Preparation method of nanometer silver particles

A nano-silver particle and silver source technology, applied in the field of nano-materials, can solve problems such as inconvenient storage, easy agglomeration, and instability of nano-silver particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention discloses a preparation method of nano-silver particles, comprising the following steps:

[0024] a), under the condition of stirring and heating, silver source, coating agent and ammoniacal liquor are added in water, obtain the reaction solution that pH value is 7~12, the molar ratio of described silver source and coating agent is 1: (1 ~5);

[0025] b), adding crown ether to the reaction solution under stirring, the molar ratio of the crown ether to the silver source is (1-3): 1;

[0026] c) adding a reducing agent containing alkali metal to the mixed solution obtained in step b under stirring to obtain silver nanoparticles; the molar ratio of the reducing agent to silver is (1-3):1.

[0027] In the present invention, in order to enable the nano-silver particles to be stably dispersed in water, crown ether is added to the reaction system during the reaction process, and at the same time, a reducing agent containing alkali metal...

Embodiment 1

[0037]1. Dissolve 0.01mol silver nitrate, 0.02mol ammonia water and 0.05mol polyvinylpyrrolidone in water at 80°C and stir for 30 minutes to obtain a reaction solution.

[0038] 2. Add 0.01 mol of 15-crown-5 to the reaction liquid obtained in step 1, adjust the pH value to 9-10, and stir for 20 minutes.

[0039] 3. Add 0.01 mol reducing agent sodium borohydride to the mixture obtained in step 2, and continue to stir and react for 40 minutes to obtain nano-silver.

