Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Adapt to processing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

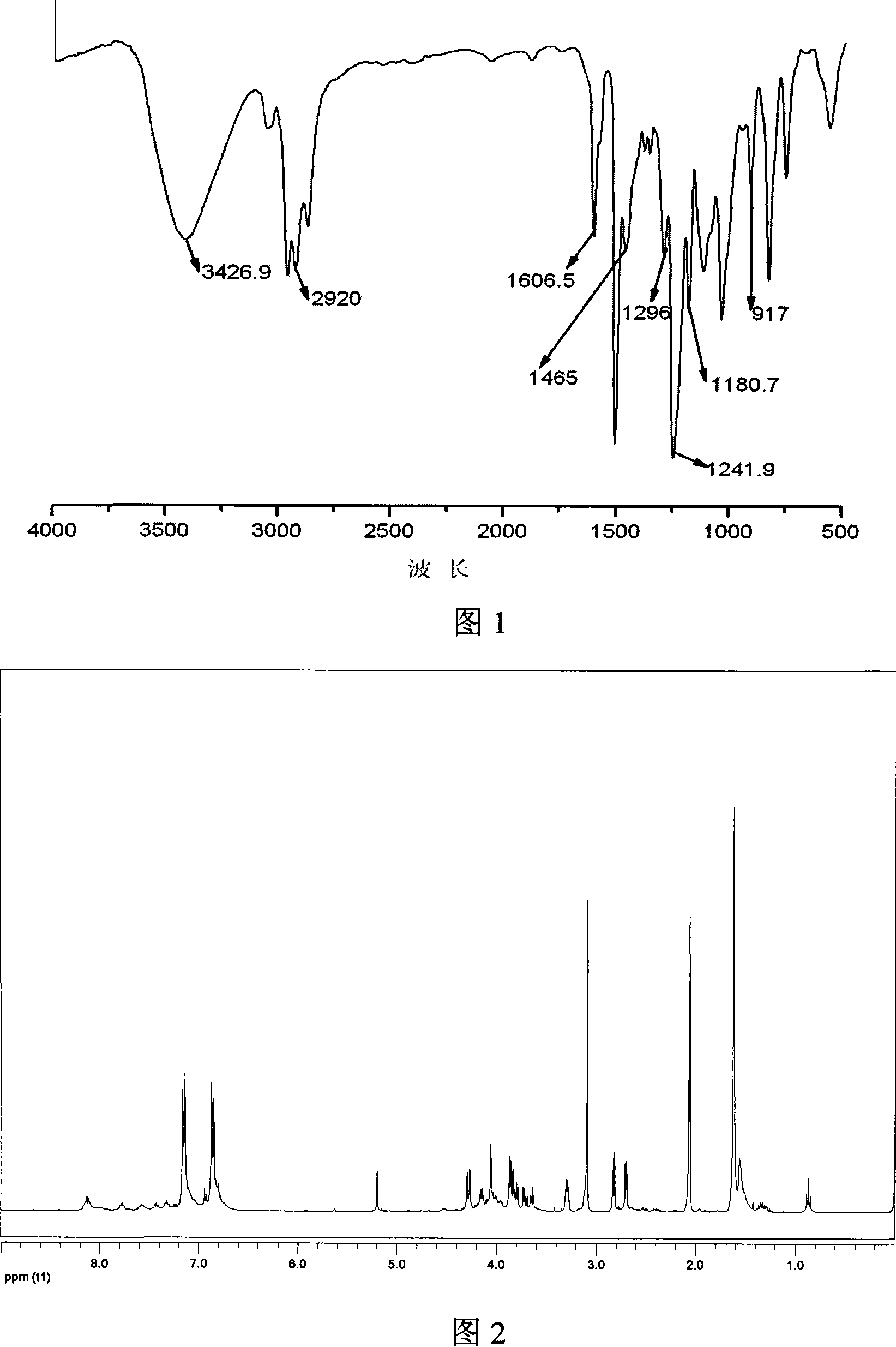

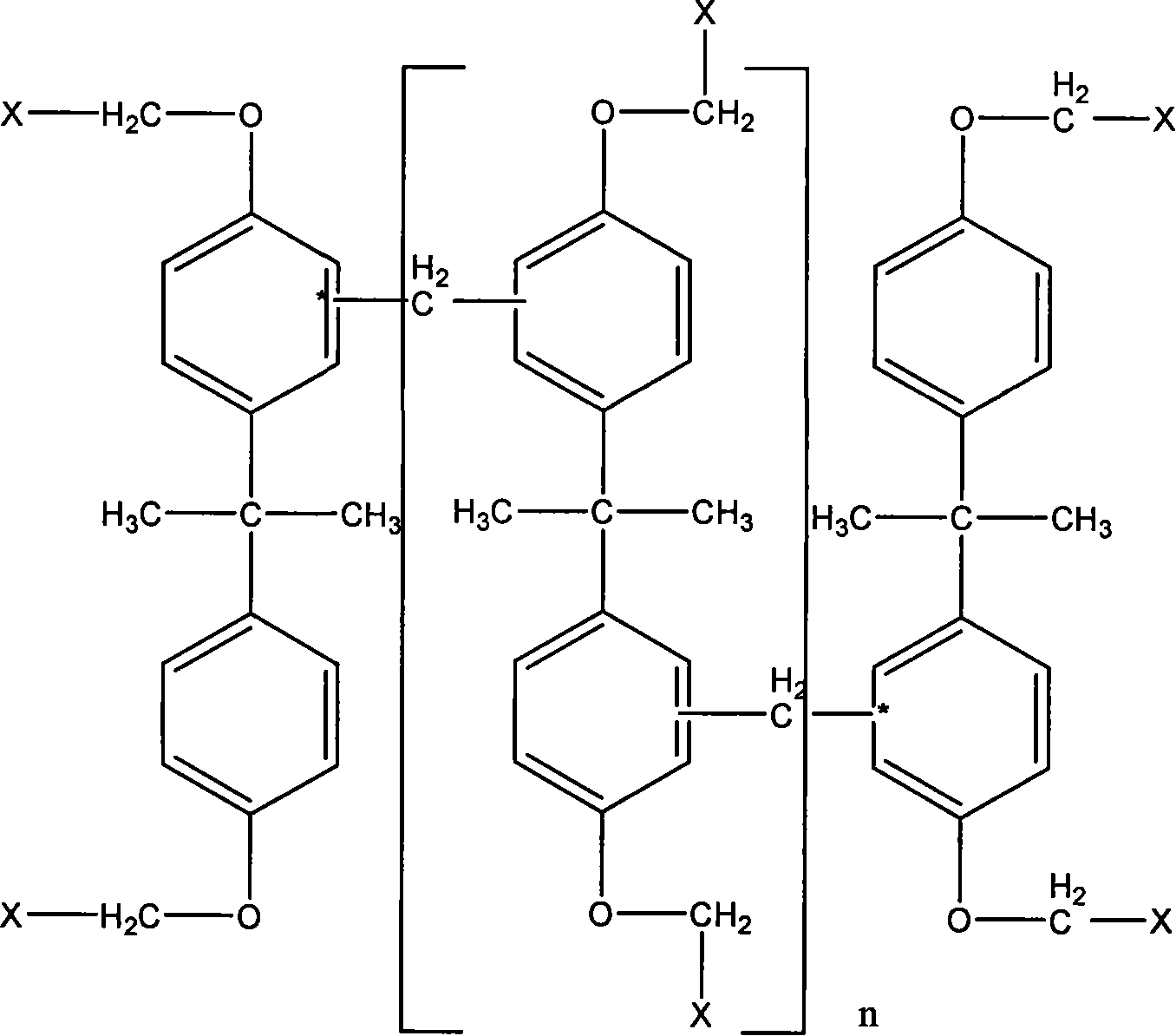

Phosphor A containing novolac epoxy and method for producing the same

InactiveCN101195676AImprove heat resistanceReduce the impactPlastic/resin/waxes insulatorsOrganophosphorous compoundsMechanical property

The invention relates to the technical field of novolac epoxy resin, in particular to a bisphenol A novolac epoxy resin containing phosphorous and a relative preparation method, wherein the compound formula is represented as below, n is 0-7. The invention condensates formaldehyde or cavaform and bisphenol A in the presence of acid catalyst to prepare phenol resin compound, processes etherification with epichlorohydrin in the presence of phase transfer catalyst, generates bisphenol A novolac epoxy resin in the presence of alkal catalyst, and reacts the bisphenol A novolac epoxy resin with organic phosphorous compound in the presence of catalyst to obtain bisphenol A novolac epoxy resin containing phosphorous. The solid product has good thermal resistance, flameproof, mechanical property and wide application in the technical fields of laminated board, insulated material, semi-conductor package and composite material.

