Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

309results about How to "Not easy to save" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for preparing phosphorus pentafluoride gas and preparing lithium hexafluorophosphate using the gas

ActiveCN101353161AEasily hydrolyzedStrong moisture absorptionPhosphorus halides/oxyhalidesLithiumPhysical chemistry

A preparation method of phosphorus pentafluoride gas comprises a step of causing phosphorus pentachloride to react with anhydrous hydrogen fluoride, wherein, the reaction occurs in the presence of a solvent. A preparation method of lithium hexaflourophosphate comprises a contact reaction between solid lithium fluoride and phosphorus pentafluoride gas, wherein the phosphorus pentafluoride gas is prepared by the method of the invention. Compared with the preparation method of the lithium hexaflourophosphate with the phosphorus pentafluoride gas as the raw material in the prior art, the phosphorus pentafluoride gas prepared by the preparation method of the invention has higher purity and lower cost. The yield of the lithium hexaflourophosphate prepared by the method of the invention is higher than 93%, and the purity thereof is up to 99.95%.

Owner:BYD CO LTD

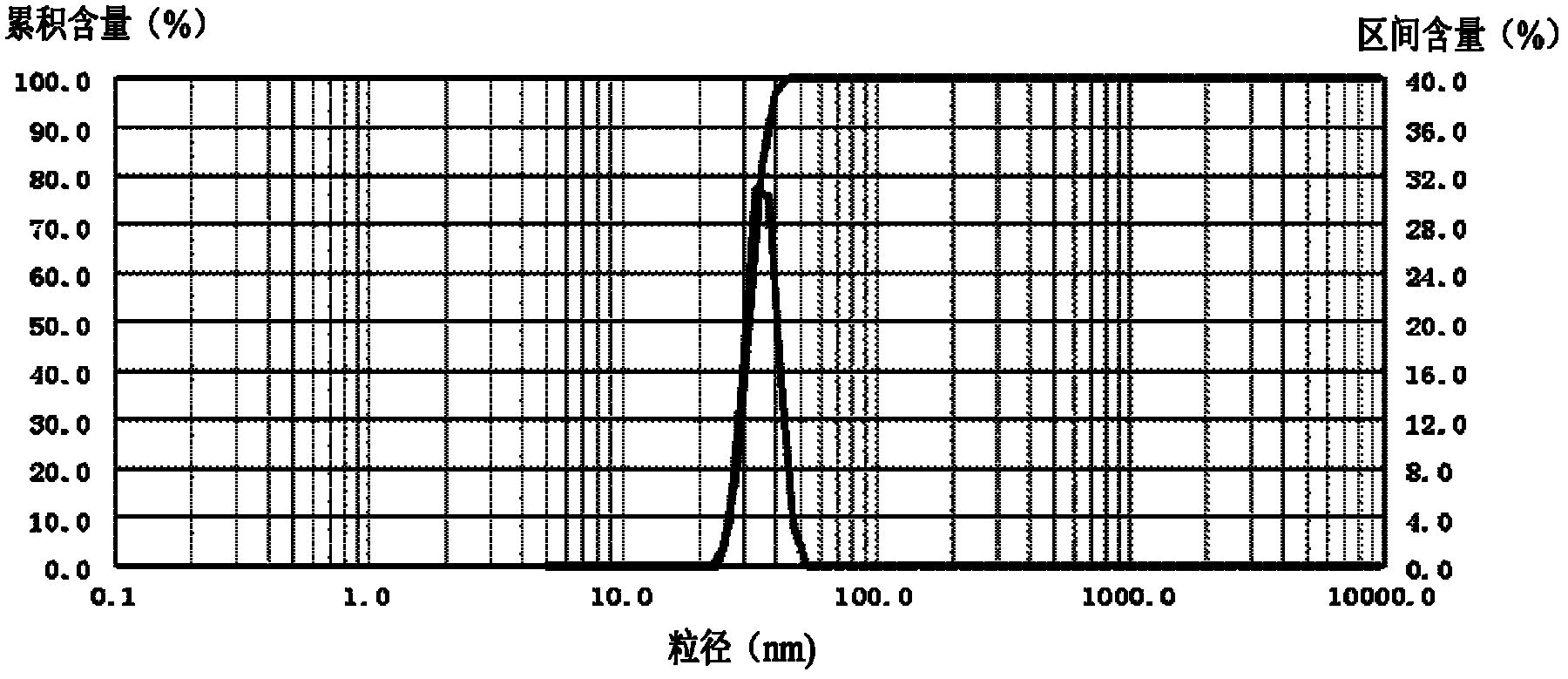

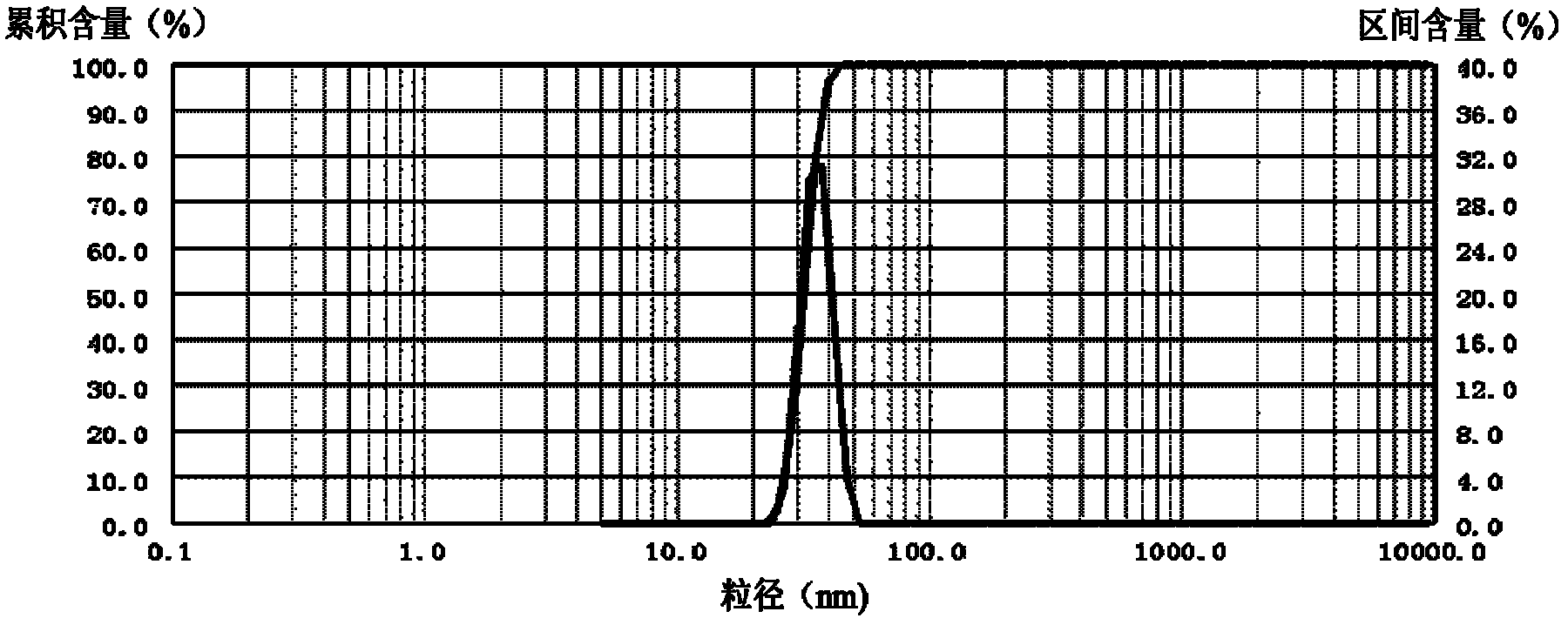

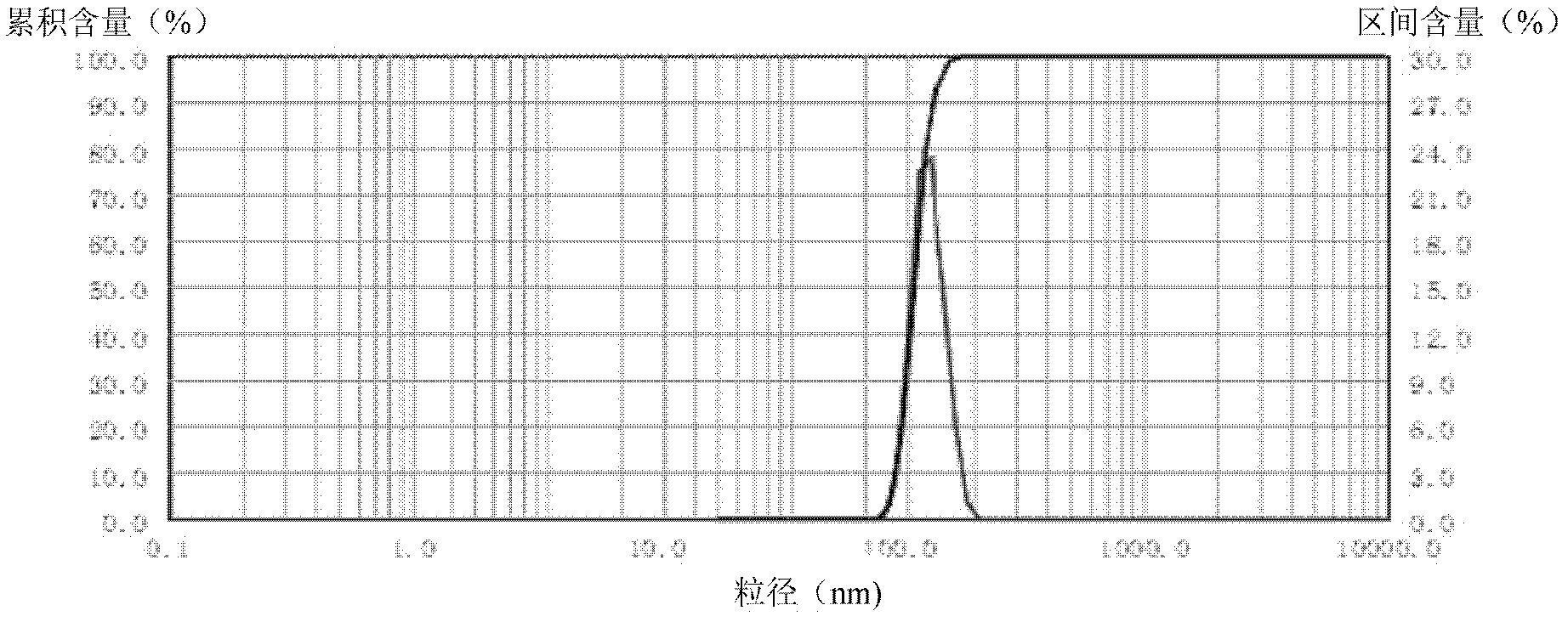

Preparation method of nanometer silver particles

The invention provides a preparation method of nanometer silver particles. The preparation method comprises the following steps of: (a) adding a silver source, a coating agent and ammonia water into water under the conditions of stirring and heating to obtain a reaction solution with the pH value being 7-12, wherein the molar ratio of the silver source to the coating agent is 1:(1-5); (b) adding crown ether into the reaction solution under a stirring state, wherein the molar ratio of the crown ether to the silver source is (1-3):1; and (c) adding a reducing agent containing alkali metal into a mixture solution obtained in (b) under a stirring state to obtain nanometer silver particles, wherein the molar ratio of the reducing agent to the silver source is (1-3):1. According to the invention, the crown ether is added into the reaction system in a reaction process, meanwhile, the reducing agent containing the alkali metal is used in a matching manner. The crown ether is added to facilitate distantiation between positive charges and negative charges in a nano-silver system, so that nano-silver can stably disperse in a water solution without agglomeration.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Method for preparing rice bran oil from rice bran

InactiveCN1935963AImprove stabilityReduced activityFatty-oils/fats productionRice Bran ExtractRice bran oil

The invention relates to rice bran oil preparing method. It includes the following steps: processing the rice bran by micro wave with 800W power, 60s, 60mm height of layer, 7.4% humidity after processing; using supercritical carbon dioxide to extract rice bran oil at 25-60 degree centigrade, 10MPa-40MPa pressure, 15L / h-90L / h rate of CO2 flow for 30-150min. The prepared rice bran oil will not be rancidity and resolved by lipase to increase its stability. The product is easy to store. The rice bran oil yield is 20-22%.

