Composite insulation material for cable and preparation method thereof

A composite insulation and cable technology, used in rubber insulators, organic insulators, etc., can solve the problems of poor weather resistance, unsuitable insulation materials, poor electrical insulation performance of chlorinated polyethylene, etc., to achieve good processability and improve insulation. Good electrical properties, mechanical properties and electrical insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

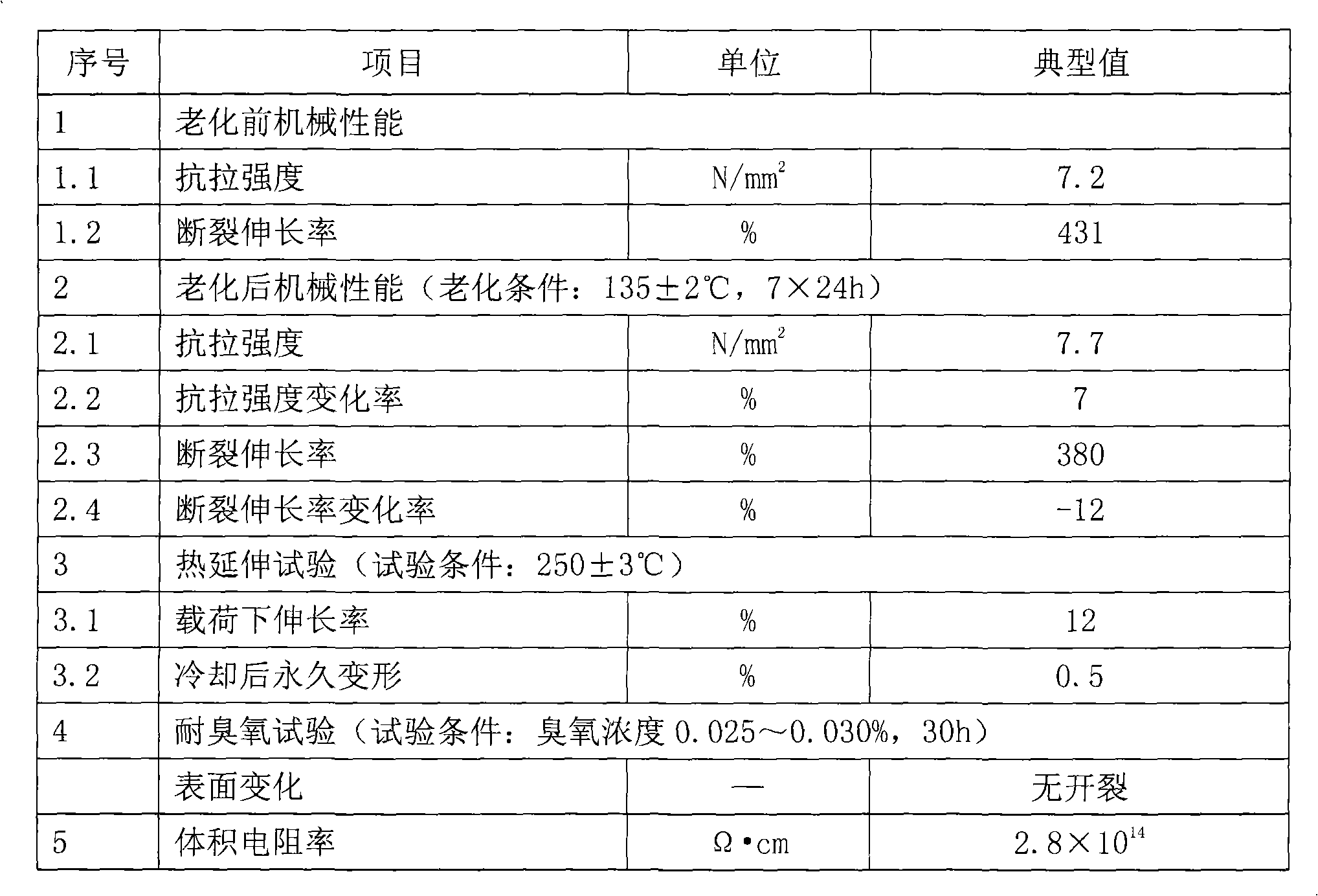

Embodiment 1

[0057] A composite insulating material for cables, comprising the following components in parts by weight:

[0058] 30 parts of EPDM rubber,

[0059] 70 parts of styrene-butadiene rubber,

[0060] 1 part of cross-linking agent,

[0061] 1 part of crosslinking agent auxiliary agent,

[0062] 4 parts of vulcanization activator,

[0063] Anti-aging agent 1 part,

[0064] 10 parts of plasticizer,

[0065] 1 part of coupling agent,

[0066] Reinforcing filler 100 parts.

[0067] A method for preparing a composite insulating material for cables, comprising the steps of:

[0068] a. Weighing by weight, 30 parts of EPDM rubber, 70 parts of styrene-butadiene rubber, 1 part of cross-linking agent, 1 part of cross-linking agent auxiliary agent, 4 parts of vulcanization activator, 1 part of anti-aging agent, plasticizer 10 parts of agent, 1 part of coupling agent, 100 parts of reinforcing filler;

[0069] b. Mixing, first mix and knead styrene-butadiene rubber and EPDM rubber for...

