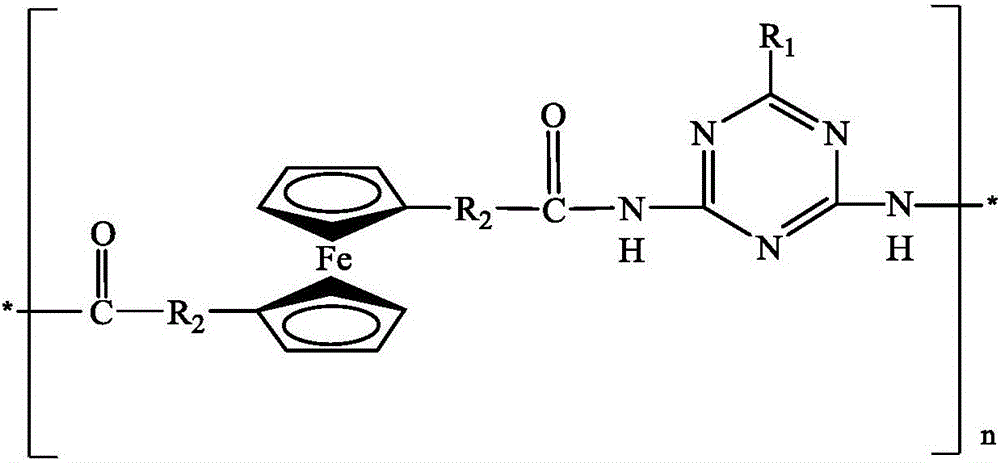

Ferrocene-thiotriazinone biradical polyamide synergistic charring agent and preparation method and application thereof

A technology of triazine ring double base polyamide and ferrocene, applied in chemical instruments and methods, metallocene, organic chemistry, etc., can solve the problem of large amount of flame retardant added, decreased flame retardant performance, low heat resistance, etc. problem, to achieve the effect of small processing performance, good flame retardant effect and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 1 mol of methanol, 6 mol of distilled water and 1 mol of sodium hydroxide into dichloromethane that is 7 times the weight of the raw material methanol, add 1 mol of cyanuric chloride to it when the temperature is lowered to 5°C, and then raise the temperature to 30°C for reaction After 50 minutes, cool down to about 5°C, add distilled water 5 times the volume of the reacted material, stir continuously, filter with suction, wash, and vacuum dry the filter cake to obtain Intermediate I.

[0039] Add 0.5 mol of intermediate I and 1 mol of potassium carbonate to toluene that is 6 times the weight of intermediate I, gradually raise the temperature to 45°C, then drop in 1.25 mol of ammonia water with a mass percentage of 25%, and react for 1 hour after dropping Then heat up to 85°C and react for 8 hours. After the reaction, cool to room temperature, filter with suction, wash with ethanol and distilled water, dry in vacuum and grind to obtain Intermediate II.

[0040] Add ...

Embodiment 2

[0043] Add 1 mol of phenol, 5 mol of distilled water and 1 mol of sodium hydroxide to acetone that is 7 times the weight of the raw material methanol, add 1 mol of cyanuric chloride to it when the temperature is lowered to 0°C, and then raise the temperature to 20°C for 30 minutes. Cool down to about 8°C, add distilled water 6 times the volume of the reacted material, stir continuously, filter with suction, wash, and vacuum-dry the filter cake to obtain Intermediate I.

[0044] Add 0.5 mol of intermediate I and 1 mol of sodium carbonate to toluene that is 7 times the weight of intermediate I, gradually raise the temperature to 45°C, then drop 1 mol of ammonia water with a mass percentage of 25%, and react for 2 hours after the drop Raise the temperature to 90°C and react for 6 hours. After the reaction, cool to room temperature, filter with suction, wash with ethanol and distilled water, dry in vacuum and grind to obtain Intermediate II.

[0045] To a reaction vessel containin...

Embodiment 3

[0047] Add 1.2 mol of ethanol, 8 mol of distilled water and 1 mol of sodium carbonate to acetone that is 5 times the weight of the raw material methanol, add 1 mol of cyanuric chloride to it when the temperature is lowered to 10°C, and then raise the temperature to 35°C for 40 minutes, Cool down to about 12°C, add distilled water that is 4 times the volume of the reacted material, stir continuously, filter with suction, wash, and vacuum dry the filter cake to obtain Intermediate I.

[0048] Add 0.5 mol of intermediate I to acetonitrile that is 8 times the weight of intermediate I, gradually raise the temperature to 40°C, then drop in 2.5 mol of ammonia water with a mass percentage of 25%, and heat up to 100°C after 3 hours of reaction. React at ℃ for 4 hours. After the reaction, cool to room temperature, filter with suction, wash with ethanol and distilled water, dry in vacuum and grind to obtain Intermediate II.

[0049] Add 2.5 mmol of dicyclohexylcarbodiimide to a reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aggregation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com