Owner:南京远望富硒农产品有限责任公司 +1

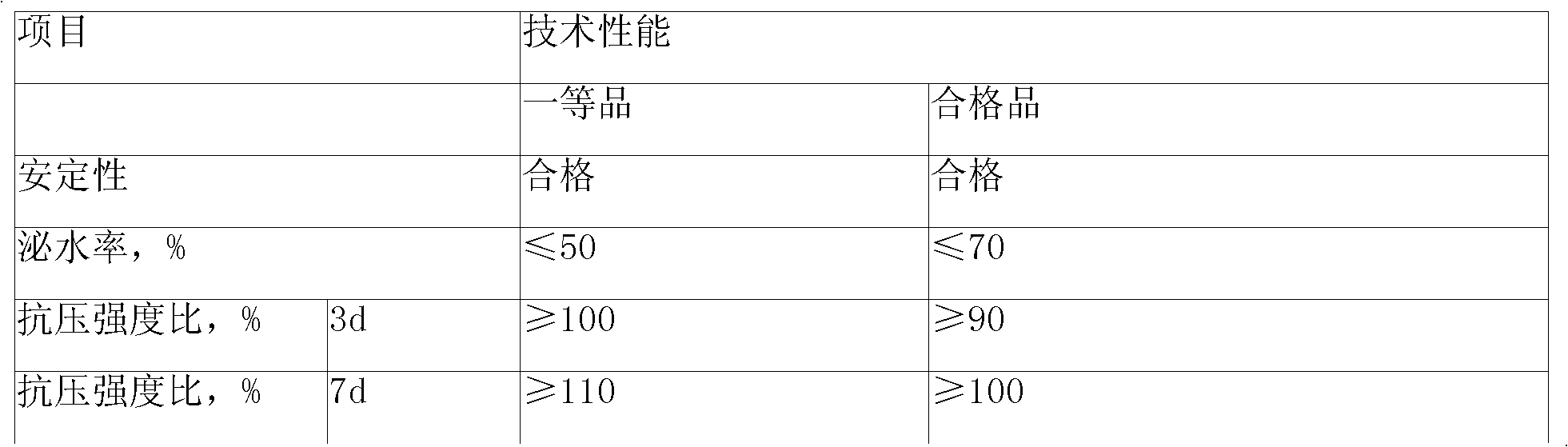

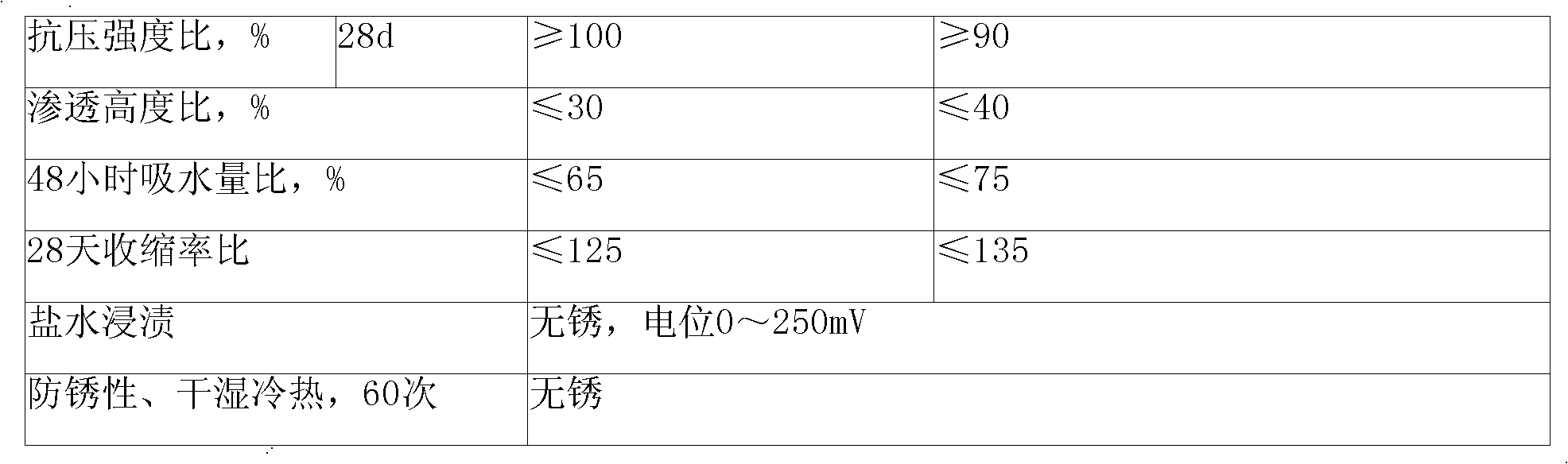

Water-proof corrosion inhibitor and preparation method thereof

The present invention discloses a water-proof rust-resistant agent with the ingredients by the following weight percent: 10 to 20 percent of modified organosilicone, 10 to 30 percent of alkamine, and 60 to 70 percent of water. The modified organosilicone is alkyl alkaoxy silane with the chemical formula of R'Si(OR3)3, wherein, R' and R represent the alkyl. The present invention is free from negative influence on the condensation time and the strength of the concrete, and has the advantages of low consumption volume and high rust-resistant performance. The present invention has remarkable functions on the self water prevention of the concrete structure and the rusty corrosion of the steel bar, and also has the functions such as water reduction, air introduction, plasticity preservation and corrosion prevention, thereby can be used as the additive for the concrete pumping agent, the water-proof agent and the rust-resistant agent.

Owner:北京东方建宇混凝土科学技术研究院有限公司 +1

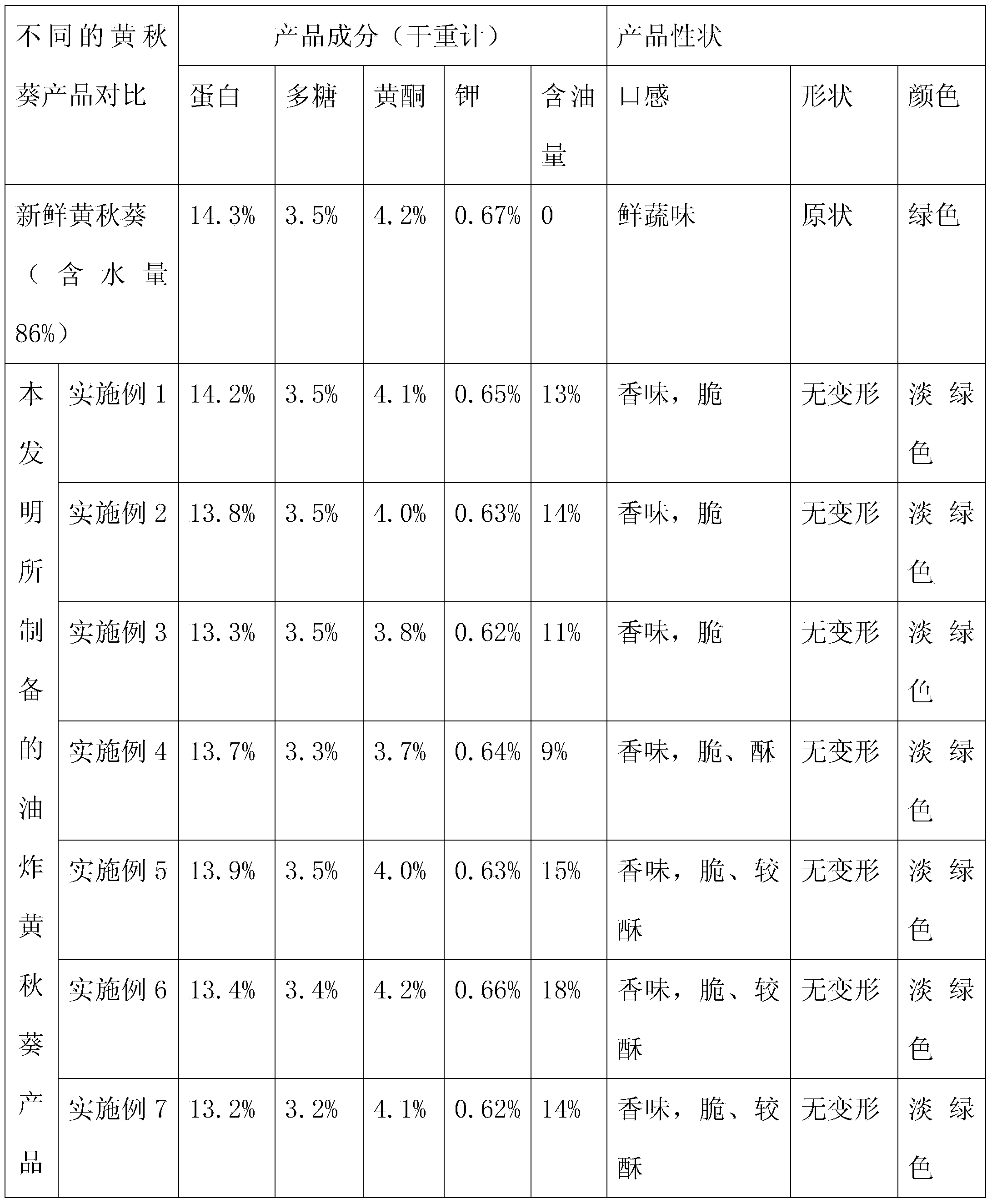

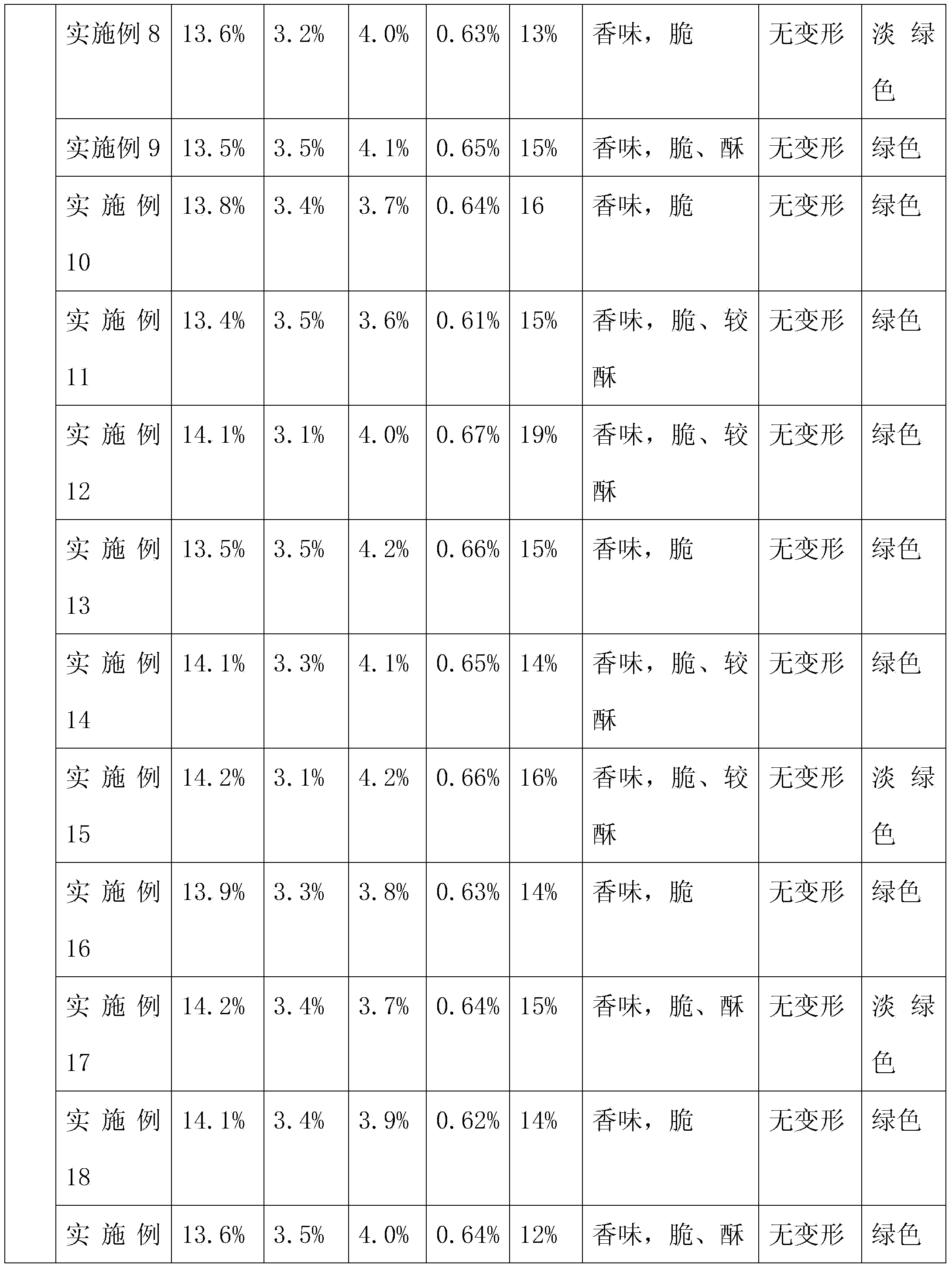

Production process for frying abelmoschus esculentus with different tastes at low temperature in vacuum

ActiveCN103919074ANotable featuresSignificant positive effectFood freezingFood thermal treatmentDiabetes mellitusAdditive ingredient

The invention discloses a production process for frying abelmoschus esculentus with different tastes at low temperature in vacuum. The production process comprises the following steps: blanching washed abelmoschus esculentus in hot water; cooling and putting the abelmoschus esculentus into an instant freezer to be instantly frozen; putting the frozen abelmoschus esculentus into a seasoning solution to be immersed in vacuum; leaching and putting the abelmoschus esculentus into the instant freezer to be instantly frozen; carrying out vacuum low-temperature frying on the frozen abelmoschus esculentus; centrifuging and removing oil to obtain a product. The instant abelmoschus esculentus food prepared by the invention keeps the color, aroma, taste and nutritional components of the abelmoschus esculentus; meanwhile, the fried abelmoschus esculentus with different tastes are prepared and are suitable for different crowds including children, youngsters, middle-aged and aged people, diabetes mellitus patients and the like.

