Heavy rim rounder

A technology of rounding machine and rim, which is applied in the field of heavy-duty rounding machine, which can solve the problems that the roundness accuracy of the pipe body is difficult to meet the welding requirements of round parts at both ends, the processing requirements of heavy-duty rims, and the limitation of stretching force. To achieve the effect of compact structure, short action stroke and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

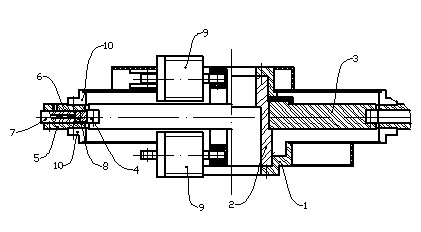

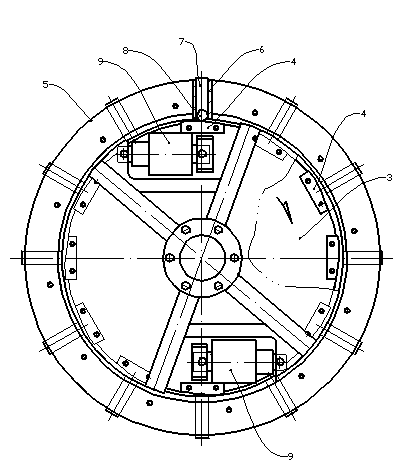

[0011] As shown in the figure, the heavy-duty rim supporter includes a central shaft 2 mounted on a fixed seat 1 and a circular anti-compression ring 3 that can rotate around the central shaft. The outer circumference of the anti-compression ring is evenly distributed with a cam block 4; on the periphery of the compression ring 3, there is an annular ejector plate 5 coaxial with the anti-pressure ring and fixedly connected with the holder 1, and the ejector plate 5 is evenly arranged along the circumference with each cam block 4 The radially penetrating guide hole 6 is located in the opposite position, and the ejector rod 7 that can expand and contract radially along the guide hole is arranged in the guide hole 6; On the cam surface of the cam surface, when the anti-pressure ring 3 rotates, the movement of the cam surface can push the push rod 7 outward; several synchronous oil cylinders 9 capable of driving the anti-pressure ring to rotate are installed on the fixed base 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com