Regenerated cellulose fiber and preparation method thereof

A technology of regenerated cellulose and fiber, which is applied in the field of cellulose fiber, can solve the problems of small contact area between fiber and asphalt mixture, small specific surface area of fiber, and influence on fiber utilization, and achieve clear processing route, large specific surface area, Effect of improving anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

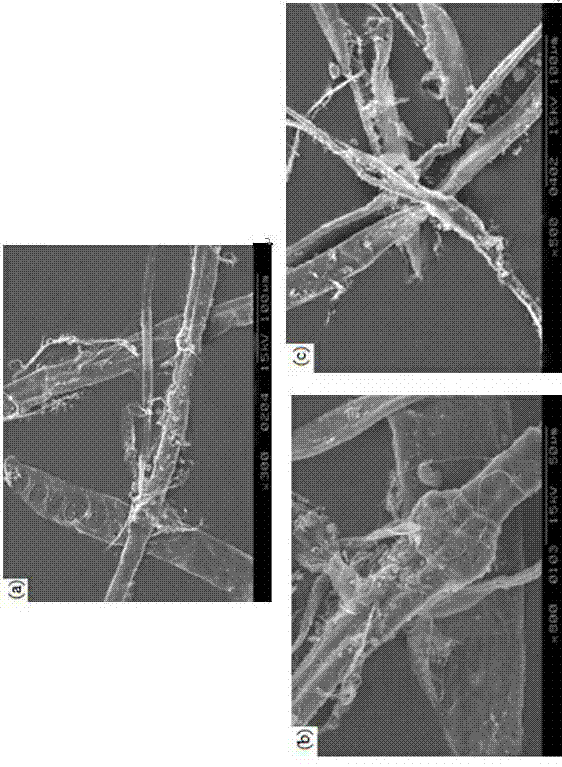

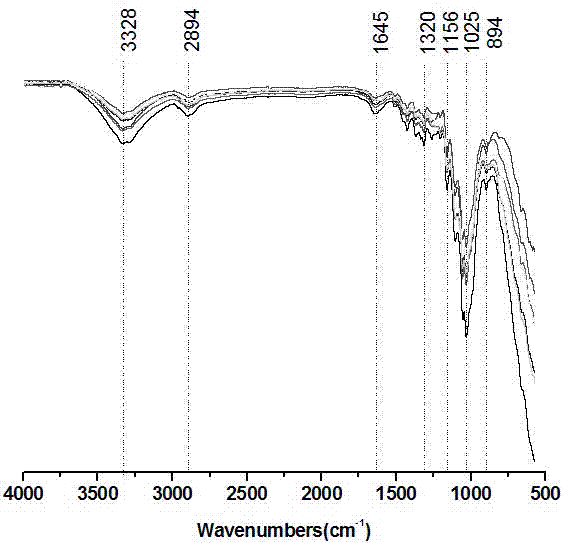

Embodiment 1

[0041] 1. Waste paper disintegration: tear the kraft paper into 2×5cm pieces, soak in water for 24 hours, put the soaked paper into the PL12-00 high-consistency hydraulic pulper, control the pulp concentration to 8%, and the pulping temperature is 55°C ~60°C, the speed of the pulper is 350 r / min, and the disintegration time is 30 min. The disintegrated pulp was filtered through a 80-mesh sieve, vacuum filtered, and then dried in an electric blast drying oven at 105 °C for 24 h until constant weight and bagged for later use.

[0042] 2. Suspension preparation: prepare 2% slurry and stir evenly to make the fibers in a suspended state.

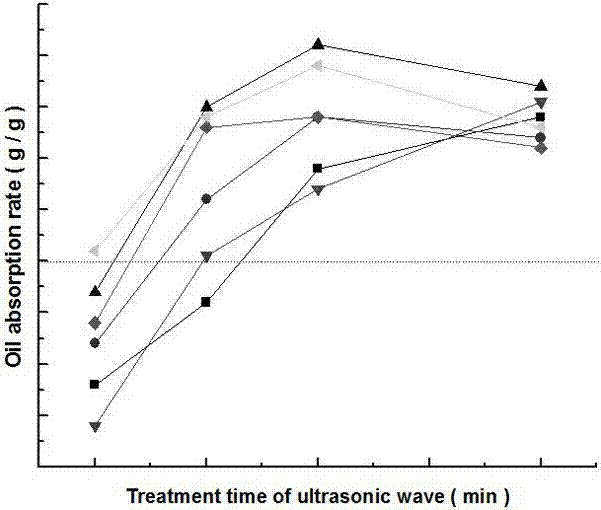

[0043] 3. Ultrasonic treatment: use an ultrasonic cell pulverizer as an ultrasonic generator, ultrasonic power 300w, ultrasonic time 10min, ultrasonic 5s, gap 5s, initial temperature 30°C, material volume 60ml.

[0044] 4. Composite solution preparation: Add disperse rosin gum, aluminum sulfate, superfine kaolin, and cetyl ammonium chloride t...

Embodiment 2

[0050] 1. Waste paper disintegration: Tear domestic waste and old newsprint into 2×5cm pieces, soak in water for 24 hours, put the soaked paper into PL12-00 high-consistency hydraulic pulper, control the pulp concentration to 10%, and the pulping temperature 55℃~60℃, the speed of the pulper is 350 r / min, and the crushing time is 30 minutes. The disintegrated pulp was filtered through a 80-mesh sieve, vacuum filtered, and then dried in an electric blast drying oven at 105 °C for 24 h until constant weight and bagged for later use.

[0051] 2. Fiber swelling: Prepare 1% sodium hydroxide solution, add waste paper fiber dry pulp to make a 5% suspension solution, stir evenly and soak for 2 hours to make the fiber swell and show a downward state.

[0052] 3. Suspension preparation: Add deionized water to the fiber suspension to a concentration of 1%, and stir evenly to make the fibers in a suspended state.

[0053] 4. Ultrasonic treatment: Ultrasonic cell pulverizer is used ...

Embodiment 3

[0060] 1. Waste paper disintegration: Tear domestic waste and old newsprint into 2×5cm pieces, soak in water for 24 hours, put the soaked paper into PL12-00 high-consistency hydraulic pulper, control the pulp concentration to 10%, and the pulping temperature 55℃~60℃, the speed of the pulper is 350 r / min, and the crushing time is 30 minutes. The disintegrated pulp was filtered through a 80-mesh sieve, vacuum filtered, and then dried in an electric blast drying oven at 105 °C for 24 h until constant weight and bagged for later use.

[0061] 2. Fiber swelling: Prepare 2% sodium hydroxide solution, add waste paper fiber dry pulp to make a 5% suspension solution, stir evenly and soak for 2 hours to make the fiber swell and show a downward state.

[0062] 3. Suspension preparation: Add deionized water to the fiber suspension to a concentration of 1%, and stir evenly to make the fibers in a suspended state.

[0063] 4. Ultrasonic treatment: use an ultrasonic cell pulverizer as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com