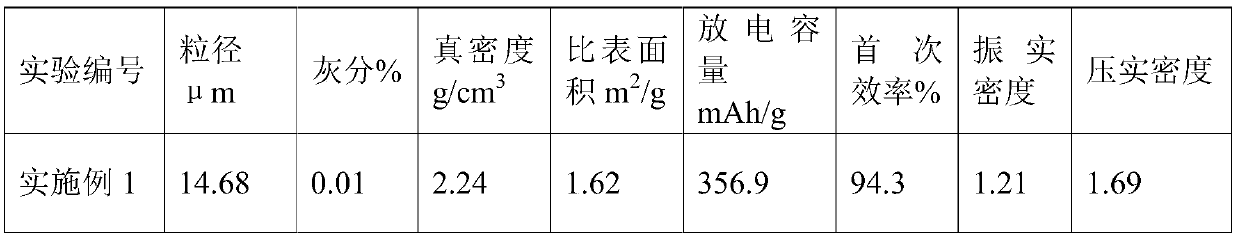

High-capacity and high-rate composite graphite negative electrode material preparation method

ActiveCN109911892AIncrease capacityHigh rate charge and discharge performanceCarbon compoundsCell electrodesLithium electrodeLarge capacity

The invention relates to the technical field of a lithium ion battery negative electrode materials, particularly to a high-capacity and high-rate composite graphite negative electrode material preparation method, which comprises: carrying out low-temperature carbonization on an artificial graphite particle material, crushing to achieve a particle size of 8-11 [mu]m, carrying out room temperature surface modification on the raw ball of mesophase carbon microspheres, mixing the two obtained materials and a binder, carrying out secondary coating modification granulation, and carrying out high temperature graphitization treatment to obtain the high-capacity and high-rate composite graphite negative electrode material. Compared with the material in the prior art, the material of the present invention has the following advantages that the disadvantages of poor rate of artificial graphite and low capacity of mesophase carbon microspheres are overcome, and the prepared product has advantages of high capacity and high rate charge and discharge performance. With the prepared product of the present invention, the single particle and the secondary coated particle are stacked and filled throughthe prepared product, the directional distribution of the particles is increased, the bounce of the electrode sheet is low, rebounds small, the electrolytic solution is smoothly inserted into the carbon and graphite material, and the cycle performance is excellent.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

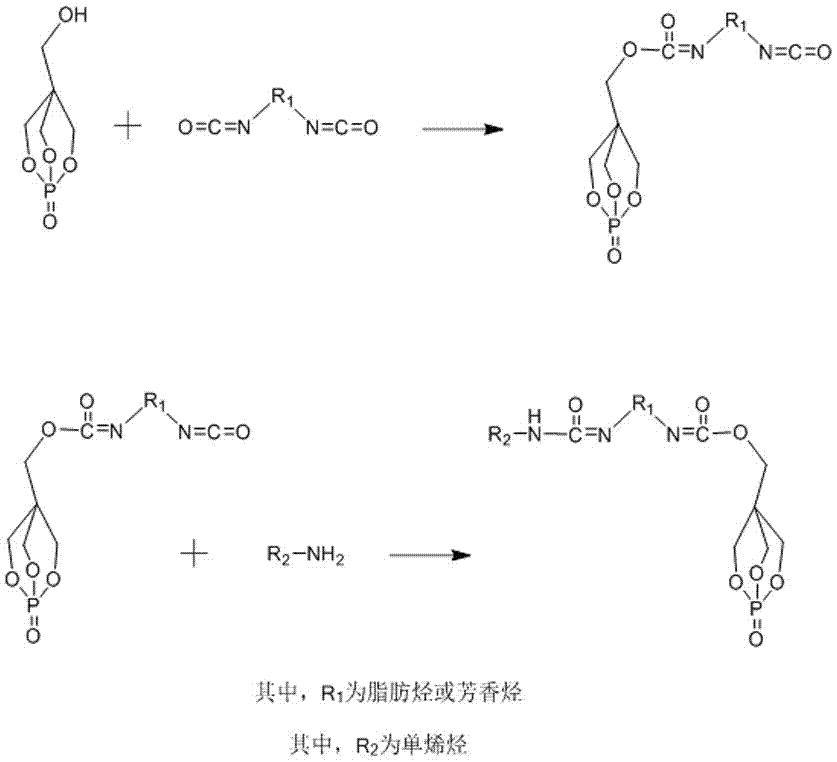

Preparation method for reaction type nitrogen-phosphorus flame retardant

ActiveCN107056840AReduce the emission of toxic and harmful gasesReduce environmental pollutionGroup 5/15 element organic compoundsSolventUnsaturated fat

The invention discloses a preparation method for a reaction type nitrogen-phosphorus flame retardant and relates to the technical field of a nitrogen-phosphorus flame retardant and a preparation method thereof. The method comprises the following steps: 1) purifying pentaerythritol phosphonate (PEPA); 2) activating PEPA with isocyanic acid; and 3) preparing the reaction type nitrogen-phosphorus flame retardant: weighting unsaturated aliphatic amine (alcohol), dropwise adding into the PEPA activated with isocyanic acid in the step 2, reacting for 4-10h at the revolving speed of 80-230r / min in a water bath kettle at 40-120 DEG C, ending the reaction, washing with a xylene solvent for 2-4 times, and performing vacuum drying for 10-72h at 70-120 DEG C, thereby acquiring the reaction type nitrogen-phosphorus flame retardant. The fire retardant disclosed by the invention is mainly composed of nitrogen, phosphorus and carbon elements, has excellent thermal stability and chemical stability, is halogen-free, low-smoke, low-toxicity and environment-friendly, contains double active bonds, can be directly used as a chain extender for reacting with a monomer for compounding an anti-flaming macromolecule material, and is simple in bonding mode.

Owner:广州喜嘉新材料有限公司

Special halogen-free flame-retardant master batch for polypropylene and preparation method for halogen-free flame retardant master batch

The invention discloses a special halogen-free flame-retardant master batch for polypropylene and a preparation method for the halogen-free flame retardant master batch. Components of the master batch comprise, in mass percent, 75-90% of phosphorus-nitrogen halogen-free flame retardant, 8-22% of carrier and 0.1-5% of modified ethylene bis-fatty acid amide. By the aid of the master batch, quality instability of materials due to non-uniform mixing of powder and granules is effectively avoided, easiness in generation of chippings or powder during granule cutting is avoided, production efficiency is improved, and production cost is lowered. Adopting a continuous banburying-extrusion production process leads production efficiency to be high. The master batch effectively solves the problems of easiness in moisture absorption, degradation and foaming of halogen-free flame retardant, so that storage time of the phosphorus-nitrogen halogen-free flame retardant is prolonged, and processability of the phosphorus-nitrogen halogen-free flame retardant is improved. Besides, the special halogen-free flame-retardant master batch for the polypropylene has the advantages of easiness in dispersion, high flame-retardant efficiency and low production cost, and has less influence on physical and mechanical properties, heat resistance, processability and surface color of composite materials than a special traditional halogen-free flame-retardant master batch for polypropylene.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS +1

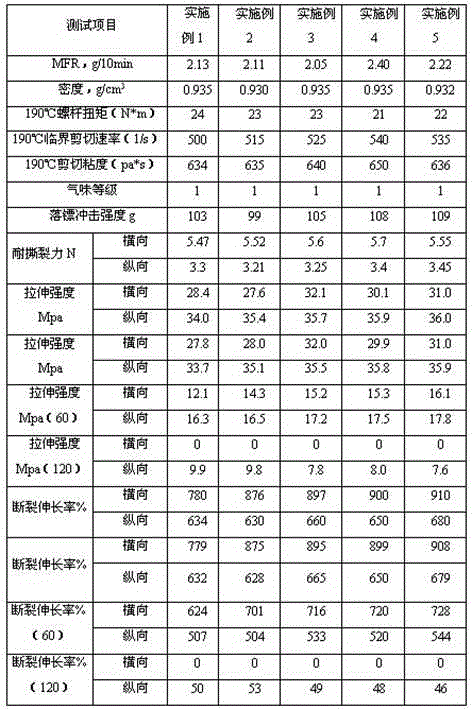

Polyethylene composition low in energy consumption and easy to light-degrade and preparation method thereof

The invention discloses a polyethylene composition low in energy consumption and easy to light-degrade and a preparation method thereof, and belongs to the technical field of polyethylene film processing. The composition is prepared from the following components in parts by weight: 70-85 parts of polyethylene a, 10-30 parts of polyethylene b, 3-10 parts of polyethylene c, 0.025-0.1 parts of a phosphite ester antioxidant, 0.5-3 parts of a photosensitive degrading agent, 0.5-1 part of an auxiliary photodegradable agent and 0.05-0.3 part of a processing lubrication additive. The polyethylene composition low in energy consumption and easy to light-degrade is high in degrading efficiency, uniform in dispersion, free of additionally carrying out surface modification on the degrading agent and low in processing energy consumption; the degrading effect of the degrading agent is remarkably superior to the degrading agent of the conventional biodegrading principle; the dosage of the degrading agent is less; the film prepared from the composition has excellent tensile strength, dart drop impact strength and tear resistance.

Owner:CHINA PETROLEUM & CHEM CORP

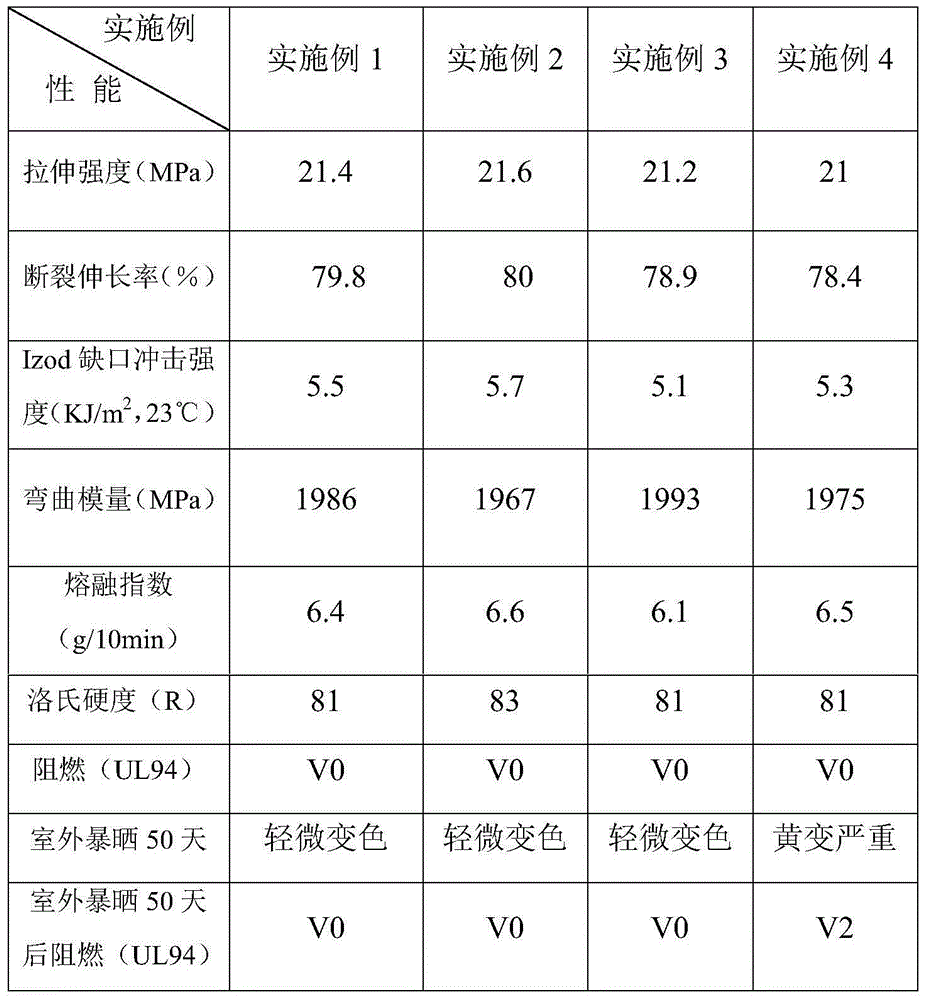

Environment-friendly weather-resistant flame-retardant PP material and preparation method thereof