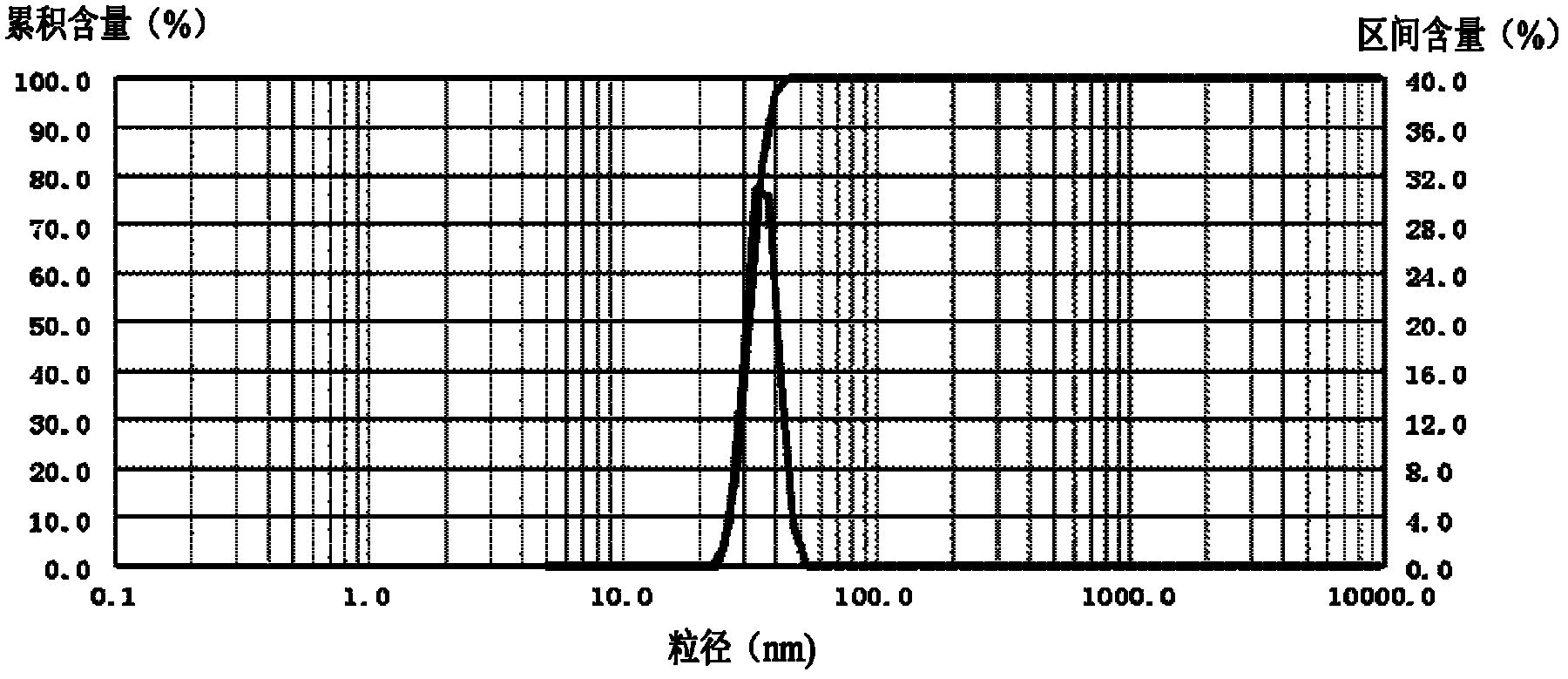

[0040] Such as figure 1 Shown is the particle size distribution diagram of the newly prepared nano-silver. The area surrounded by the red curve in the figure is the particle size partition interval, and the blue curve is the cumulative content curve. The particle size distribution results are listed in Table 1.

[0041] The nano-silver particle size distribution result that table 1 embodiment 1 prepares

[0042]

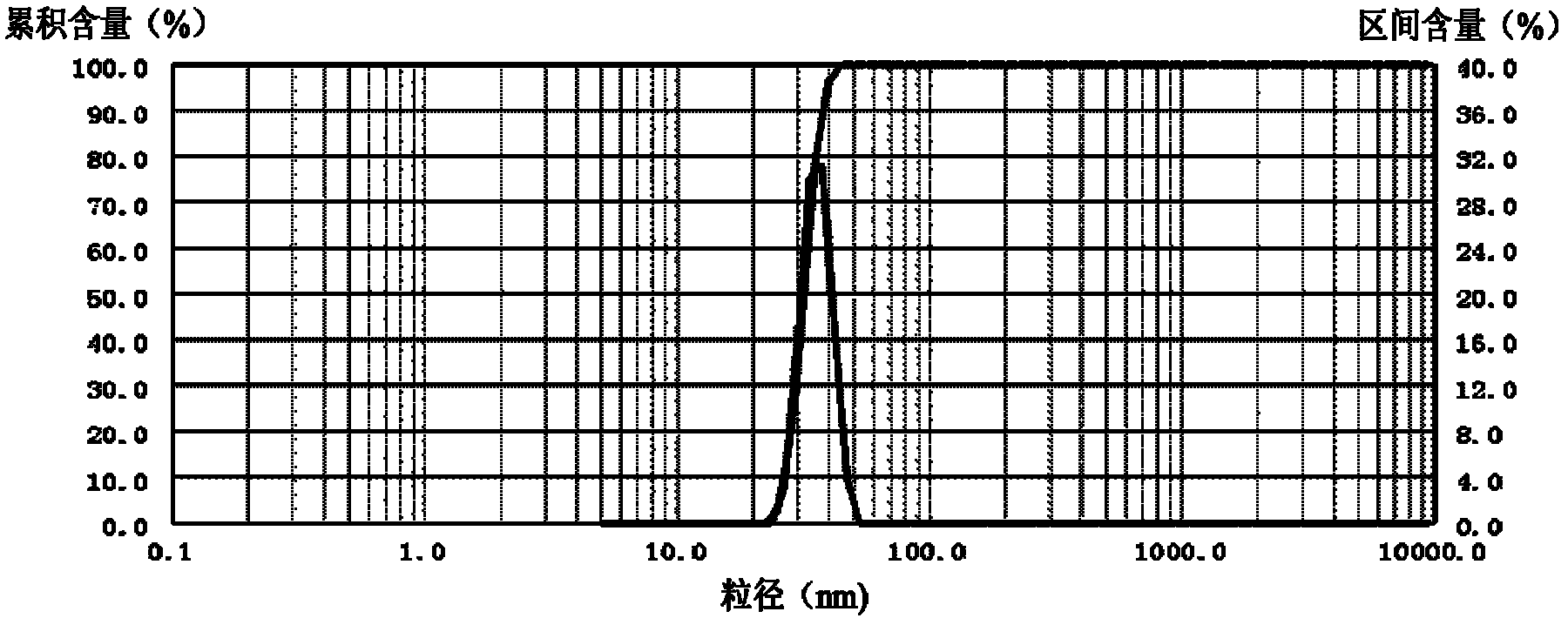

[0043] Such as figure 2 Shown is the particle size distribution diagram of the nano-silver prep...

