One-step bundling shaping method of culvert pipe multi-layer reinforcement cage and bundling shaping device

A molding device and molding method technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of difficult to meet the requirements of specifications, difficult binding work, slow binding speed, etc., saving labor, large size range, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

[0010] The one-time bundling and forming method of the culvert tube multi-layer steel cage is to use a bundling and molding device, adjust the diameter of the bundling and molding device, and bundle layer by layer from the outside to the inside.

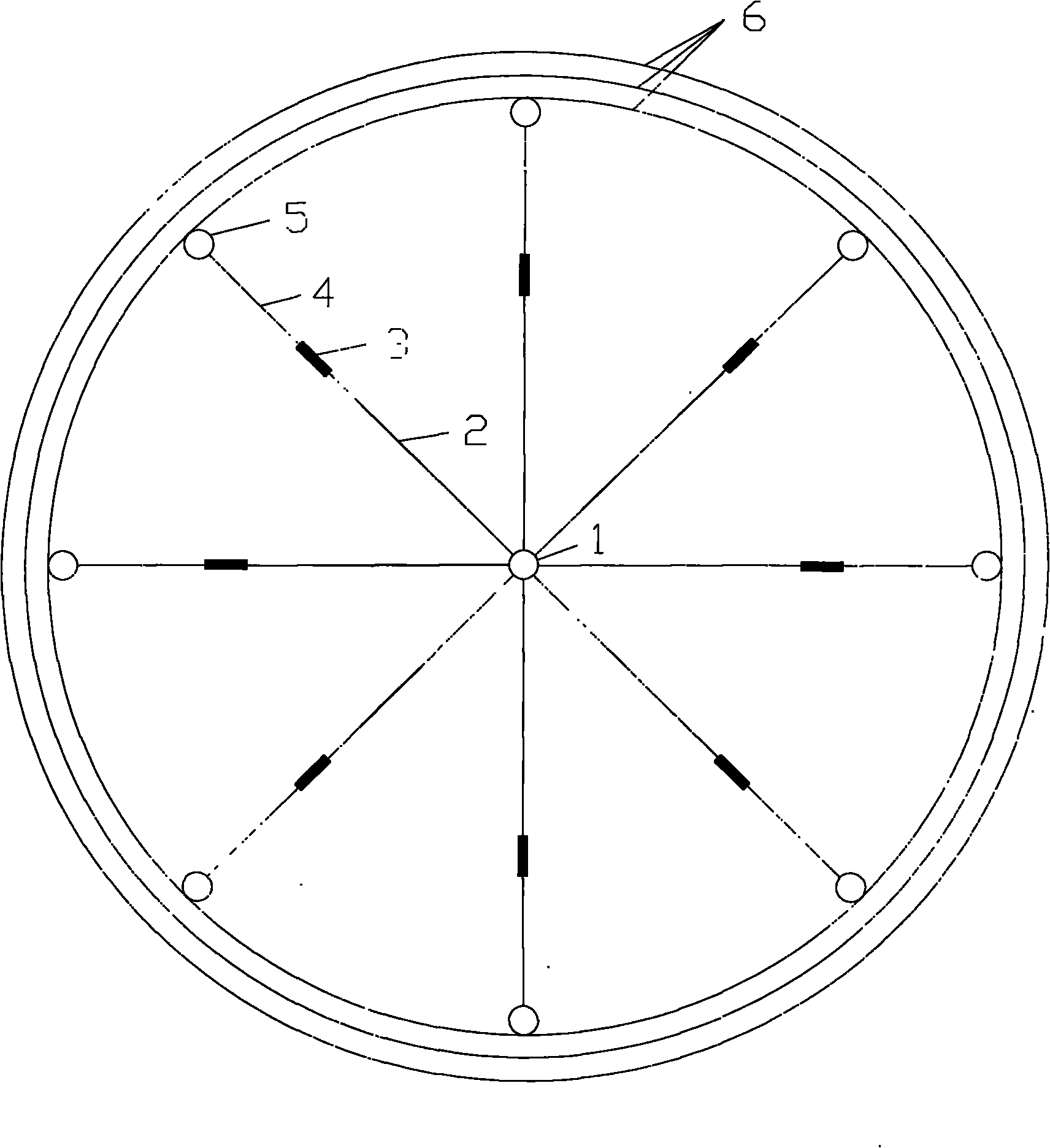

[0011] Referring to the accompanying drawings, the binding forming device of the present invention includes a radial adjustment mechanism, a central rod 1 and an axial strut 5, the central rod 1 is sheathed in the radial adjustment mechanism, and both ends are supported by brackets; the axial strut 5 and the The radial adjustment mechanism is fixed together. The radial adjustment mechanism includes a bearing, a radial fixed section 2, an adjustment mechanism 3 and a radial adjustment rod 4. A shaft sleeve is installed outside the bearing, and the radial fixed section 2 is fixed on the outer circumference of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com