InactiveCN104448574AMeet environmental protection requirementsDoes not produce corrosive gasesEnvironmental resistanceUltraviolet lights

The invention relates to an environment-friendly weather-resistant flame-retardant PP material and a preparation method thereof. The PP material is prepared from the following components in percentage by weight: 20-30% of homo-polypropylene, 35-45% of polypropylene copolymer, 25-30% of a compound expansive type halogen-free flame-retardant, 5-10% of talcum powder, 0.2-0.4% of an ultraviolet light absorber, 0.2-0.4% of an antioxidant and 0.2-0.5% of a lubricant. The process comprises the following steps: firstly adding the materials in proportion into a mixing barrel to be uniformly mixed; then adding the mixture into a twin-screw extruder to be mixed, wherein the extruding temperatures of the first and second sections of the twin-screw extruder are 160-170 DEG C while the extruding temperatures of other sections are 170-190 DEG C and the total standing time of reactants in the twin-screw extruder is 3-5 minutes; and finally, cooling and slicing the extruded material obtained to obtain the environment-friendly weather-resistant flame-retardant PP material. By modifying PP, the material is environmentally friendly and flame-retardant, and also can satisfy the long-term anti-aging using requirement outdoors.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

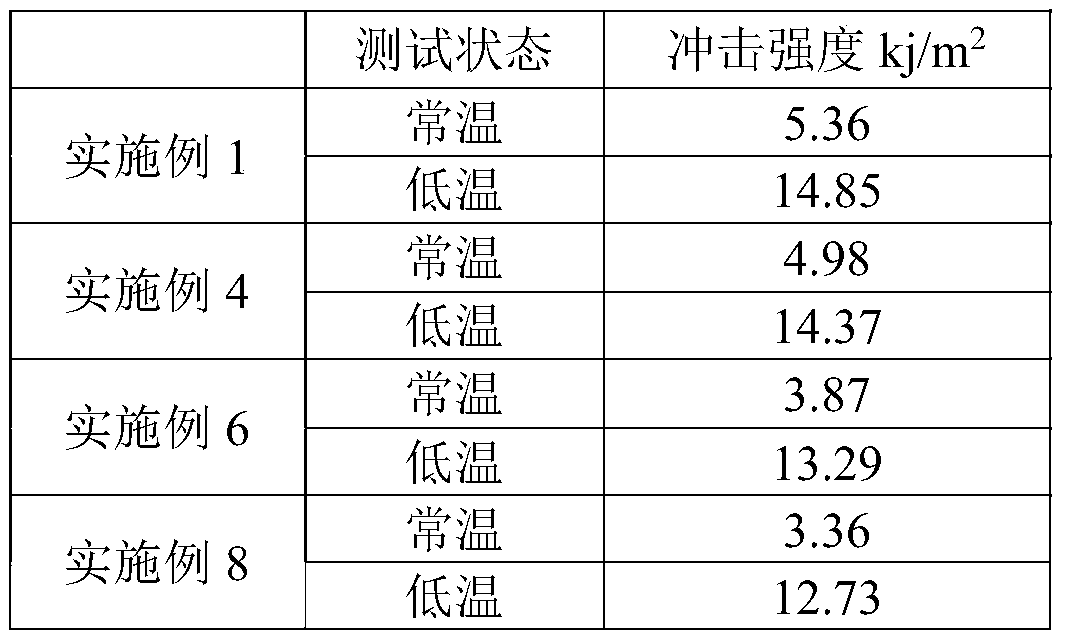

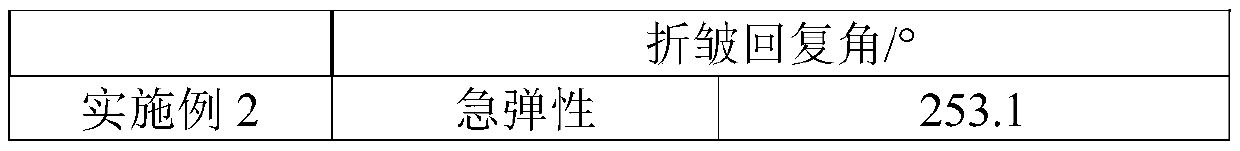

U-PVC pipe with high impact resistant performance

The invention relates to a U-PVC pipe with a high impact resistant performance. The U-PVC pipe comprises the following components in parts by weight: 100 parts of PVC-SG8 resin, 1 to 10 parts of ABS resin powder, 1 to 10 parts of solubilizer, 1 to 10 parts of heat stabilizer, 0.1 to 5 parts of lubricant, 0 to 5 parts of processing modifier, 5 to 50 parts of filling agent, and 0.5 to 5 parts of titanium dioxide. The pipe comprises ABS powder, the chain sections of butadiene rubber of ABS can absorb the impact energy, and thus the pipe can well resist the impact. At the same time, the amount of added ABS powder is little, the influence on the processing property and product stability is small, and the production is barely affected. A proper amount of CPE is added to increase the capacity of the ABS / PVC system, in the microscopic view, the phase separation degree is decreased, and thus the impact resistant effect is enhanced.

Owner:ZHEJIANG TONGZHENG PIPE TECH

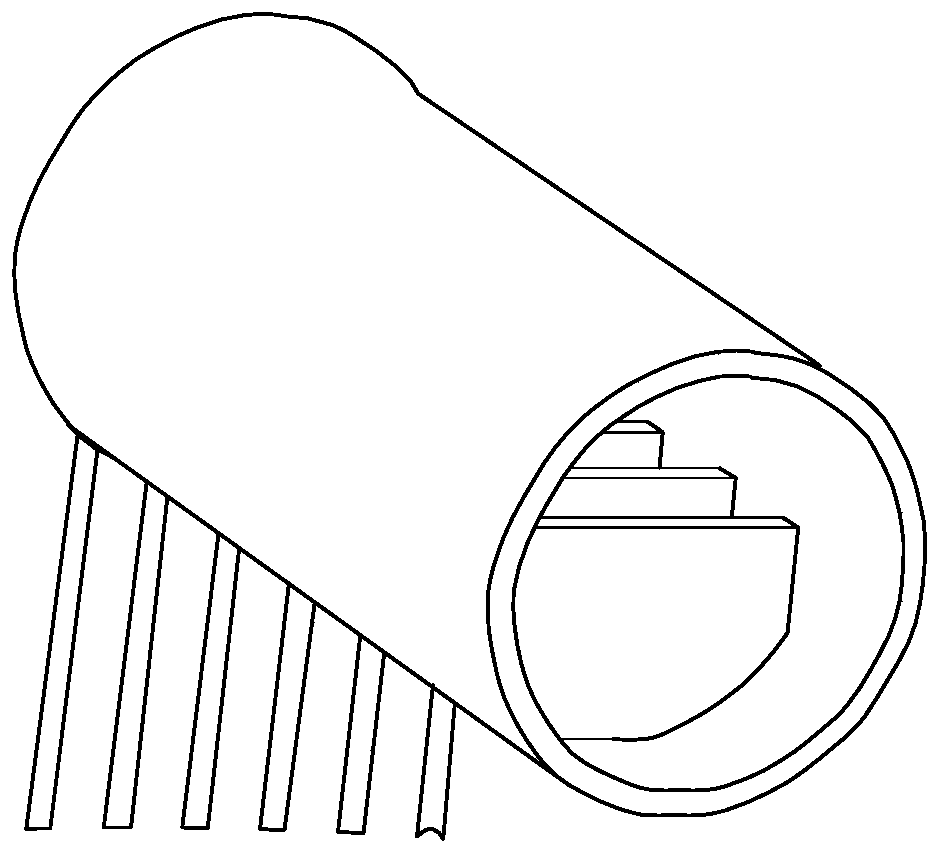

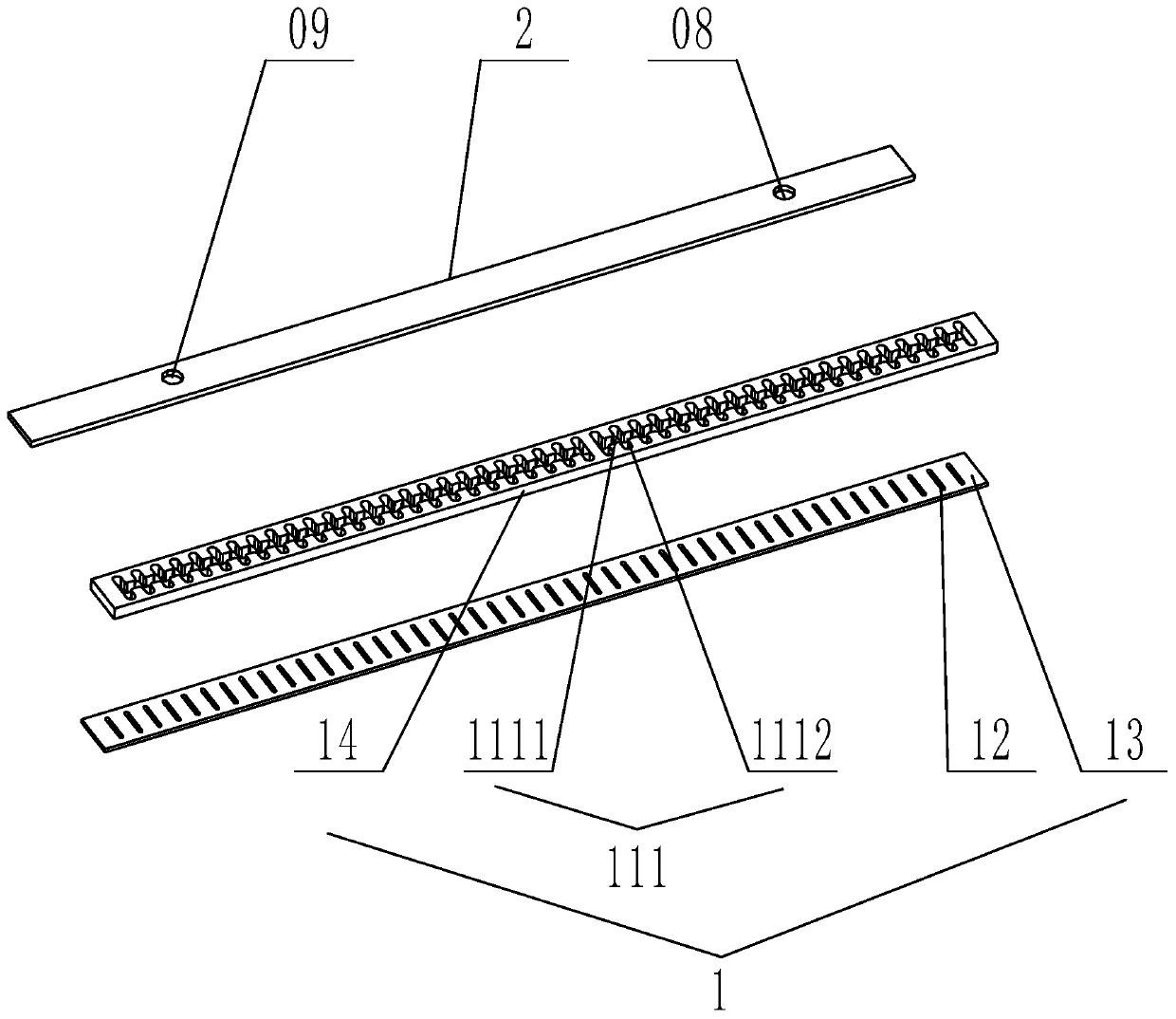

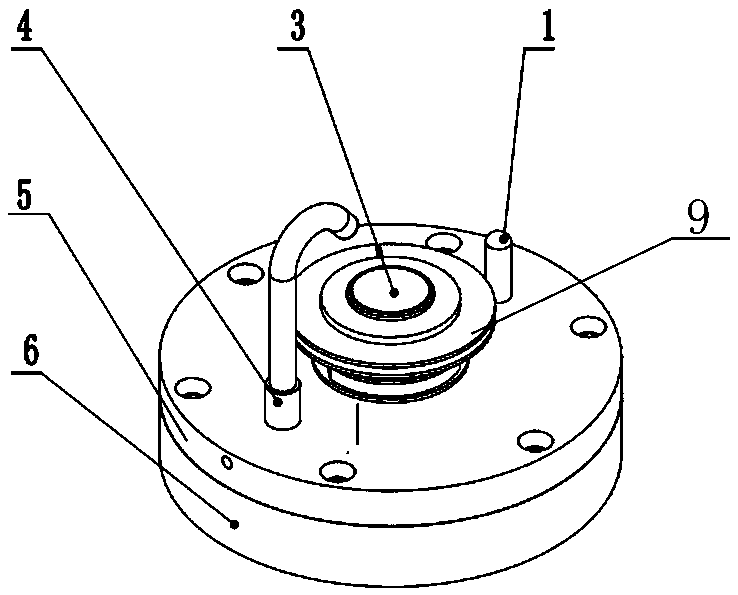

Flow collecting pipe assembly and heat exchanger

PendingCN110118505ASufficient stress resistanceIncrease wall thicknessEvaporators/condensersStationary conduit assembliesEngineeringUltimate tensile strength

