Phosphor A containing novolac epoxy and method for producing the same

A technology of phenolic epoxy resin and phenolic resin, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor heat resistance and poor flame retardancy, and achieve excellent flame retardancy, small environmental impact, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 228g of bisphenol A, 81g of 37% formaldehyde aqueous solution and 250ml of n-butanol as a reaction medium to a reaction flask equipped with a thermometer, agitator, temperature controller and condenser tube, heat to 90°C, and add 6.3g of acidic catalyst oxalic acid , reflux reaction for 8 hours. After the reaction is completed, pressurize to remove n-butanol and water, then neutralize the above reaction mixture with 5% aqueous sodium hydroxide solution, wash with distilled water until neutral, and remove water under reduced pressure to obtain bisphenol A phenolic resin.

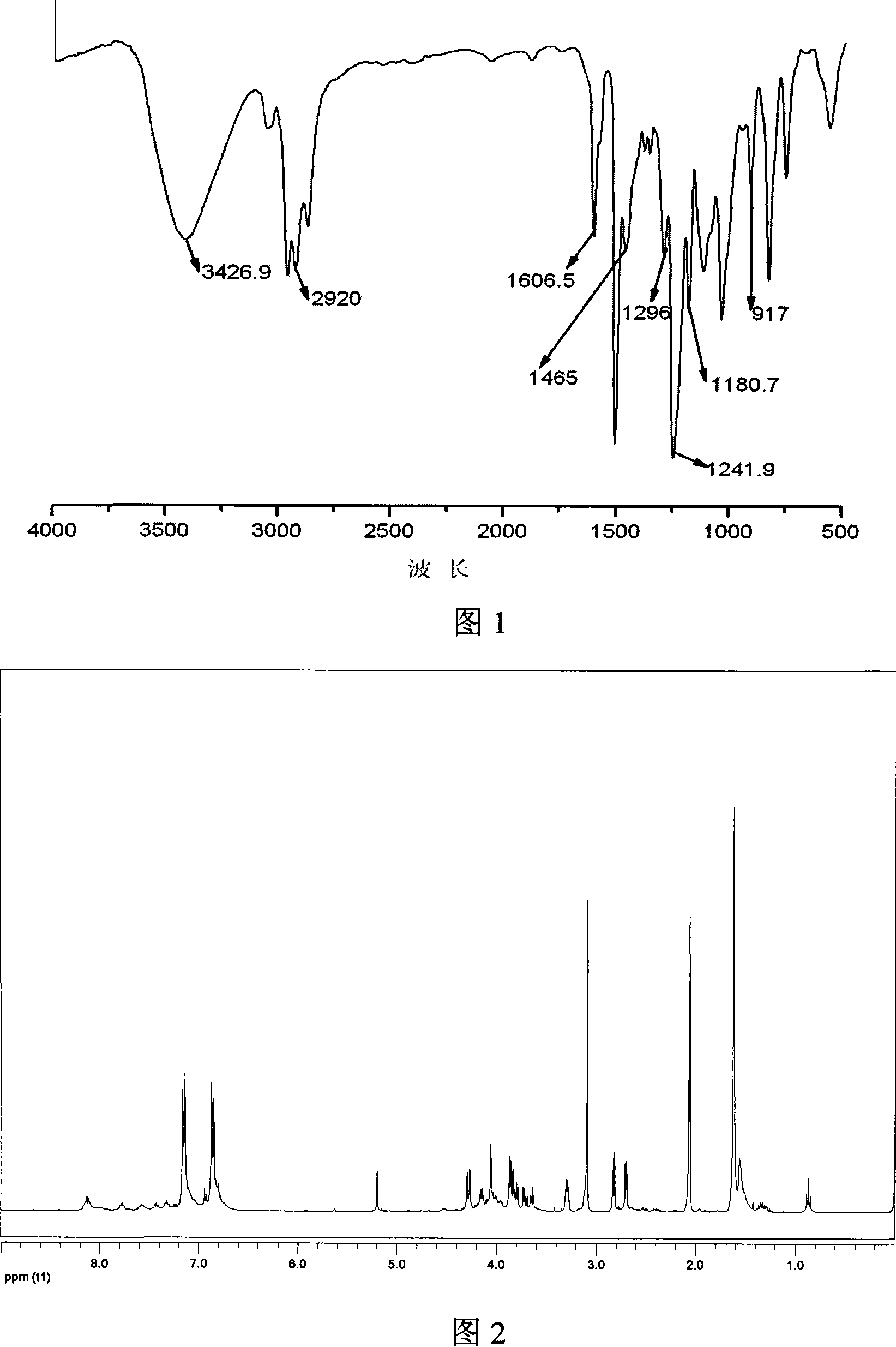

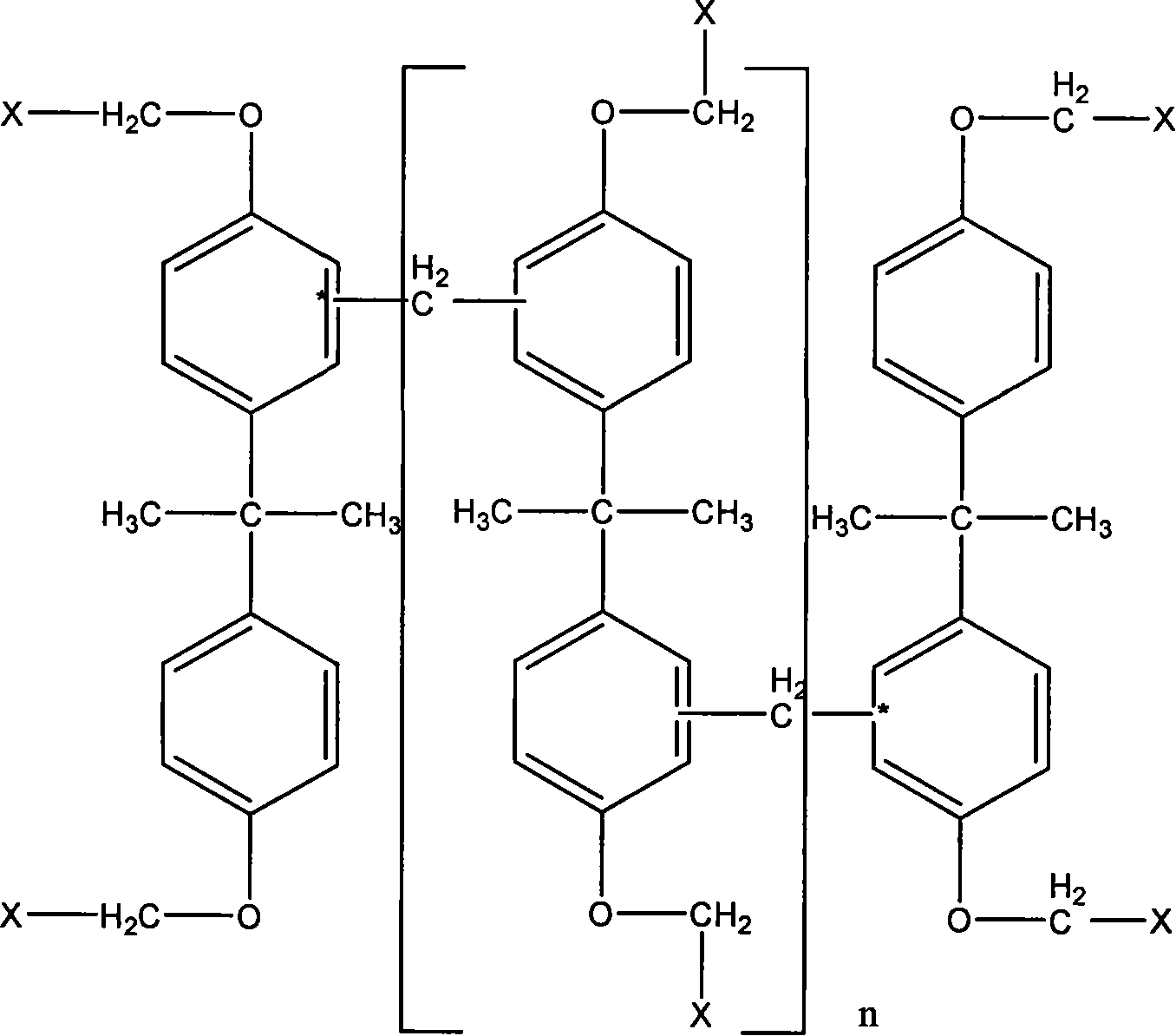

[0028] In another reaction flask equipped with a thermometer, a stirrer, and a condenser tube, add 30g of the bisphenol A type phenolic resin obtained by the above reaction and 90g of epichlorohydrin, and after dissolving, add 0.5g of the phase transfer catalyst hexadecyltri Methyl ammonium bromide, reacted at 95°C for 3 hours, cooled to 50°C, then added dropwise 24g10% alkaline catalyst sodium hyd...

Embodiment 2

[0031] Add 228g of bisphenol A, 81g of 37% formaldehyde aqueous solution and 250ml of n-butanol as a reaction medium to a reaction flask equipped with a thermometer, agitator, temperature controller and condenser, heat to 100°C, and add 6.3g of acid catalyst oxalic acid , reflux reaction for 6 hours. After the