Owner:DONGGUAN UNIV OF TECH

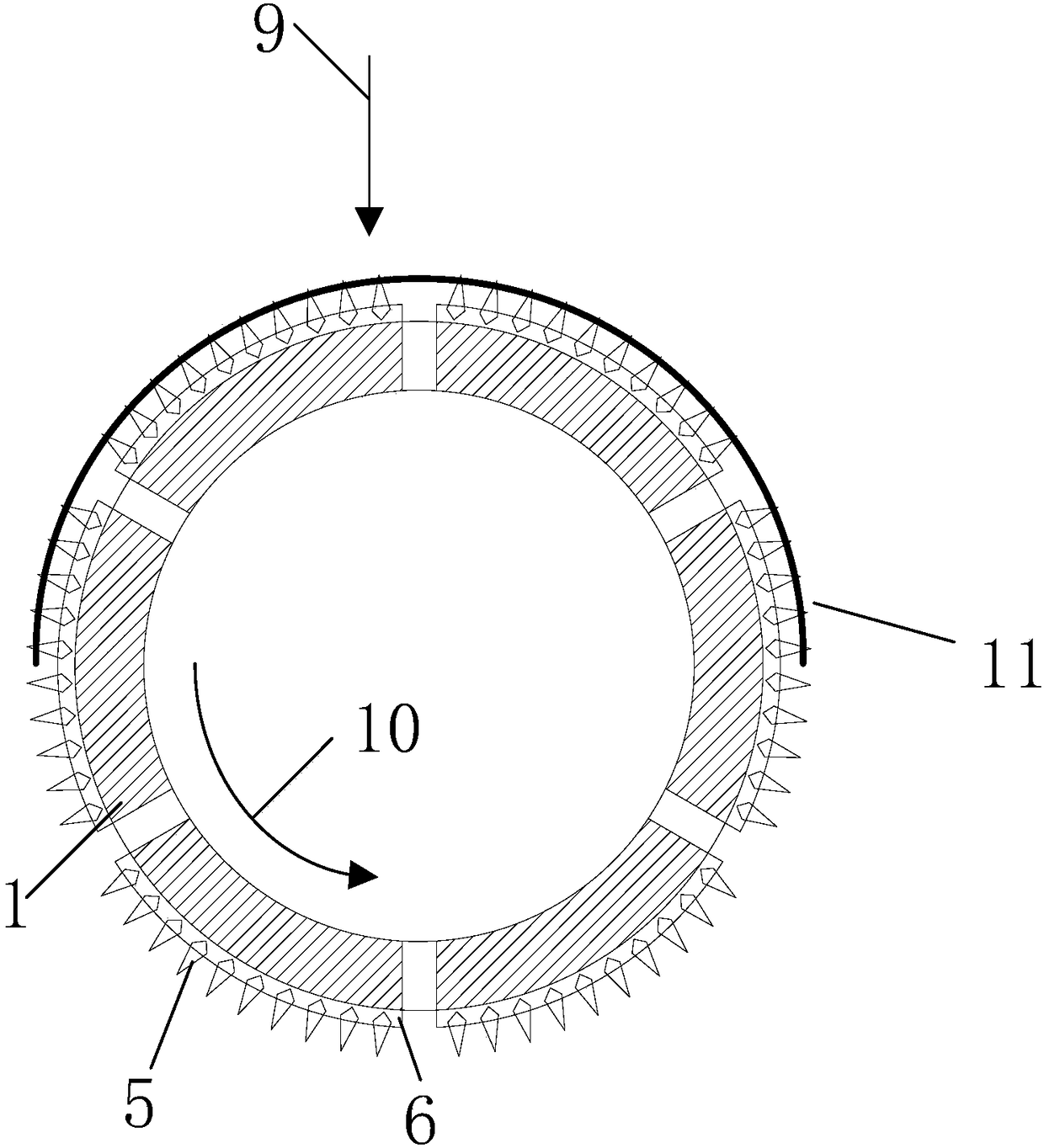

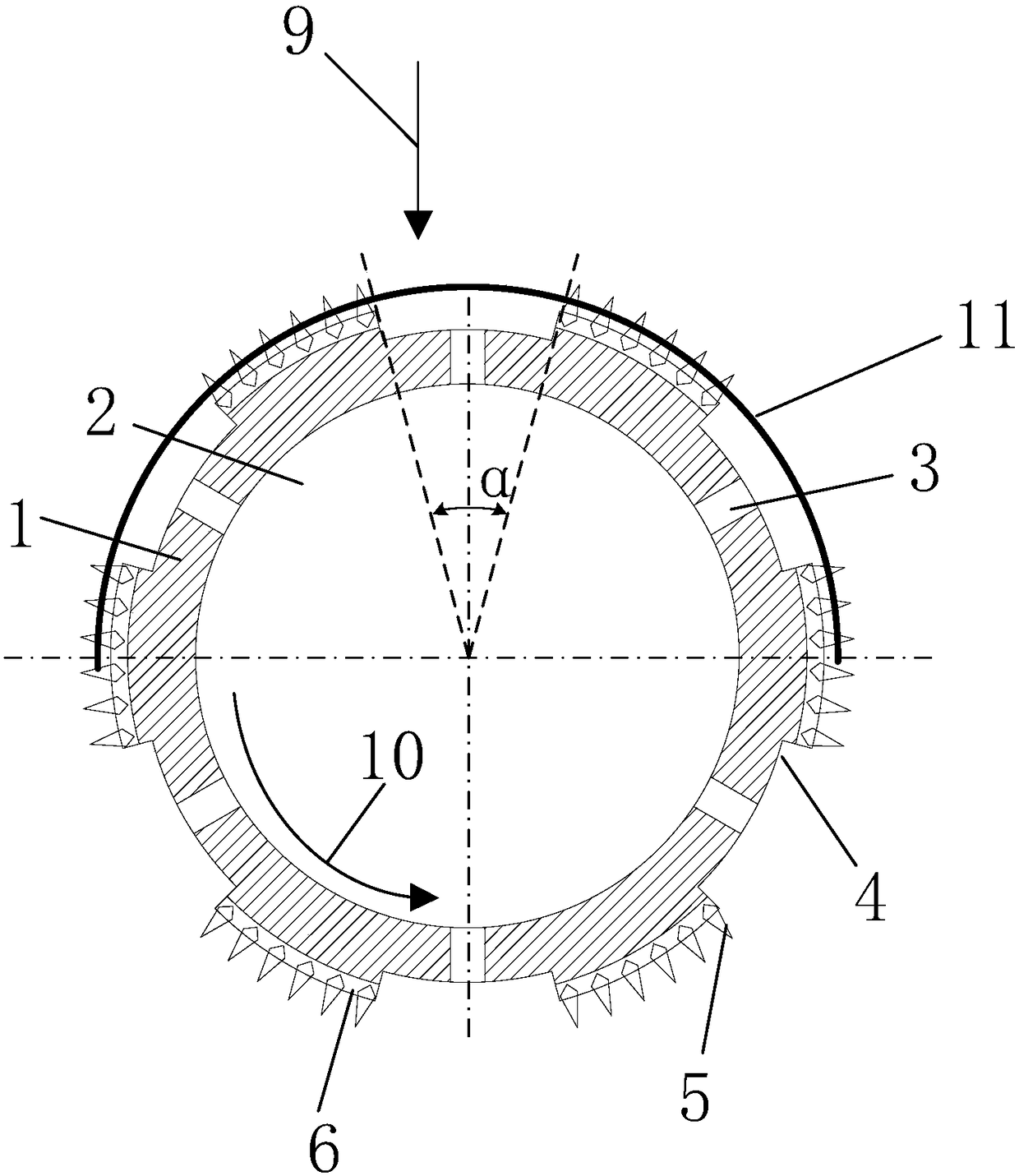

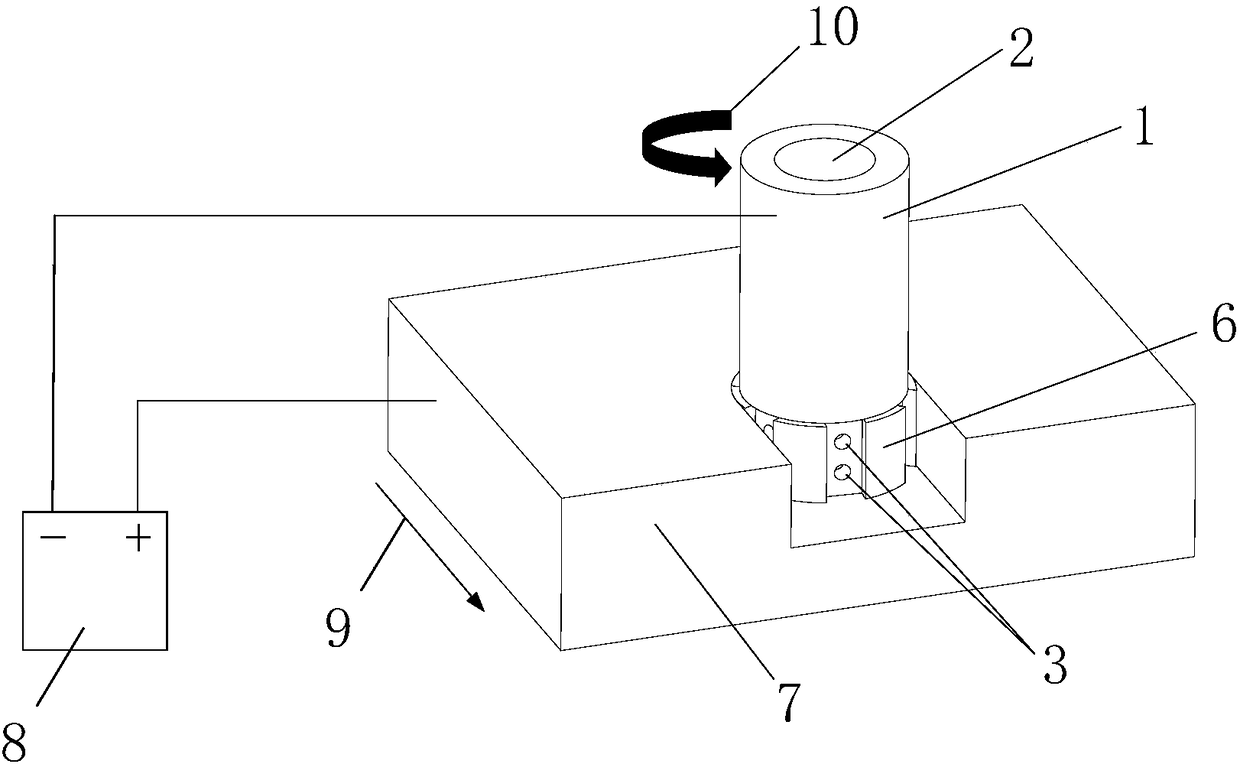

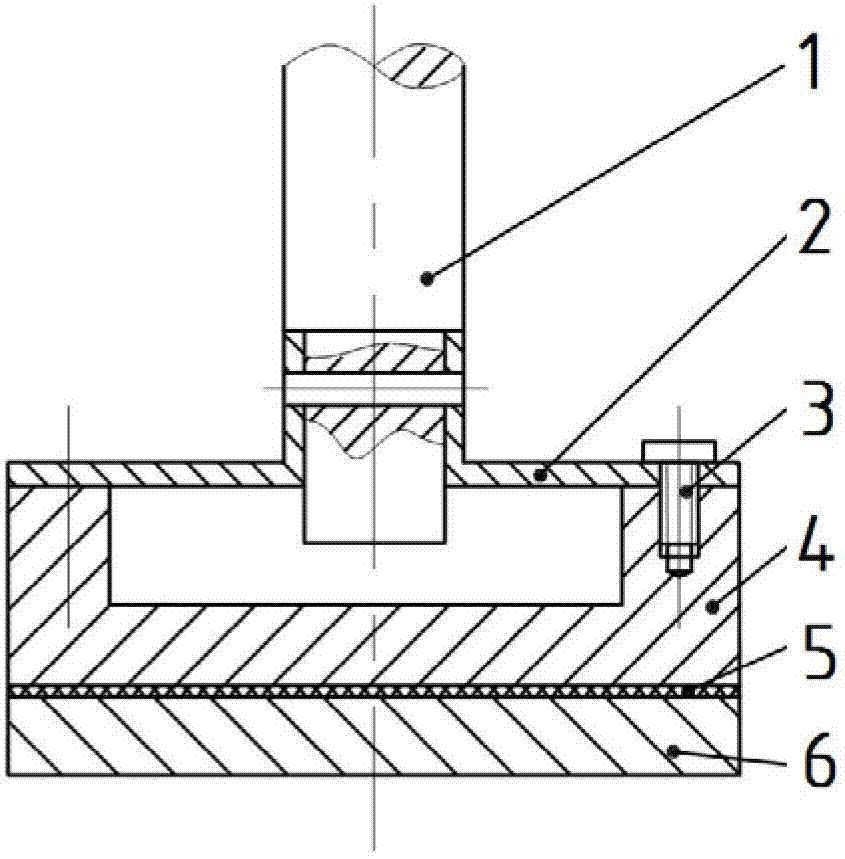

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Production method of non heat seal teabag paper

InactiveCN102877378ARetain fiber lengthGuaranteed bondingReinforcing agents additionPaper/cardboardProcess engineeringSizing

The invention discloses a production method of non heat seal teabag paper. Final products can be obtained through a surface sizing process or a coating process in the existing production method of the non heat seal teabag paper, and a plurality of adhesives and additives are needed to add. The production method includes subjecting plant fibers to special processing, and reserving the length of fibers as far as possible during fully fibrillation; and adding appropriate thermosetting type reinforcing agent into the fiber after the special processing to obtain a body paper product through papermaking. The body paper product can be used directly without the surface sizing and the follow-up coating processing and can adapt to processing requirements for modern high-speed packing machines. According to the production method, the defect that final products can be obtained through the surface sizing or coating in the existing production method of the non heat seal teabag paper is overcome, the paper is formed once, the surface sizing or coating process is reduced, usage of chemical additives in the non heat seal teabag paper is reduced, obtained products are environment-friendly and good in processability, simultaneously, the production process is simplified, and the energy consumption and cost are reduced.

Owner:ZHEJIANG WINBON SPECIALTY PAPER

Directional kernel taking and skin removing machine and kernel taking and skin removing method

InactiveCN102342566AAvoid damageSolve the coreFruit stoningVegetable peelingCircular discEngineering

The invention discloses a directional kernel taking and skin removing machine and a kernel taking and skin removing method. The device comprises a speed reduction motor, a station indexing mechanism, an annular fruit skin removing device, a kernel taking device and a fruit skin complete peeling device, wherein the station indexing mechanism and the kernel taking device are both driven by the speed reduction motor; the station indexing mechanism comprises an indexing circular disc and a material clip; the indexing circular disc is connected with a material loading mechanism and a material unloading mechanism outside; the annular fruit skin removing device is driven by a speed adjusting motor and comprises an annular cutting combined knife; the kernel taking device comprises a kernel taking knife and a kernel taking movement mechanism; and the fruit skin complete peeling device is mounted in a kernel taking knife movement travel. The method comprises the following steps of: trisecting fruits on the station indexing mechanism by using the annular fruit skin removing device; and then taking kernels by using the kernel taking device; pulling fruit skins away from the fruit skins; separating upper fruit skins from fruit fleshes under the effect of the fruit flesh complete peeling device; removing the upper fruit skins; and finally, removing the lower fruit skins through the material unloading mechanism to finish the kernel taking and skin removing. The directional kernel taking and skin removing machine and the kernel taking and skin removing method, disclosed by the invention, have the advantages of high production efficiency and no pollution in machining.