The invention relates to the technical field of heat exchange devices, in particular to a flow collecting pipe assembly and a heat exchanger. The flow collecting pipe assembly comprises a flow collecting plate and a cover plate. The flow collecting plate comprises a flow collecting plate body, a flow collecting channel and multiple insertion grooves, wherein the flow collecting channel and the multiple insertion grooves are formed in the flow collecting plate body. The multiple insertion grooves communicate with the flow collecting channel. In addition, in the thickness direction of the flow collecting plate, one end of the flow collecting channel is closed, and the other end of the flow collecting channel is opened. The cover plate is connected to the flow collecting plate in an overlapped manner so as to seal the other end of the flow collecting channel. The flow collecting pipe assembly is high in strength and convenient to machine.

Owner:ZHEJIANG YINLUN MACHINERY

Preparation method of high-strength PP material containing coffee grounds

The invention provides a high-strength PP material containing coffee grounds. The high-strength PP material comprises the following components: 35-45% of copolymerized PP, 30-45% of the coffee grounds, 5-10% of talcum powder, 0.2-0.4% of an ultraviolet light absorber, 0.2-0.4% of an antioxidant and 0.2-0.5% of a lubricant. The method comprises the following steps: adding the components into a mixing cylinder according to the ratio, and uniformly mixing; adding the mixture into a double-screw extruder for mixing; wherein the extrusion temperature of the first section and the second section of the double-screw extruder is 160-170 DEG C, the extrusion temperature of other sections is 170-190 DEG C, and the total residence time of reactants in the double-screw extruder is 3-5 minutes; and finally, extruding the obtained material, cooling and dicing to obtain the high-strength PP material containing the coffee grounds. By modifying PP, environmental protection and flame retardance are achieved, and the outdoor long-term anti-aging use requirement can be met.

Owner:咖法科技(上海)有限公司

Long-acting, washable, low-temperature-resistant, colorless and transparent liquid antistatic agent for rubber and plastic and preparation of long-acting, washable, low-temperature-resistant, colorless and transparent liquid antistatic agent

The invention relates to the field of antistatic agents and discloses a long-acting, washable, low-temperature-resistant, colorless and transparent liquid antistatic agent and a preparation method ofthe long-acting, washable, low-temperature-resistant, colorless and transparent liquid antistatic agent. The antistatic agent comprises 20-55% of polyoxyethylene type nonionic surfactant, 5-10% of polyester polyol, 5-15% of ionic compound, 30-45% of dispersing agent and 5-10% of functional auxiliaries. The preparation method is simple in process and equipment and easy to operate, and the preparedantistatic agent is colorless and transparent, excellent in low temperature resistance, good in compatibility with rubber, low in use amount, capable of allowing a product to have a lasting antistatic effect, good in washability, especially suitable for a rubber system and widely applicable to the static resistance of products such as oil-resistant rubber pipes, conveying bels, sealing products and printing and dyeing products.

Owner:杭实科技发展(杭州)有限公司

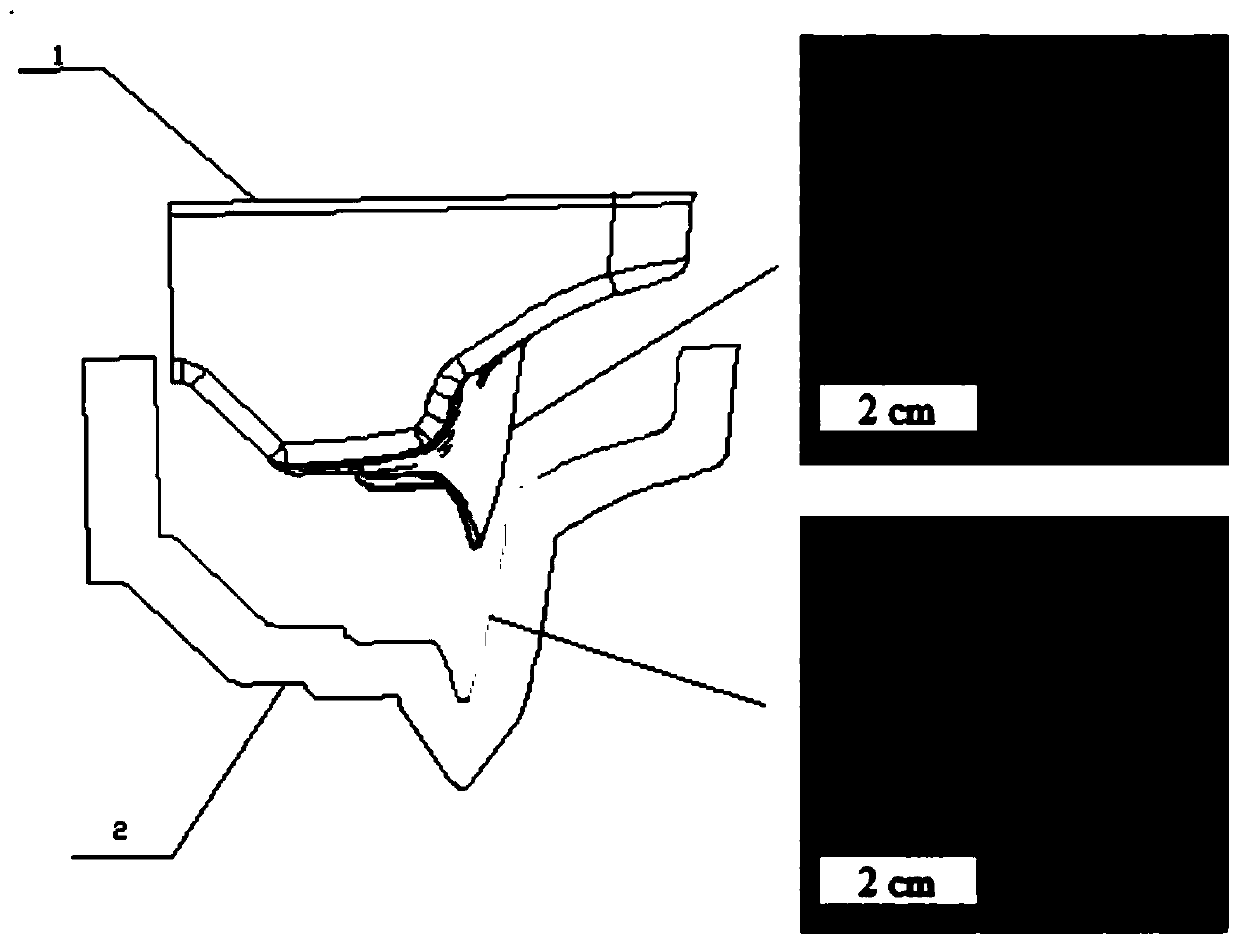

Method and milling cutter for repairing surface defect of cement concrete construction member

InactiveCN101876208AGuaranteed cutting forceGuaranteed StrengthBuilding repairsCeramic shaping apparatusMilling cutterArchitectural engineering

The invention discloses a method and a milling cutter for repairing surface defect of a cement concrete construction member, which is used for repairing the surface defects of the building construction members, such as cement concrete wall, piers, girders, plates and the like. For defects of cracks, local damage, voids and pits and the like on the surface of the building construction member, the method and the special milling cutter of the invention firstly remove defects, form a repairing groove and pour concrete again to repair. The method and the milling cutter of the invention can process the surface of the construction member into geometry, such as a plane, a cambered surface, a groove and the like, and especially processes the boundary surface of the repairing groove into regular, smooth, rough and circular-arc corner, which is favourable for construction stress and combination of new and old concrete, improves appearance quality and solves the difficulty problem that the surface of the cement concrete construction member is difficult to repair.

