Colorful high-elastoplastic pen and making method thereof

A high-elasticity and plasticity technology, applied in pencil lead, household utensils, applications, etc., can solve the problems of short-term storage, inconvenient use, and inconvenient carrying, etc., and achieve the effect of bright colors, easy to carry, simple and environmentally friendly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

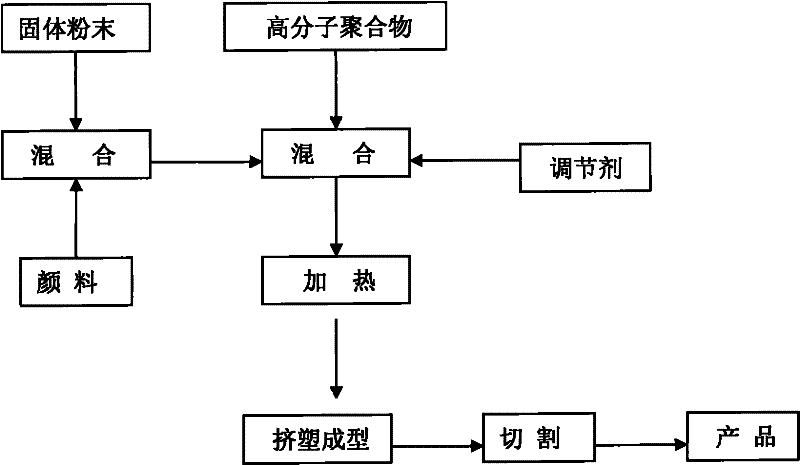

Method used

Image

Examples

Embodiment 1

[0012] The formula composition of the red high elastic plastic pen is as follows:

[0013] 40 parts of polyvinyl chloride; 38 parts of calcium carbonate; 2 parts of pigment red;

[0014] 10 parts of chlorinated paraffin; 5 parts of paraffin

[0015] After the above-mentioned raw materials are mixed evenly in a high-speed mixer, they are added to extrusion equipment, heated, extruded and stretched at a temperature of 250°C, and processed into strip products of certain specifications, sizes and shapes. After cutting, they are the products of the present invention. product.

Embodiment 2

[0017] The formula composition of the pink high elastic plastic pen is as follows:

[0018] 20 parts of polypropylene; 20 parts of polyethylene; 25 parts of calcium carbonate; 12 parts of talcum powder;

[0019] 10 parts of pigment pink; 8 parts of chlorinated paraffin; 5 parts of stearic acid

[0020] After the above-mentioned raw materials are mixed evenly in a high-speed mixer, they are added to the extrusion equipment, heated, extruded and stretched at a temperature of 100°C, and processed into strip products of certain specifications, sizes and shapes, which are the products of the present invention after cutting. product.

Embodiment 3

[0022] The formula composition of fuchsia high elastic plastic pen is as follows:

[0023] 20 parts of polyethylene; 32 parts of talcum powder; 5 parts of diatomaceous earth;

[0024] 13 parts of purple pigment; 12 parts of stearic acid; 8 parts of rosin resin

[0025] After the above-mentioned raw materials are mixed evenly in a high-speed mixer, they are added to extrusion equipment, heated, extruded and stretched at a temperature of 150°C, and processed into strip products of certain specifications, sizes and shapes. After cutting, they are the products of the present invention. product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com