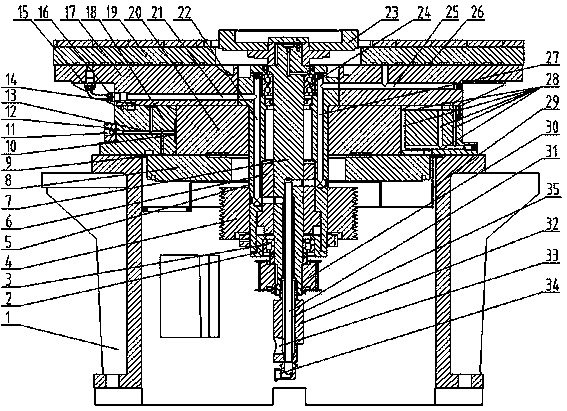

Lower disc device for two-sided precision grinding and polishing combined machine tool

A technology of precision grinding and combined machine tools, which is applied to machine tools suitable for grinding workpiece planes, parts of grinding machine tools, and grinding devices, etc. It can solve the problem of low polishing pressure, inability to cool the disc surface, and inability to adapt to hard and brittle materials such as sapphire. Processing and other issues to achieve the effect of improving the shock absorption capacity of the equipment and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] see figure 1 , the lower plate device used for double-sided precision grinding and grinding combination machine tools, including chassis support 1, an upper static pressure plate 18 arranged on the chassis support 1, a lower static pressure plate 8 located at the bottom of the upper static pressure plate 18, The central shaft 7 located in the middle of the upper static pressure plate 18 and the lower static pressure plate 8, and the hollow shaft 5 movably sleeved on the central shaft 7; the top of the central shaft 7 is equipped with a sun gear 23; A central rotating disk 20 that is slidably engaged with the inner peripheral surface of the upper static pressure plate 18 and that is slidably engaged with the upper surface of the lower static pressure plate 8 and a lower tray 17 fixed on the central rotating disk 20 are fixed, and a lower plate is installed on the lower tray 17. The grinding wheel 19 and the lower tray 17 are slidingly fitted with the upper surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com