Owner:HEFEI UNIV OF TECH

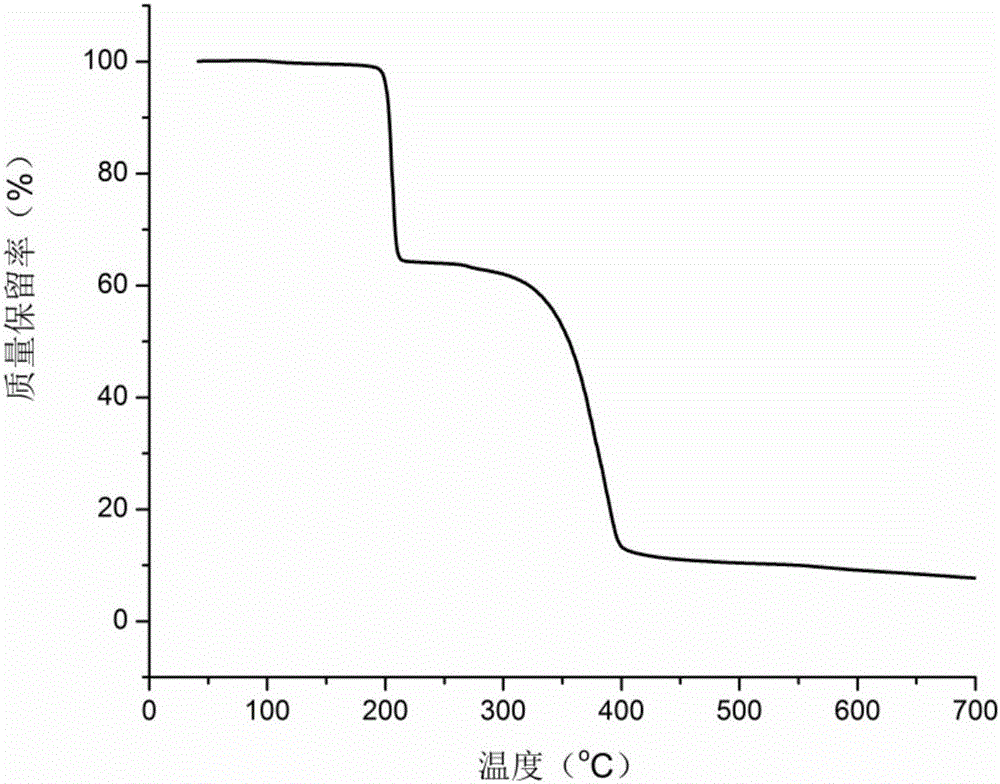

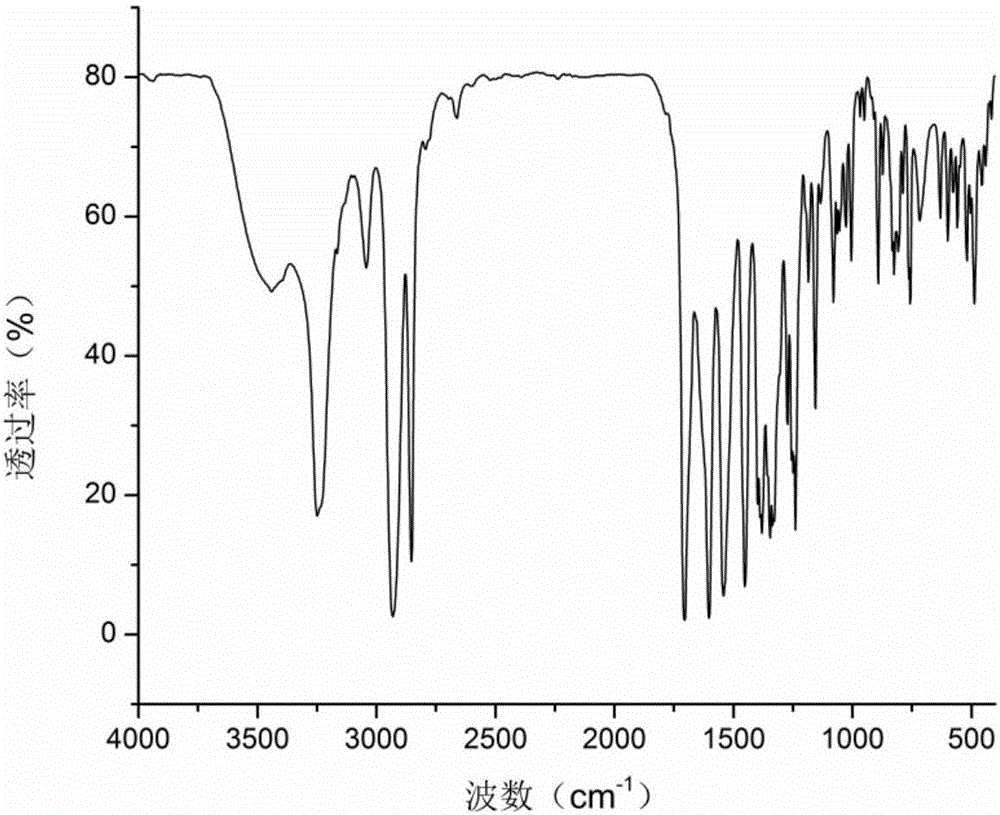

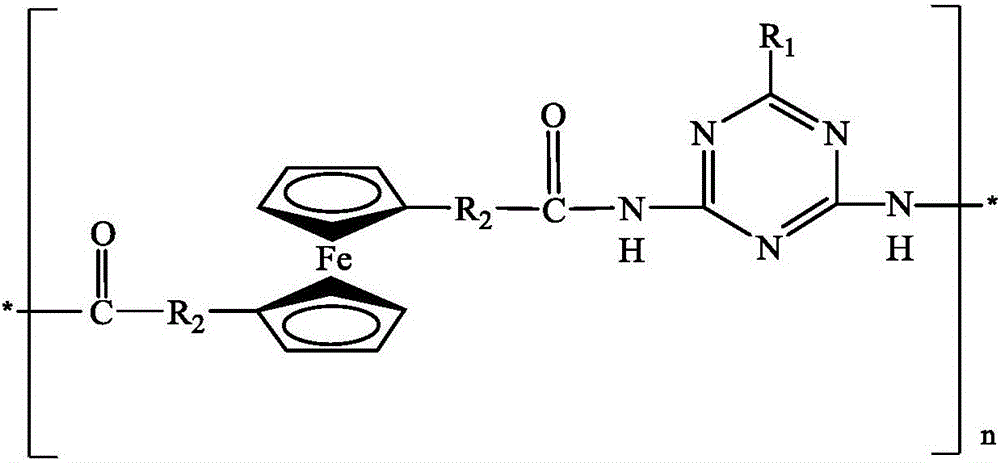

Ferrocene-thiotriazinone biradical polyamide synergistic charring agent and preparation method and application thereof

The invention discloses a ferrocene-thiotriazinone biradical polyamide synergistic charring agent shown in the formula (I) and a preparation method thereof.The preparation method of the polymer includes the steps that phenol, distilled water, an acid-binding agent I, cyanuric chloride, an organic solvent I and the like serve as raw materials and are prepared into an intermediate I through chemical reaction, the intermediate I, an acid-binding agent II, ammonia water, an organic solvent II and the like are prepared into an intermediate II through chemical reaction, and then the intermediate II, a raw material I, a dehydration agent, organic alkali, an organic solvent III and the like are prepared into the ferrocene-thiotriazinone biradical polyamide synergistic charring agent through chemical reaction.The polyamide synergistic charring agent is a polymerization type flame-retardant agent, can be used for flame retardance of plastic and other organic high polymer materials, can effectively improve heat stability and increase the residual carbon amount of a system, promotes matrix degradation cross-linking charring and compact carbon layer forming, and reduces release of smoke.The preparation method is simple and easy to control, and the polyamide synergistic charring agent is easy to obtain, good in performance and high in practicality.The formula (I) is as shown in the description.