Owner:LAIYANG HENGRUN FOODSTUFF

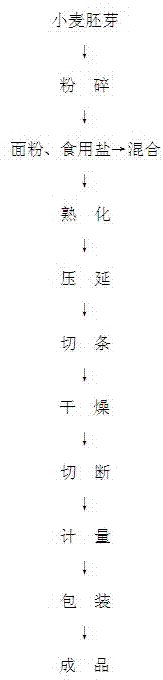

Wheat germ alimentary noodles and manufacturing method thereof

The invention discloses wheat germ alimentary noodles and a manufacturing method thereof. The wheat germ alimentary noodles comprise, by weight, 5 to 10 parts of wheat germ powder, 86 to 94 parts of flour and 1 to 4 parts of table salt. The manufacturing method comprises the following steps of processing wheat germs into wheat germ powder, mixing the wheat germ powder and the above raw materials, and carrying out aging, rolling, strip cutting, drying, cutting, metering and packaging of the mixture to obtain the wheat germ alimentary noodles. Through low-temperature drying, biological activity is kept. Through an air-flow crushing process, biological cell integrity is kept; a nutrient loss is avoided; a smooth taste is obtained; a quality guarantee period is prolonged; and the problem that based on the prior art, wheat germs have a short quality guarantee period and a poor taste is solved. The wheat germ alimentary noodles have an original flavor of wheat germ powder, retain nutrients, have a good taste, are extended products of agricultural fine-processing products, are convenient for taking, have a very nutritive value and can be accepted by people easily. A small amount of the wheat germ alimentary noodles can supply a large amount of nutrients to people.

Owner:HUBEI SANJIE AGRI INDZATION

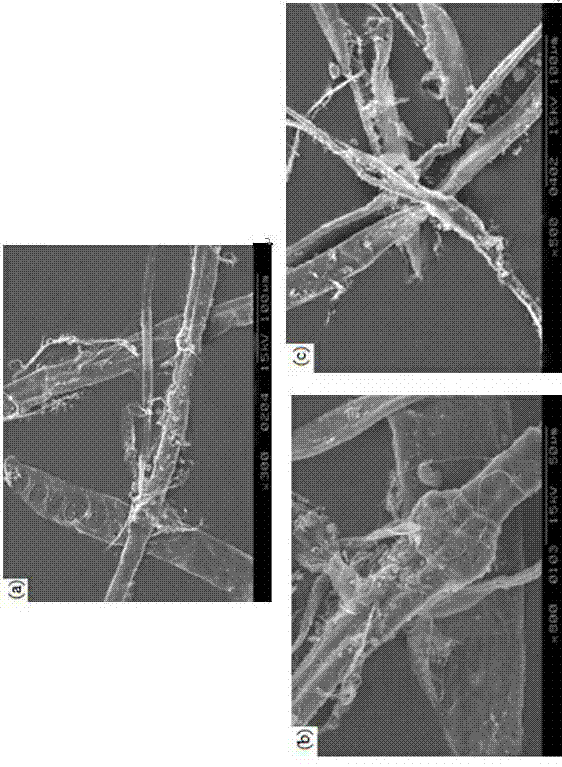

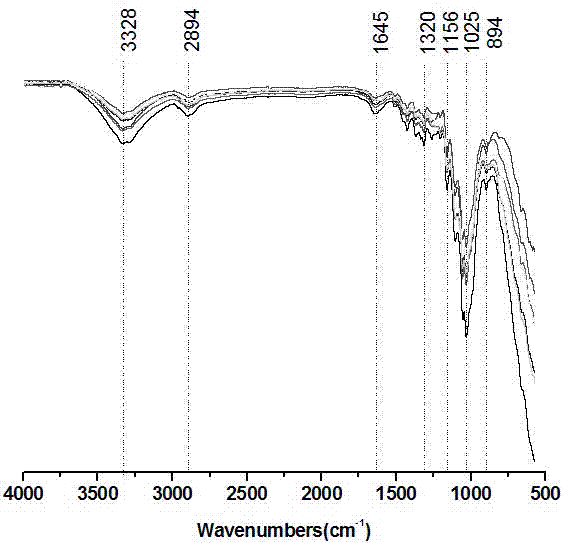

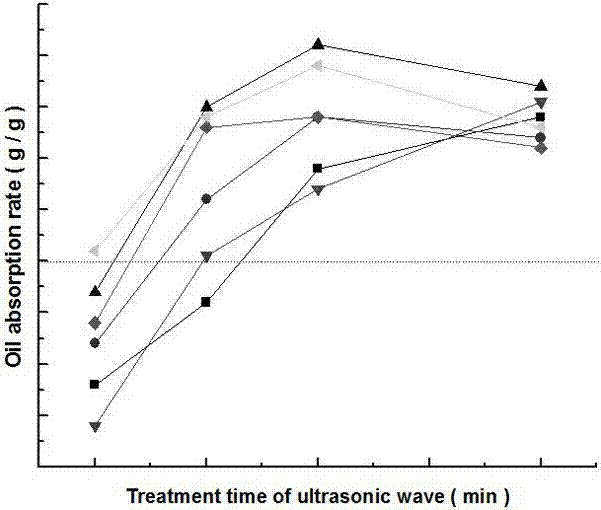

Regenerated cellulose fiber and preparation method thereof

InactiveCN103755190AAvoid complex processesReduce manufacturing costSolid waste managementCardboardHigh energy

The invention discloses a regenerated cellulose fiber and a preparation method thereof. The regenerated cellulose fiber takes waste newspaper with ink, office paper, kraft paper or cardboard paper and the like as raw materials, after ultrasonic treatment, the raw materials are mixed with filler, a surfactant, a waterproof agent and special coating according to a certain proportion so as to prepare the regenerated cellulose fiber. The preparation method comprises the following steps of defibering the raw material waste paper by a high energy aquapulper and then screening to remove dregs, after ultrasonic treatment on the purified sizing agent, mixing with mixed filler uniformly, slowly stoving at above 60 DEG C so as to obtain oven dry stock, ball milling and dispersing the oven dry stock so as to obtain villiform monofilament fiber, adding nano TiO2 coating through a dry method in the process so as to obtain the regenerated cellulose fiber product.

Owner:TONGJI UNIV

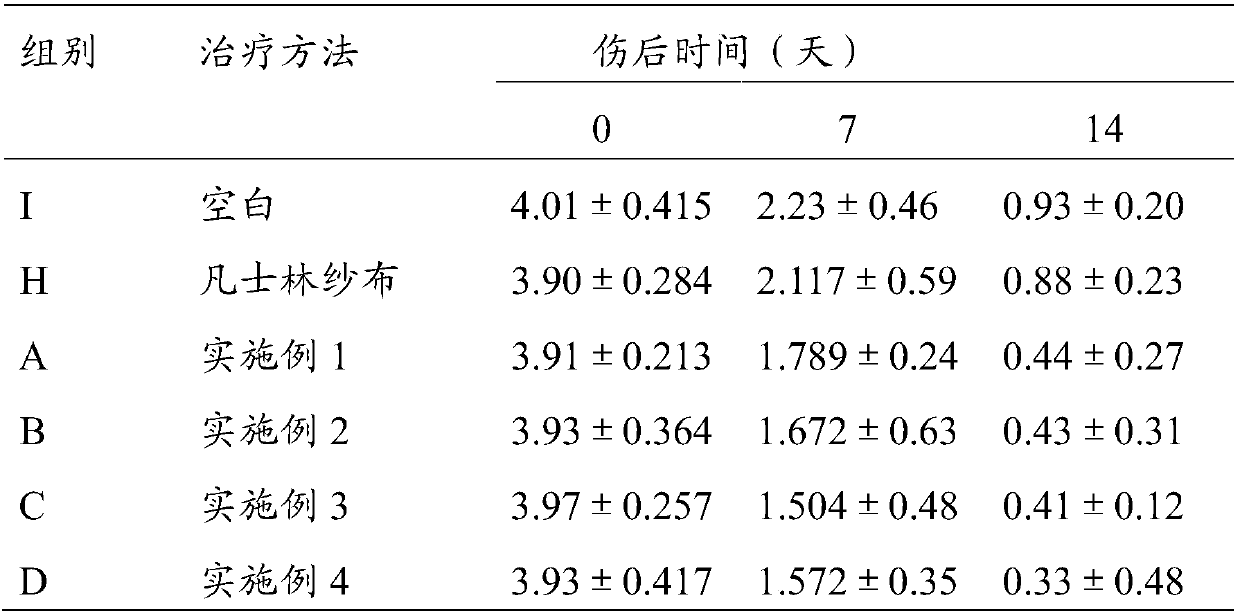

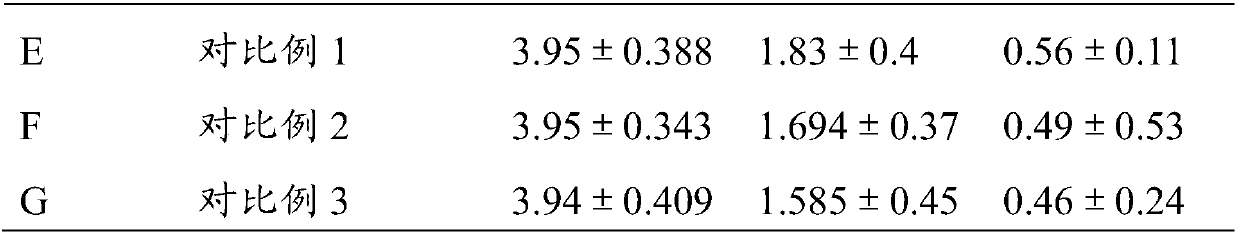

Hydrocolloid oil yarn and preparation method thereof

ActiveCN108126232AGood air permeabilityGood compatibilityAbsorbent padsBandagesParaffin waxSodium carboxymethylcellulose

The invention relates to a hydrocolloid oil yarn. The hydrocolloid oil yarn comprises a base material and a hydrocolloid ingredient, wherein the base material is netty polyester fiber; the hydrocolloid ingredient comprises the following raw materials in parts by weight: 8 to 10 parts of thermoplastic elastomers, 16 to 30 parts of sodium carboxymethylcellulose, 1 to 5 parts of growth factor microspheres, 1 to 5 parts of chitosan, 100 to 200 parts of liquid paraffin, 30 to 40 parts of Vaseline and 5 to 10 parts of wool fat. The content of grown factors inside the grown factor microspheres is 0.01wt% to 0.03wt%.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

Method of protecting archives with red-ink handwriting from spreading and sinking in during process of papering and repairing

ActiveCN102166916AWater permeableGood water permeabilityPaper/cardboardPaperhangingHandwritingPhosphoric acid

Provided is a method of protecting archives with red-ink handwriting from spreading and sinking in during process of papering and repairing. The method comprises the steps of uniformly mixing, by mass, 1 part of phospho-tungstic acid, 2.3 to 3.9 parts of phosphoric acid, 48.8 to 52.0 parts of acetone and 2.8 to 9.2 parts of tetraeththyl orthosiliate to prepare a first reinforcing agent and coating the agent on red-ink handwritings; preparing a second reinforcing agent with 1 part by mass of ethyl cellulose, 6.25 parts by mass of barium hydroxide and 40 parts by mass of methanol and coating the agent on the red-ink handwritings coated with the first reinforcing agent; and preparing a third reinforcing agent with, by mass, 1 part of ethyl cellulose banana oil solution and 0.03 to 0.17 part of polymethylmethacrylate banana oil solution, wherein mass percentage of the ethyl cellulose banana oil solution is 4% and mass percentage of the polymethylmethacrylate banana oil solution is 4%, and coating the third reinforcing agent on the red-ink handwritings coated with the second reinforcing agent. The method of protecting the red-ink handwritings enables improvement in tensile strength, folding strength and tearability of testing paper after dry heating aging, hydrothermal aging and ultraviolet aging tests. After the aging process, the handwritings which are reinforced by the reinforcing agents exhibit minor chromatic aberration. Pigments of the handwritings are not easy to fade and the handwritings can be durably kept.

Owner:SHAANXI NORMAL UNIV

Method for freeze preservation of sea cucumbers

The invention relates to a method for freeze preservation of sea cucumbers, in particular to a novel process for freeze preservation storage of the sea cucumbers by adopting a desalination method to process and freeze the sea cucumbers, which comprises the following steps: paunching to remove intestines, soaking to desalt, hot boiling to form, desalting and reducing the temperature, individual quick freezing and vacuum packaging. The method adopts a process of repeated soaking desalination with fresh water to reduce the salinity in the sea cucumbers to be equal to the salt content in fish meat so that the sea cucumbers can completely reach the freezing point easily during freezing and autolytic enzymes in the sea cucumbers do not act so as to achieve the aim of avoiding autolysis of the sea cucumbers. The method has the characteristics of high desalinating efficiency of the sea cucumbers, good freezing effect of the sea cucumbers, no automatic self dissolving of the sea cucumbers, easy storage, no loss of the nutritive value of the sea cucumbers, convenience for eating, and the like.