reaction is completed, pressurize to remove n-butanol and water, then neutralize the above reaction mixture with 5% aqueous sodium hydroxide solution, wash with distilled water until neutral, and remove water under reduced pressure to obtain bisphenol A phenolic resin.

[0032]In another reaction flask equipped with a thermometer, a stirrer, and a condenser tube, add 30g of the bisphenol A type phenolic resin obtained by the above reaction and 120g of epichlorohydrin, and after dissolving, add 0.6g of the phase transfer catalyst hexadecyltri Methyl ammonium bromide, react at 100°C for 3 hours, cool down to 55°C, then dropwise add 30g of 10% aqueous sodium hydroxide solut...

Embodiment 3

[0035] Add 228g of bisphenol A, 90g of 37% formaldehyde aqueous solution and 250ml of n-butanol as a reaction medium to a reaction flask equipped with a thermometer, agitator, temperature controller and condenser tube, heat to 90°C, and add 8g of acid catalyst citric acid . The reaction was refluxed for 6 hours. After the reaction is completed, pressurize to remove n-butanol and water, then neutralize the above reaction mixture with 5% aqueous sodium hydroxide solution, wash with distilled water until neutral, and remove water under reduced pressure to obtain bisphenol A phenolic resin.

[0036] In another reaction flask equipped with a thermometer, a stirrer, and a condenser tube, add 30g of the bisphenol A type phenolic resin obtained by the above reaction and 140g of epichlorohydrin, and after dissolving, add 0.7g of the phase transfer catalyst hexadecyltri Methyl ammonium bromide, react at 100°C for 3 hours, cool down to 65°C, add dropwise 30g of 10% sodium hydroxide aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com