Owner:SOUTHWEAT UNIV OF SCI & TECH

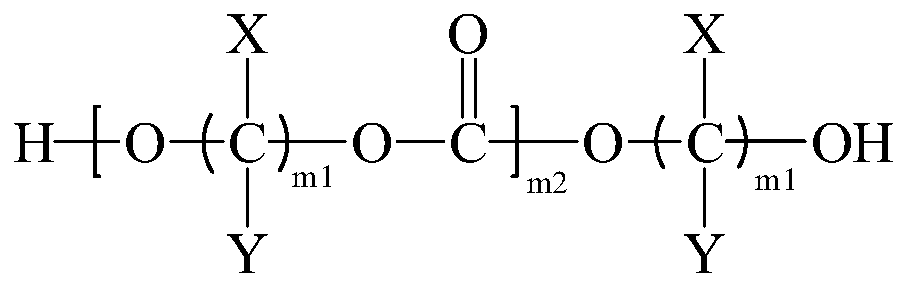

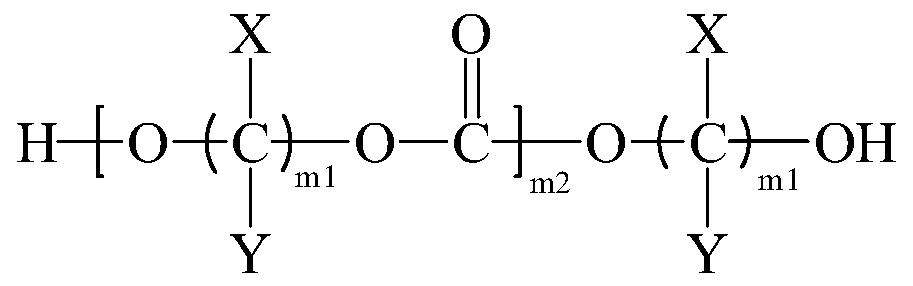

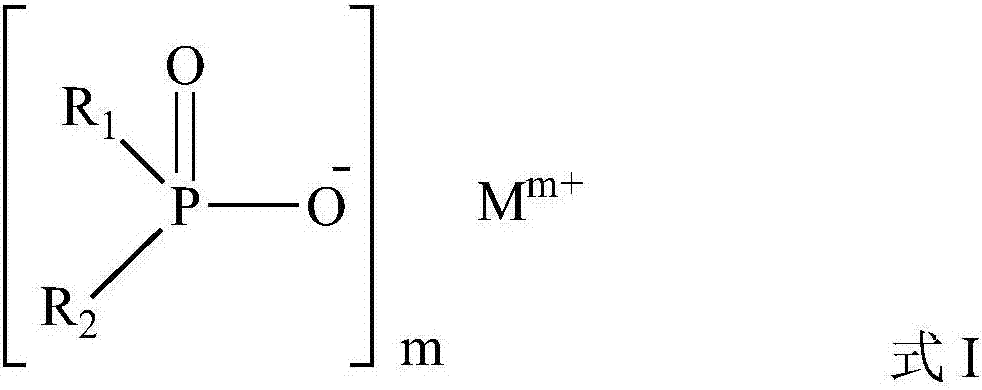

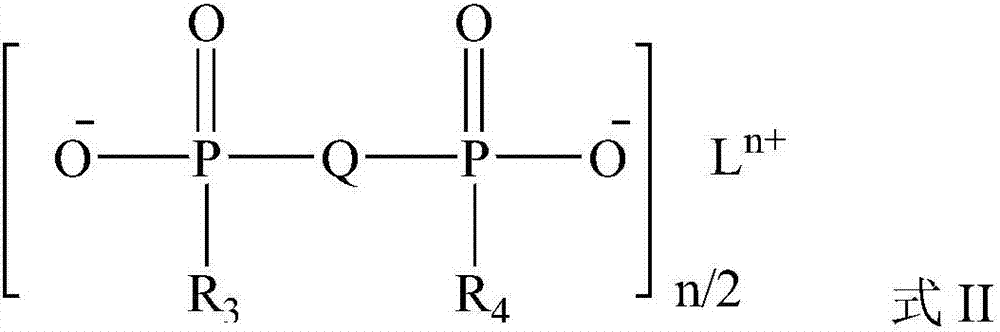

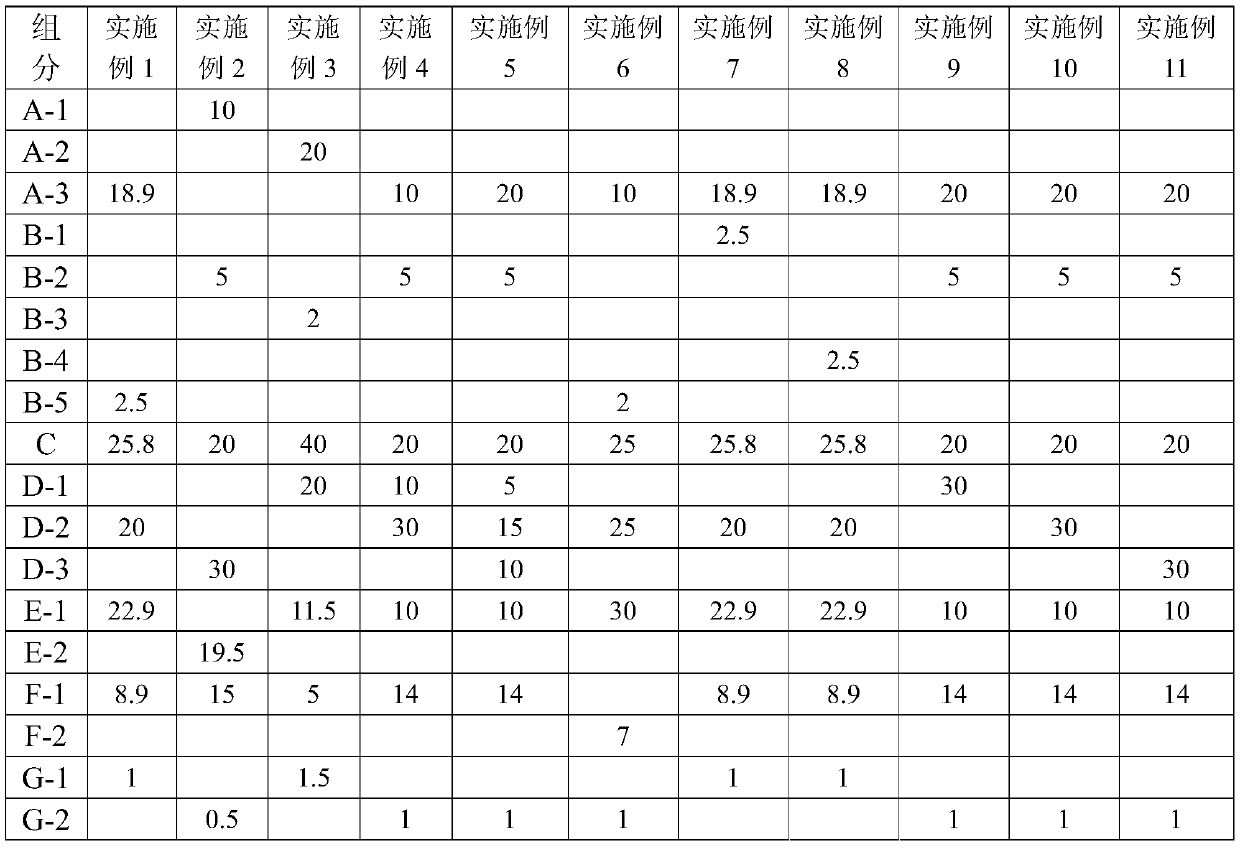

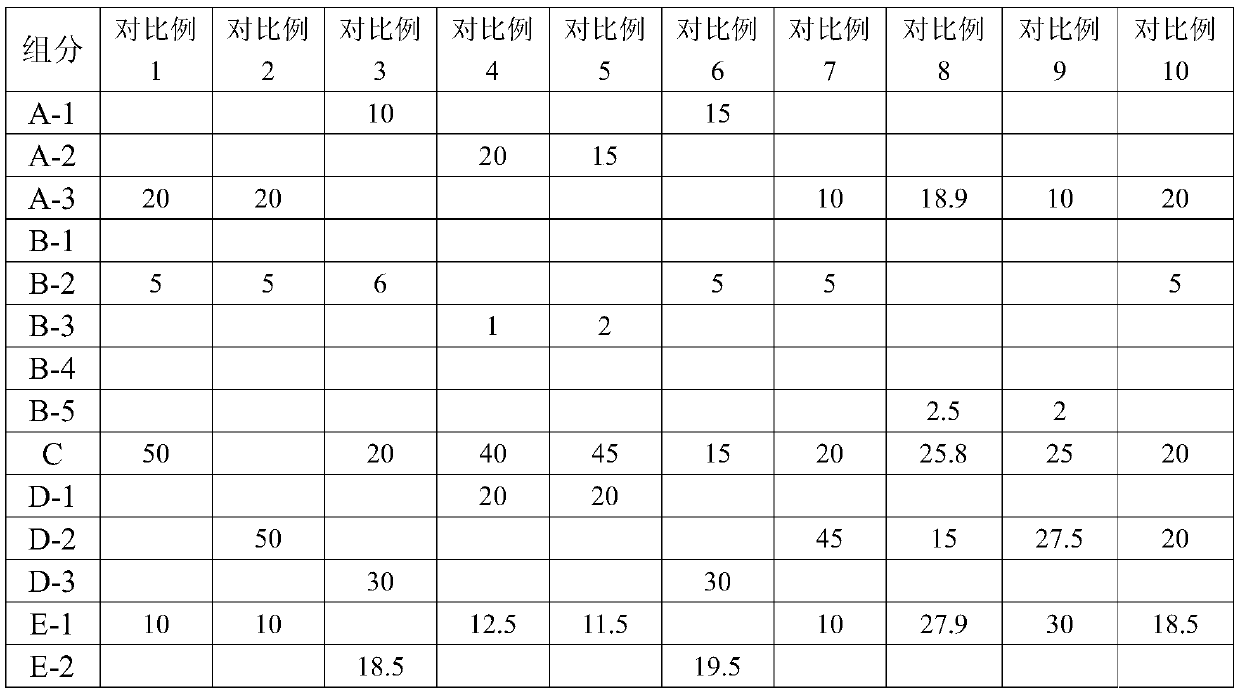

Halogen-free flame retardant and high-polymer material with same

ActiveCN107057300AImprove thermal stabilityHigh flame retardant efficiencyPentaerythritolCarboxylic salt

The invention discloses a halogen-free flame retardant. The halogen-free flame retardant is characterized by comprising components A and components B; the components A selectively comprise at least one type of compounds in chemical formulas shown as a formula I and compounds in chemical formulas shown as a formula II; the components B selectively comprise at least one type of phosphite of pentaerythritol, organophosphate of pentaerythritol and carboxylate ester of pentaerythritol. The halogen-free flame retardant has the advantages that the shortcoming of low flame retardant efficiency of dialkyl phosphinates for engineering plastics can be overcome by the aid of the halogen-free flame retardant, and the problems of low heat stability, poor flame retardant efficiency, narrow application range and possible defects in the aspects of processing and physical properties of dialkyl phosphinates synergists in the prior art can be solved by the aid of the halogen-free flame retardant.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Resin composition, prepreg containing resin composition, dielectric substrate and printed circuit board

ActiveCN111378242AReduce the amount required for individual additionsImprove drilling processabilitySynthetic resin layered productsElectrical equipmentPolymer scienceHexagonal boron nitride

The invention provides a resin composition, a prepreg containing the resin composition, a dielectric substrate and a printed circuit board. The resin composition comprises the following components: (A) thermosetting resin with unsaturated double bonds; (B) a resin film-forming property improving material; (C) Hexagonal boron nitride; D, any one or a combination of at least two of aluminum nitride,silicon nitride or silicon carbide; (E) other inorganic fillers except the components (C) and (D); (F) a flame retardant and (G) an initiator, wherein the mass sum of the component (C), the component(D) and the component (E) accounts for 60-80% of the total mass of the resin composition, and the mass ratio of the component (C) to the component (D) is (1-4): 2. The dielectric substrate obtained by using the resin composition provided by the invention has the advantages of low dielectric constant, low dielectric loss, high thermal conductivity and stable thickness and dielectric constant, andcan fully meet the requirements of a high-frequency high-thermal-conductivity dielectric substrate.

Owner:GUANGDONG SHENGYI SCI TECH

Brominated polystyrene masterbatch and preparation method thereof

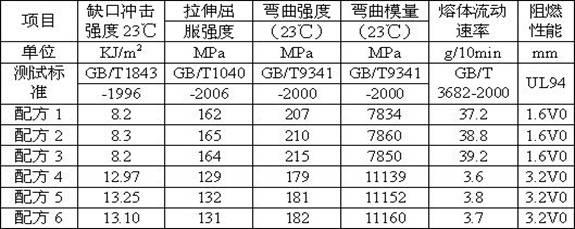

ActiveCN102627812AImprove flame retardant performanceSmall mechanical propertiesMasterbatchPolymer science

The invention discloses a brominated polystyrene masterbatch and a preparation method thereof. The brominated polystyrene masterbatch is prepared from the following components, by mass, 85-95% of brominated polystyrene, 3-14% of a carrier and 0.1-5% of modified ethylene bisfatty acid amide. The brominated polystyrene masterbatch prepared in the invention can effectively avoid unstable material quality caused by nonuniform mixing of powder and pellets; the preparation method which adopts a mixing-extruding continuous production technology has the advantages of high production efficiency, low production cost, clean production, good dispersion effect, substantial improvement of the loading amount of the brominated polystyrene masterbatch, and good mixing effect; and the brominated polystyrene masterbatch prepared in the invention has the characteristics of easy dispersion, high flame resisting efficiency, and low production cost, and has influences on physical and mechanical properties, the heat resistance, the processing performance and the surface color of a composite material smaller than influences of brominated polystyrene powder.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Environment-friendly cable sheath material resisting high and low temperatures

InactiveCN103897252AImprove water resistanceGood flexibilityPlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethyleneDibasic acid

The invention discloses an environment-friendly cable sheath material resisting high and low temperatures. The environment-friendly cable sheath material resisting high and low temperatures is produced from the following raw materials in parts by weight: 20-50 parts of ethylene-vinyl acetate copolymer, 50-80 parts of linear low density polyethylene, 8-12 parts of aliphatic dibasic acid ester cold-resistant plasticizer, 35-40 parts of phthalate plasticizer, 7-15 parts of terephthalate plasticizer, 15-20 parts of intumescent phosphorus-nitrogen halogen-free flame retardant, 7-9 parts of calcium / zinc composite stabilizer, 0.5-0.8 part of lubricant, 22-25 parts of filler, 0.4-0.8 part of coloring agent, 0.3-0.8 part of tetrapropylpentaerythritol ester1010 and 3-6 parts of polyethylene wax. The environment-friendly cable sheath material resisting to high and low temperatures does not pollute the environment, and is low in price, convenient to process and manufacture, relatively excellent in cold resistance and heat resistance, and long in service life.

Owner:ANHUI DINGXING CABLE

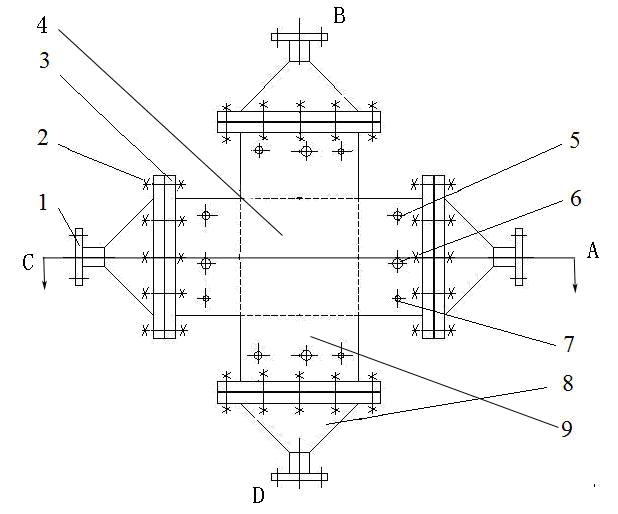

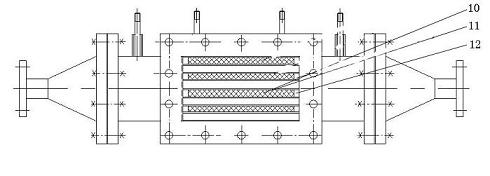

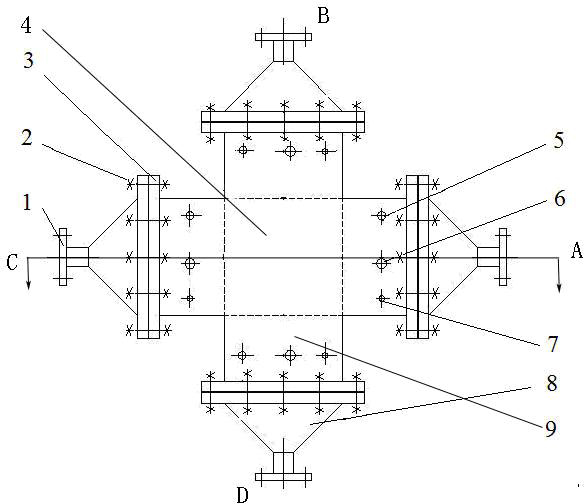

Plate-type heat exchanger

InactiveCN102425964AFast heat conductionLarge specific surface areaLaminated elementsStationary plate conduit assembliesPorosityPlate heat exchanger

Aiming at the problems, such as large volume, great weight, high metal consumption, stable heat exchange parameter and the like, of the existing plate-type heat exchanger, the invention discloses a plate-type heat exchanger which is filled with foamed metals and can change the heat exchange parameter at any time according to technological requirements. According to the invention, by virtue of a method of filling modular foamed metals with various porosity factors between plate layers of the plate-type heat exchanger, the heat exchange performance of the plate-type heat exchanger is improved, so that the plate-type heat exchanger has the advantages of lowering the metal consumption and reducing the equipment volume on the premise of obtaining a same heat exchange effect; the heat-exchange equipment structure is compact and standard; and the heat exchange parameter can be changed through filling foamed metal materials with different porosity factors, so as to meet different technical heat exchange requirements.