Owner:傅建华

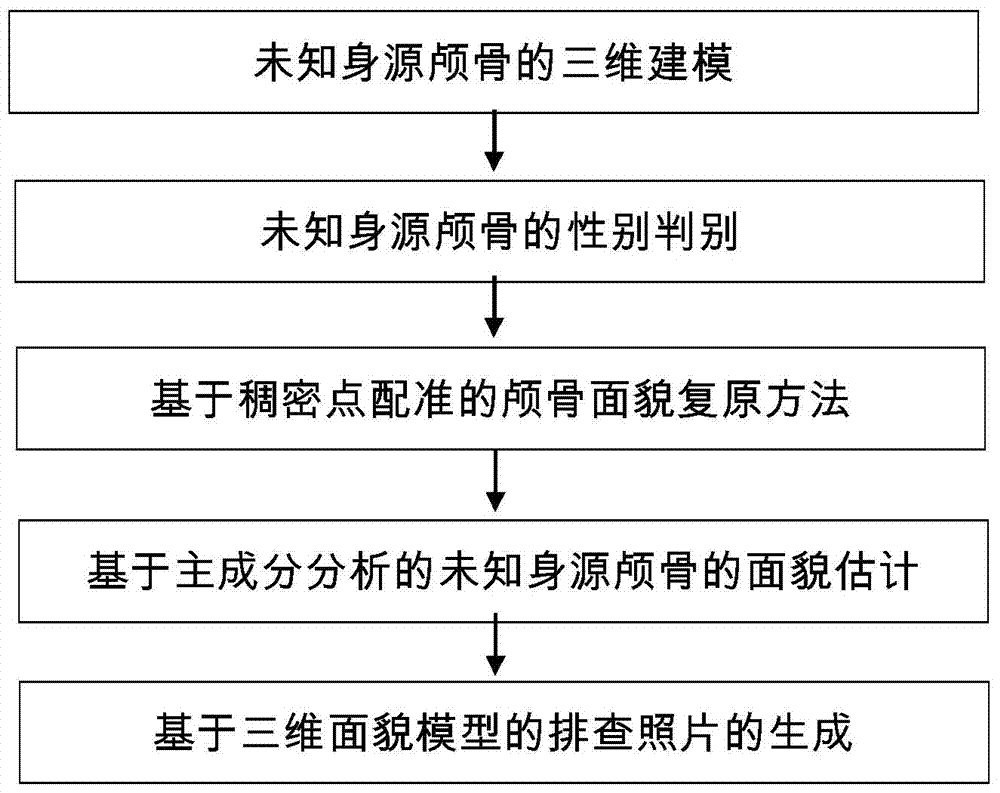

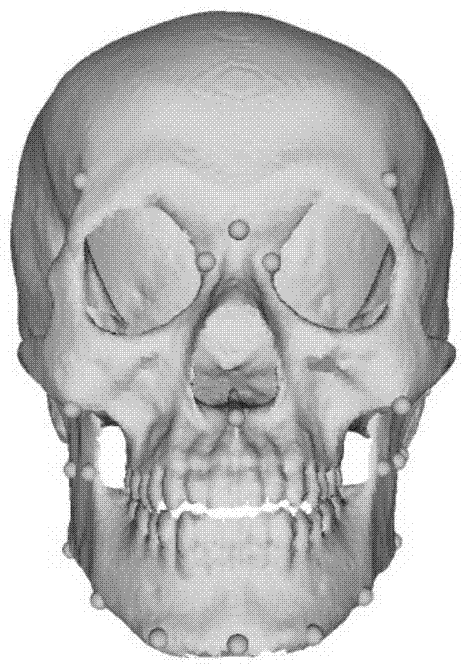

Criminology-oriented computer-assisted facial reconstruction method for skulls of unknown body sources

InactiveCN103679816AImprove reliabilityAchieve gender discrimination3D modellingPoint registrationPrincipal component analysis

The invention belongs to the fields of forensic anthropology and computer graphics and relates to a criminology-oriented computer-assisted facial reconstruction method for skulls of unknown body sources. The criminology-oriented computer-assisted facial reconstruction method mainly includes steps of 1 three-dimensional modeling of a skull of an unknown body source, 2 gender discrimination of the skull of the unknown body source, 3 dense point based facial soft tissue rule analysis, 4 dense point registration based skull facial reconstruction method, 5 principal component analysis based facial estimation of the skull of the unknown body source, 6 generating of investigated photos based on three-dimensional facial model. The criminology-oriented computer-assisted facial reconstruction method can fast achieve facial reconstruction for skulls of unknown body sources, and can predict the facial features of victims before their death for criminal case investigation.

Owner:BEIJING NORMAL UNIVERSITY

Flower and fruit-flavored brown sugar solid drink and preparation method thereof

InactiveCN106261329AGood molding effectAvoid deformationNatural extract food ingredientsFood ingredient as mouthfeel improving agentUltrasonic assistedFruit juice

The invention discloses flower and fruit-flavored brown sugar solid drink and a preparation method thereof. The brown sugar solid drink comprises the following components in parts by weight: 94-97 parts of brown sugar and 3-6 parts of a compound extract juice, wherein the compound extract juice consists of medlar juice, longan juice, red jujube juice and rose juice; the medlar juice, the longan juice, the red jujube juice and the rose juice are prepared through ultrasonic-assisted extraction. According to the brown sugar solid drink, flower and fruit juice is extracted through ultrasonic-assisted extraction, so that the brown sugar solid drink has the advantages of high nutrient leaching rate, time conservation, energy conservation and high efficiency; meanwhile, no additive is added, so that the nutritional value and the mouth feel of the drink are enhanced.

Owner:赖维新

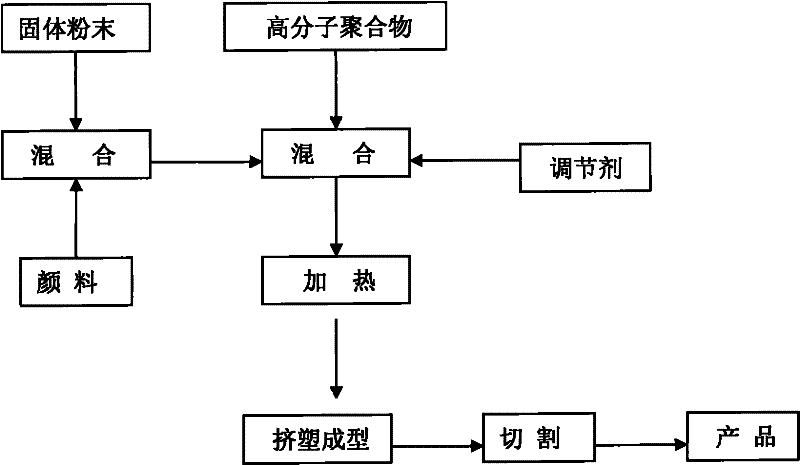

Colorful high-elastoplastic pen and making method thereof

The invention discloses a colorful high-elastoplastic pen and a making method thereof. In the making method, 20-40% of polymer is used as a main body, 20-38% of white or colorless solid powder is used as a color carrying body, 2-20% of pigment is used as a dyeing body, and 2-20% of regulating agent is assisted properly; and after evenly mixing, the product disclosed by the invention is obtained by extrusion molding, cooling, solidifying and cutting at the temperature of 120-250 DEG C. The making process of the method is simple and environment-friendly, equipment is compact and convenient for use; the colorful high-elastoplastic pen does not adhere hands, is not broken off, is not faded and is not dyed, and color is clear when the colorful high-elastoplastic pen performs writing; and the colorful high-elastoplastic pen is convenient for carrying and storage, and has wide applicability and reliable safety. Because the pen disclosed by the invention has high elasticity and plasticity, the pen disclosed by the invention does not cause hard damage to a human body when in use; and simultaneously, in the pen, natural compounds or green chemical raw materials are adopted, thus the pen is safe to the human body, does not pollute environment, and is an environment-friendly and safe product.

Owner:南京乐士新材料科技发展有限公司

Dendritic macromolecule catalytic hair dyeing agent and preparation and use methods thereof

InactiveCN110123670ANot easily oxidizedGood saveCosmetic preparationsHair cosmeticsMiddle medullaPhosphoric acid

The invention discloses a dendritic macromolecule catalytic hair dyeing agent and preparation and use methods thereof, wherein the dendritic macromolecule catalytic hair dyeing agent comprises an agent A and an agent B. The agent A consists of the following components: 5,6-dihydroxy indole, cetostearyl alcohol, oleic acid, propylene glycol, isopropanol, sodium dodecyl sulfonate, a polyethylenediamine dendritic polymer, ammonia water and water. The agent B consists of the following components: hydrogen peroxide, cetostearyl alcohol, oleic acid, propylene glycol, isopropanol, sodium dodecyl sulfonate, phosphoric acid and the like. The preparation method comprises the steps: firstly, preparing the agent A, and then preparing the agent B. The use method comprises the steps: mixing the agent Aand the agent B in a proportion of 1:1, stirring evenly, then applying to hair, and 30 min later, cleaning the hair. The 5,6-dihydroxyindole in the hair dyeing agent is not easy to oxidize and is easyto preserve in air, has quite obvious dyeing effect is and can enter the interior of hair medulla of hair and the hair dyeing agent is washed and is not easy to fade after dyeing.

Owner:SICHUAN UNIV

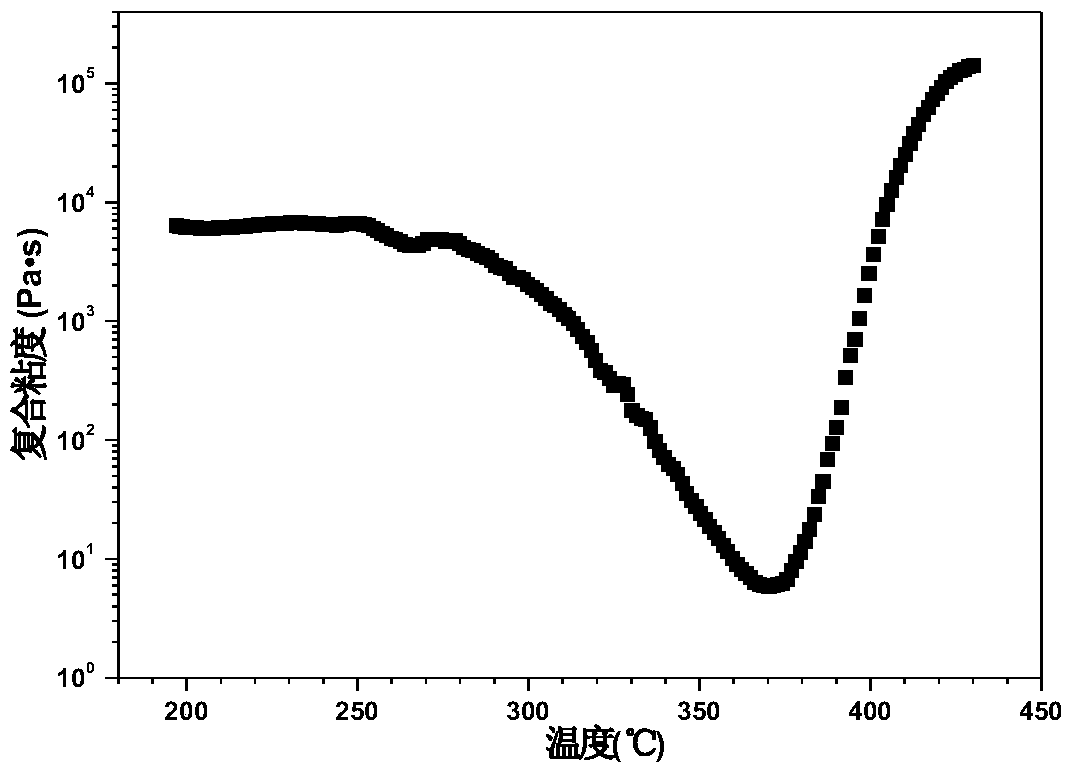

Polyimide adhesive and preparation method thereof

The invention relates to a polyimide adhesive and a preparation method thereof and belongs to the technical field of adhesives. The polyimide adhesive solves the problem that the polyimide adhesive ata temperature of greater than 350 DEG C has poor thermal instability and low adhesive properties. The polyimide adhesive is prepared from a polyimide adhesive prepolymer through curing. The preparation raw materials of the polyimide adhesive prepolymer comprise aromatic diamine containing a biphenyl structure, aromatic diamine containing a siloxane structure, aromatic dianhydride and a blocking agent. The preparation method comprises dissolving the polyimide adhesive prepolymer in an organic solvent to obtain a homogeneous solution, coating the surface of the adherend with the homogeneous solution, removing the organic solvent, carrying out curing to obtain the polyimide adhesive and bonding the adherend The polyimide adhesive can be used for the bonding of high temperature resistant parts in the fields of aviation, aerospace, precision machinery and petrochemical industry.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Polymer amine-based hair dye and preparation and use methods thereof

InactiveCN110151599AEasy to storeObvious stainingCosmetic preparationsHair cosmeticsAmmonium hydroxideDodecylsulfonic acid

The invention discloses a polymer amine-based hair dye and preparation and use methods thereof. The hair dye is prepared from an agent A and an agent B; the agent A is prepared from 5,6-dihydroxyindole, cetearyl alcohol, oleic acid, propylene glycol, isopropanol, sodium dodecyl sulfate, polymer amine, ammonium hydroxide and water; the agent B is prepared from hydrogen peroxide, oleyl alcohol, oleic acid, propylene glycol, isopropanol, sodium dodecyl sulfate and phosphoric acid. The preparation method comprises the steps that the agent A is prepared at first, and then the agent B is prepared. The use method comprises the steps that the agent A and the agent B are mixed at the proportion of 1:1, stirred to be uniform and then applied to hair, and then the hair is washed after 30 minutes. Accordingly, 5,6-dihydroxyindole in the hair dye is not likely to be oxidized in the air and easy to store, the dyeing effect is very obvious, the dye can enter the medulla of the hair, and when people wash the hair after dyeing, fading is not likely to occur.