Owner:SOUTH CHINA AGRI UNIV

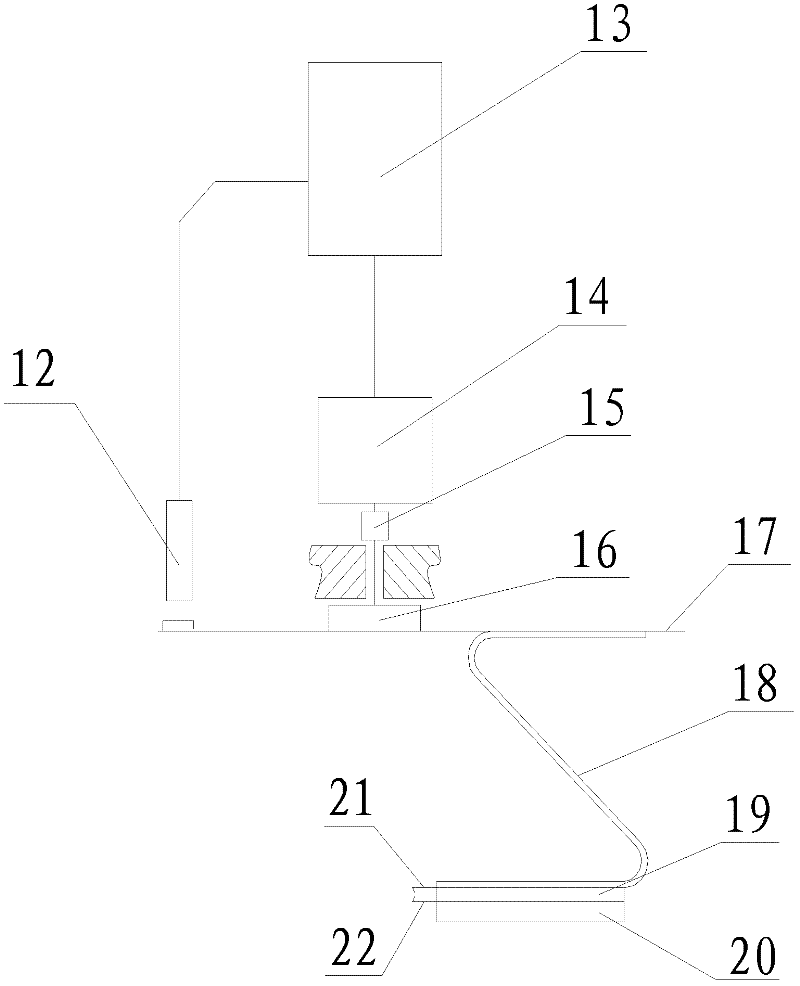

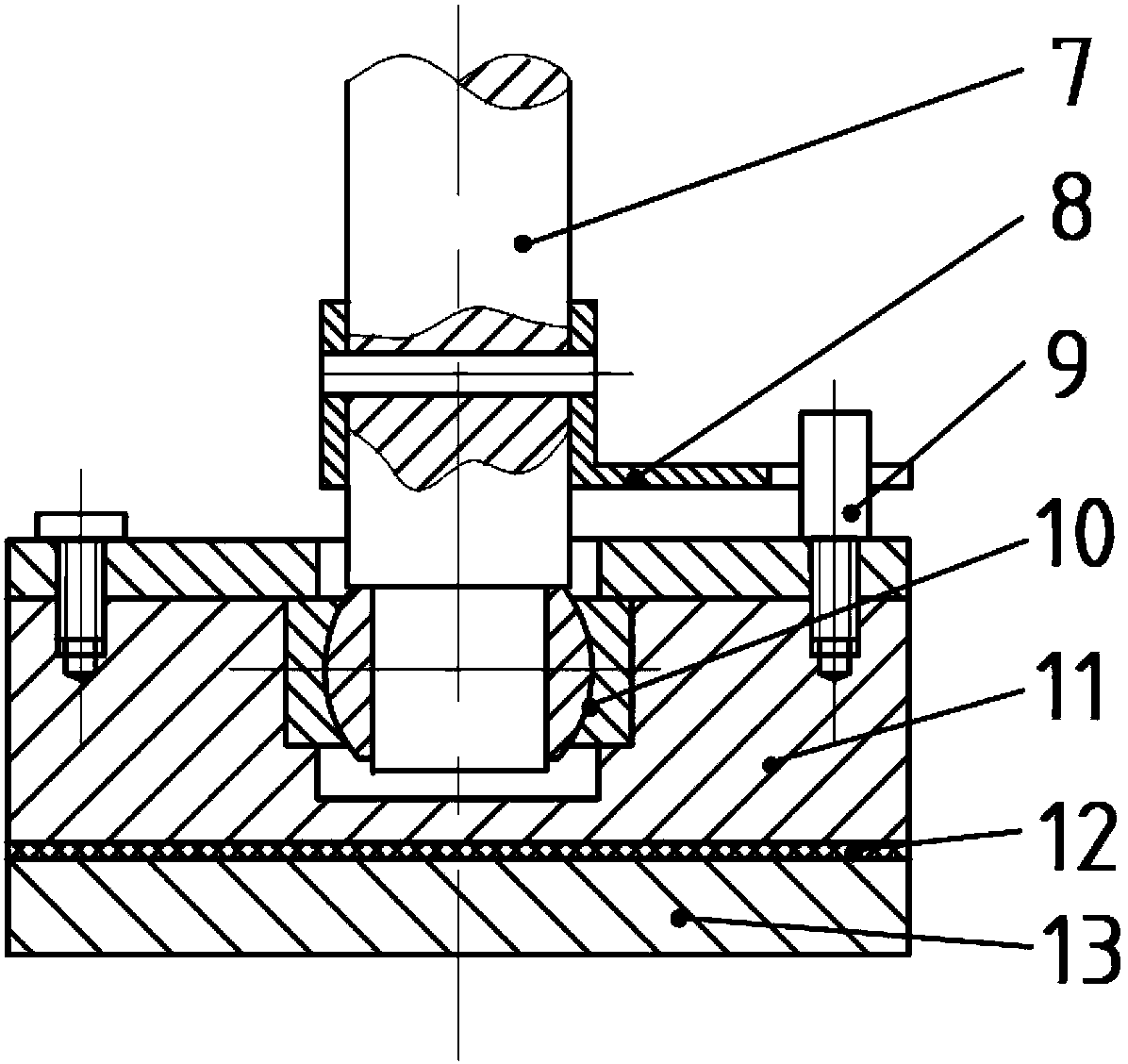

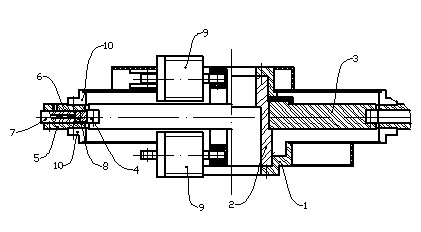

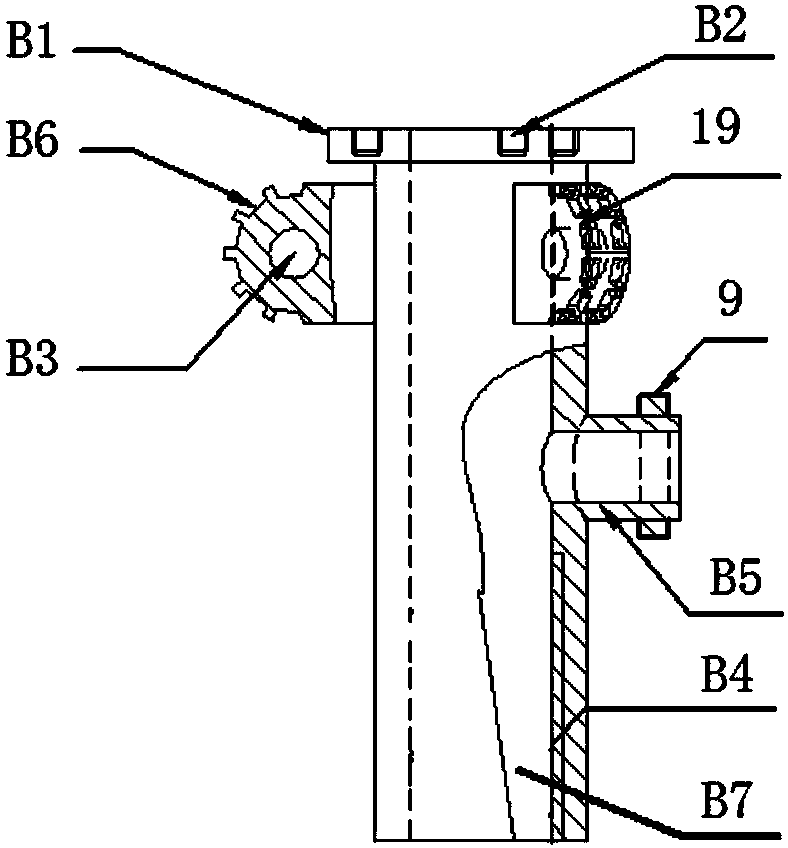

Float polishing head

InactiveCN103203683AFree swing does not affectPrevent inflowLapping machinesLapping toolsContact pressureMachined surface

The invention introduces a float polishing head with a double spherical rolling bearing structure replacing a common joint bearing structure. The float polishing head comprises a transmission shaft, an upper cover, a lower cover, an upper ball, a lower ball, an upper retainer, a lower retainer, pull rods, a rubber bellows, fastening screws, a clamping portion and the like, sphere centers are overlapped to form a swinging instant center of a joint after four spherical parts are assembled, the swinging instant center can be designed on a contact plane of a workpiece and a polishing pad, the moment arm of grinding resistance to the swinging instant center is zero, accordingly, overturning moment is thoroughly eliminated, and uniform contact pressure is applied to the machined surface of the workpiece. The polishing head transmits driving torque through the two pull rods, a swinging joint structure is protected from corrosion by the rubber bellows, and workpiece plane machining precision can be structurally improved.

Owner:DALIAN UNIV OF TECH

Processing method and device for carrying out microwave cutting on brittle material

InactiveCN102179635AReach the processing trackHigh quality cut surfaceWelding/cutting auxillary devicesAuxillary welding devicesHigh densityHigh energy

The invention relates to a processing method for carrying out focused microwave cutting on a brittle material, which is characterized in that microwave energy high-density focusing is realized by using a tapered waveguide, and microwave beams are emitted to the surface of a workpiece from the front end of the tapered waveguide in a high energy density beam mode so as to heat the workpiece, thereby realizing the cutting processing according to the principle of a hot cracking method. The waveguide comprises a cone-shaped mode converter by which the microwave focusing can be realized; and the processing device is provided with a three-dimensional operating platform by which the processing requirements of any curve can be realized. The invention also relates to a processing device for carrying out microwave cutting on a brittle material by using the processing method.

Owner:HARBIN INST OF TECH

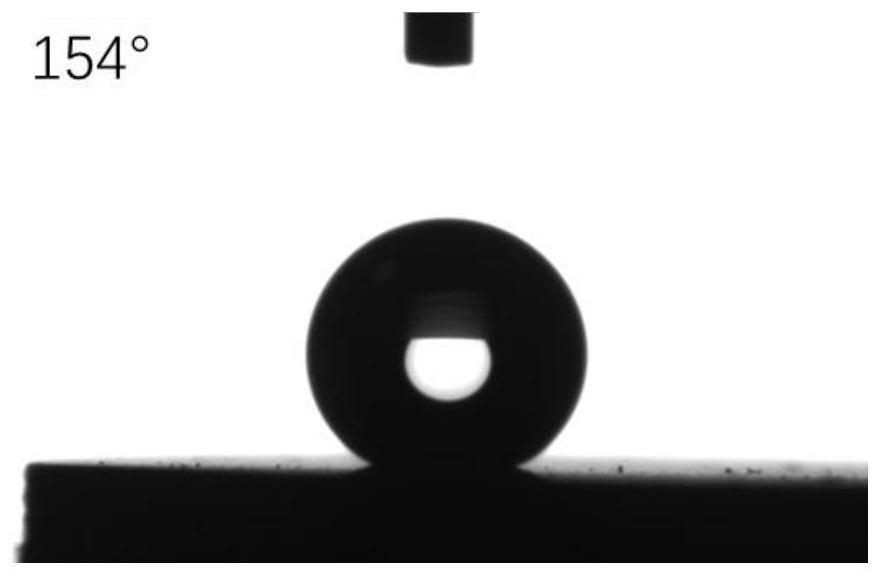

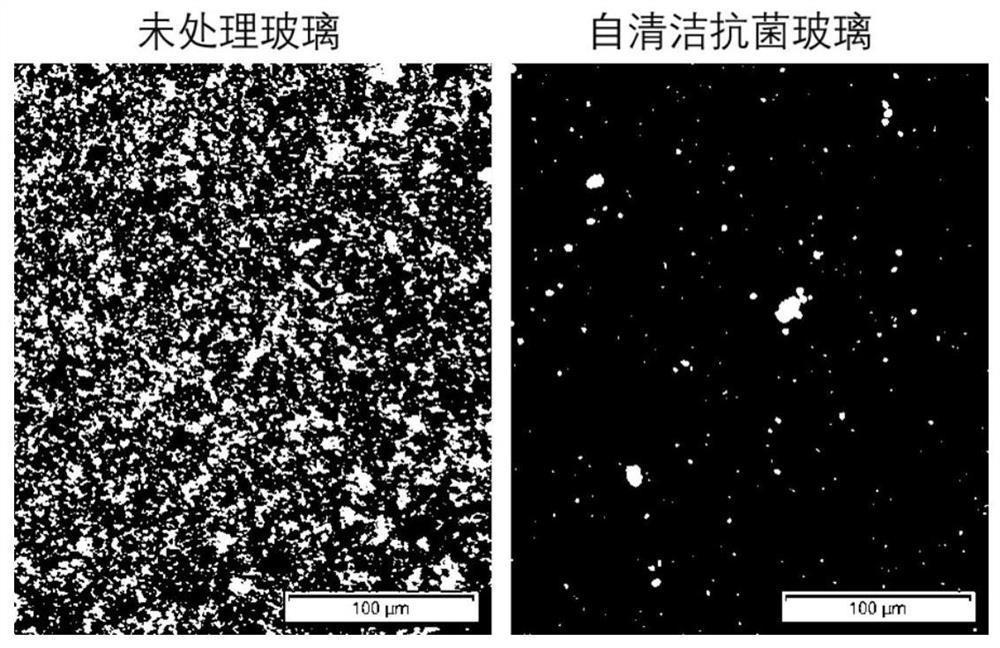

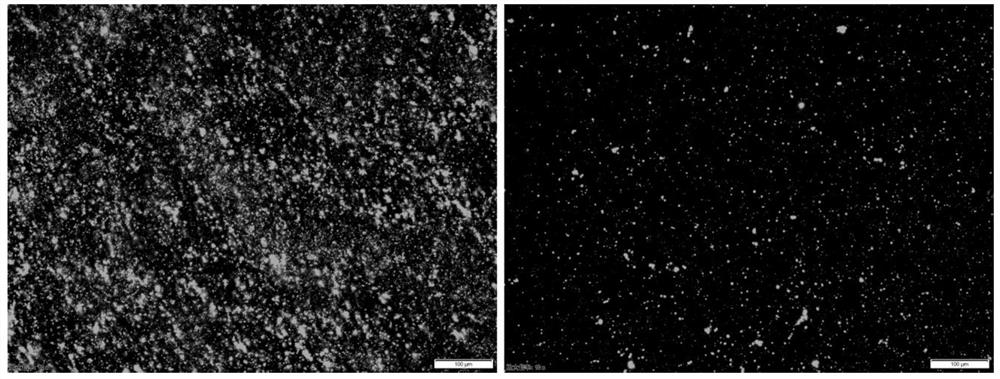

Laser preparation method of self-cleaning antibacterial glass

ActiveCN112062479AAdapt to processing requirementsMade preciselyGlass reforming apparatusCoatingsChemical solutionGlass cover

The invention discloses a laser preparation method of self-cleaning antibacterial glass. Firstly, a prepared chemical solution is scoured to the surface of a metal substrate, and meanwhile, the bottomsurface of glass covers the metal substrate; thirdly, ultrafast laser penetrates through the glass to irradiate the metal substrate, the glass at the interface is molten, the microstructure on the metal is transferred to the glass, meanwhile, the nanoparticles in the solution are reduced and adsorbed to the glass microstructure, and then the glass is subjected to annealing treatment, so that a dual-size micro-nano structure covering the non-polar nanoparticles is generated on the surface of the glass. The surface has an excellent self-cleaning super-hydrophobic function, greasy dirt and the like on the surface of the glass can be removed by using a small amount of water and labor, almost no water stain is left, and the cleaning difficulty in the using process is reduced. Moreover, the super-hydrophobic property can resist bacterial adhesion, and the nanoparticles can kill the adhered bacteria, so that the surface of the glass has excellent antibacterial / bactericidal functions. The preparation method is simple, has universality and is suitable for glass made of various materials. The prepared glass has the advantages of unchanged mechanical properties and favorable light permeability, and is suitable for large-scale commercial production.

Owner:BEIHANG UNIV

Multi-tool efficient synchronous dynamic balance turning machine tool and machining method

PendingCN110508832AReduce processing efficiencyImprove processing efficiencyFeeding apparatusLarge fixed membersNumerical controlGrating

The invention relates to a multi-tool efficient synchronous dynamic balance turning machine tool and a machining method, and belongs to the technical field of mechanical manufacturing. A tailstock isfixed to the tail of a machine tool body, and an electric main shaft system is fixed to the head of the machine tool body through first screws; guide rails are fixed to the two sides of the middle ofthe machine tool body, and a numerical control scale grating is fixed to one side of the middle of the machine tool body; and a workbench driving module is fixed to the center of the middle of the machine tool body, and a workbench module is fixed to the workbench driving module. The multi-tool efficient synchronous dynamic balance turning machine tool and the machining method have the advantagesthat three turning tools are installed and fixed at 120-degree intervals, when the three turning tools conduct machining at the same time, acting forces of the turning tools to a to-be-machined workpiece cancel each other out, self supporting and dynamic balance can be achieved, stress deformation of the to-be-machined workpiece is reduced, thus, the machining precision is improved, moreover, theworkload is decreased, the time is saved, the efficiency is improved, and the machine tool has the high universality.

Owner:JILIN UNIV

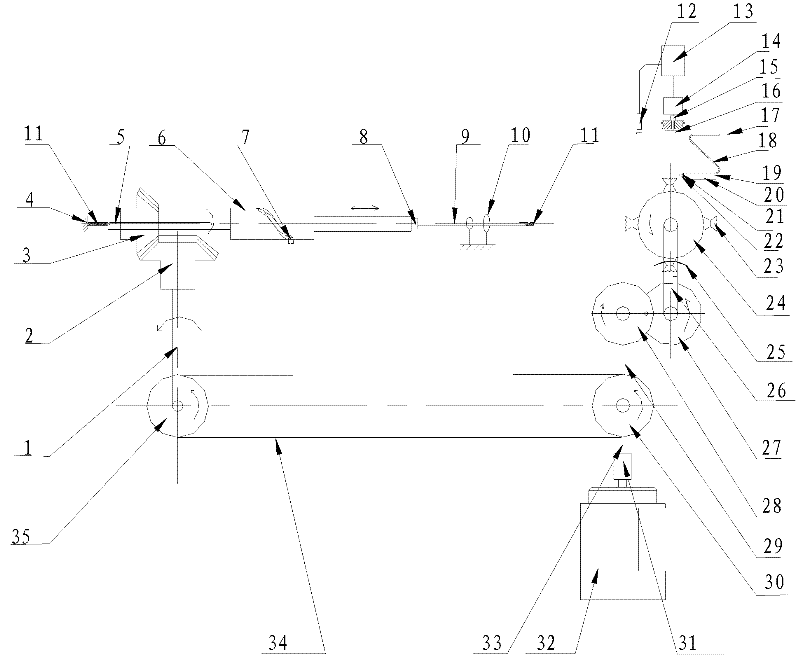

Suspension spring automatic production process

InactiveCN102275062ALow costRealize full automationMetal working apparatusAutomotive engineeringCoil spring

The invention relates to an automatic suspension spring manufacturing technique, which solves the defect that the traditional spring processing technique is not suitable for the processing of suspension springs. The automatic suspension spring manufacturing technique comprises the following steps: selecting a material and coiling into a spring; performing heat treatment; strongly compressing; shot-blasting; painting dressing; load sorting and color marking; and marking and packing, wherein different compression techniques are determined according to the load requirements, coil springs with different load requirements can be differentiated through load sorting, and meanwhile, the coil springs which do not conform to the requirements are sorted out and remedied, thereby reducing the cost. The automatic suspension spring manufacturing technique provided by the invention is applicable to the processing requirements of suspension springs with different loads, at the same time, a conveying device is controlled by a controller to automatically complete the changover of operational sequences, and automation in the overall process is realized.

