Large-sized inner gear ring machining device

A processing device and the technology of the inner ring gear, which is applied in the field of gear milling devices, can solve the problems of high cost and power that cannot meet the processing requirements of the inner ring gear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

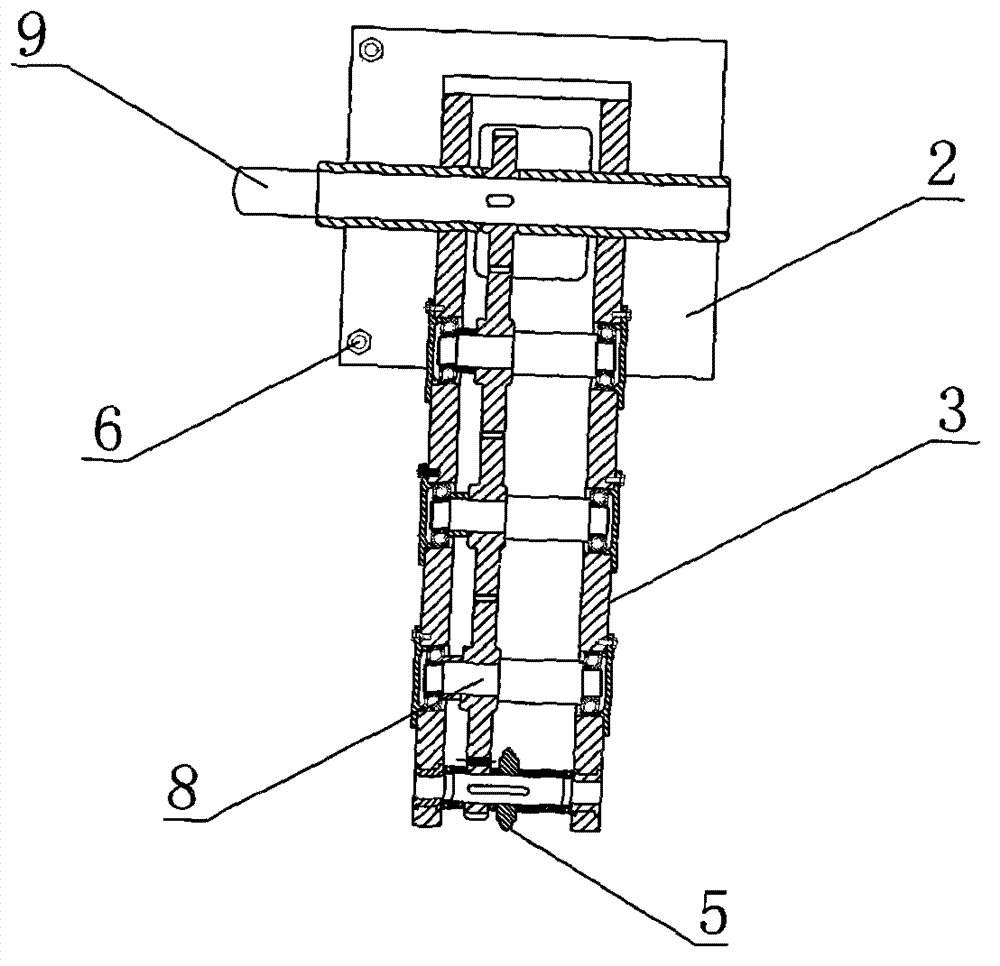

[0012] The large-scale inner ring gear processing device of the present invention includes a connecting part 2 that can be connected with the tool rest 1 of the ordinary gear hobbing machine, a curved casing 3 that matches the shape of the inner ring gear, and a power transmission mechanism 4 that can transmit the mechanical power of the ordinary gear hobbing machine. The milling cutter 5 connected to the power transmission mechanism 4, the connection part 2 includes the bolt 6 and the positioning key 7 that match the tool holder 1 of the original ordinary gear hobbing machine, and the transmission mechanism is a group of two ends that are respectively connected to the tool holder 1 of the original ordinary gear hobbing machine. The gear set 8 matching the output end of the milling cutter 5 and the input end of the milling cutter 5.

[0013] When working, it is connected to the tool holder 1 of the ordinary gear hobbing machine through the connecting part 2, tightened with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com