Owner:SICHUAN UNIV

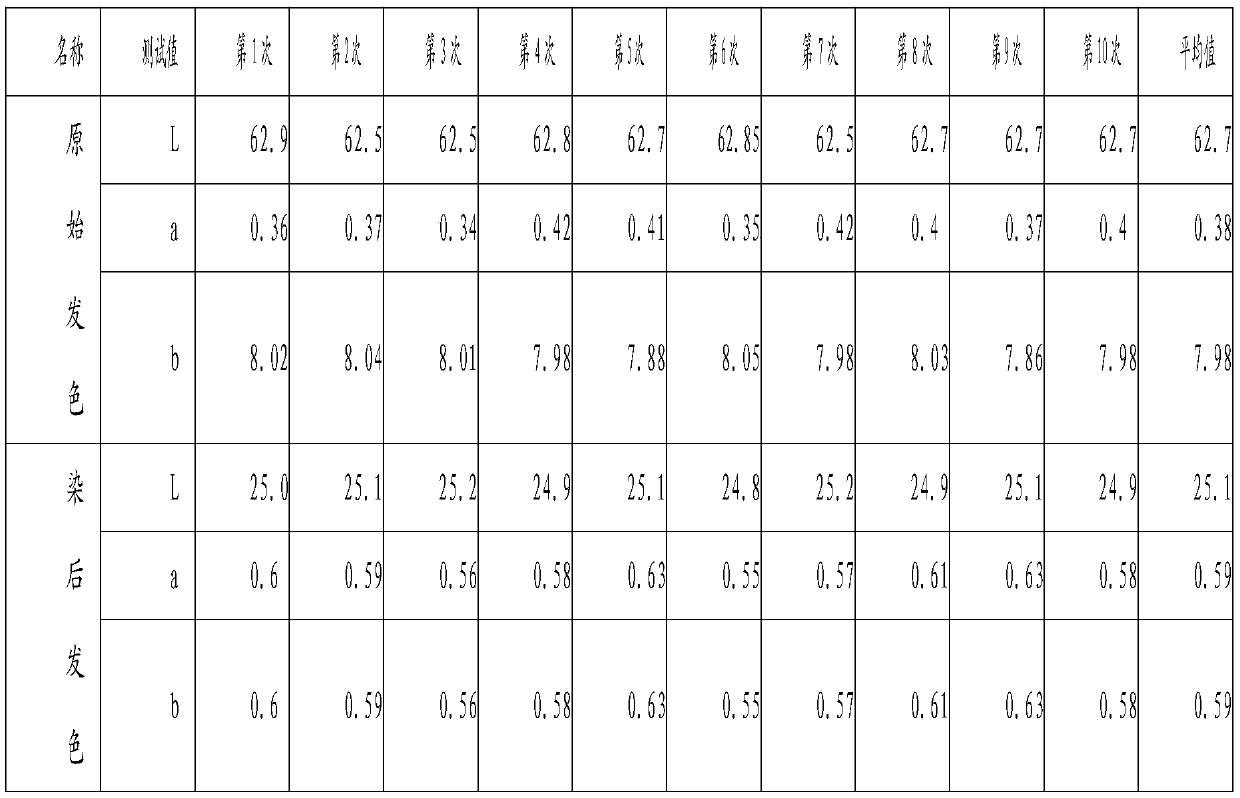

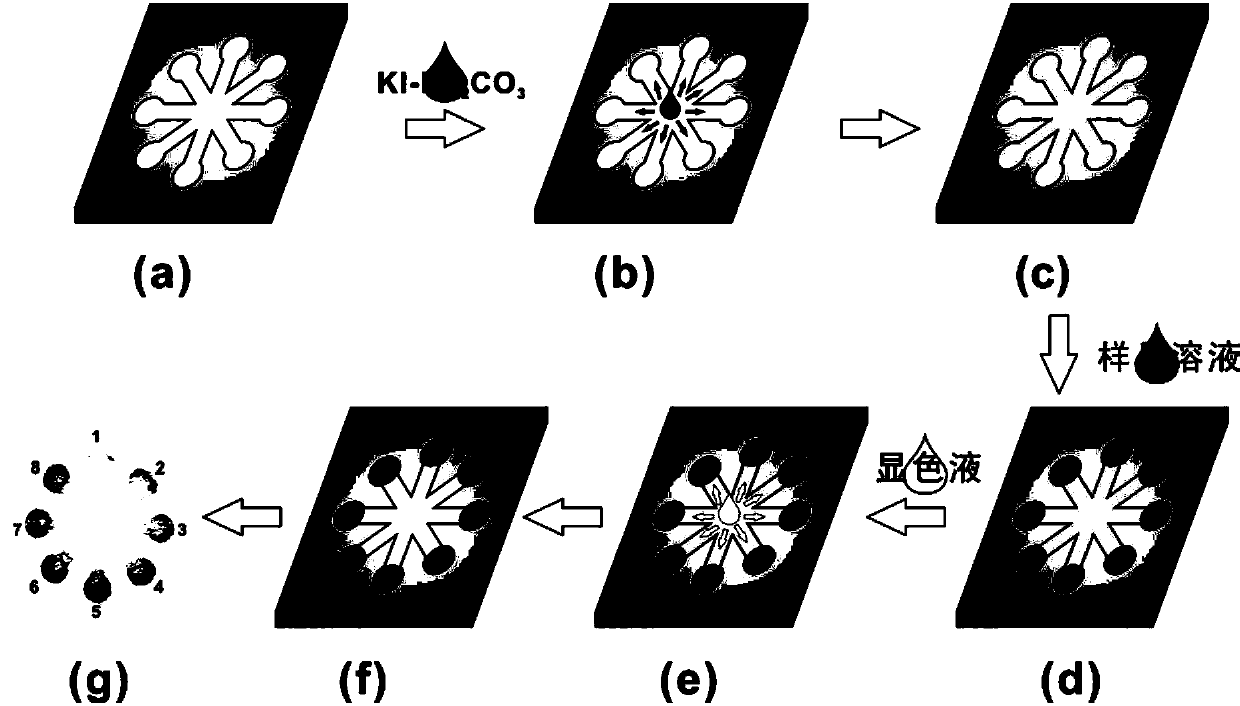

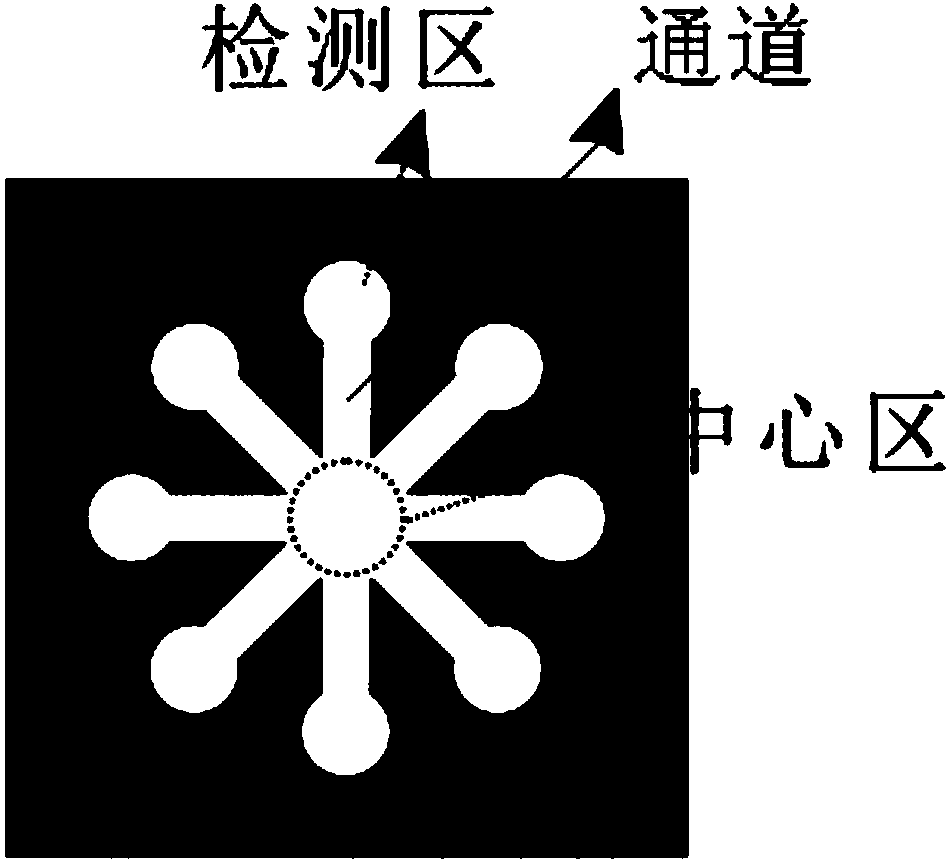

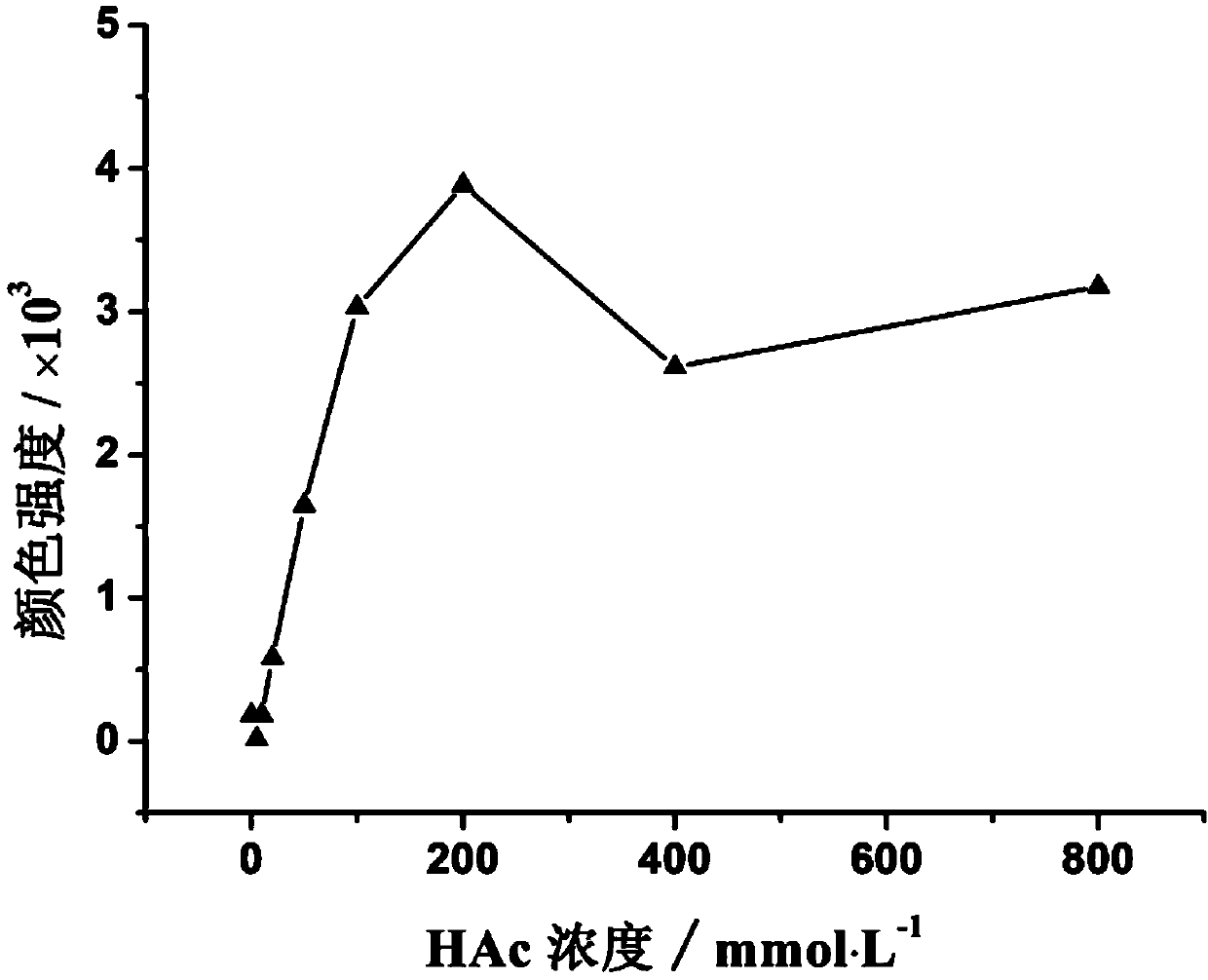

Paper chip detection method for rapidly determining content of amylose in paddy rice and application system adopted in paper chip detection system for rapidly determining content of amylose in paddy rice