Owner:QIANJIANG SPRING HANGZHOU CO LTD

Black and odorous water body treatment agent and application method thereof

InactiveCN107572610AShort processEasy to operateWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationChemistryPolyacrylamide

The invention provides a black and odorous water body treatment agent. The black and odorous water body treatment agent comprises an early-stage reaction reagent and a later-stage coagulant aid, and is characterized in that chemical components in the early-stage reaction reagent comprise calcium oxide, Fe powder (a mineral substance) and silica; the early-stage reaction reagent is prepared from the chemical components in parts by mass: 20 to 40 parts of the calcium oxide, 10 to 30 parts of the Fe powder (the mineral substance) and 5 to 25 parts of the silica; chemical components in the later-stage coagulant aid comprise SiO2, CaCO3 and PAM (Polyacrylamide); the later-stage coagulant aid is prepared from the chemical components in parts by mass: 5 to 25 parts of the SiO2, 15 to 35 parts ofthe CaCO3 and 0.5 to 2.5 parts of the PAM. Compared with an existing treatment method, after the reagent is added, pH regulation before treatment and the reagent are carried out at the same time; thetreatment method has the characteristics of shortened flow, convenience for operation, consumption reduction and the like and can be adaptive to treatment requirements of different black and odorous water bodies.

Owner:佛山市顺德区伟润环保科技实业有限公司

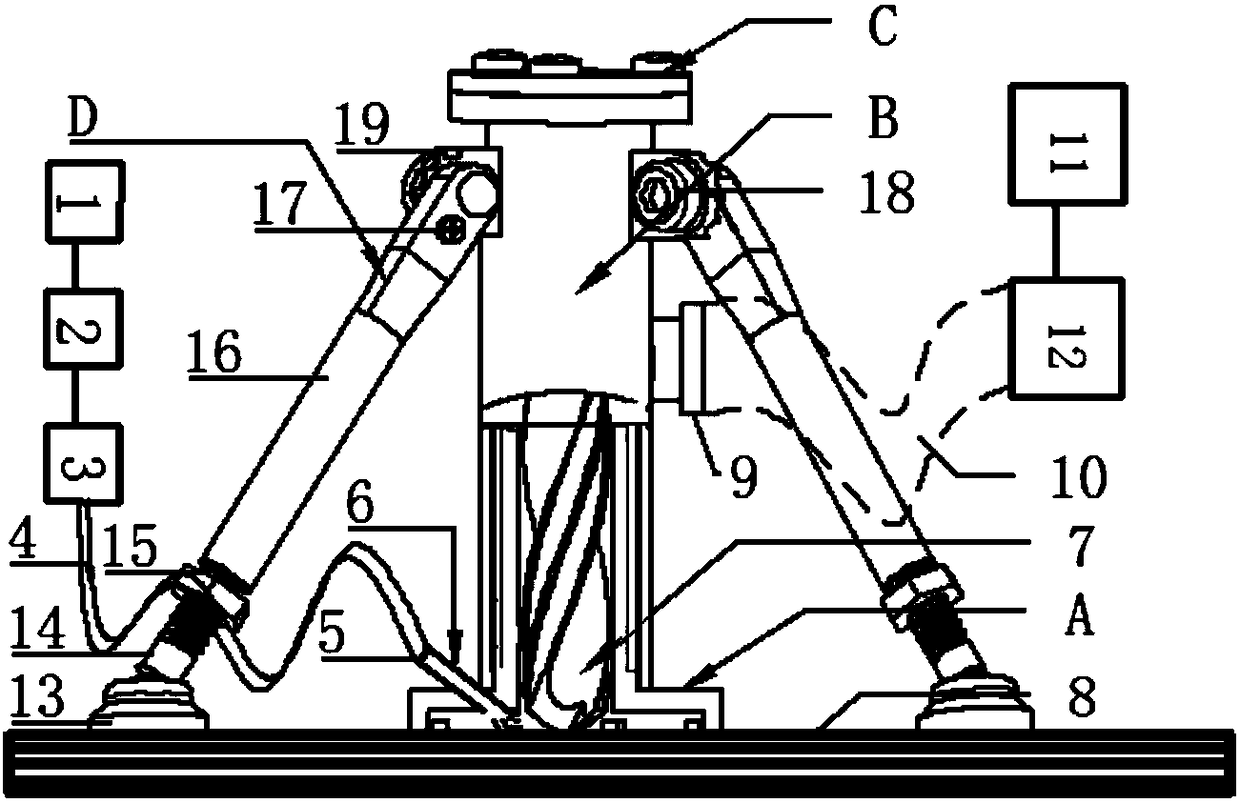

Roboticized intelligent fixture system

InactiveCN100551609CSimple mechanical structureReduce complexityProgramme-controlled manipulatorPositioning apparatusFlight vehicleManipulator

The invention relates to a roboticized intelligent manufacture-equipment system, which is used for the processing field of airborne craft thin-wall curved parts. The roboticized intelligent manufacture-equipment system is characterized in that the whole system comprises a base component, a dynamic beam component, a saddle component, a telescopic unit, a universal vacuum sucker, a left robot and a right robot, as well as a control computer. Under the control of the computer, after realizing the accurate abutting joint on the dynamic beam component through a docking mechanism, the robots do the synchronized motion together for adjusting to a certain position in the X direction, and the dynamic beam component realizes that the base component is locked through a retaining mechanism; at the same time, after the large arm of the robot main machine hand is rotated to the horizontal position, small arms extend out in turn, the palm moves, and then the fingers extend to grasp the telescopic unit fixed on the saddle component, so as to ensure that the telescopic unit moves in the Y direction for adjusting to a certain position; later, the telescopic unit moves in the Z direction for adjusting; in the end, through the universal vacuum sucker fixed on a telescopic mast, the curved face shape used for supporting the thin-wall curved parts is formed. The roboticized intelligent manufacture-equipment system is used for processing various parts, thereby greatly improving the flexibility of the production.

