High-capacity and high-rate composite graphite negative electrode material preparation method

A technology of composite graphite and negative electrode material, applied in the field of preparation of composite graphite negative electrode material, can solve problems such as low capacity, achieve high-rate charge-discharge performance, small rebound of pole piece, and increase the effect of anisotropic distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

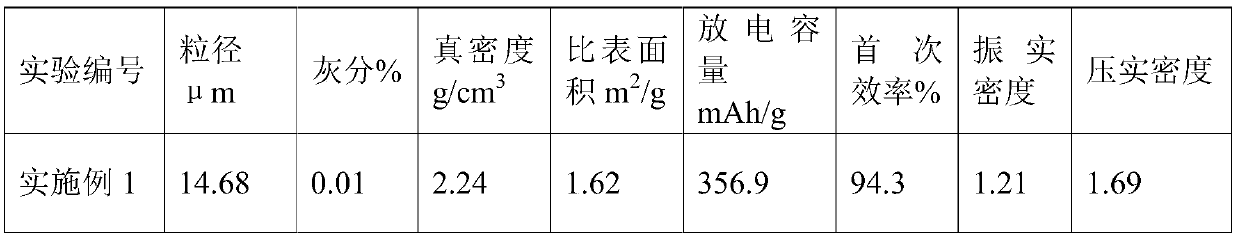

Embodiment 1

[0023] The preparation method of this example comprises the following steps:

[0024] (1) A single particle of artificial graphite is first carbonized at a low temperature, and the temperature is generally controlled at 750°C to remove some ash impurities and volatile substances;

[0025] (2), then the artificial graphite after the low-temperature carbonization treatment is carried out by mechanical milling to obtain primary particle A, and the particle diameter D50 is controlled at 9.5 μm;

[0026] (3) Put a green ball of mesophase carbon microspheres into the shaping equipment for surface modification at room temperature for 3 to 7 minutes to make the overall shape more regular and at the same time increase the roughness of the particle surface to obtain mesophase carbon microspheres. Ball raw ball B, the particle size D50 of modified particles is controlled at 15 μm;

[0027] (4), the primary particle A, the mesophase carbon microsphere green ball B, and the asphalt binder...

Embodiment 2

[0031] The preparation method of this example comprises the following steps:

[0032] (1) The single particle of artificial graphite is first carbonized at low temperature, and the temperature is generally controlled at 750°C to remove some ash impurities and volatile substances;

[0033] (2), then the artificial graphite after the low-temperature carbonization treatment is carried out by mechanical milling to obtain primary particle A, and the particle diameter D50 is controlled at 9.5 μm;

[0034] (3) Put a green ball of mesophase carbon microspheres into the shaping equipment for surface modification at room temperature for 3 to 7 minutes to make the overall shape more regular and at the same time increase the roughness of the particle surface to obtain mesophase carbon microspheres. Ball raw ball B, the particle size D50 of modified particles is controlled at 15 μm;

[0035] (4), the primary particle A, the mesophase carbon microsphere green ball B, and the asphalt binder...

Embodiment 3

[0039] The preparation method of this example comprises the following steps:

[0040] (1) A single particle of artificial graphite is first carbonized at a low temperature, and the temperature is generally controlled at 750°C to remove some ash impurities and volatile substances;

[0041] (2), then the artificial graphite after the low-temperature carbonization treatment is carried out by mechanical milling to obtain primary particle A, and the particle diameter D50 is controlled at 9.5 μm;

[0042] (3) Put a green ball of mesophase carbon microspheres into the shaping equipment for surface modification at room temperature for 3 to 7 minutes to make the overall shape more regular and at the same time increase the roughness of the particle surface to obtain mesophase carbon microspheres. Ball raw ball B, the particle size D50 of modified particles is controlled at 15 μm;

[0043] (4) Put the primary particles A, mesophase carbon microsphere green balls B, and pitch binder into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com