Multi-tool efficient synchronous dynamic balance turning machine tool and machining method

A machine tool and turning technology, applied in the field of multi-tool high-efficiency synchronous dynamic balancing turning machine tools, can solve the problems of workpiece deformation, insufficient machining accuracy, insufficient machining efficiency, etc., achieve high-efficiency and high-precision machining, and improve versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Such as figure 1 As shown, it includes a bed 1, a guide rail 5, a numerical control scale grating 8, a tailstock 2, an electric spindle system 4, a screw 7, a workbench drive module 6 and a workbench module 3; the tailstock 2 is fixed on The tail of the bed 1, the electric spindle system 4 is fixed on the head of the bed 1 by the screw 17, the guide rail 5 is fixed on both sides of the middle of the bed 1, the numerical control scale grating 8 is fixed on one side of the middle of the bed 1, and the workbench drive module 6 is fixed on the center of the middle part of the bed 1, and the workbench module 3 is fixed on the workbench drive module 6;

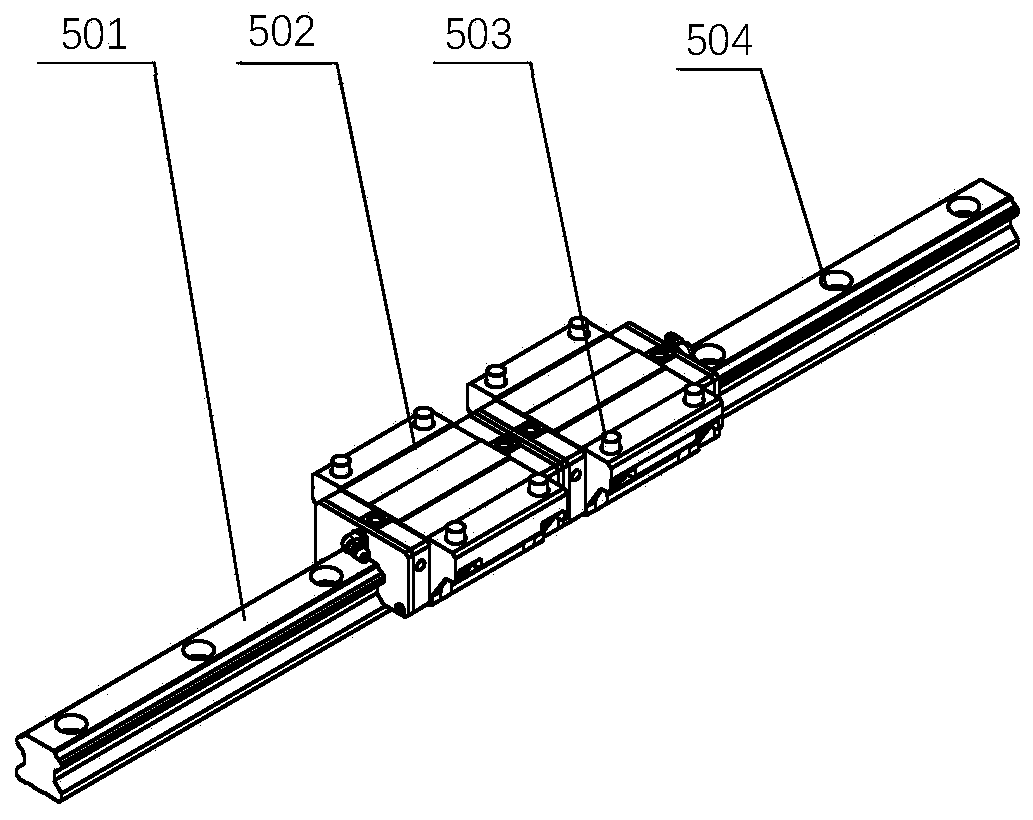

[0041] Such as figure 2 As shown, the guide rail 5 includes a rolling guide rail 501, a slider 502, a screw three 503 and a screw four 504, the rolling guide rail 501 is fixed on the bed 1 by the screw four 504, and the slider 502 is slidingly connected with the rolling guide rail 501; Therefore, the slider 502 can slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com