Owner:TSINGHUA UNIV

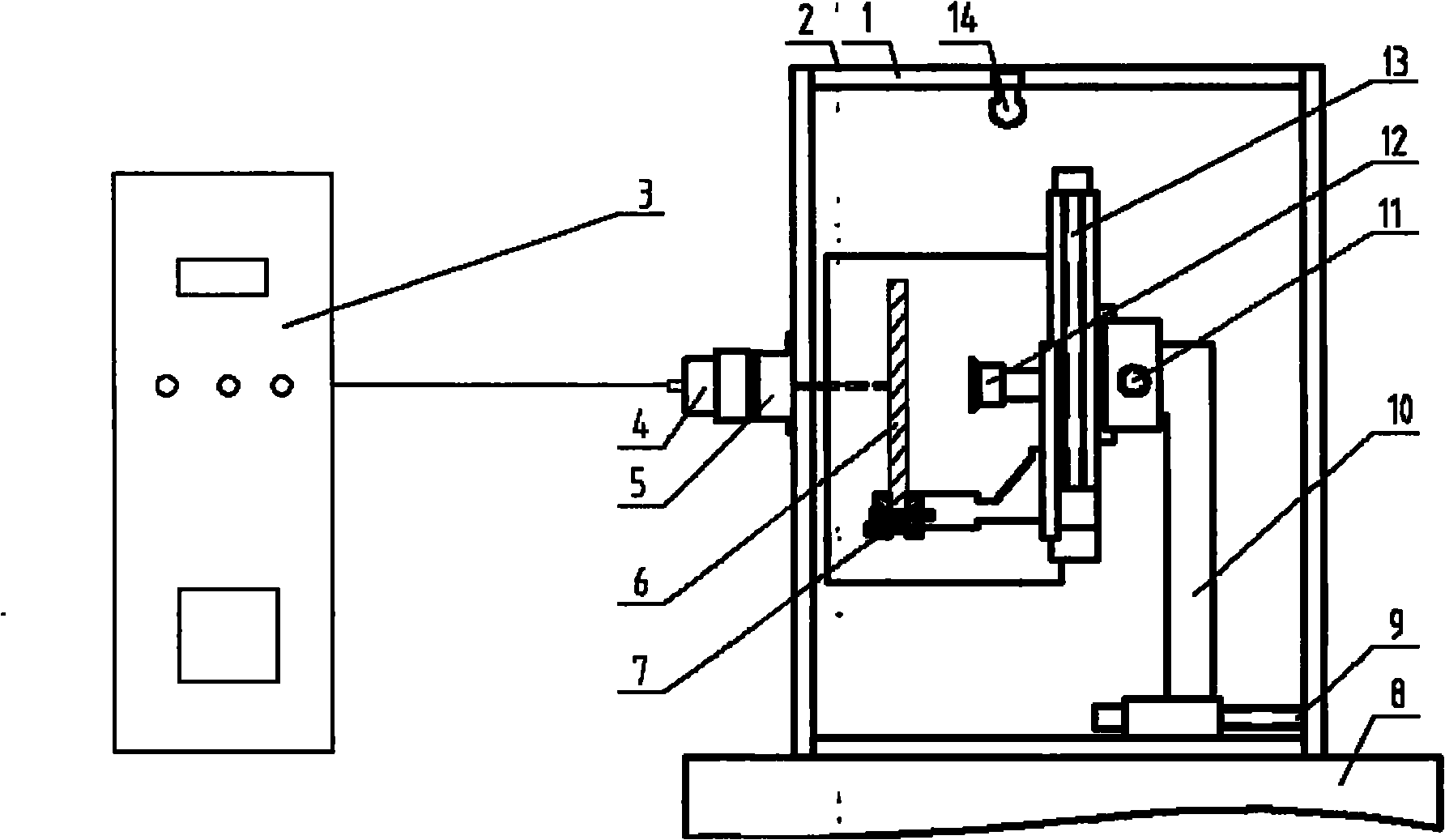

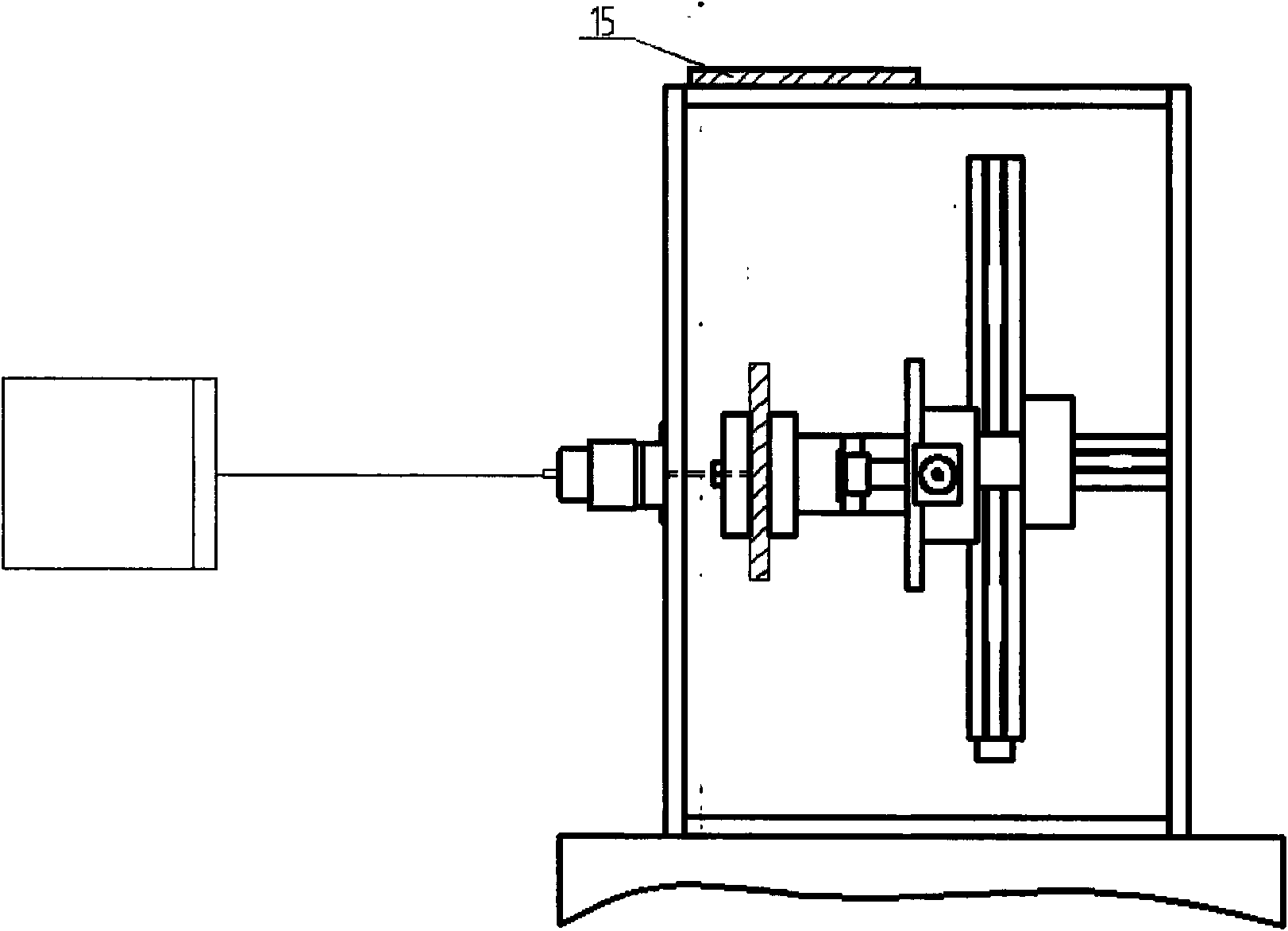

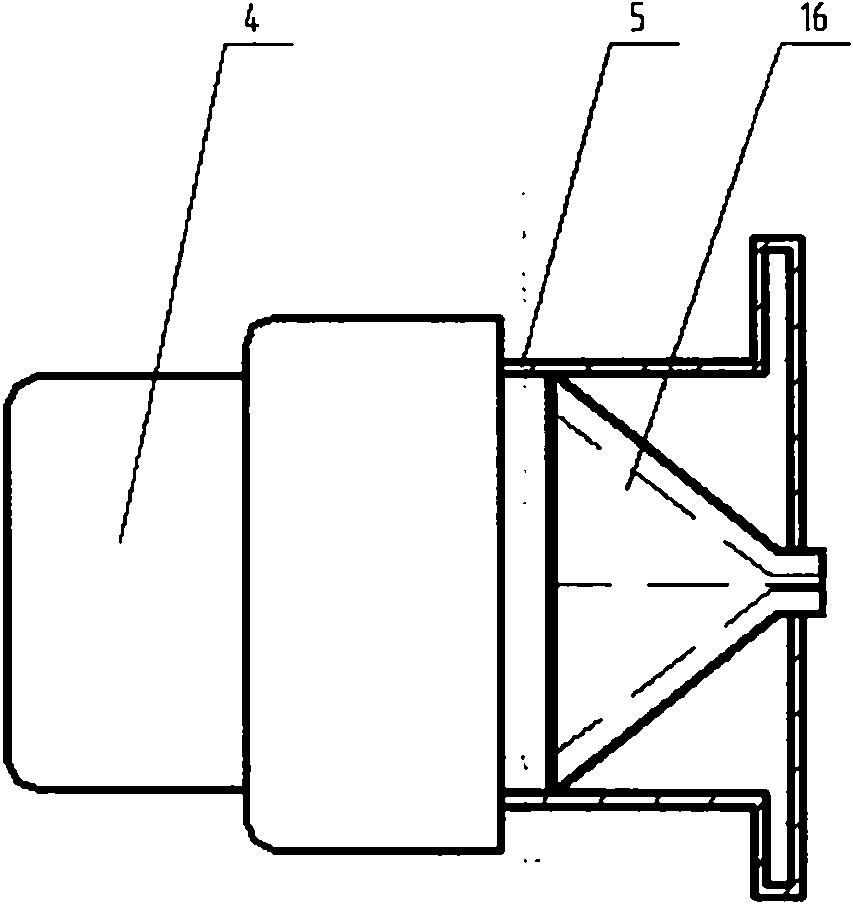

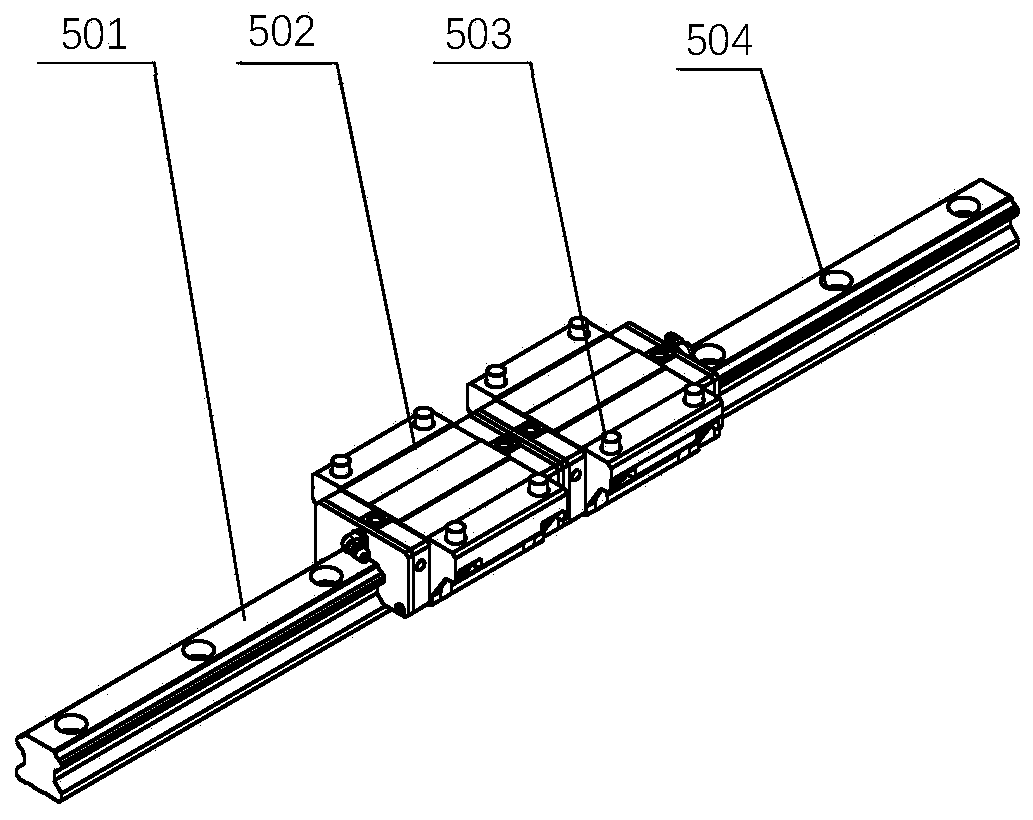

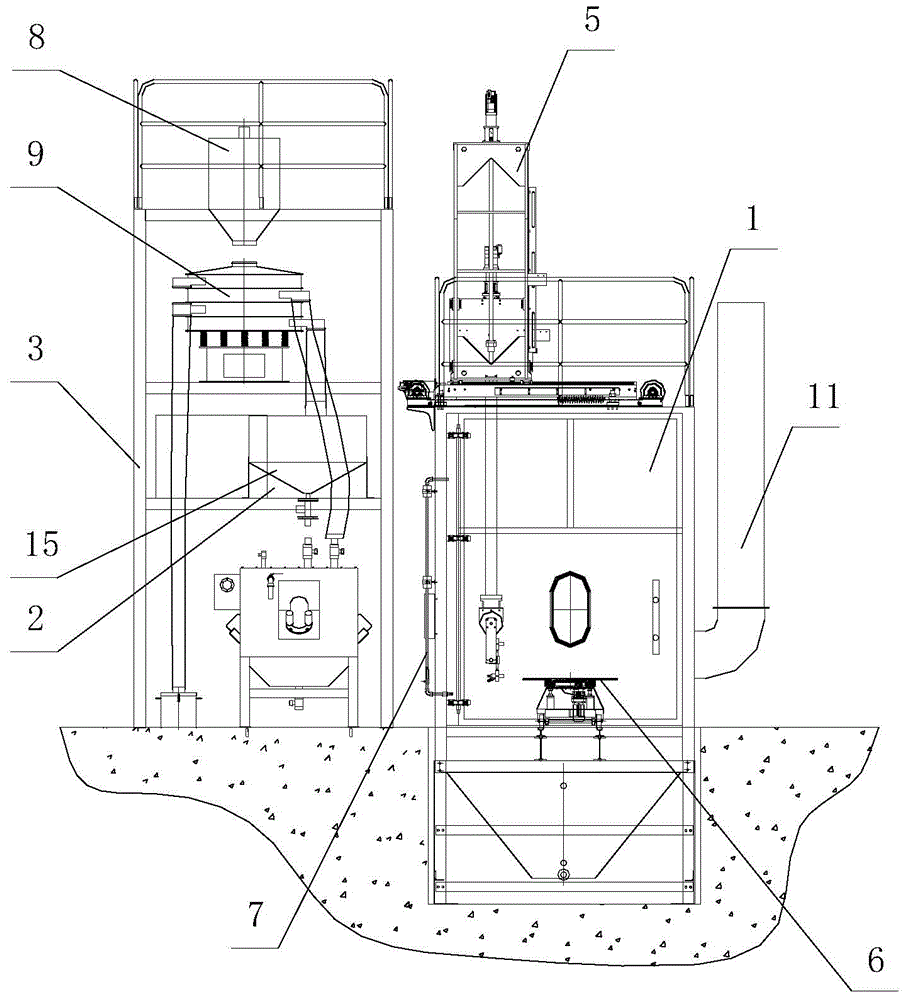

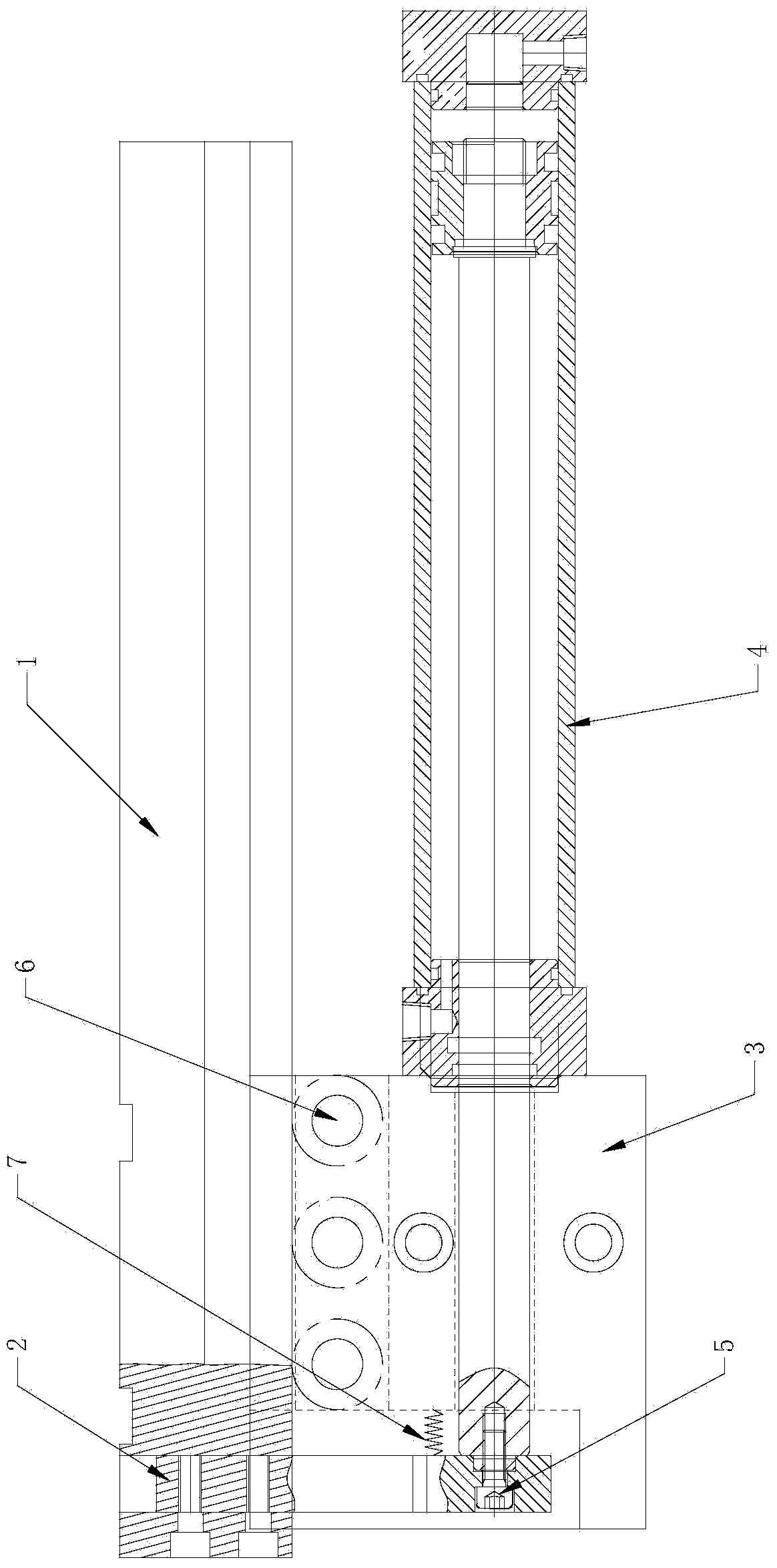

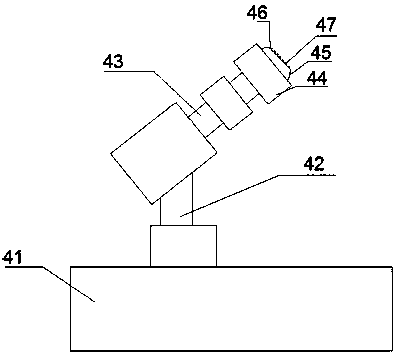

High-precision numerical control liquid shot blasting machine

InactiveCN104552013AAdapt to processing requirementsPrecise positioningAbrasive feedersAbrasive machine appurtenancesManipulatorEngineering

The invention discloses a high-precision numerical control liquid shot blasting machine, which comprises a manipulator spray gun mechanism, and a workpiece conveying turntable, wherein the manipulator spray gun mechanism comprises a spray gun mechanism, a Z-axis mechanical arm, an X-axis mechanical arm and a B-axis mechanical arm, the B-axis mechanical arm consists of a B-axis sliding seat and a steering device, the Z-axis mechanical arm and the X-axis mechanical arm are connected bya coupling and a bead lead screw, the B-axis sliding seatis connected with the Z-axis mechanical arm and the Z-axis mechanical arm respectively, and the B-axis mechanical arm is connected with the spray gun mechanism through the steering device; and the workpiece conveying turntable is positioned close to the spray gun mechanism. A workpiece is positioned on the workpiece conveying turntable, and under the driving of the Z-axis mechanical arm and the X-axis mechanical arm, the B-axis mechanical arm drives the spray gun mechanism to move, so that the sliding and accurate positioning of the spay gun mechanism along a Z axis and an X axis can be realized; the B-axis sliding seat and the steering device simultaneously drive the spray gun mechanism to rotate around the Y axis; in match withthe Y-axis direction motionof the workpiece conveying turntable, the accurate positioning in three-dimension direction and rotation around the Y axis direction of the spray gun mechanism can be realized; and the high-precision numerical control liquid shot blasting machine is applicable to processing requirement of a complicated structure.

