Portable reverse cooling and dedusting integrated device

A portable coolant technology, applied in maintenance and safety accessories, drilling/drilling equipment, boring machine/drilling machine components, etc., can solve problems such as non-existence, slow production cycle, thermal damage, etc., to reduce irreversible damage , achieve the effect of angle and length, reduce tremor and eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

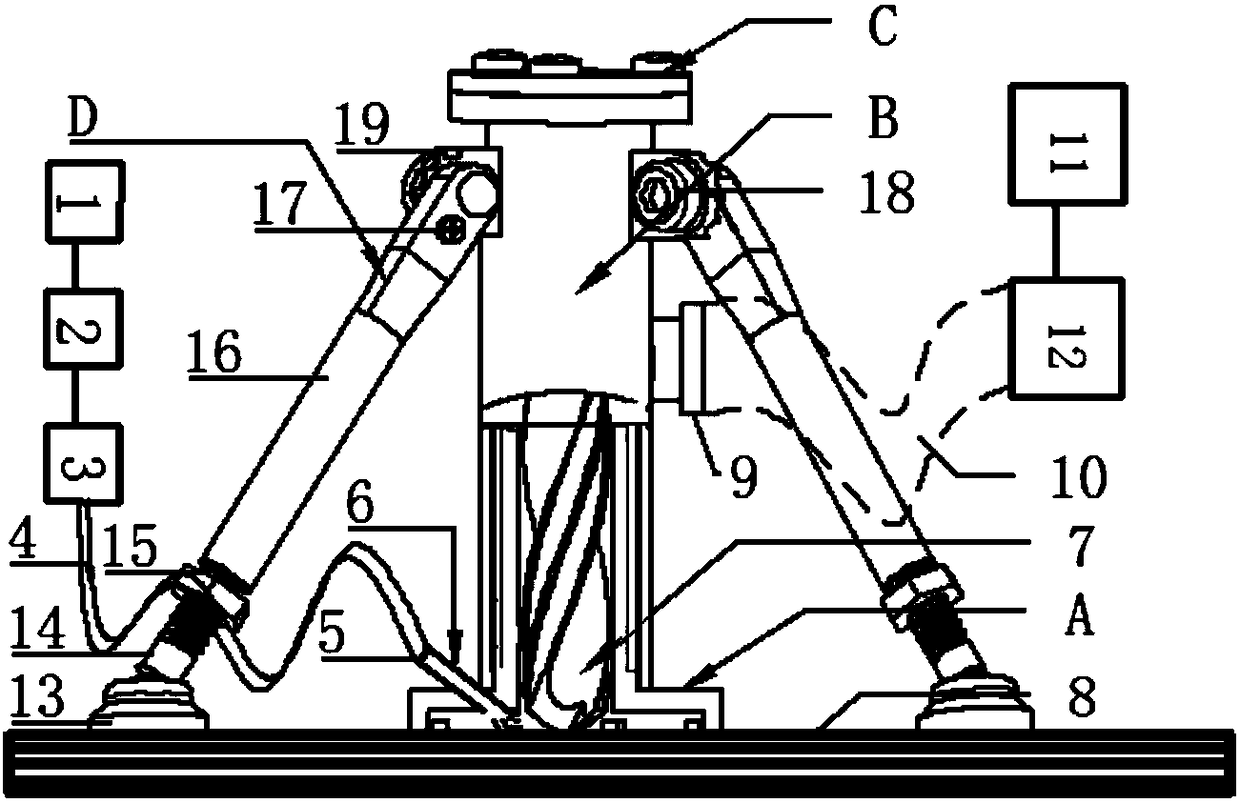

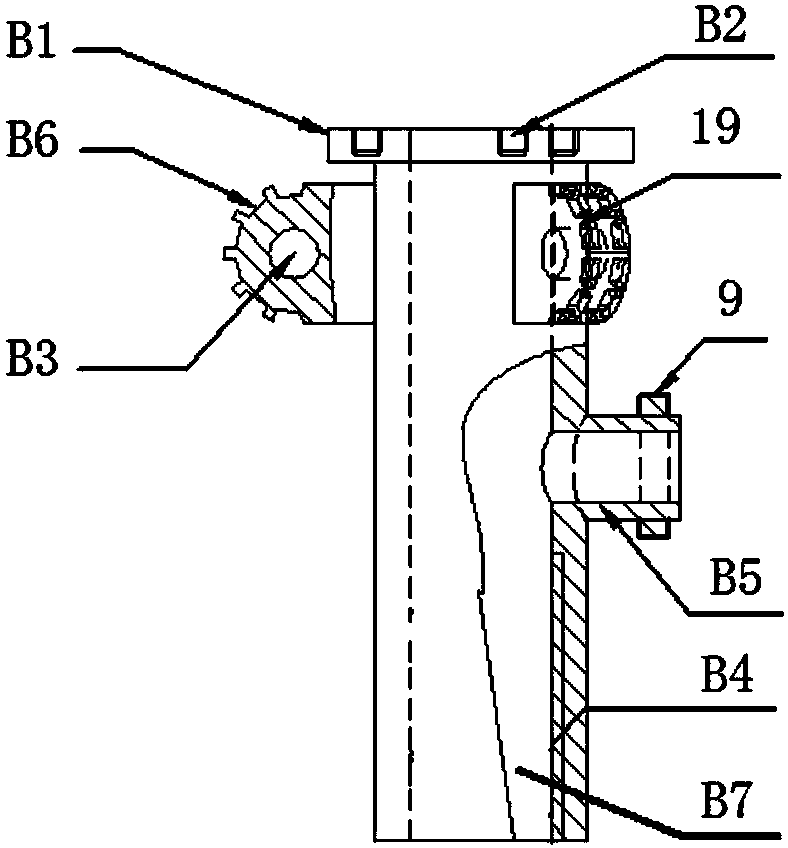

[0015] Such as figure 1 A portable reverse cooling and dust removal integrated device is shown, which is composed of six parts: threaded drill sleeve A, device main body B, sealing cover C, multi-directional support and fixing structure D, negative pressure dust processing parts and cooling liquid injection parts ; Complete the assembly of each part and the portable movement of the device through the main body B of the device.

[0016] During processing, the cutter 7 passes through the device main body B, the sealing cover C and the threaded drill sleeve A from the central axis of the device to process the material, and the threaded drill sleeve A and the cutter 7 are matched with the base shaft to position and guide the cutter for processing. Use the threaded drill sleeve A to reduce the vibration and eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com