InactiveCN104215633ANot volatileQuantitativeMaterial analysis by observing effect on chemical indicatorChannel networkPulp and paper industry

The invention discloses a paper chip detection system for rapidly determining the content of amylose in paddy rice. The paper chip detection system comprises a potassium iodide paper chip and a developing solution; a production method of the potassium iodide paper chip comprises the steps: arranging a hydrophilic channel network on a paper substrate, wherein the hydrophilic channel network comprises a central area and a channel surrounding the central area, and the part of the paper substrate, except for the hydrophilic channel network, is hydrophobic; dropwise adding a KI-Na2CO3 aqueous solution in the central area, and naturally permeating the KI-Na2CO3 aqueous solution in the hydrophilic channel network; and naturally drying the paper substrate to obtain the potassium iodide paper chip. The developing solution is an acid-strong oxidant aqueous solution. The invention also provides a detection method adopting the paper chip detection system. The detection method comprises the following steps of preparing a to-be-detected paddy rice sample solution, a paddy rice amylose standard sample solution, a blank sample solution and the like. By adopting the paper chip detection method and the paper chip detection system, the content of the amylose in the paddy rice can be rapidly and conveniently determined.

Owner:CHINA NAT RICE RES INST

Method for preparing chitosan oligosaccharide monomers by gel chromatography

ActiveCN102174064AHigh monomer purityHigh yieldSugar derivativesSugar derivatives preparationFreeze-dryingOligosaccharide

The invention relates to a method for preparing chitosan oligosaccharide monomers by gel chromatography, which is characterized by comprising the following steps of: dissolving 20 to 70 mass percent chitosan oligosaccharide in double distilled water, and performing suction-filtering to obtain filtrate, namely chitosan oligosaccharide solution after the chitosan oligosaccharide is completely dissolved; loading the chitosan oligosaccharide solution to a gel chromatographic column, eluting by using the double distilled water, collecting 0.1ml in one pipe every 30 minutes by using an automatic partial collector, dissolving sediment in distilled water after acetone is settled, and quickly detecting by thin layer chromatography (TLC) to determine the types of the chitosan oligosaccharide monomers contained in each pipe; taking a small amount of liquid from each pipe, freeze-drying, weighing solid matters to determine the concentration of chitosan oligosaccharide contained in each pipe, and drawing an elution curve; separating to obtain solution containing the chitosan oligosaccharide monomers; and concentrating under reduced pressure, and freeze-drying to obtain various chitosan oligosaccharide monomers. The method is low in cost, easy and convenient to operate and mature in technical route, and the prepared chitosan oligosaccharide monomers have high purity and can be used as standard products and research biochemical reagents.

Owner:惠州长龙生物技术有限公司

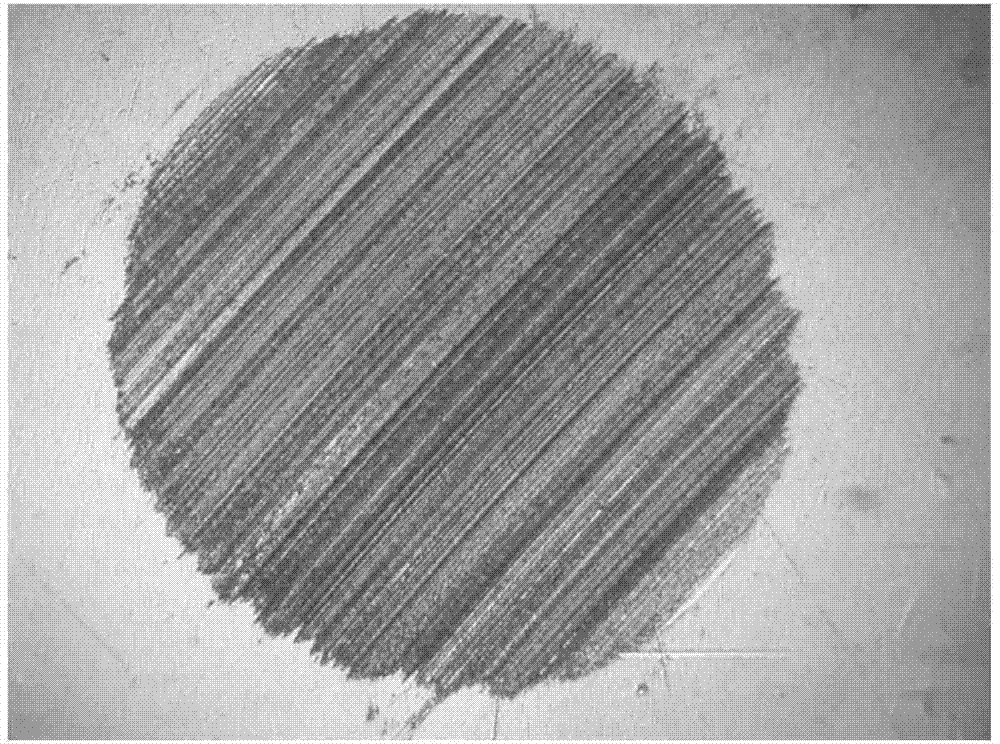

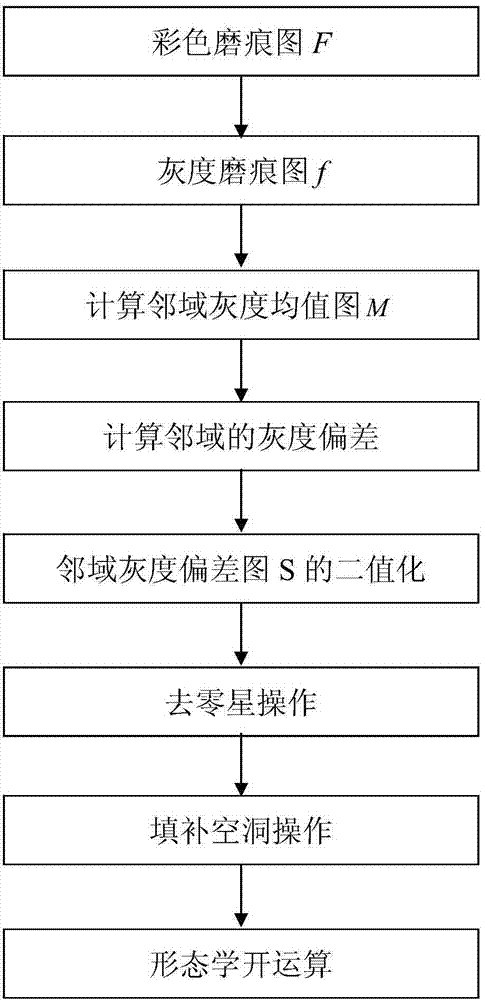

Steel ball grinding crack detection method based on neighborhood gray level similarity

The invention discloses a steel ball grinding crack detection method based on neighborhood gray level similarity. The method specifically includes the following steps that 1, a grinding crack image of a steel ball is acquired and read into a computer; 2, if the acquired grinding crack image is a color image, a step 3 is performed and if the acquired grinding crack image is a gray level image, a step 4 is performed; 3, graying is performed on the color image F; 4, a neighborhood gray level average figure M of the gray level grinding crack image f is calculated; 5, a neighborhood gray level deviation value of pixels is calculated; 6, binaryzation is performed on a neighborhood gray level deviation figure S; 7, fragment removal operation is performed on a neighborhood gray level similar figure L; 8, cavity filling operation is performed on a gray level similarity grinding crack figure D; 9, morphological opening operation is performed. According to the method, a grinding crack area of the steel ball can be detected rapidly, and accordingly the diameter of a grinding crack can be worked out directly.

Owner:CHANGAN UNIV

Quick detection troche for sulfite in food

ActiveCN102072901AGuaranteed smoothnessQuick checkMaterial analysis by observing effect on chemical indicatorAbsorption/flicker/reflection spectroscopyAdhesiveSulfate

The invention discloses a quick detection troche for sulfite in food, aiming to solve the problems that the traditional sulfite detection method can not quickly detect because of requiring certain instrument equipment and the existing quick detection kit for liquid sulfite is inconvenient to detect, transport and store and has big possibility of deteriorating. The detection troche is composed of 9.7-19% of detection agent, 15-30% of adhesive, 42-60% of thinner, 1-4% of lubricant and 2-5% of disintegrating agent. The quick detection troche can be directly applied for quickly detecting sulfite content in the food extracting solution semiquantitatively or qualitatively, has the advantages of small possibility of deterioration in the process of transportation, storage or utilization, long quality guarantee period and low product cost, and is simple in operation and easy to store, can be quickly dissolved to react with sulfite, generates colorful substance which is easy for visual inspection and can be produced in a large scale.