Owner:昆山开信精工机械股份有限公司

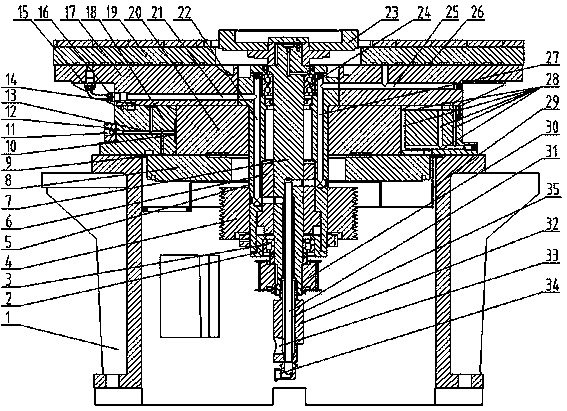

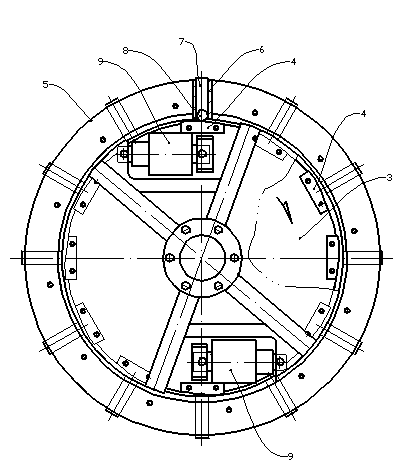

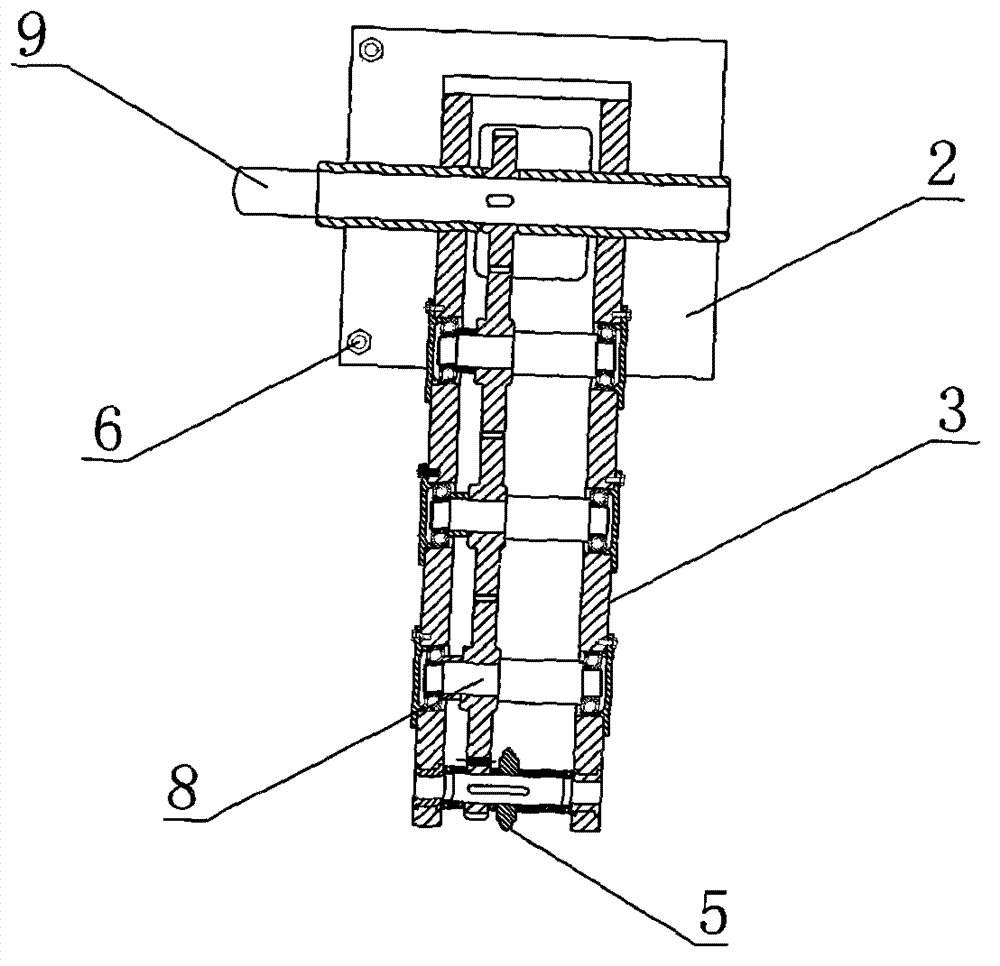

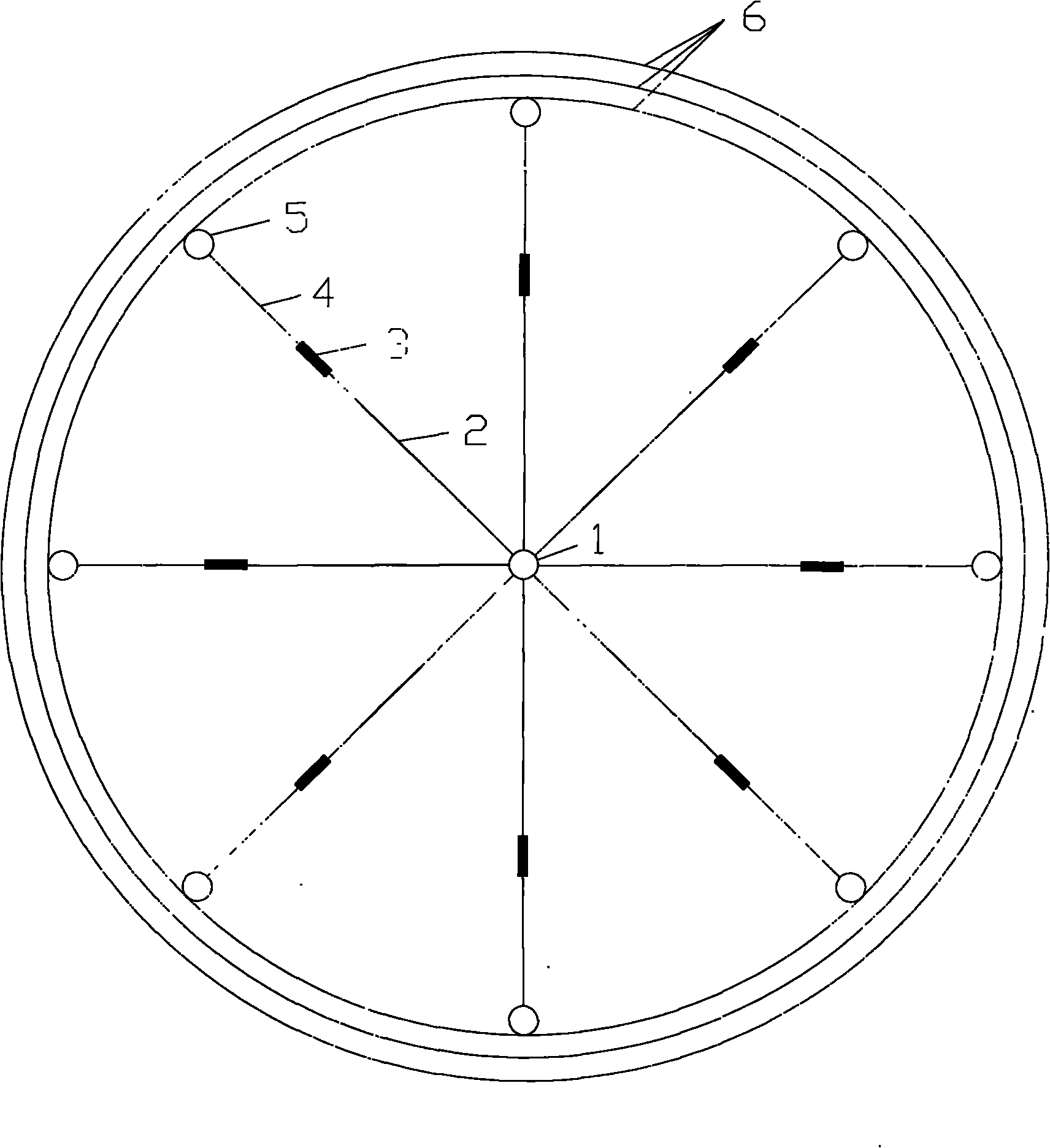

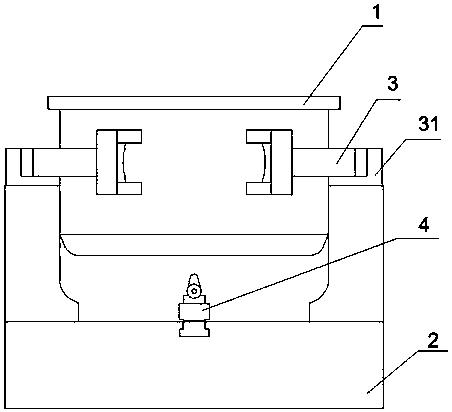

Lower disc device for two-sided precision grinding and polishing combined machine tool

ActiveCN103831712AAdapt to processing requirementsReduce vibrationGrinding machine componentsLapping machinesEngineeringGrinding wheel

The invention discloses a lower disc device for a two-sided precision grinding and polishing combined machine tool. The lower disc device comprises a chassis support, an upper static pressure disc arranged on the chassis support, a lower static pressure disc arranged at the bottom of the upper static pressure disc, a central shaft arranged in the middle of the upper static pressure disc and the lower static pressure disc, and a hollow shaft movably arranged on the central shaft in a sleeved mode. A sun wheel is arranged at the top end of the central shaft; a central rotary disc and a lower supporting disc are fixed to the hollow shaft, wherein the central rotary disc is in sliding fit with the inner circumferential face of the upper static pressure disc and the upper surface of the lower static pressure disc, and the lower supporting disc is fixed to the central rotary disc; a lower disc grinding wheel in sliding fit with the upper surface of the upper static pressure disc is arranged on the lower supporting disc; the upper face, the lower face and the inner circumferential face where the upper static pressure disc is in sliding fit with the lower supporting disc are provided with an upper oil cavity, a lower oil cavity and a middle oil cavity respectively; the upper face, the lower face and the inner circumferential face where the lower static pressure disc is in sliding fit with the central rotary disc are provided with an upper oil cavity, a lower oil cavity and a middle oil cavity respectively. According to the lower disc device, grinding and polishing accuracy and efficiency of hard and brittle materials machined by two-sided grinding and polishing equipment can be improved.

Owner:YUHUAN CNC MACHINE TOOL

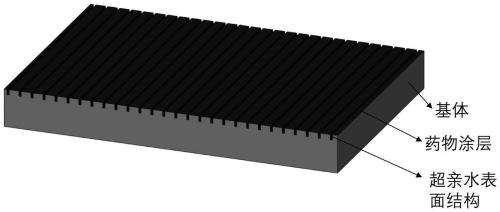

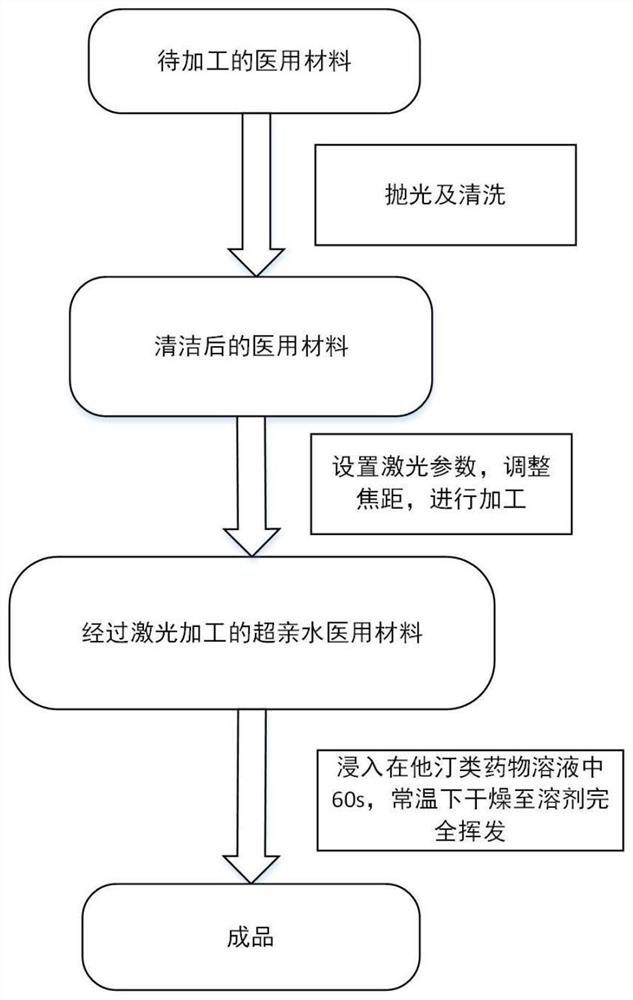

Medical implant for improving cell osteogenesis performance and preparation method thereof

InactiveCN111632195AEasy to rebuildEnhance osteogenic activityBone implantPharmaceutical delivery mechanismLaser processingHuman cell

The invention discloses a medical implant for improving cell osteogenesis performance and a preparation method thereof. The polished and cleaned medical metal is subjected to laser processing so as toobtain a surface structure with super-hydrophilic performance, and a statin drug coating is prepared on the super-hydrophilic surface, so that the drug loading is more uniform and sufficient. The medical implant with the drug coating has the function of enhancing the osteogenesis performance of human cells, is beneficial to rapid and tight combination with human tissues after being implanted intoa human body, is beneficial to smooth implementation of a transplantation operation, and effectively avoids secondary injury caused by transplantation failure.

Owner:BEIHANG UNIV

Float polishing head

InactiveCN103203683BFree swing does not affectPrevent inflowLapping machinesLapping toolsContact pressureMachined surface

The invention relates to a float polishing head with a double spherical rolling bearing structure replacing a common joint bearing structure. The float polishing head comprises a transmission shaft, an upper cover, a lower cover, an upper ball, a lower ball, an upper retainer, a lower retainer, pull rods, a rubber bellows, fastening screws, a clamping portion and the like, sphere centers are overlapped to form a swinging instant center of a joint after four spherical parts are assembled, the swinging instant center can be designed on a contact plane of a workpiece and a polishing pad, the moment arm of grinding resistance to the swinging instant center is zero, accordingly, overturning moment is thoroughly eliminated, and uniform contact pressure is applied to the machined surface of the workpiece. The polishing head transmits driving torque through the two pull rods, a swinging joint structure is protected from corrosion by the rubber bellows, and workpiece plane machining precision can be structurally improved.

Owner:DALIAN UNIV OF TECH

Heavy rim rounder

The invention relates to a heavy rim rounder comprising a center shaft mounted on a fixed base and a crush-resistance ring capable of rotating around the center shaft. Cams are distributed on the outer circumference of the crush-resistance ring. A carrier-rod disc is arranged on the periphery of the crush-resistance ring, guide holes which run through radially and are opposite to the corresponding cams are uniformly distributed along the circumference of the carrier-rod disc, and carrier rods capable of telescoping radially along the guide holes are arranged in the guide holes. The outer sides of the carrier rods can extend out of the guide holes while the inner sides of the carrier rods are abutted against outer cam surfaces; during rotation of the crush-resistance ring, the cam surfaces move so as to push the carrier rods outwards. A plurality of synchronous cylinders capable of driving the crush-resistance ring to rotate are mounted on the fixed base. As the cams output radial stretching force directly, the heavy rim rounder simple in structure and convenient to operate has the advantages of short range of motion, compact structure, high reliability and high output pressure and can meet processing requirements of heavy rims.

Owner:ZHENJIANG CORIM MFR

Production process of non-heat-seal type tea filter paper

InactiveCN106283895AHigh strengthAvoid breakingReinforcing agents additionChemical/chemomechanical pulpFiberCross-link

The invention discloses a production process of non-heat-seal type tea filter paper. The production process comprises the steps that S1, plant fibers soaked with sulfite are added into a beater, when the beating degree of slurry ranges from 15 SR to 25 SR, beating is stopped, an enhancer is added into the beater, slurry A is obtained, and the slurry is discharged for use; S2, a cross-linking agent and starch are added into the slurry A prepared in S1, the oven dry ratio of the cross-linking agent to the starch ranges from 1:120 to 45:120, then stirring is carried out for 25 min to 35 min, the materials are fully mixed to be uniform, and slurry B is obtained; S3, 5-6% flocculant is added into the slurry B prepared in S3, the mass concentration of paper pulp ranges from 0.14% to 0.16%, the materials are mixed and stirred to be uniform, then net feeding and paper manufacturing are carried out, press polishing and rolling are carried out through a paper maker, and the finished paper is made. The non-heat-seal type tea filter paper made through the process contains no harmful chemical additive, is environmentally friendly and practical, has wide market popularization value and can be widely applied and popularized.

Owner:丽水兴昌新材料科技股份有限公司

Large-sized inner gear ring machining device

The invention relates to a large-sized inner gear ring machining device which comprises a connecting part, a bent shell, a power transmission mechanism and a milling tool, wherein the connecting part can be connected with a tool post of a common gear hobbing machine; the bent shell is matched with an inner gear ring in shape; the power transmission mechanism can be used for transmitting power of the common gear hobbing machine; and the milling tool is connected to the power transmission mechanism. The connecting part comprises a bolt and a locating key, which are matched with the tool post of the original common gear hobbing machine. The transmission mechanism is a gear set, two ends of which are respectively matched with an output end of the tool post of the original common gear hobbing machine and an input end of the milling tool. After the structure is adopted, the original common gear hobbing machine can be utilized; the device is mounted on the tool post of the original common gear hobbing machine; and the power of the original gear hobbing machine is transmitted to the milling tool by the power transmission mechanism. The large-sized inner gear ring machining device provided by the invention can be designed and made according to parameters of the inner gear ring to be machined, can adapt to various machining requirements and has the advantages of simple structure, easiness in mounting and low manufacturing cost.

