Ultrafast laser preparation method facing bacteriostatic surfaces of public goods

An ultra-fast laser and article technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of poor wear resistance of antibacterial materials, unsatisfactory antibacterial effect, and reduced bacterial adhesion, etc., and achieve a processing method. Flexible, fast processing, small heat-affected zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

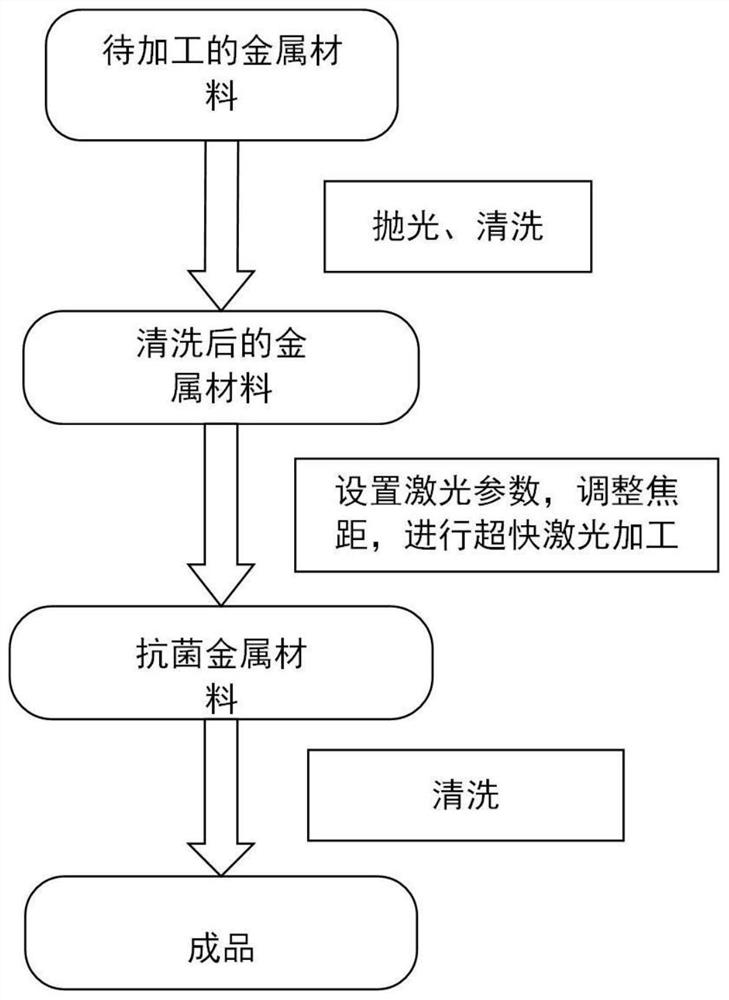

[0023] like figure 1 As shown, an ultrafast laser preparation method for the antibacterial surface of public goods mainly includes the following steps:

[0024] (1) The surface of the material is mechanically polished, and after polishing, ultrasonic cleaning and drying are performed.

[0025] (2) Place the processed material in the first step on an ultrafast laser processing platform, adjust the laser beam to make its focus on the surface of the sample, set the laser process parameters, and process to obtain a micro-nano structure surface with bacteriostatic properties.

[0026] (3) Wash and dry the processed material.

[0027] Wherein, the laser process parameters described in step (2) are specifically: the laser wavelength is 193nm-1070nm, the laser pulse width is 50fs-50ns, the pulse frequency is 1kHz-1MHz, the laser power is 1W-2000W, and the scanning speed is 1mm / s -5000mm / s.

[0028] Wherein, the micro-nano structure in step (2) is a pit array structure, a groove str...