Owner:HANGZHOU TIANMAI BIO TECH

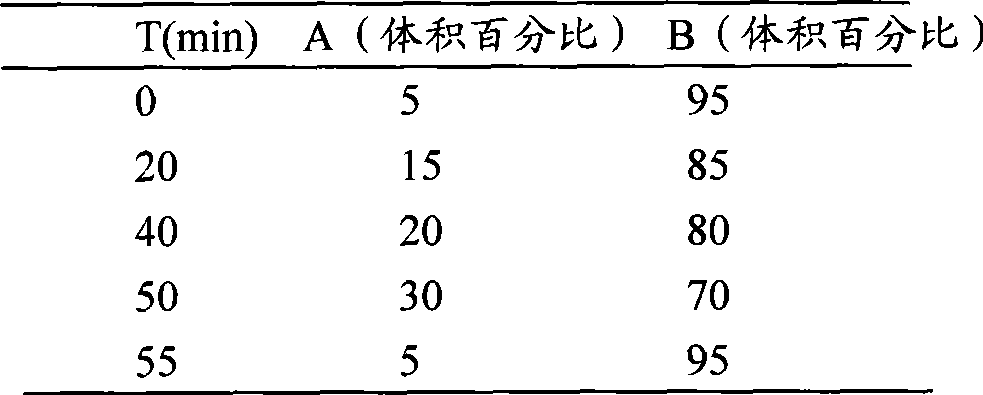

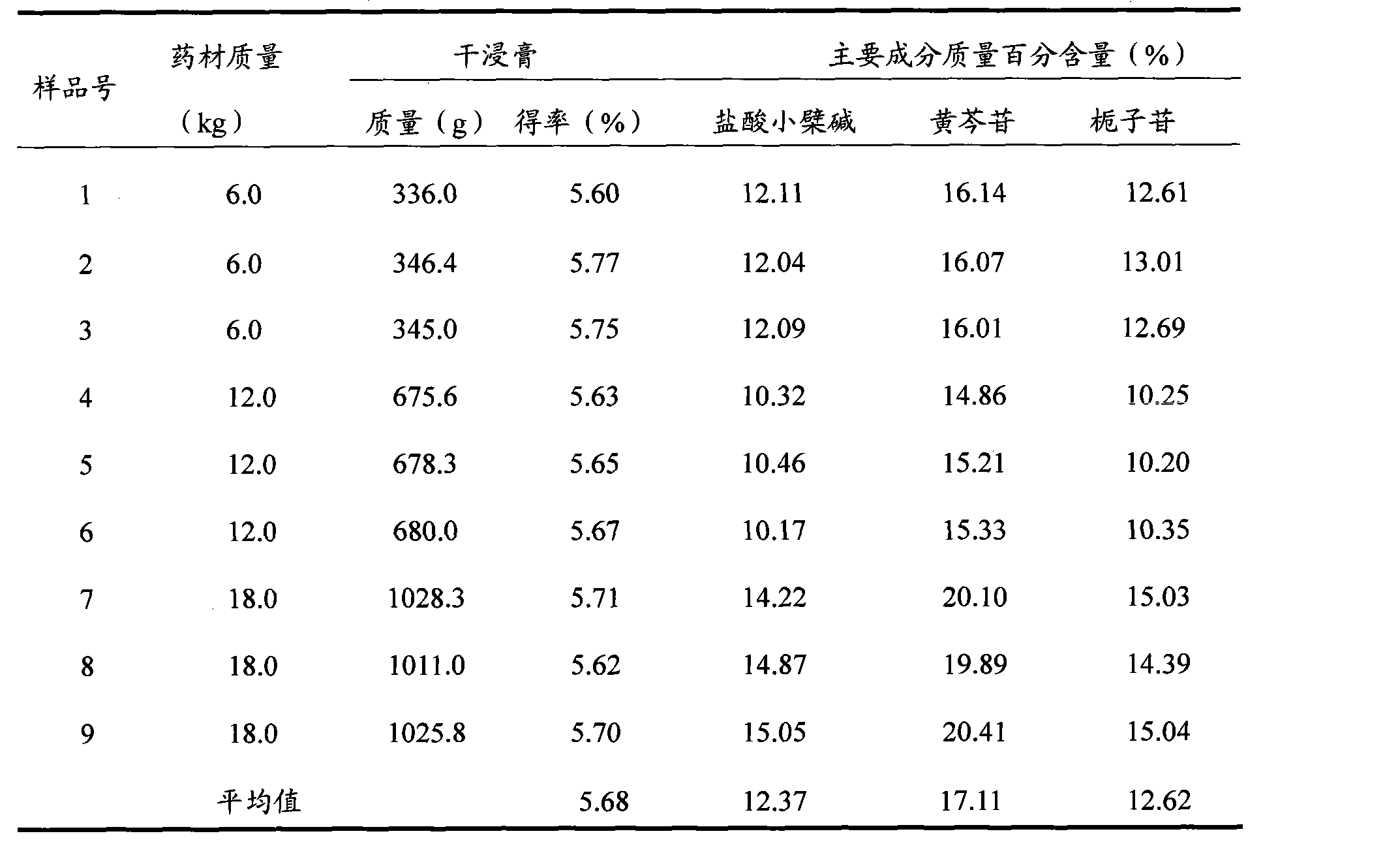

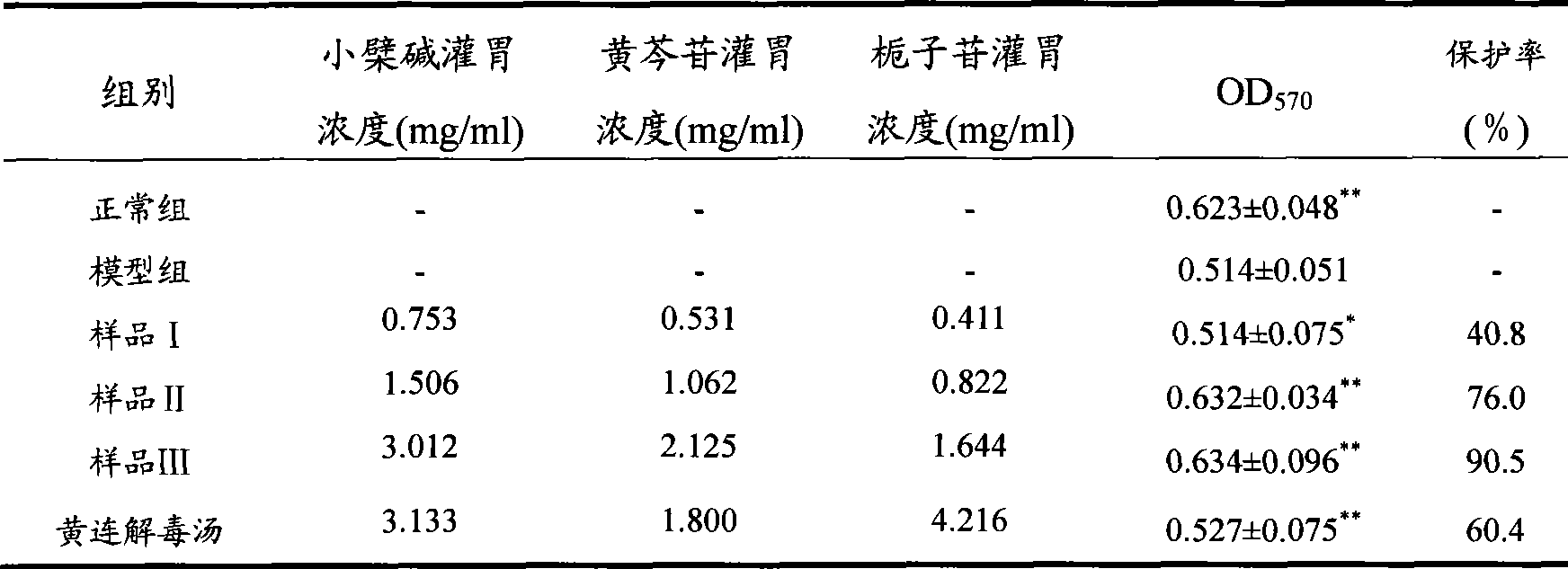

Extraction method of coptis detoxifcation decoction active site and use thereof

ActiveCN101455750AKeep active ingredientsReasonable useNervous disorderPlant ingredientsChinese traditionalFlavonoid glycosides

The invention relates to an extract method of Chinese traditional medicinal compound rhizoma coptidis alexipharmic soup active part and an application of the active part in preparing medicament resisting vascular dementia. The extract method disclosed by the invention adopts industrialized separating and refining technologies, such as microporous membrane and macroporous resin absorption, greatly decreases cream yield of the preparation, maximally retains effective components, improves transforming rate of effective components in raw materials and purity of effective components in the preparation. The extracted active part comprises three kinds of known chemical components: alkaloids, flavonoid glycosides and iridoid glycosides respectively, and has a vascular dementia resisting function.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Nano composite molten steel purifying agent and preparation method thereof

The invention discloses a nano composite molten steel purifying agent. The nano composite molten steel purifying agent comprises the following raw materials in percentage by mass: 3 to 10 percent of nano SiC, 10 to 20 percent of silico-calcium alloy powder, 4 to 15 percent of K2O powder, 5 to 16 percent of Na2O powder, 2 to 6 percent of Mg powder, 2 to 8 percent of Ti powder, 3 to 5 percent of a bonding agent and the balance of iron powder. A method for preparing the nano composite molten steel purifying agent includes: firstly mixing uniformly the nano SiC with the silico-calcium alloy powder to obtain a mixture a, then mixing uniformly the mixture a, the K2O powder and the Na2O powder to obtain a mixture b, then mixing uniformly the mixture b, the Mg powder, the Ti powder and the iron powder to obtain a mixture c, adding the bonding agent into the mixture c and stirring uniformly, finally briquetting and molding. The nano composite molten steel purifying agent can greatly improve the purification degree of molten steel, and the performance of a steel product treated by using the nano composite molten steel purifying agent is the same as that of the steel product purified by using a ladle furnace (LF), so that the nano composite molten steel purifying agent can replace the LF furnace used for refining, and the steelmaking cost can be greatly reduced.

Owner:成天有限公司

Bagel bread containing raw material of chia seeds and preparation method of bagel bread

ActiveCN104970060ASoft tasteIncrease elasticityDough treatmentPre-baking dough treatmentBiotechnologyNutritive values

The invention discloses bagel bread containing a raw material of chia seeds. The bagel bread is mainly prepared from the following raw materials: strong flour, chia seed powder, yeast, a bread modifier, sugar, cream, salt and water. The invention further discloses a preparation method of the bagel bread containing the raw material of the chia seeds. The preparation method comprises the following working procedures: preparing overnight sour dough, preparing main dough, fermenting the prepared main dough, dividing the fermented main dough, shaping the divided main dough so as to form much dough, fermenting the dough for the first time, performing decoration, fermenting the dough for the second time, cooking the fermented dough, baking the cooked dough and the like. The bagel bread prepared by the method has the characteristics that the fragrance is pure, the mouth feel is elastic and chewy, the distribution of the chia seeds is obvious, and the content of linolenic acid is high, and the nutritional value is high.

Owner:广州市传稻食品有限公司 +1

Hair dye based on phenylboronic acid and preparation and use method thereof

InactiveCN110200823ANot easily oxidizedGood saveCosmetic preparationsHair cosmeticsPhosphoric acidOleic Acid Triglyceride

The invention discloses a hair dye based on phenylboronic acid and a preparation and use method thereof. The hair dye comprises an agent A and an agent B, and the agent A is composed of the followingcomponents: 5,6-dihydroxyindole, phenylboronic acid, oleyl alcohol, oleic acid, propylene glycol, isopropanol, sodium dodecanesulphonate, ammonia water and water; and the agent B consists of hydrogenperoxide, oleyl alcohol, oleic acid, propylene glycol, isopropanol, sodium dodecanesulphonate, phosphoric acid and water. The preparation method comprises the following steps: preparing the agent A and then preparing the agent B; the use method comprises the following steps: mixing the agent A and the agent B in a ratio of 1:1, uniformly stirring and applying a mixture to the hair, and then washing the hair after 30 minutes. An intermediate 5,6-dihydroxyindole in the hair dye of the invention is not easily oxidized in the air and is easy to preserve, and the dyeing effect is very obvious, andthe hair dye can enter the inside of the hair pulp of the hair, and the hair dye is not easy to fade after washing.

Owner:SICHUAN UNIV

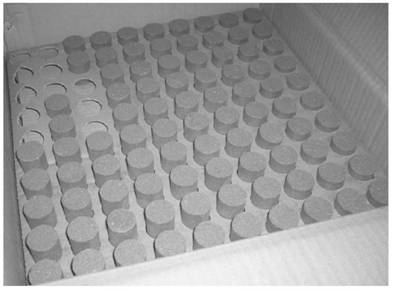

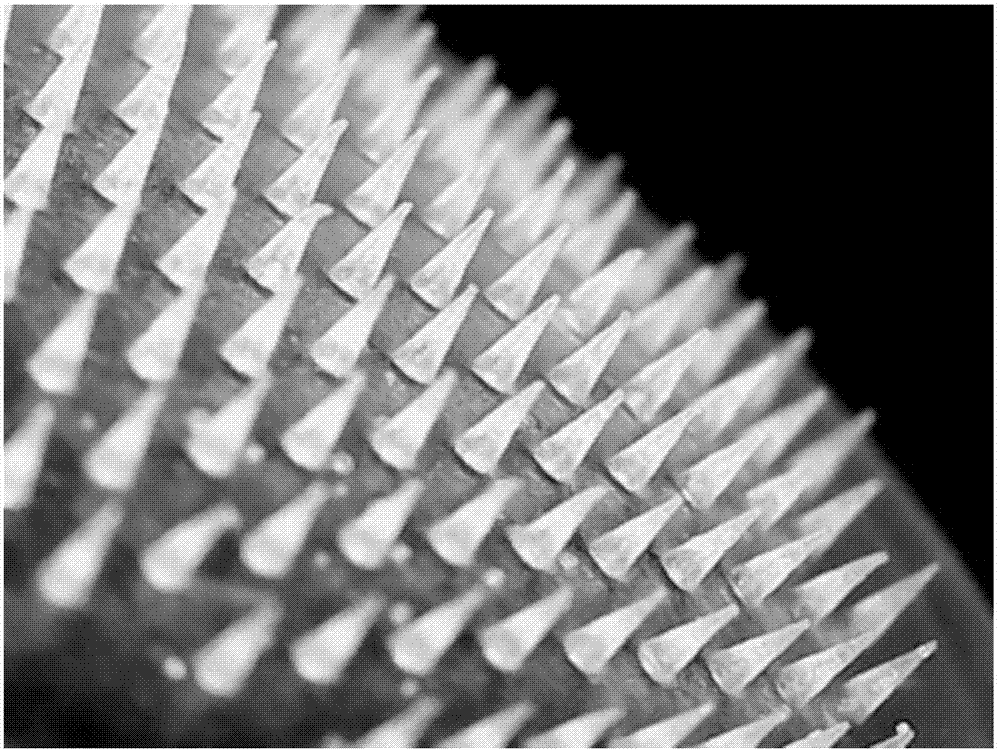

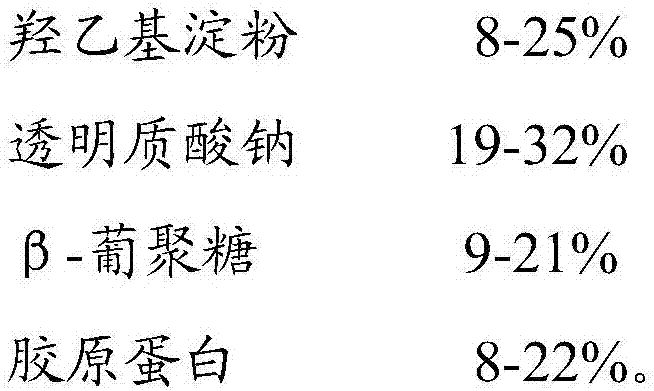

Skin aging resisting composition, soluble micro-needle patch and preparation method thereof

ActiveCN107440934AHigh mechanical strengthReduce loosenessCosmetic preparationsToilet preparationsHydroxyethyl starchBULK ACTIVE INGREDIENT