Owner:青岛青锻锻压机械有限公司

Dual-purpose auxiliary pushing device for pipe bending machine

The invention discloses a dual-purpose auxiliary pushing device for a pipe bending machine. The auxiliary pushing device is arranged on a rack of the pipe bending machine, is positioned behind a pipe bending die and comprises an auxiliary pushing die sleeve, an auxiliary pushing plate, an auxiliary pushing connection block and an auxiliary pushing oil cylinder; the axis of the auxiliary pushing oil cylinder is horizontally arranged; a cylinder body of the auxiliary pushing oil cylinder is fixed with the auxiliary pushing die sleeve and a piston rod of the auxiliary pushing oil cylinder runs through the auxiliary pushing die sleeve; the auxiliary pushing connection block is fixedly arranged on the piston rod in a detachable manner; the auxiliary pushing plate is fixedly connected with the auxiliary pushing connection block; supporting rollers for supporting the auxiliary pushing plate to horizontally reciprocate are rotationally arranged on the auxiliary pushing die sleeve; an elastic resetting part is arranged between the auxiliary pushing connection block and the auxiliary pushing plate. The auxiliary pushing device not only can be suitable for the fine pipe bending requirement of a thin-wall bent small-radius steel pipe, but also is suitable for the rapid pipe bending requirement of a thick-wall bent large-radius steel pipe.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST

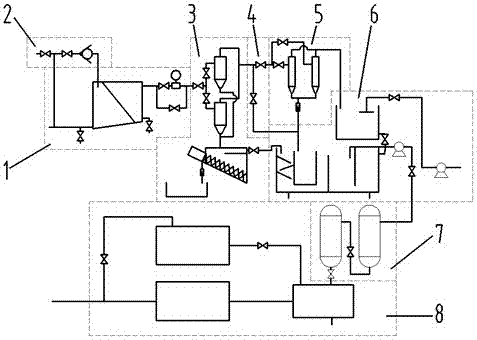

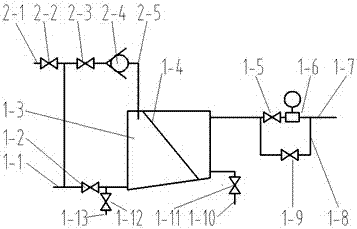

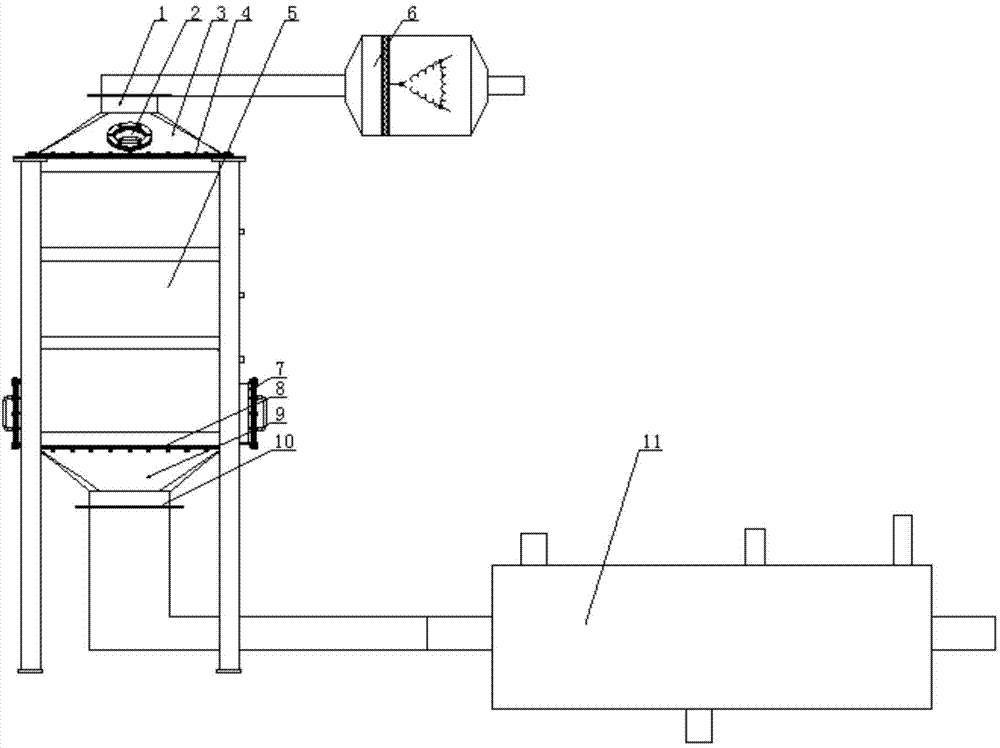

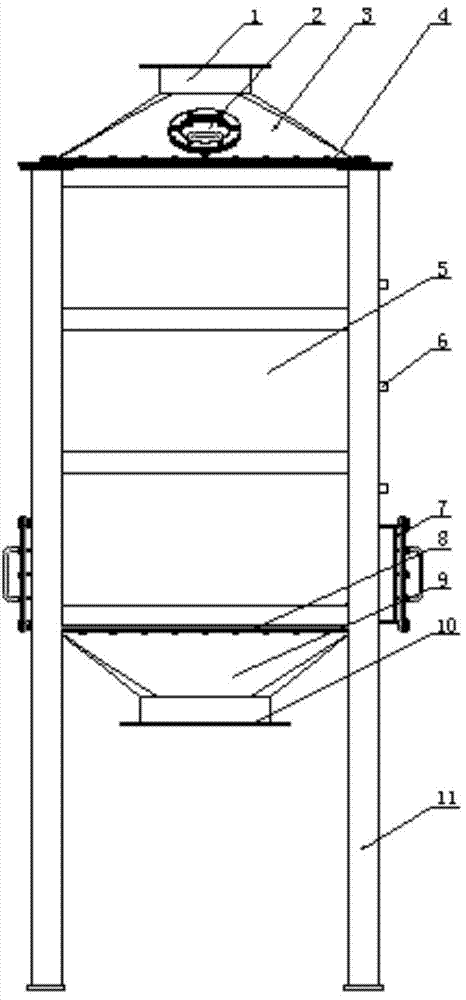

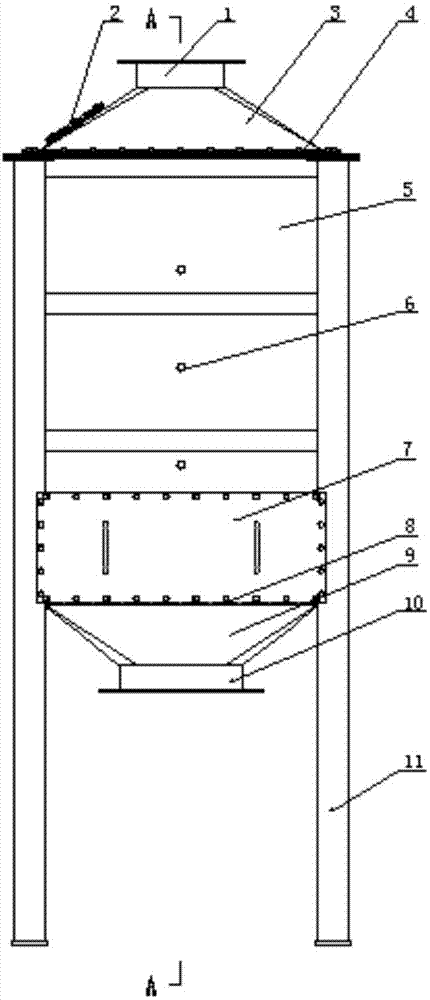

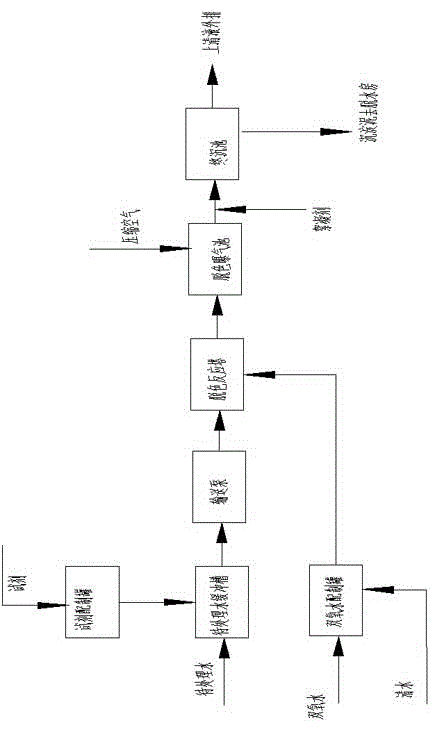

Skid-mounted well repair operation flushing fluid recycling device and method

ActiveCN107489384ALow water quality requirementsReduce labor intensityFlushingSites treatmentProcess engineering

The invention discloses a skid-mounted well repair operation flushing fluid recycling device and method. The skid-mounted well repair operation flushing fluid recycling device comprises a pretreatment process, a sand removal process, an oil removal process, a sedimentation pond process, a filtering process, a well entering process, a well outlet fluid detecting process and an oil removal exceeding process. The sand removal process is connected with the pretreatment process, the oil removal exceeding process and the sedimentation pond process, the oil removal process is connected with the oil removal exceeding process and the sedimentation pond process, the filtering process is connected with the sedimentation pond process and the well entering process, and the well outlet fluid detecting process is connected to the pretreatment process. According to the skid-mounted well repair operation flushing fluid recycling device and method, on-site treatment of well repair operation flushing fluid can be achieved, on-site cyclic treatment of sandblasting flushing fluid and oil water well flushing fluid are simultaneously achieved, the treated flushing fluid can reach well-entering standard and can directly enter a well, and thus recycling of the flushing fluid is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy-saving type catalytic bed system with controllable temperature

InactiveCN103486601AUniform air intakeUniform adsorptionIncinerator apparatusDesorptionHeat exchanger

The invention relates to an energy-saving type catalytic bed system with the controllable temperature. The energy-saving type catalytic system comprises a gas inlet heater, a catalytic bed and a heat exchanger. A gas inlet channel and a gas outlet channel are alternately formed between a furnace body inner surrounding plate and a furnace body outer surrounding plate. The inlet of the gas inlet channel is formed in an upper end plate, and the outlet of the gas inlet channel is formed between a lower end plate and the furnace body inner surrounding plate. The inlet of the gas outlet channel is formed between the upper end plate and the furnace body inner surrounding plate, and the outlet of the gas outlet channel is formed in the lower end plate. The heater is arranged in a furnace body corresponding to the outlet of the gas inlet channel. A gas outlet flow guide cover is arranged on the lower face of the middle of the lower end plate corresponding to the outlet of a gas outlet cover. A catalytic tail gas inlet, a catalytic tail gas outlet, a catalytic gas inlet, a catalytic gas outlet, a desorption gas supply inlet and a desorption gas supply outlet are formed in the heat exchanger. By the adoption of the energy-saving type catalytic bed system, heat efficiency of the catalytic bed is effectively improved, the heat loss is reduced, the heat recovery utilization rate, combustion efficiency and the purification rate are improved, heat exchange is increased, heat energy is more reasonably utilized, and the energy saving and emission reduction requirements are met.

Owner:赛智环保科技(天津)有限公司

Integrated waveguide-coaxial-microstrip transition structure

The invention discloses an integrated waveguide-coaxial-microstrip transition structure which comprises a microwave box body, an insulator and a waveguide cover plate. A circuit groove is formed in the top surface of the microwave box body in a depth direction to install a microwave circuit, and the cover plate is arranged above the circuit groove; an end face groove is formed in one end face of the microwave box body, an end face waveguide cavity is formed in the end face groove, an external waveguide port is formed at the corresponding position above the end face waveguide cavity, namely the top face of the microwave box body, and waveguide mounting holes are formed in the two sides of the external waveguide port; the insulator is transversely arranged between the end face waveguide cavity and the circuit groove, one end of the insulator extends into the end face waveguide cavity, and the other end of the insulator is electrically connected with the microwave circuit in the circuit groove, and the waveguide cover plate is tightly matched with the end surface groove. According to the present invention, a main cavity is formed through one-time machining, and the waveguide cavity and the microwave box body are manufactured on one structural part, so that the machining and manufacturing are convenient and fast; the requirement for alignment between the waveguide cover plate and the microwave box body is low, and the performance deterioration caused by the matching precision problem of the waveguide cavity and the microwave box body is avoided.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Sewage treatment agent and usage method therefor

InactiveCN105036282AAdapt to processing requirementsShort processWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationShortening procedureChemical composition

Provided by the present invention is a sewage treatment agent. The sewage treatment agent comprises an early reaction agent and a late flocculant. The reaction agent contains chemical components of H2SO4 and FeSO4, wherein the mass ratio of Fe2+ to H+ in the agent is 0.75:1.20. The flocculant contains chemical components of SiO2, NaOH and PAM, wherein the mass ratio of SiO2 to NaOH to PAM is 3: 2: 1. The early reaction agent is added into an agent blending tank for blending. To-be-treated sewage reacts and then enters into a decoloring aeration tank; the treated water is aerated for 30-40 mins in the aeration tank; then, the flocculant is added; the treated sewage after the reaction enters into a final precipitation tank for such late reactions as precipitation; and precipitated mud is sent into a dewatering house and a supernatant liquid is discharged. By adding the agent disclosed by the invention, PH adjustment before treatment is performed simultaneously with the reaction agent, and PH adjustment after treatment is performed simultaneously with the flocculant. The sewage treatment agent and usage method provided by the invention have the advantages of shortening procedures, convenient operation and reducing consumption, and can meet different sewage treatment requirements.

Owner:TANGSHAN SANYOU GRP DONGGUANG PULP CO LTD

Portable reverse cooling and dedusting integrated device

ActiveCN108555356AAdapt to processing requirementsRealize positioning processingDrilling/boring measurement devicesMetal working apparatusMachining vibrationsCooling fluid

The invention discloses a portable reverse cooling and dedusting integrated device, belongs to the field of cutting machining, and relates to a portable cooling and dedusting device capable of drilling structure parts of large curvature. The portable reverse cooling and dedusting integrated device is composed of six parts, namely a threaded drilling sleeve, a device main body, a sealing cover, multi-directional supporting and fixing structures, a negative pressure dust treatment part and a cooling liquid spraying part. The multi-directional supporting and fixing structures are symmetrically and uniformly distributed and composed of universal adjusting feet and angle adjusting mechanisms. The angle adjusting mechanisms are composed of positioning lifting lugs, fastening bolts and positioning bolts, wherein the positioning lifting lugs, the fastening bolts and the positioning bolts mutually cooperate to achieve angle changing and foot end fixing of the multi-directional supporting and fixing structures. The negative pressure dust treatment part is composed of a dust sucking connector, a dust sucking guiding pipe, a negative pressure dust collector and a collecting device. The portable reverse cooling and dedusting integrated device integrates the functions of dust sucking, reverse cooling, portability, quick station changing and the like, machining vibration of a long cutter is effectively reduced, independent change of the angles and lengths of the supporting structures is achieved, and complex structural surfaces can be positioned and machined in a high quality mode.