Embodiment 1

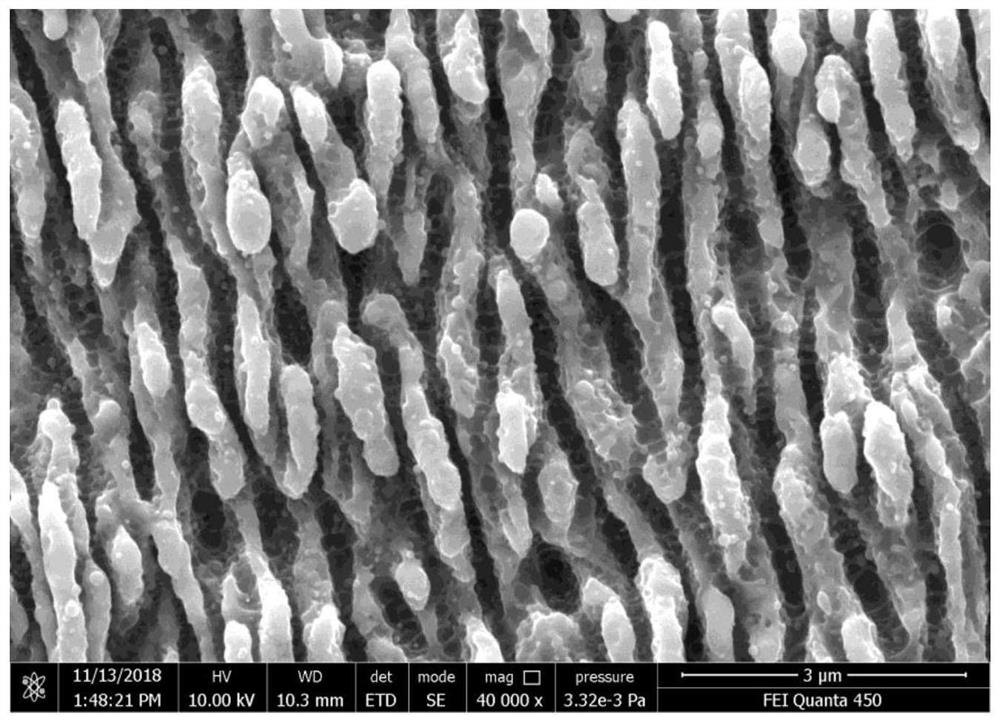

[0033] (1): Take a titanium alloy sample with a thickness of 2 mm and polish it to 1200 mesh, place it in anhydrous alcohol for ultrasonic cleaning for 5 minutes, and dry it.

[0034] (2): Place the polished and cleaned sample on the workbench of the femtosecond laser processing system (wavelength 1064nm), set the laser power to 6W, the pulse width to 500fs, the frequency to be 800KHz, the scanning speed to be 800mm / s, and the scanning distance to be 800mm / s. It is 70 μm, the number of scans is 6 times, the laser processing system is started to start processing, and the LIPSS structure is obtained.

[0035] (3): Use anhydrous alcohol to clean the processed titanium alloy sample and dry it.

Embodiment 2

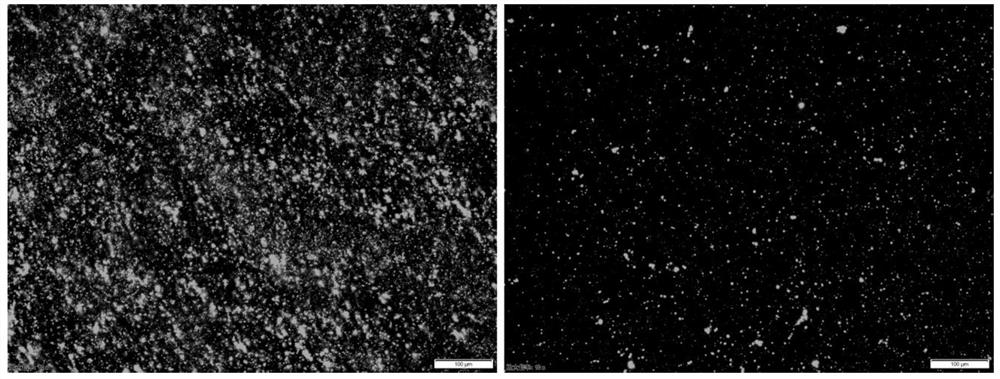

[0037] (1): Take a stainless steel sample with a thickness of 2 mm and polish it to 1200 mesh, place it in anhydrous alcohol for ultrasonic cleaning for 5 minutes, and dry it.

[0038] (2): Place the polished and cleaned sample on the workbench of the femtosecond laser processing system (wavelength 1064nm), set the laser power to 8W, the pulse width to 500fs, the frequency to be 500KHz, the scan speed to be 600mm / s, and the scan spacing to be 600mm / s. It is 60 μm, the number of scans is 10 times, the laser processing system is started to start processing, and the pit array structure is obtained.

[0039] (3): Use anhydrous alcohol to clean the processed stainless steel samples and dry them.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com