The invention relates to a skin aging resisting composition, a soluble micro-needle patch and a preparation method thereof. The skin aging resisting composition consists of the following components in percentages by weight: 5-50% of copper peptide, 8-25% of hydroxyethyl starch 19-32% of sodium hyaluronate, 9-21% of [beta]-glucan and 8-22% of collagen. The composition has a synergistic effect of resisting skin aging; and the composition has good effects of resisting wrinkles, removing freckles and removing dark skin. The composition can be prepared into the soluble micro-needle patch which is good in mechanical intensity, so that a skin-care effect is further enhanced; and in comparison with a smearing mode, the micro-needle patch is capable of effectively improving epidermal penetration rate of an active ingredient, reducing dosage, accelerating speed of taking effects and improving the utilization rate of the copper peptide.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

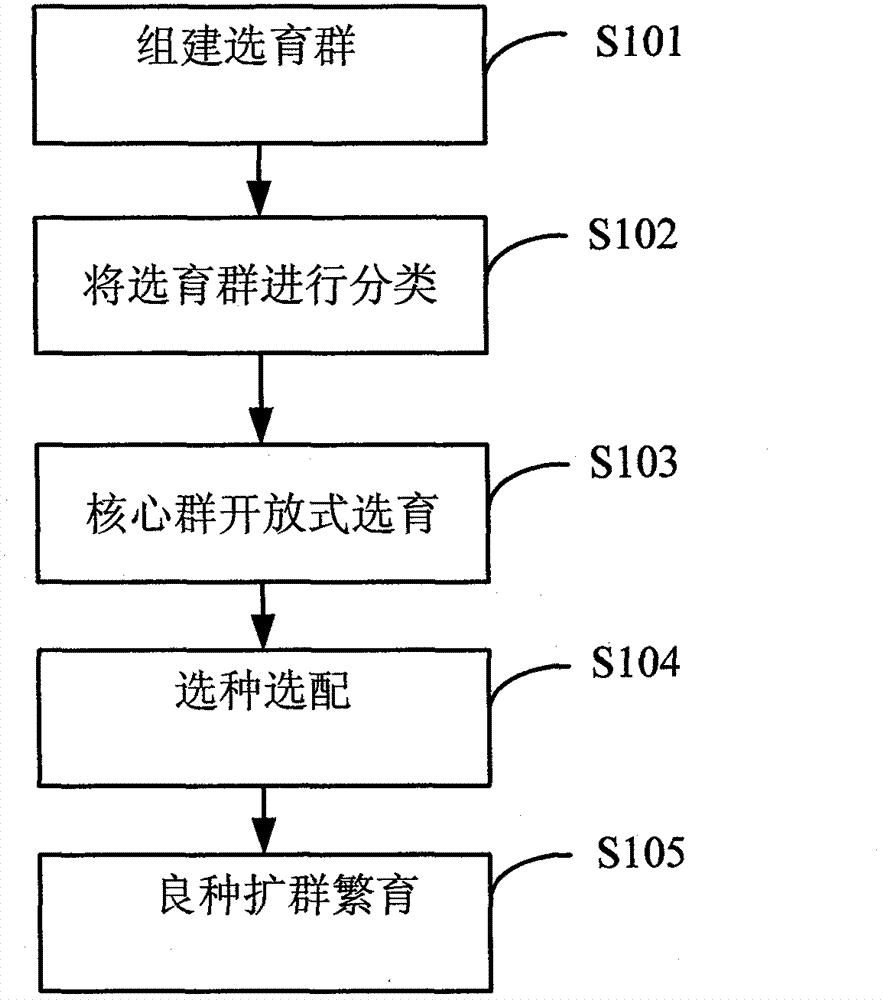

Purification and rejuvenation method of sheep and goat breeds

The invention discloses a purification and rejuvenation method of sheep and goat breeds. The purification and rejuvenation method adopts a core group open type breeding method for establishing a core group and an underlying group among peasant households and realizes the transform from a small scale of the core group of conventional field construction, breed protection and breeding to a large scale of the core group of open type breeding established among the peasant households, fully reflects the breeding advantages of large core group, high frequency of elite genotypes, wide influence surface and wide radiation scope, and improves the production level of the breed protection and breeding group faster; the purification and rejuvenation method realizes the transform from the conventional field construction, breed protection and breeding with high maintenance cost and difficulty in long-term preservation of the core group to the dispersed establishment of the core group among the peasant households, with easiness in maintenance, long-term preservation and consolidation, fully reflects the advantages of large group and small breeding risk, and enables the development of the breed protection and breeding group to have a solid foundation; and the inbreeding coefficient of the open type breeding is slow in increase and difficult to cause the inbreeding depression phenomenon.

Owner:BIJIE INST OF ANIMAL HUSBANDRY & VETERINARY SCI

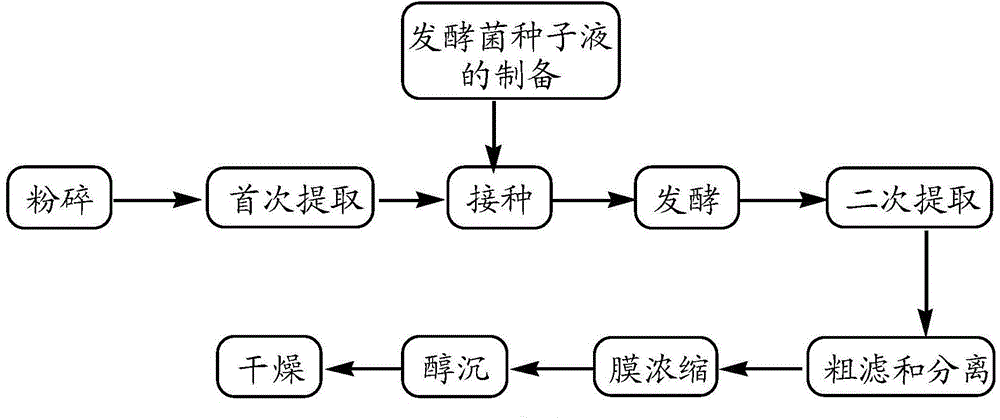

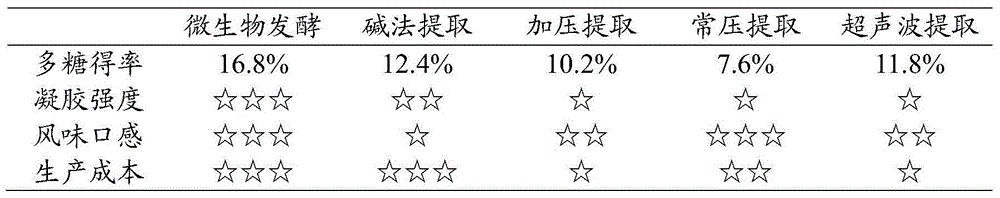

Method for extracting mesona chinensis benth polysaccharide through microbial fermentation

The invention discloses a method for extracting mesona chinensis benth polysaccharide through microbial fermentation. The method comprises steps of smashing, firstly extracting, preparing of zymophyte seed liquid, inoculating, fermenting, secondary extracting, rough filtering, membrane concentrating, alcohol precipitation and drying. The method integrates biofermentation, membrane concentration and alcohol precipitation technologies, the yield for extracting the mesona chinensis benth polysaccharide is high, the process is environmental friendly, and the production cost is low. The extracting, separating and concentrating processes are mild in conditions, and the extracted mesona chinensis benth polysaccharide is good in taste, high in purity, high in gel strength and good in texture.

Owner:SHENZHEN SHENBAO HUACHENG TECH

Grinding crack diameter measurement method based on steel ball grinding crack gradient

InactiveCN103712565AProcessing speedReduce running timeImage enhancementImage analysisMetallurgySteel ball

The invention discloses a grinding crack diameter measurement method based on the steel ball grinding crack gradient. The method specially includes the following steps of collecting a grinding crack image of a steel ball through a scanning mirror, inputting the grinding crack image into a computer, graying the colorful grinding crack image to obtain a grinding crack gray-scale map f, conducting scale detection to obtain a grinding crack scale initial map CC, calculating the length HD of a unit pixel, calculating the gradient of the grinding crack grey-scale map f to obtain a gradient map G of the grinding crack grey-scale map f, conducting binarization processing on the gradient map G to obtain gradient segmentation maps MG, conducting mathematical morphology closed operation on the gradient segmentation maps MG to obtain a gradient connection map OG, conducting mathematical morphology open operation on the gradient connection map OG to obtain a gradient grinding crack map CG, conducting fragment removing operation on the gradient grinding crack map CG to obtain a grinding crack initial map CM, conducting cavity filling operation on the grinding crack initial map CM to obtain a grinding crack map FM, and calculating the grinding crack diameter of the steel ball. The method is high in processing speed, high in measurement accuracy, capable of being conveniently stored for a long time as permanent data, and capable of being used for development work of novel lubricants.

Owner:CHANGAN UNIV

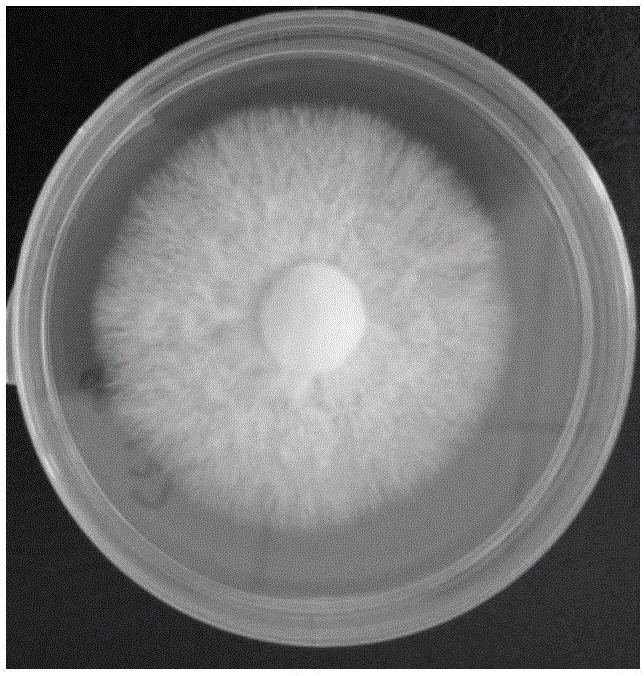

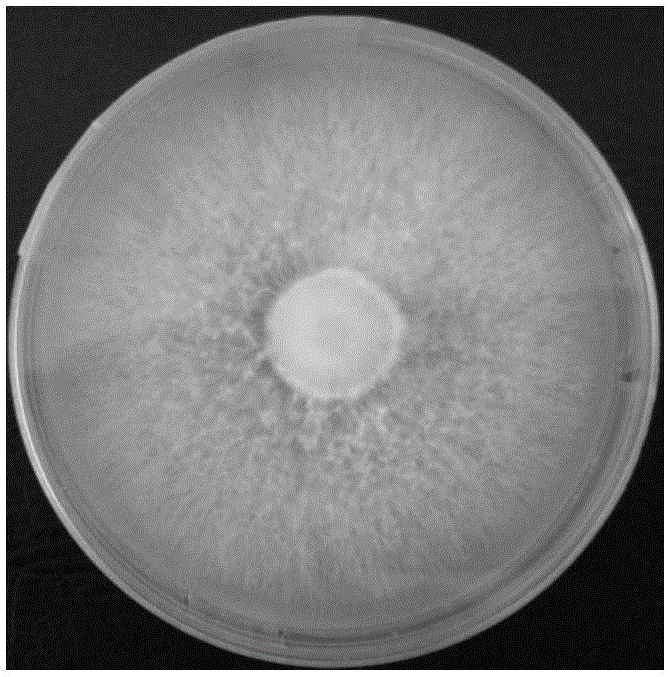

Application of potato whole powder in preparing PDA (potato dextrose agar) medium

PendingCN106367354AMeet growth requirementsGood saveFungiCulture processAdditive ingredientNutrients substances

The invention discloses an application of potato whole powder in preparing a PDA (potato dextrose agar) medium, and belongs to the field of microbial culture mediums. The invention also discloses a potato whole powder medium, wherein the potato whole powder medium consists of the following components according to proportions: 10-20g of the potato whole powder, 2-10g of glucose, 12-20g of agar powder and 1000ml of water. The invention also discloses an application of the potato whole powder medium in fungal culture. According to the potato whole powder medium provided by the invention, such nutrient substances as starch, protein, vitamins, mineral substances and the like in potatoes are completely reserved, so that comprehensive nutrition is guaranteed, and edible fungi, on the potato whole powder medium, are high in mycelia growth speed and vigorous in growth; moreover, the potato whole powder medium provided by the invention is simple in preparation method and the preparation method is free from such processes as preparing potato juice and the like, so that a preparation time is greatly shortened; in addition, the potato whole powder medium provided by the invention is low in production cost; and the potato whole powder medium provided by the invention, since all ingredients are in the form of dry powder, are quite convenient to store and transport.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Compound squash powder of multiple nourishing foods

InactiveCN101151999AGood saveMask bad tasteFood preparationPlant ingredientsDiabetes mellitusPolygonum fagopyrum

A multi-nutrient compound pumpkin powder comprises arrowroot, pumpkin powder and buckwheat powder. The invention utilizes the advantages of the formula so as to reach the goals of improving the function of the human body and treating the diabetes mellitus adjunctively.

Owner:彭贵书

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com