Owner:DALIAN UNIV OF TECH

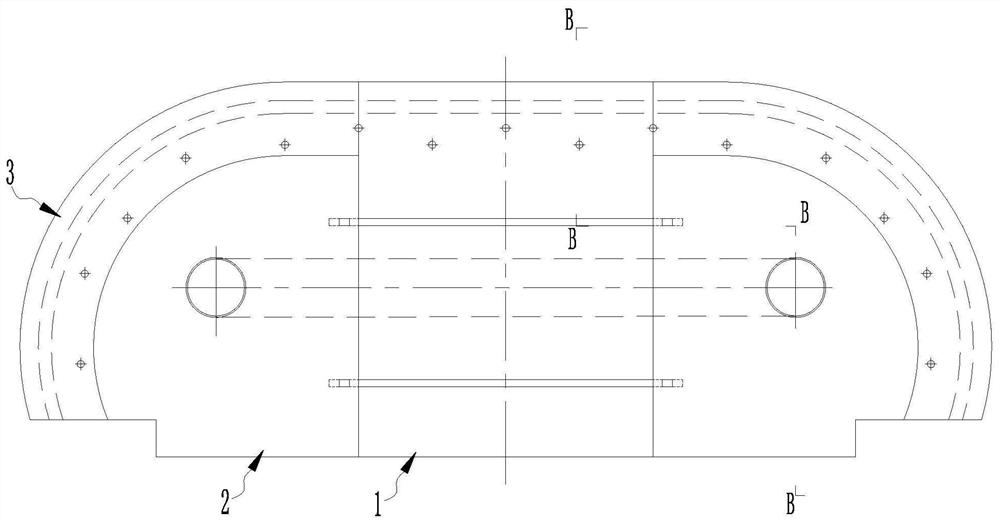

One-step bundling shaping method of culvert pipe multi-layer reinforcement cage and bundling shaping device

ActiveCN101892746AAdapt to processing requirementsReduce or enlarge diameterArtificial water canalsBuilding material handlingEngineeringRebar

The invention discloses a one-step bundling shaping method of a culvert pipe multi-layer reinforcement cage and a bundling shaping device, aiming at bundling and shaping the multi-layer reinforcement cage for culvert pipes for construction in one step and improving the processing speed of the culvert pipe reinforcement cage. The one-step bundling shaping method of the culvert pipe multi-layer reinforcement cage comprises the steps of with the bundling shaping device, adjusting the diameter of the bundling shaping device and bundling layer by layer from outside to inside. The bundling shaping device comprises a radial adjusting mechanism, a centre rod and an axial support rod, wherein the centre rod is sleeved in the radial adjusting mechanism and the both ends thereof are supported by a bracket; and the radial support rod is fixed together with the radial adjusting mechanism. The diameter of the device can be reduced or enlarged by adjusting the radial adjusting mechanism to meet the processing requirement of reinforcement cages with various sizes, the applied size range is large and the maintenance is simple. The invention can effectively improve the processing efficiency, reduce the labor intensity of workers and improve the construction progress of the project and is beneficial to reducing the cost and increasing the benefits.

Owner:中石化石油工程技术服务有限公司

Positioning anti-sinking device for processing automobile brake drum and processing method thereof

ActiveCN107790743ASuppress stressNovel structureTurning machinesPositioning apparatusEngineeringMechanical engineering

The invention discloses a positioning anti-sinking device for processing an automobile brake drum and a processing method thereof. The device is arranged on a workbench of a vertical lathe, two sets of clamping claws are symmetrically arranged on the workbench, the device comprises two or more sets of anti-sinking mechanisms, and the anti-sinking mechanisms comprises bases, height adjustment parts, length adjustment parts and supporting parts. The positioning anti-sinking device for processing the automobile brake drum is novel in structure and practical in function, the anti-sinking mechanisms are arranged on the workbench, pressure which is generated by a cutting tool from top to bottom can be effectively inhibited, sinking or local shifting of products can be avoided, then, processing errors which are generated due to sinking or shifting are avoided, and the product quality is improved; the lower portion of the base is connected with the upper end surface of the workbench through arail, and the rail is arranged in the radial direction of the workbench; the anti-sinking mechanisms can totally move along the workbench in the radial direction, the position where the supporting parts act on the bottoms of products is adjusted, and the positioning anti-sinking device meets processing operation requirements of more products.

Owner:JIANGXI JIUWANG AUTO PARTS MFG CO LTD

Robot intelligent tooling system

InactiveCN105537987ASimple mechanical structureReduce complexityMachine tool componentsPositioning apparatusCurve shapeLocking mechanism

The invention discloses a robot intelligent tooling system characterized in that the whole system comprises base parts, moving beam parts, sliding saddle parts, telescopic units, universal vacuum suction heads, left and right robots, and control computers. Under the control of the computers, the robots realize accurate abut jointing of the moving beam parts through abut jointing mechanism, do synchronous movement together in X direction for adjustment in place, and then realize locking of the moving beam parts to the base parts through locking mechanism; meanwhile, after big arms of robot master manipulators are rotated to horizontal positions, small arms are stretched out sequentially, palm are moved, fingers are stretched out to hold telescopic units fixed on the sliding saddle parts to enable the movement in Y direction to be adjusted in place, then Z direction movement of the telescopic units are adjusted, and finally the universal vacuum suction heads fixed on telescopic columns form curved shapes for supporting thin-walled curved parts. The robot intelligent tooling system is used for processing of different parts, so as to greatly improve the manufacturing flexibility.

Owner:XINGYU YINGHUI BEIJING TECH CO LTD

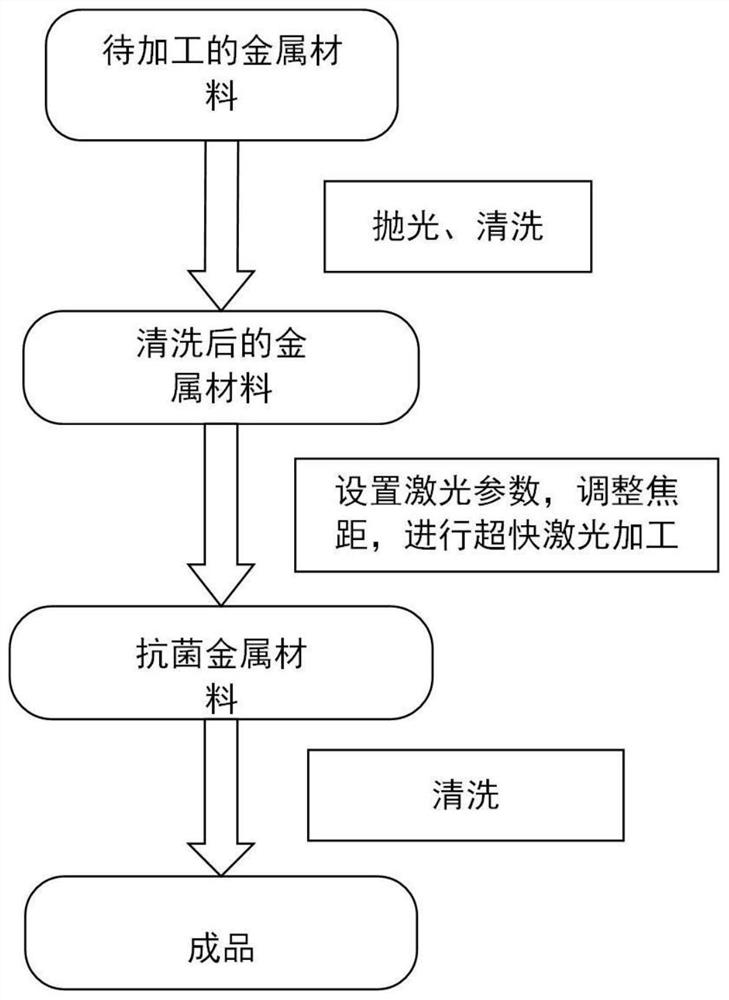

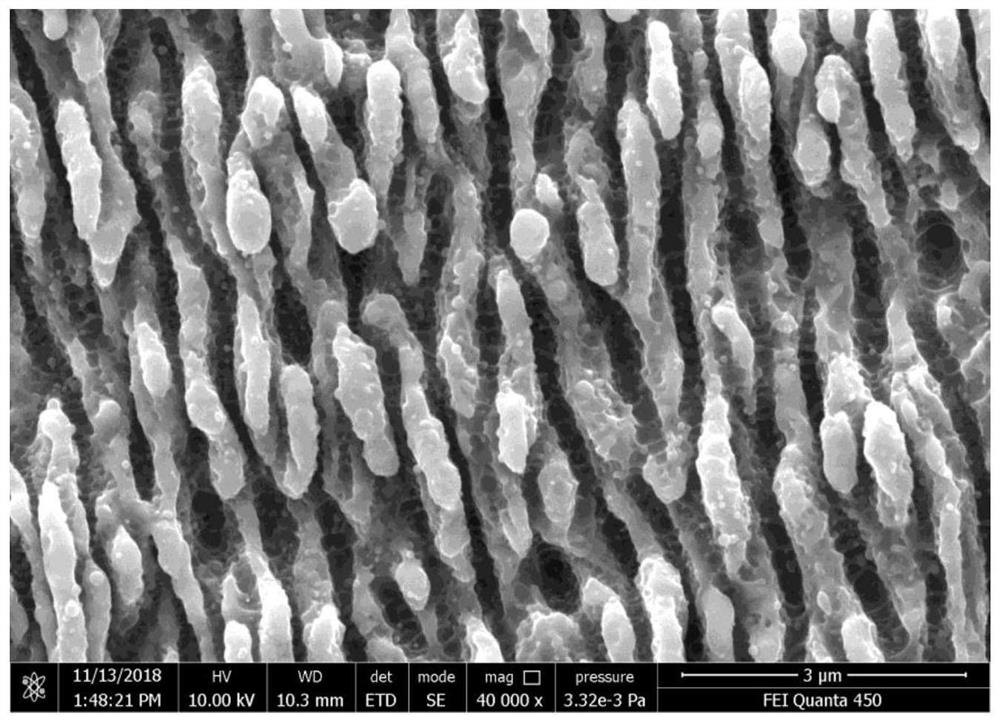

Ultrafast laser preparation method facing bacteriostatic surfaces of public goods

InactiveCN111774731AReduce heat damageSmall heat affected zoneLaser beam welding apparatusPublic placeOptics

The invention discloses an ultrafast laser preparation method facing bacteriostatic surfaces of public goods. A micro-nano structure is prepared on the surface of a cleaned and polished material by using ultrafast laser, so that the functional surface with bacteriostatic performance can be obtained. The method is simple and convenient to operate, high in processing efficiency and wide in application field, the bacteriostatic surfaces prepared by the method are applied to daily articles commonly used in public places, bacterial adhesion on the surfaces of the articles can be obviously reduced,and long-acting bacteriostasis of the daily articles in public places is realized.

Owner:BEIHANG UNIV

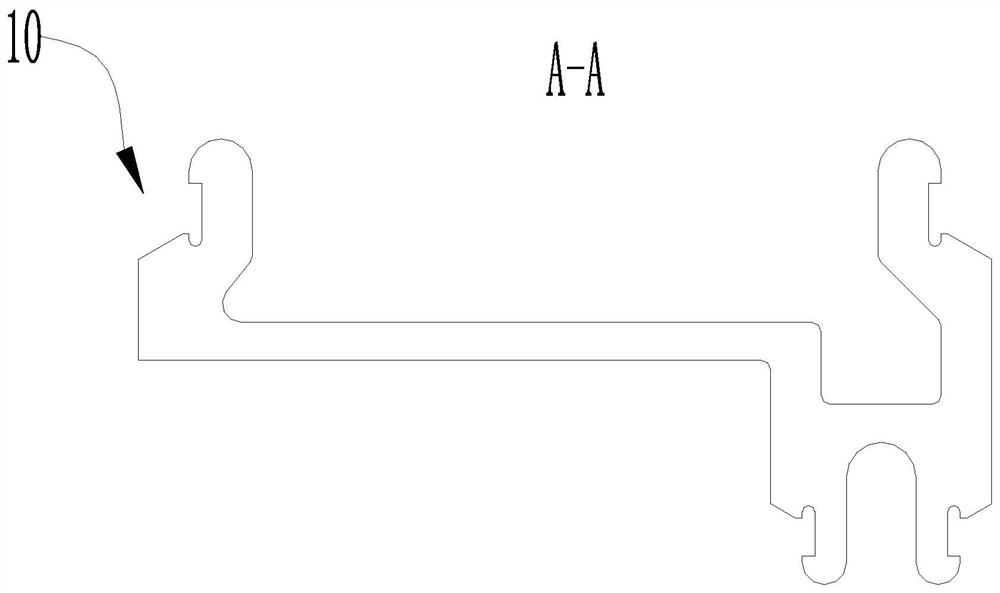

Split type mould structure for bent beam processing

PendingCN111992604AIncrease productivityReduce tire weightShaping toolsVehicle componentsCurved beamStructural engineering

The invention discloses a split type mould structure for bent beam processing. The split type mould structure comprises a front plate, a rear plate group and a stretch-bending mould integrated betweenthe front plate and the rear plate group, wherein the front plate is in fastening connection to the stretch-bending mould through a bolt; the rear plate group is in fastening connection to the stretch-bending mould through the bolt; the rear plate group comprises two rear plates which are symmetrically arranged; a distance between the two rear plates is regulated to adapt to curved beams of different lengths; and the front plate, the rear plate group and the end part of the stretch-bending mould define a section slot. The split type mould structure defines a mould through the front plate, thestretch-bending mould and the rear plate bodies in a sectional mode, and the rear plates and the stretch-bending mould can be designed in a split mode to reduce mould weight to the greatest extent; and moreover, the split type mould structure can be adaptive to extending lengths of different front plate horizontal bodies to adapt to processing requirements of the curved beams of different lengths.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Large high-precision flange machining machine

InactiveCN108972018AReduce weightReduce the difficulty of assemblyLarge fixed membersDriving apparatusEngineeringSlewing bearing

The invention belongs to the field of ship manufacturing, and discloses a large high-precision flange machining machine. The large high-precision flange machining machine comprises a machine base which is arranged in the center of a flange to be machined, a main shaft is arranged inside the machine base, a rotating arm is arranged at the top of the main shaft, a rotary bearing is arranged on the machine base, a driving mechanism which is in transmission connection with the rotary bearing is arranged in the rotating arm, and a cutting mechanism used for machining the flange is arranged at one end of the rotating arm. The large high-precision flange machining machine is high in machining efficiency and good in stability.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com