Owner:TAIYUAN UNIV OF TECH

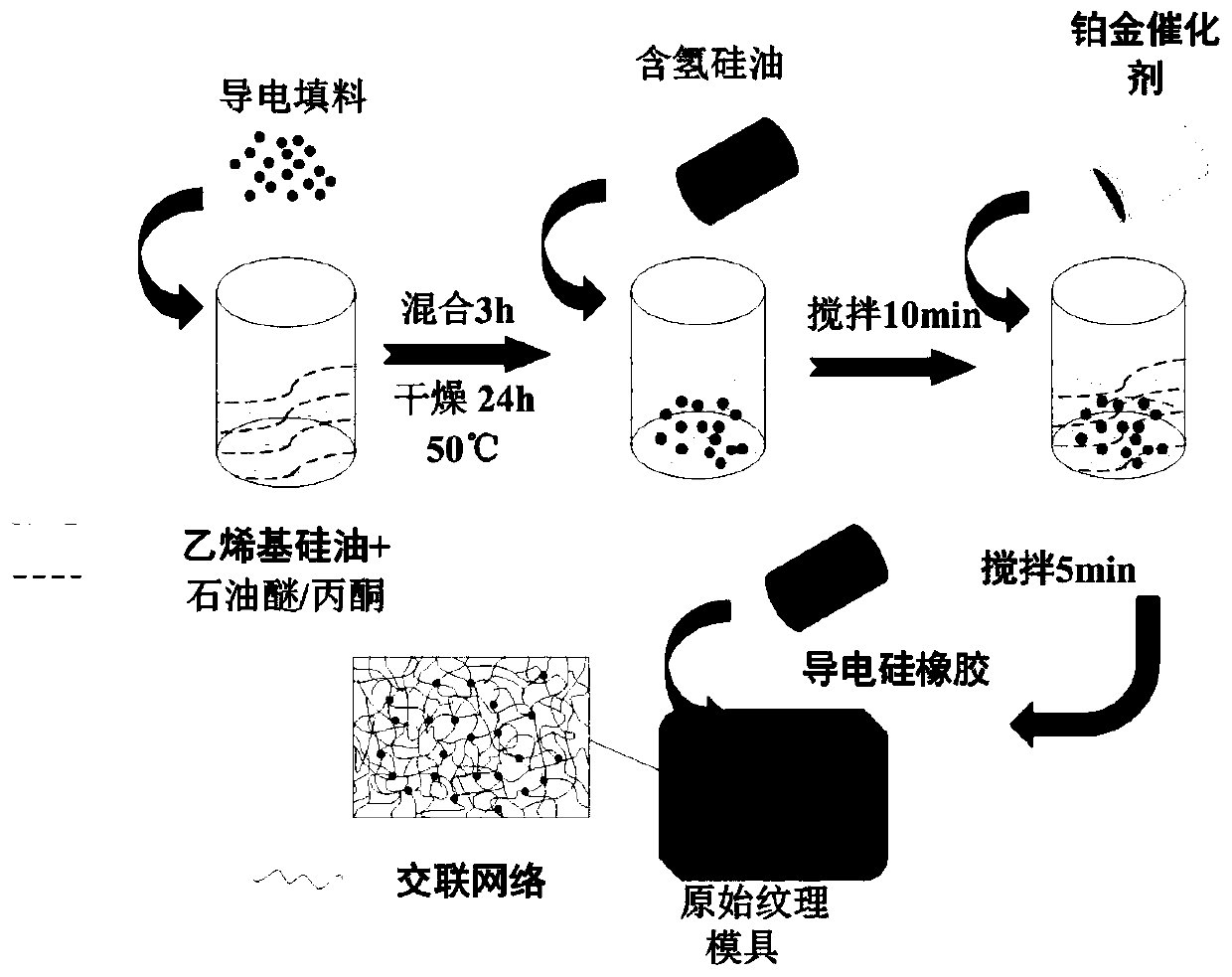

Direct-electrodeposition conductive silicone rubber material

The invention discloses a direct-electrodeposition conductive silicone rubber material, and a preparation method and an application thereof, and belongs to the technical field of manufacturing of precision texture molds. Raw materials for preparing the direct-electrodeposition conductive silicone rubber material include, by weight, 80-100 parts of silicone resin, 20-50 parts of a crosslinking agent, 0.5-5 parts of a catalyst, 5-30 parts of a conductive filler and 5-30 parts of a solvent, the silicone resin is a vinyl-terminated linear vinyl silicone oil having a viscosity of 100-500 CP, the crosslinking agent is a hydrogen-containing silicone oil having a hydrogen content of 0.5-3%, and the solvent is any one or a composition containing more of deionized water, ethanol, acetone and petroleum ether. The preparation method and the application of the direct-electrodeposition conductive silicone rubber material solve the problem of failed preparation of reprinted models using precision texture molds, caused by high molding temperature, high viscosity, difficult operation, high linear shrinkage and other defects of raw rubber for existing commercial conductive silicone rubbers; and thedirect-electrodeposition conductive silicone rubber material is highly economical and practical.

Owner:JILIN UNIV

Preparation method of photocatalyst environment-friendly fabric

PendingCN110258145ACraft smallSmall processing performanceBiochemical fibre treatmentDyeing processChemistryPhotocatalysis

The invention discloses a preparation method of photocatalyst environment-friendly fabric and particularly relates to the field of curtain manufacturing. The photocatalyst environment-friendly fabric comprises cotton spun cloth, a binder, active dye, plant oil, pickling liquid, soaping powder, finishing liquid, a photocatalyst and a penetrant, the binder, the active dye, the plant oil, the pickling liquid, the soaping powder, the finishing liquid, the photocatalyst and the penetrant are combined to the cotton spun cloth physically and chemically, the physical mode refers to combining the active dye with the cotton spun cloth through the binder, and the chemical mode refers to combining the photocatalyst with the cotton spun cloth through the penetrant. Through photocatalyst loading, processing is performed by mainly using the photocatalyst, the processing technique is slightly different from conventional processing techniques, a conventional overflow cylinder can use the technology, and a manufacturer does not need to additionally purchase any equipment, so that resources are saved, and production cost is lowered; nano titanium dioxide is adopted, has certain antibacterial and mildewproof effects under illumination and can remove formaldehyde under light excitation, so that effects of purifying air and beautifying environment are realized.

Owner:浙江迈实科技有限公司 +1

Conductive composite materials with positive temperature coefficient effect and process for making same

InactiveCN1328309CImprove PTC performance stabilityImprove conductivityNon-conductive material with dispersed conductive materialEpoxyConductive polymer

Disclosed is a conductive composite materials with positive temperature coefficient effect comprising conductive filler and polymer, wherein the conductive filler includes one-dimensional nano carbon having a diameter of 1-500nm, i.e. single-walled carbon nanotubes, multi-walled carbon nanotubes, carbon nanofibers or their compounds, the weight content of the one-dimensional nano carbon material is 0.1-50%, preferably 1-15%. The polymer is selected from polyethylene, polypropylene, polyvinylidene fluoride, nylon, epoxy resin, ethane-vinyl acetate copolymer, ethene-ethyl acrylate copolymer and EPT rubber.

Owner:SHENZHEN JINKE SPECIAL MATERIALS CO LTD

Novel spark detector with functions of self-cleaning and mutual dust detection

PendingCN110530522AGood effectImprove securitySensing radiation from gases/flamesInfraredElectricity

The invention discloses a novel spark detector with functions of self-cleaning and mutual dust detection. The novel spark detector comprises a fixed upper shell and a fixed lower shell. A light sourcesignal receiving element is arranged between the fixed upper shell and the lower shell; an infrared photosensitive element is arranged on the light source signal receiving element; a detection windowend is arranged at the top of the fixed upper shell, and a transparent glass lens is arranged at the top of the detection window end. The top end of the light source signal receiving element corresponds to the transparent glass lens. A self-cleaning air blowing pipe and a mutual inductance element are arranged at the top of the fixed upper shell; and the mutual inductance element, an electromagnetic valve, an air pump, the light source signal receiving element and the infrared photosensitive element are electrically connected with an electric controller. The self-cleaning air blowing pipe iscontrolled by the electromagnetic valve; the opening action of the electromagnetic valve is automatically controlled by signals of the mutual inductance element; normal work of the spark detector is guaranteed and automatic control operation is convenient. The spark detector does not need to be disassembled, and automatic control over rapid detection and rapid cleaning is realized.

Owner:山东智邦环境工程有限公司

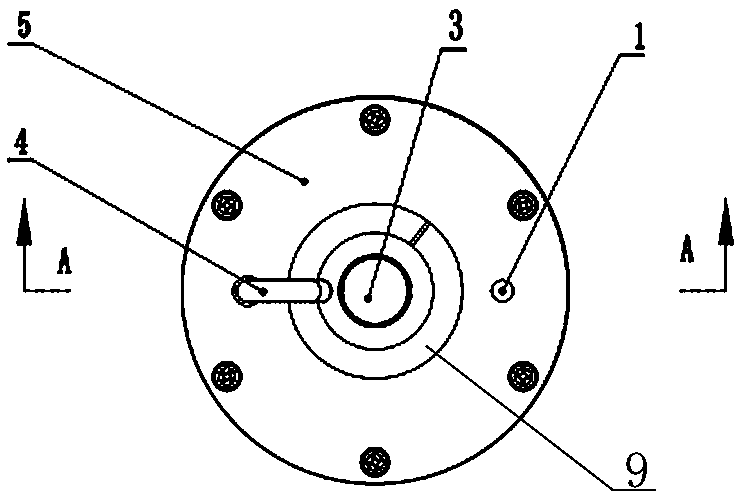

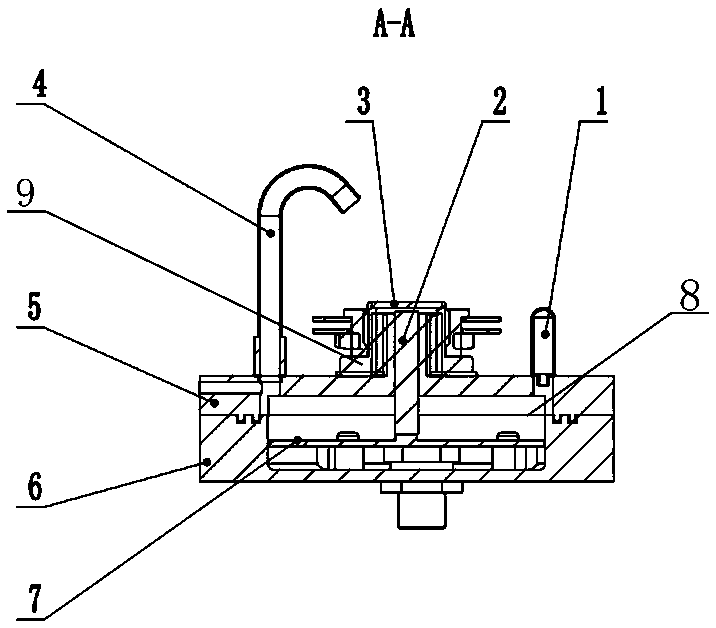

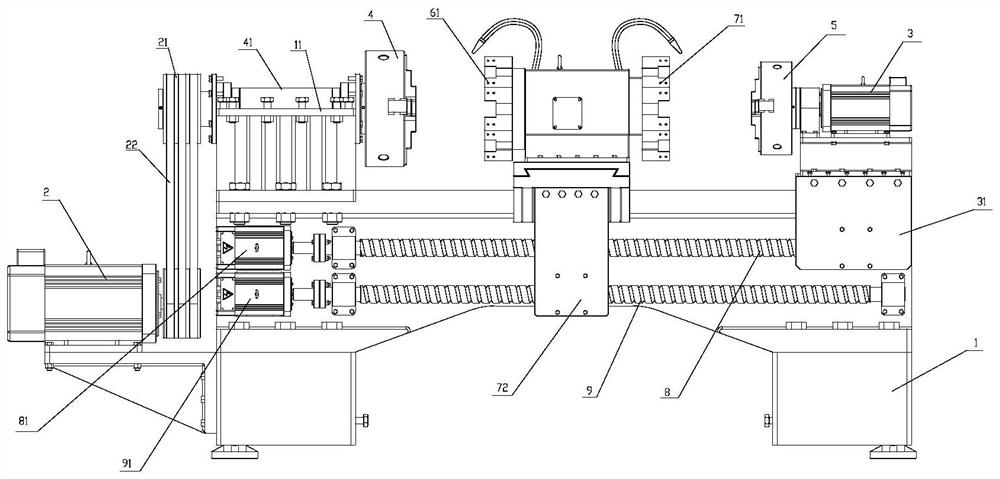

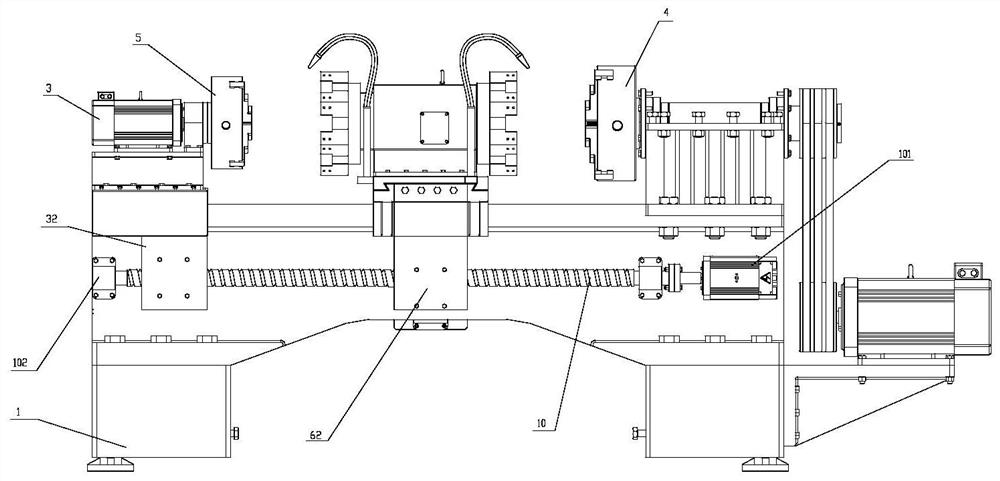

Double-spindle type numerical control lathe

InactiveCN111604507AImprove the ability to process small partsAvoid colliding with each otherAutomatic/semiautomatic turning machinesNumerical controlControl engineering