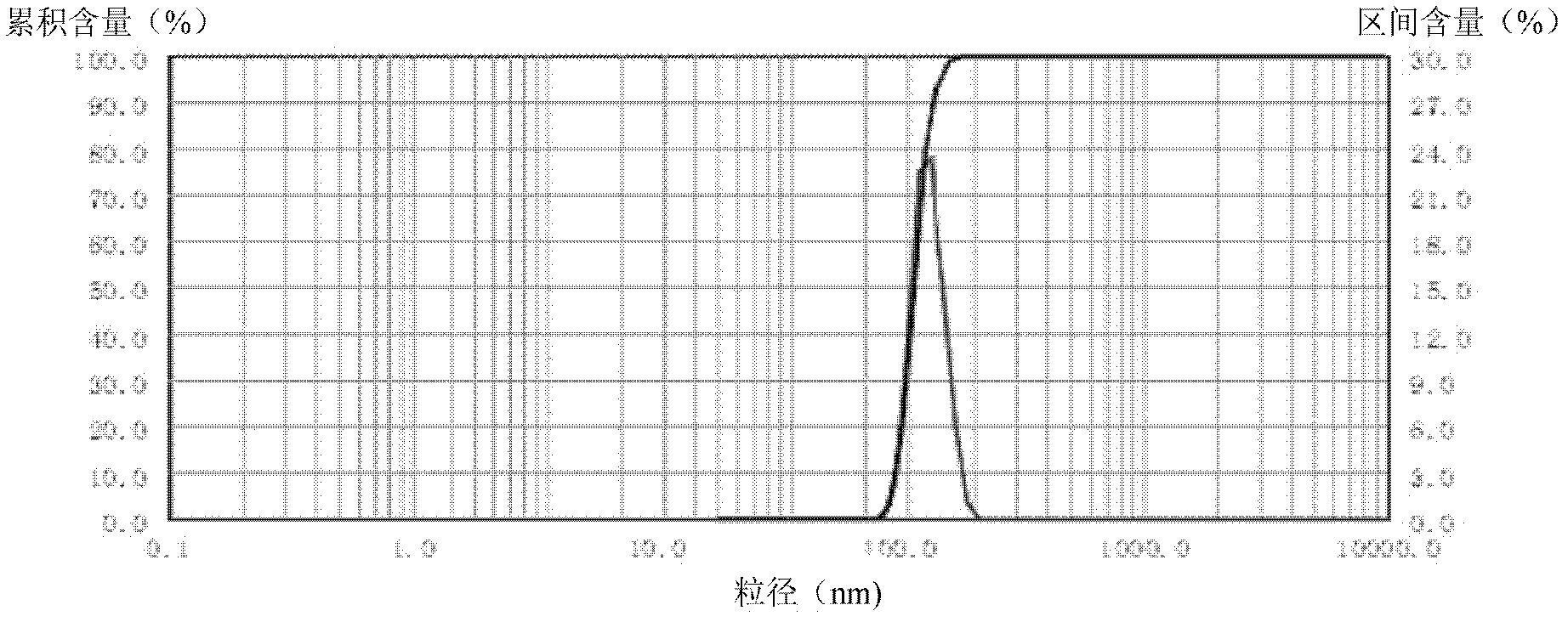

Embodiment 2

[0048] 1. Dissolve 0.01mol silver nitrate, 0.02mol ammonia water and 0.05mol polyvinylpyrrolidone in water at 80°C and stir for 20 minutes to obtain a reaction solution.

[0049] 2. Add 18-crown-6 to the reaction liquid obtained in step 1, adjust the pH value to 9-10, and stir for 20 minutes.

[0050] 3. Add 0.01 mol reducing agent potassium borohydride to the mixture obtained in step 2, and continue stirring for 40 minutes to obtain nano-silver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com