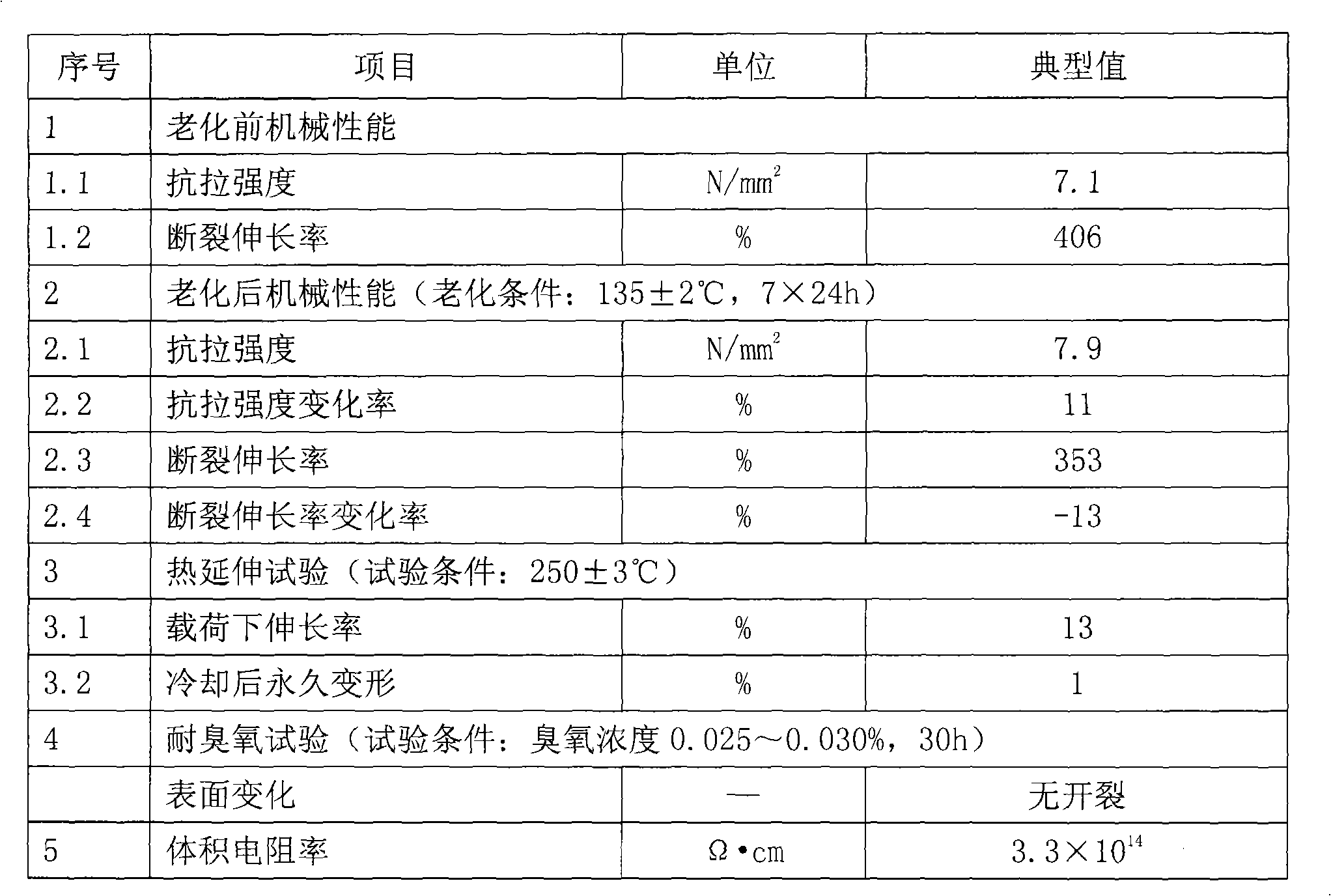

Embodiment 2

[0079] A composite insulating material for cables, comprising the following components in parts by weight:

[0080] 60 parts of EPDM rubber,

[0081] 40 parts of styrene-butadiene rubber,

[0082] 4 parts of cross-linking agent,

[0083] 6 parts of cross-linking agent auxiliary agent,

[0084] 16 parts of vulcanization active agent,

[0085] Anti-aging agent 4 parts,

[0086] 40 parts of plasticizer,

[0087] 3 parts of coupling agent,

[0088] Reinforcing filler 200 parts.

[0089] A method for preparing a composite insulating material for cables, comprising the steps of:

[0090] a. Weighing by weight, 60 parts of EPDM rubber, 40 parts of styrene-butadiene rubber, 4 parts of crosslinking agent, 6 parts of crosslinking agent auxiliary agent, 16 parts of vulcanization activator, 4 parts of antioxidant, plasticizer 40 parts of agent, 3 parts of coupling agent, 200 parts of reinforcing filler;

[0091] b. Mixing, first mix and knead styrene-butadiene rubber and EPDM rub...

Embodiment 3

[0101] A composite insulating material for cables, comprising the following components in parts by weight:

[0102] 40 parts of EPDM rubber,

[0103] 60 parts of styrene-butadiene rubber,

[0104] 2 parts of cross-linking agent,

[0105] 2 parts of cross-linking agent auxiliary agent,

[0106] 5 parts of vulcanization active agent,

[0107] Anti-aging agent 2 parts,

[0108] 20 parts of plasticizer,

[0109] 2 parts of coupling agent,

[0110] 120 parts of reinforcing filler.

[0111] A method for preparing a composite insulating material for cables, comprising the steps of:

[0112] a. Weighing by weight, 40 parts of EPDM rubber, 60 parts of styrene-butadiene rubber, 2 parts of crosslinking agent, 2 parts of crosslinking agent auxiliary agent, 5 parts of vulcanization activator, 2 parts of antioxidant, plasticizer 20 parts of agent, 2 parts of coupling agent, 120 parts of reinforcing filler;

[0113] b. Mixing, first mix and knead styrene-butadiene rubber and EPDM ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com