The invention provides a double-spindle type numerical control lathe. The double-spindle type numerical control lathe comprises a lathe body for supporting a machine tool. A fixed main spindle frame and a movable auxiliary spindle frame are separately installed on the upper parts of two ends of a casting of the lathe body. Tracks for the movement of tool holders are arranged between the auxiliaryspindle frame and the main spindle frame, and the auxiliary spindle frame is installed on the tracks. The tracks are two parallel linear rails. The movable main spindle tool holder and the movable auxiliary spindle tool holder are separately installed on the two parallel linear rails, and the main spindle tool holder and the auxiliary spindle tool holder are relatively independent. The double machining capacity of the numerical control machine tool can be additionally arranged, and the position of an auxiliary spindle can be stably adjusted according to the machining requirement, an ejector pin can be arranged in a clamped mode to plays the role of the ejector pin, the machine tool can be used in a plurality of machining methods, and flexible changing can be achieved at the same time of efficient machining, the ability of numerical control machine tools to machine small parts is improved, the cost is saved, and the rhythm of production is accelerated.

Owner:常州市瑾瑜精密科技有限公司

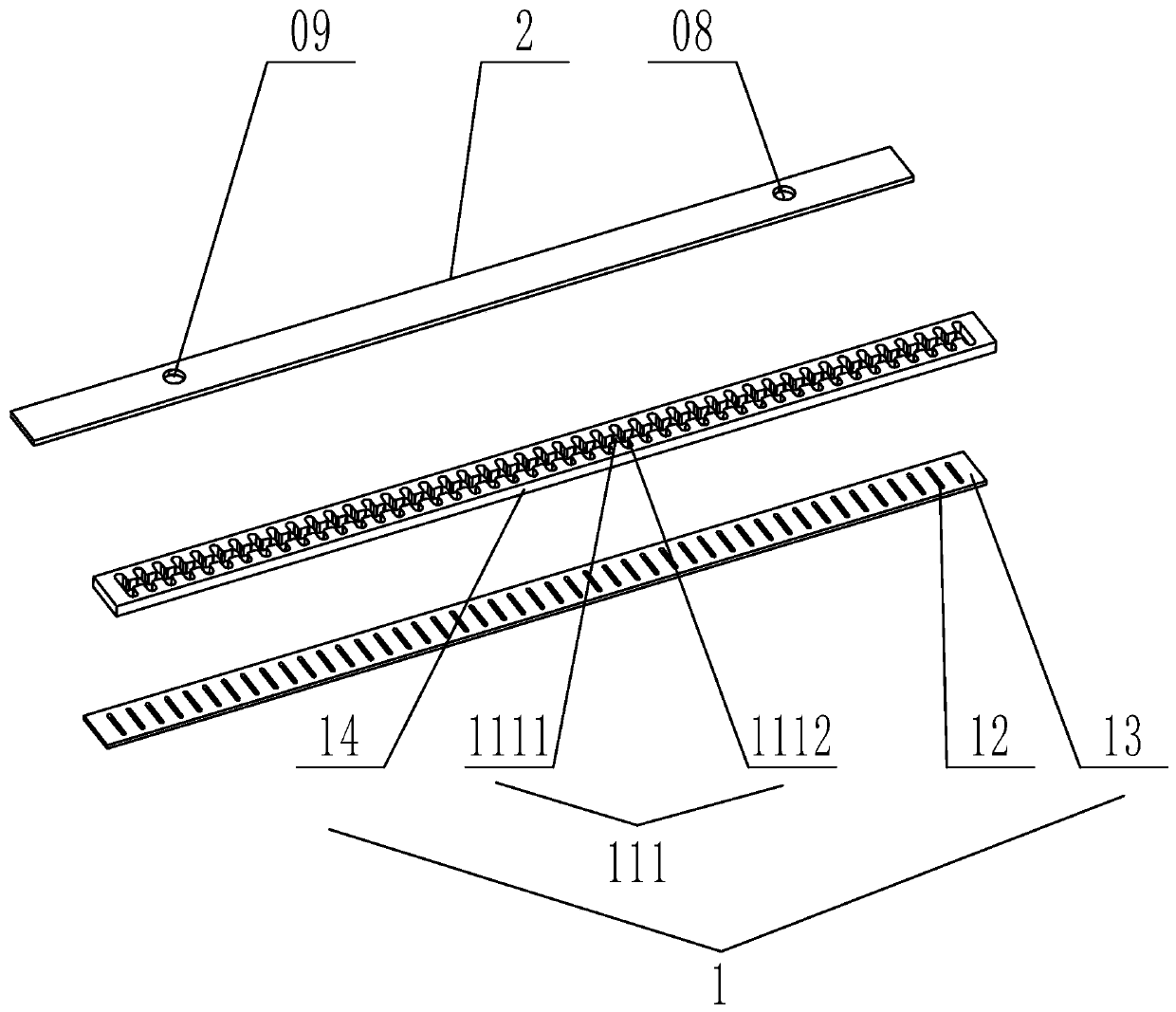

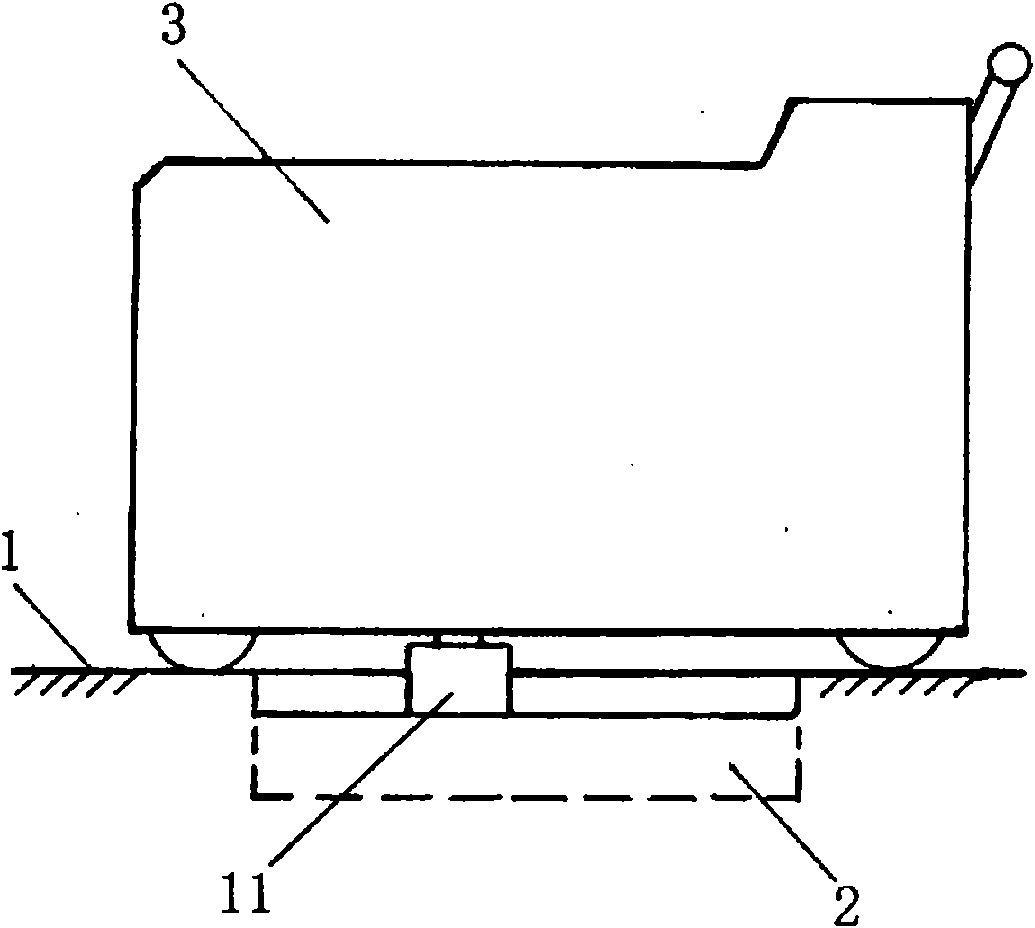

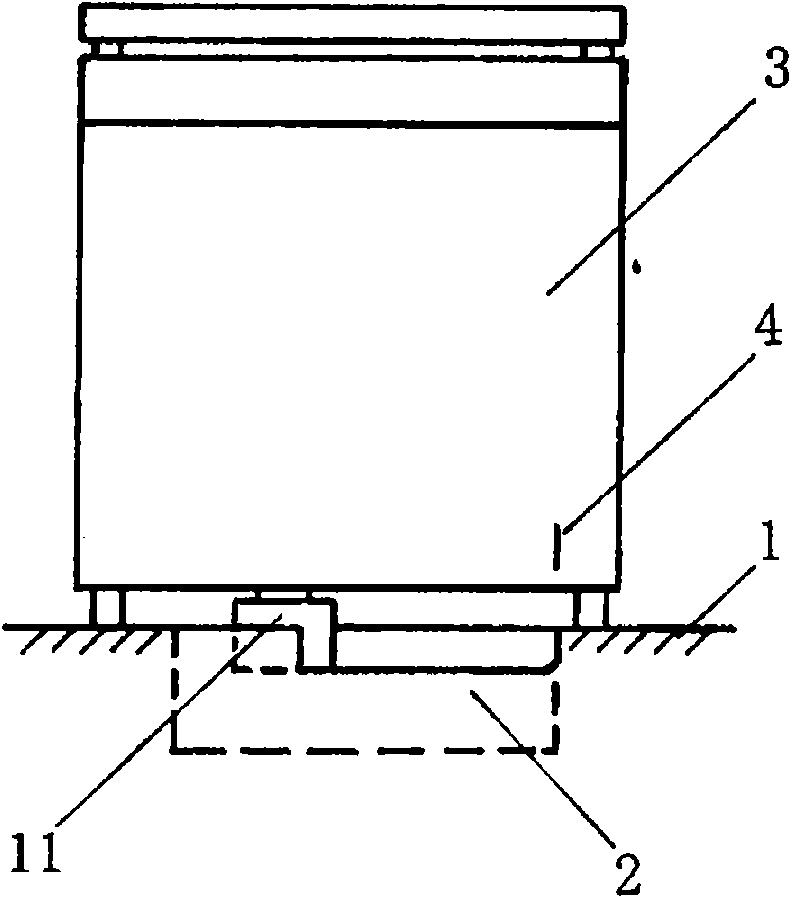

Unribbed double-plate-connection concrete-filled steel tube combined special-shaped column

InactiveCN105649272ASmall processing performanceSmall construction impactStrutsPillarsSheet steelUnit structure

The invention discloses an unribbed double-plate-connection concrete-filled steel tube combined special-shaped column. The unribbed double-plate-connection concrete-filled steel tube combined special-shaped column comprises a middle rectangular steel tube and at least two peripheral rectangular steel tubes. The middle rectangular steel tube is connected with each peripheral rectangular steel tube through two connecting steel plates with the same height as the steel tubes. The connecting steel plates are arranged vertically and are perpendicular to the side faces of the middle rectangular steel tube and the peripheral rectangular steel tubes. Concrete structures I are cast in the middle rectangular steel tube and the peripheral rectangular steel tubes correspondingly. A concrete structure II is cast in the space formed by the middle rectangular steel tube, each peripheral rectangular steel tube and the corresponding two opposite connecting steel plates in an enclosed mode. The cross section of a unit structure comprising the middle rectangular steel tube and two adjacent peripheral rectangular steel tubes is in an L shape. The unribbed double-plate-connection concrete-filled steel tube combined special-shaped column is high in bearing capacity, can be applied to high-rise buildings and meanwhile has good ductility and seismic performance.

Owner:TIANJIN UNIV

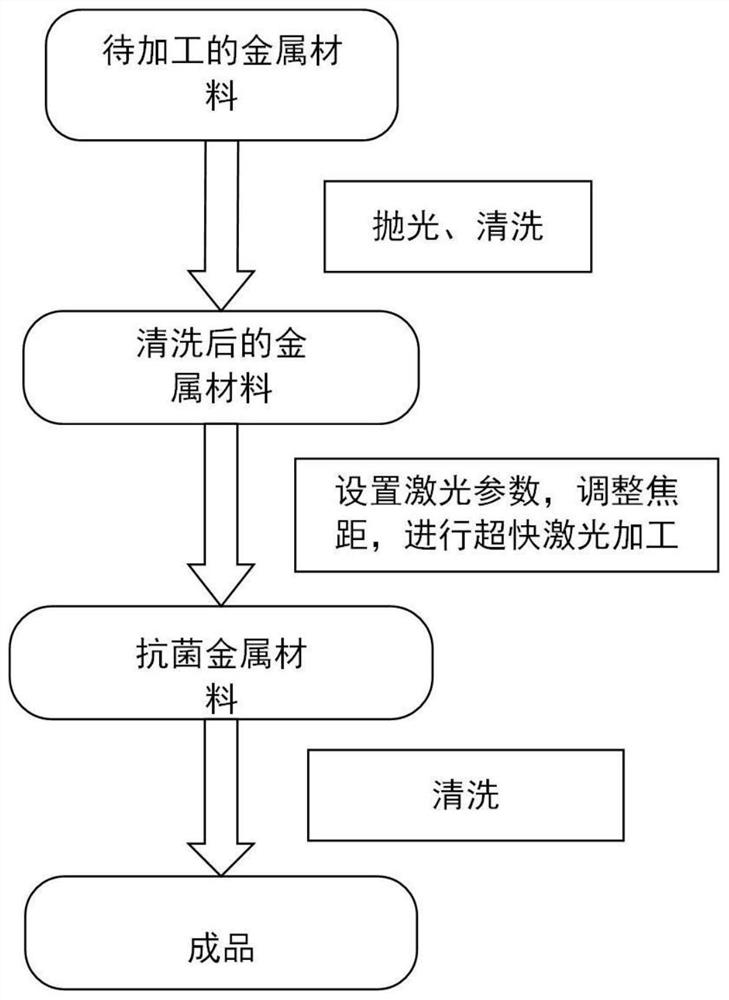

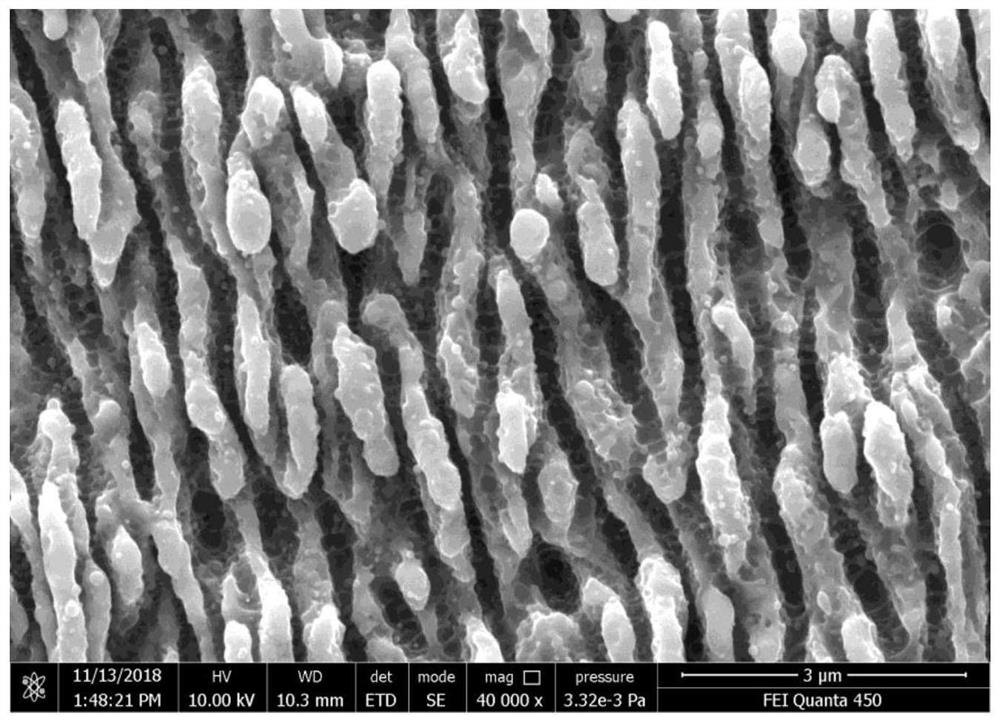

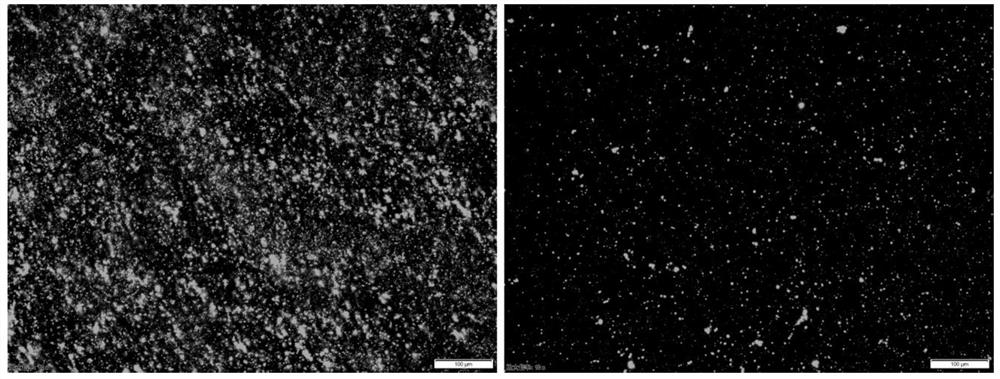

Ultrafast laser preparation method facing bacteriostatic surfaces of public goods

InactiveCN111774731AReduce heat damageSmall heat affected zoneLaser beam welding apparatusPublic placeOptics

The invention discloses an ultrafast laser preparation method facing bacteriostatic surfaces of public goods. A micro-nano structure is prepared on the surface of a cleaned and polished material by using ultrafast laser, so that the functional surface with bacteriostatic performance can be obtained. The method is simple and convenient to operate, high in processing efficiency and wide in application field, the bacteriostatic surfaces prepared by the method are applied to daily articles commonly used in public places, bacterial adhesion on the surfaces of the articles can be obviously reduced,and long-acting bacteriostasis of the daily articles in public places is realized.

Owner:BEIHANG UNIV

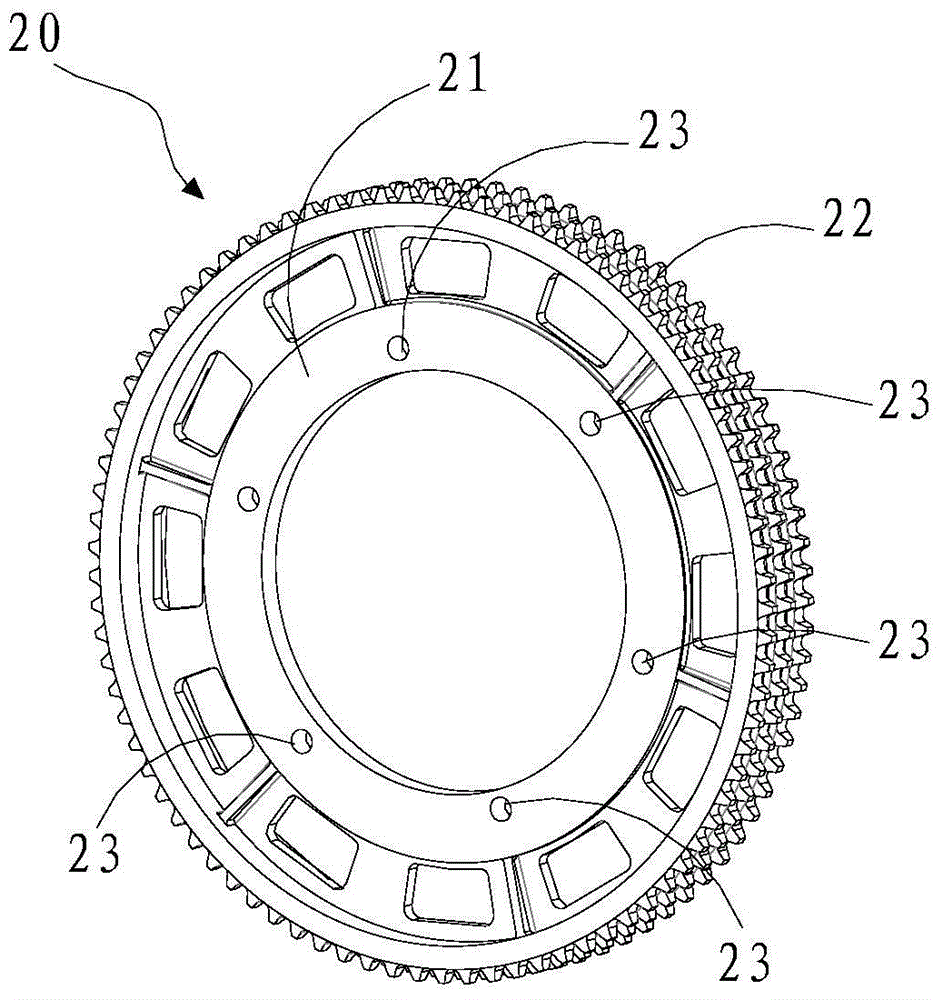

Escalator drive sprocket and manufacture method thereof

ActiveCN104986652AOvercoming shrinkageOvercome trachoma defectsPortable liftingEscalatorsMature technologySprocket

The invention discloses an escalator drive sprocket and a manufacture method thereof. The escalator drive sprocket comprises a wheel spoke and a tooth ring, the tooth ring sleeves the outer side of the wheel spoke, and the wheel spoke is connected and fixed with the tooth ring through intermittent welding. Compared with the drive sprocket in the prior art which is obtained through casting or cutting, and in which the wheel spoke and the tooth ring are connected into one body, the escalator drive sprocket provided by the invention is advantaged in that the wheel spoke and the tooth ring can be made of steel materials in different kinds, and are separately manufactured through an existing relatively-mature technology. According to invention, shrinkage cavity and sand hole defects, of a casting type drive sprocket, caused by integral body casting can be prevented, defects of large machining amount, high cost and the like, of a cutting type drive sprocket, caused by integral body cutting can be prevented, and therefore the escalator drive sprocket is high in product molding ratio, low in cost and low in machining amount.

Owner:HITACHI ELEVATOR GUANGZHOU ESCALATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com